An Automatic Lifting Roller Bed for Body Welding

An automatic lifting and body technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reduced work efficiency, long lifting time, difficult welding process, etc., and achieves convenient operation, simple structure, Ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

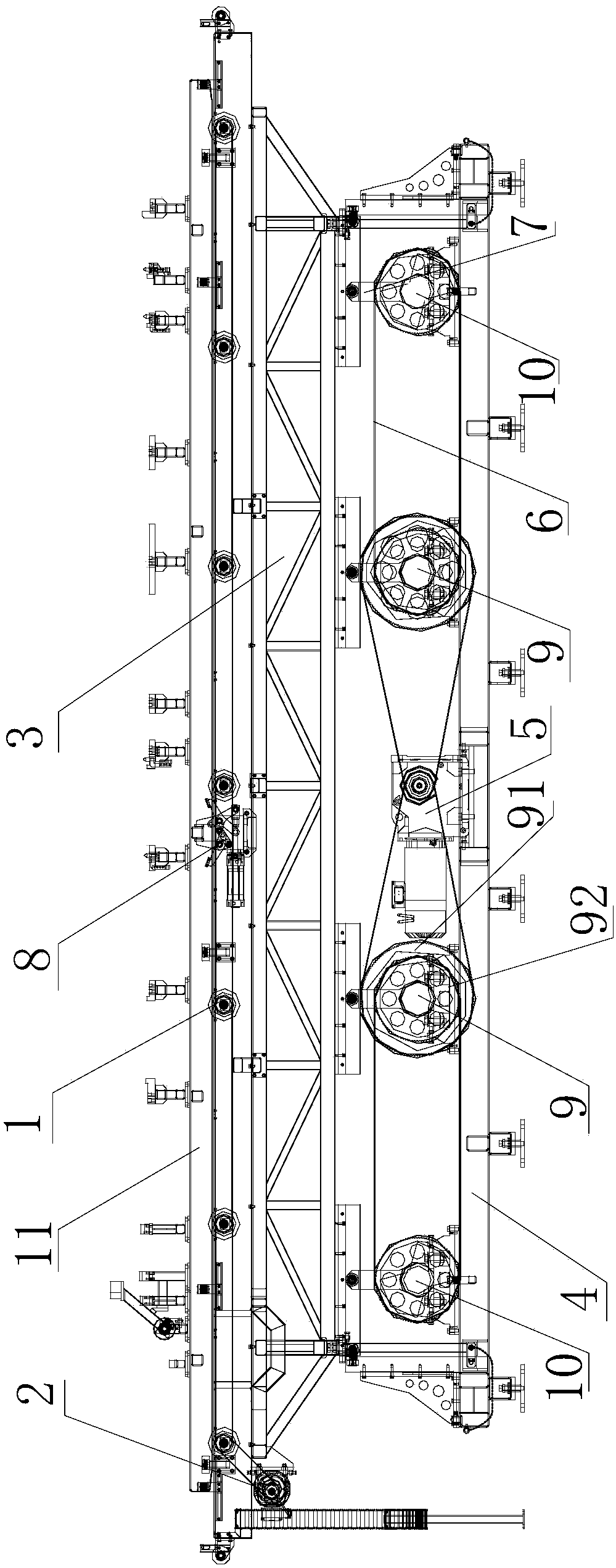

[0022] An automatic lifting roller bed for body welding, such as figure 1 As shown, it includes a roller table 1, a roller table driving mechanism 2, a welding frame 3, a bottom bracket 4 and a lifting mechanism. The roller table 1 is driven by the roller table driving mechanism 2 and is fixed on the welding frame 3. The roller table driving mechanism 2 is composed of The roller table driving motor, pulley and belt are composed, and the roller table driving motor is fixed on the welding frame. The bottom bracket 4 is provided with vertical slide rails, and the welding frame 3 is provided with sliders or guide wheels matching the slide rails, and the welding frame 3 and the bottom bracket 4 slide vertically through the sliders or guide wheels and the slide rails Connection, the slide rail is provided with a lifting limit block. The lifting mechanism is arranged between the welding frame 3 and the bottom bracket 4. The lifting mechanism includes a motor assembly 5 composed of a...

Embodiment 2

[0025] The automatic lifting roller bed used for body welding of this embodiment is basically the same as that of Embodiment 1, the difference is that the big wheel 91 of the first synchronous pulley 9 of this embodiment is fixed on the rotating shaft of the first synchronous pulley 9 On the top, the small wheel 92 is rotatably sleeved on the rotating shaft of the first synchronous pulley 9, and a clutch mechanism is provided between the large wheel 91 and the small wheel 92, and the rocker arms 7 on the two first synchronous pulleys 9 The length is the same, the length of the rocking arm 7 on the two second synchronous pulleys 10 is the same, and the length of the rocking arm 7 on the first synchronous pulley 9 is greater than the length of the rocking arm 7 on the second synchronous pulley 10 . Wherein, the clutch mechanism includes a latch, a cylinder for driving the latch to reciprocate, and latch holes respectively arranged on the big wheel 91 and the small wheel 92 .

[...

Embodiment 3

[0028] This embodiment is basically the same as Embodiment 1, except that each synchronous pulley of this embodiment is provided with a hole for weight reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com