Electric driving mechanism for bus door

A technology of electric drive and transmission mechanism, which is applied to doors, vehicle parts, transportation and packaging, etc. It can solve the problems of bulky, slow response, complex structure, etc., and achieve the effect of stable and reliable transmission, large lifting stroke and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

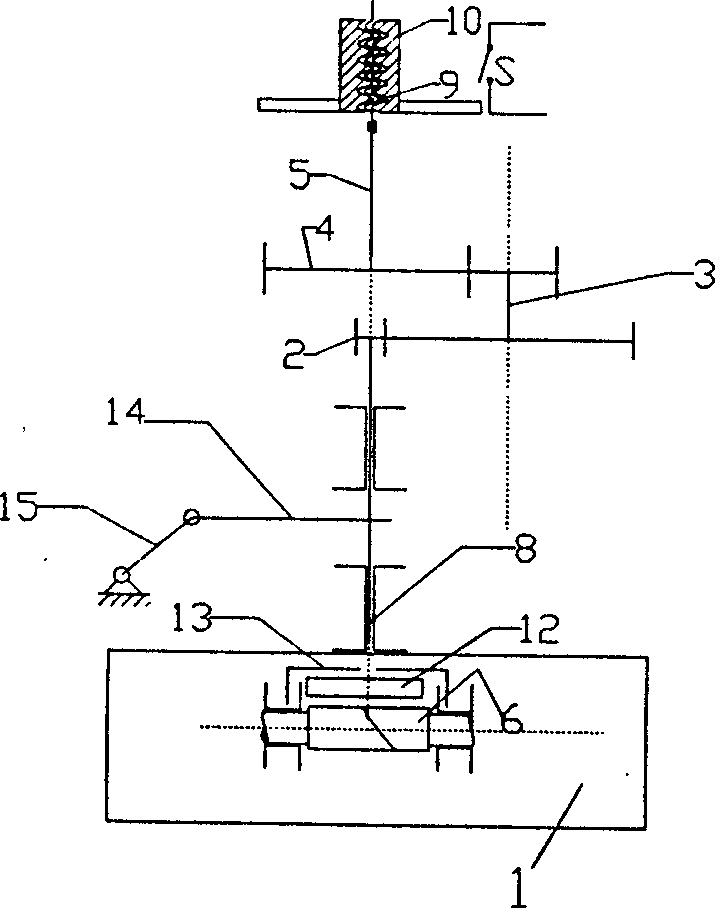

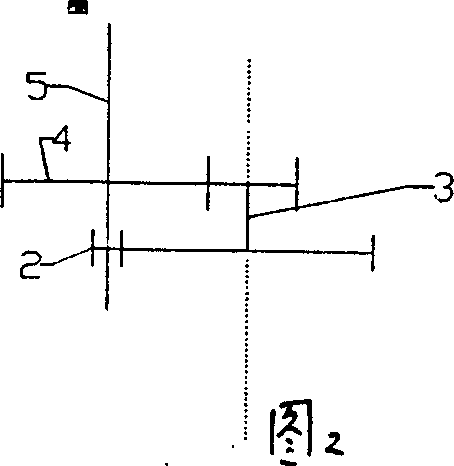

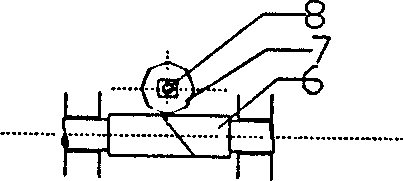

[0012] Control attached figure 1 , The driving mechanism is composed of a transmission mechanism, a self-locking mechanism, a lifting mechanism, an anti-pinch device, and a manual switching mechanism. Wherein the transmission mechanism is made up of motor 1, pinion 2, duplex gear 3, bull gear 4, door pump output shaft 5; The lifting mechanism has multi-thread 9 and multi-head nut 10; the anti-pinch device has anti-pinch nut 11, anti-pinch switch S, and anti-pinch switch S is connected to the controller. The controller is mainly composed of a single-chip microcomputer (model 16C57); manual switching The mechanism includes a motor output shaft 8, a blade paddle 12, a blade groove 13, a connecting rod 15, and a shift fork 14.

[0013] With reference to accompanying drawing 2, wherein pinion 2 is installed on the motor output shaft, pinion 2 meshes with the big tooth of double gear 3, and the small tooth of double gear 3 meshes with big gear 4. When the motor 1 is working, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com