Off-line assembling method of large flotation machine rotor

An assembly method and flotation machine technology, applied in flotation, solid separation and other directions, can solve the problems of many parts, long installation period, large on-site installation workload, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0016] A large-scale flotation machine rotor offline assembly method, the assembly method steps are:

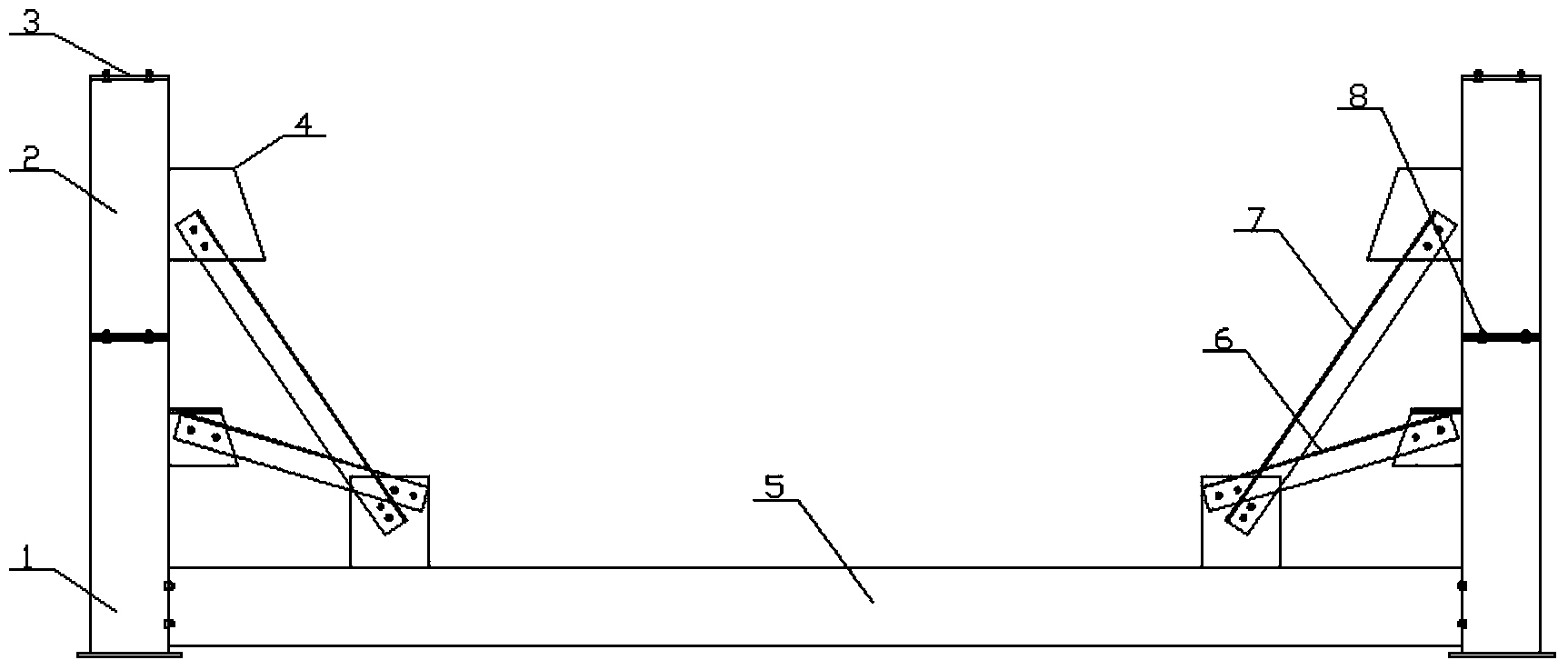

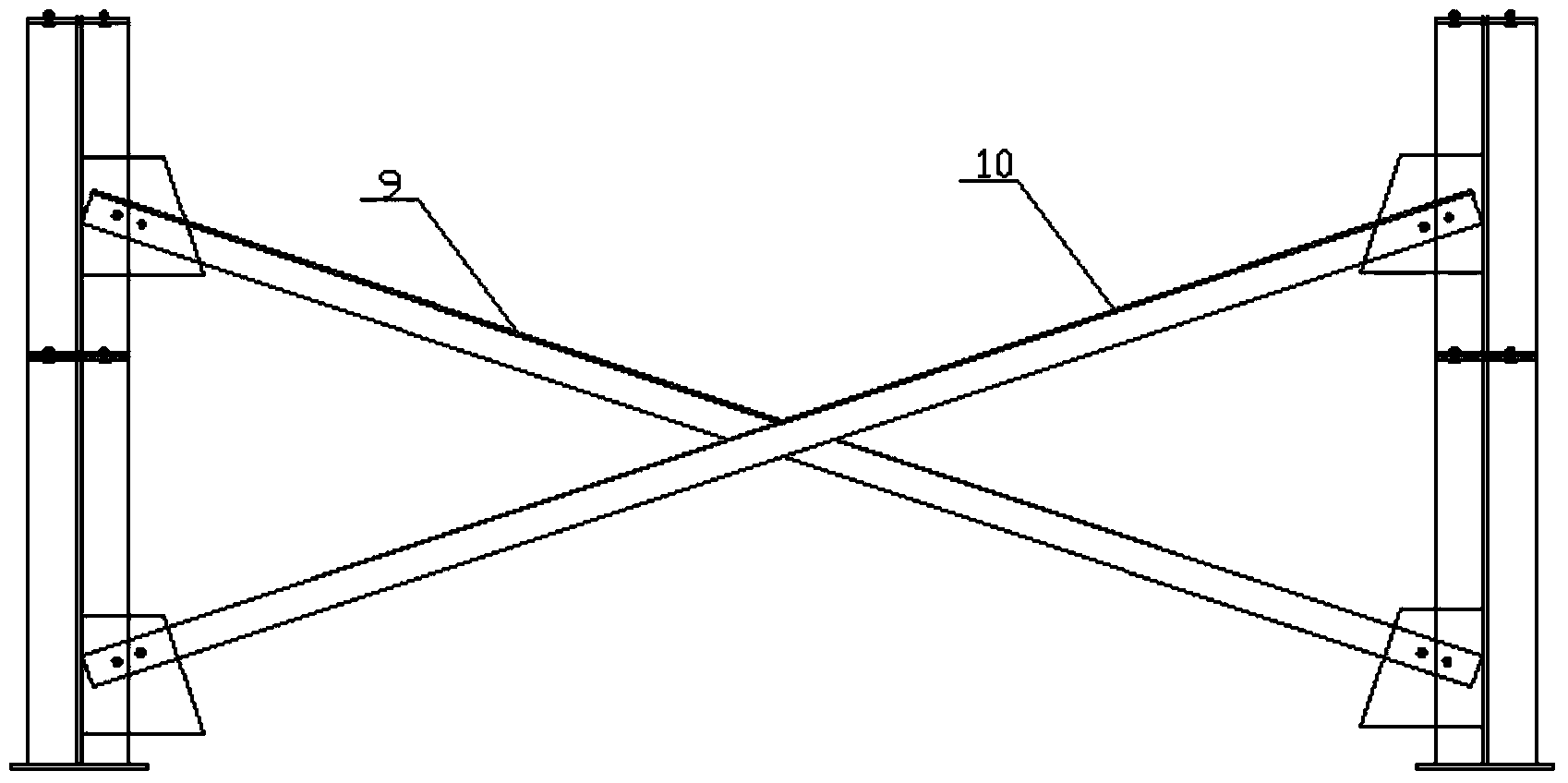

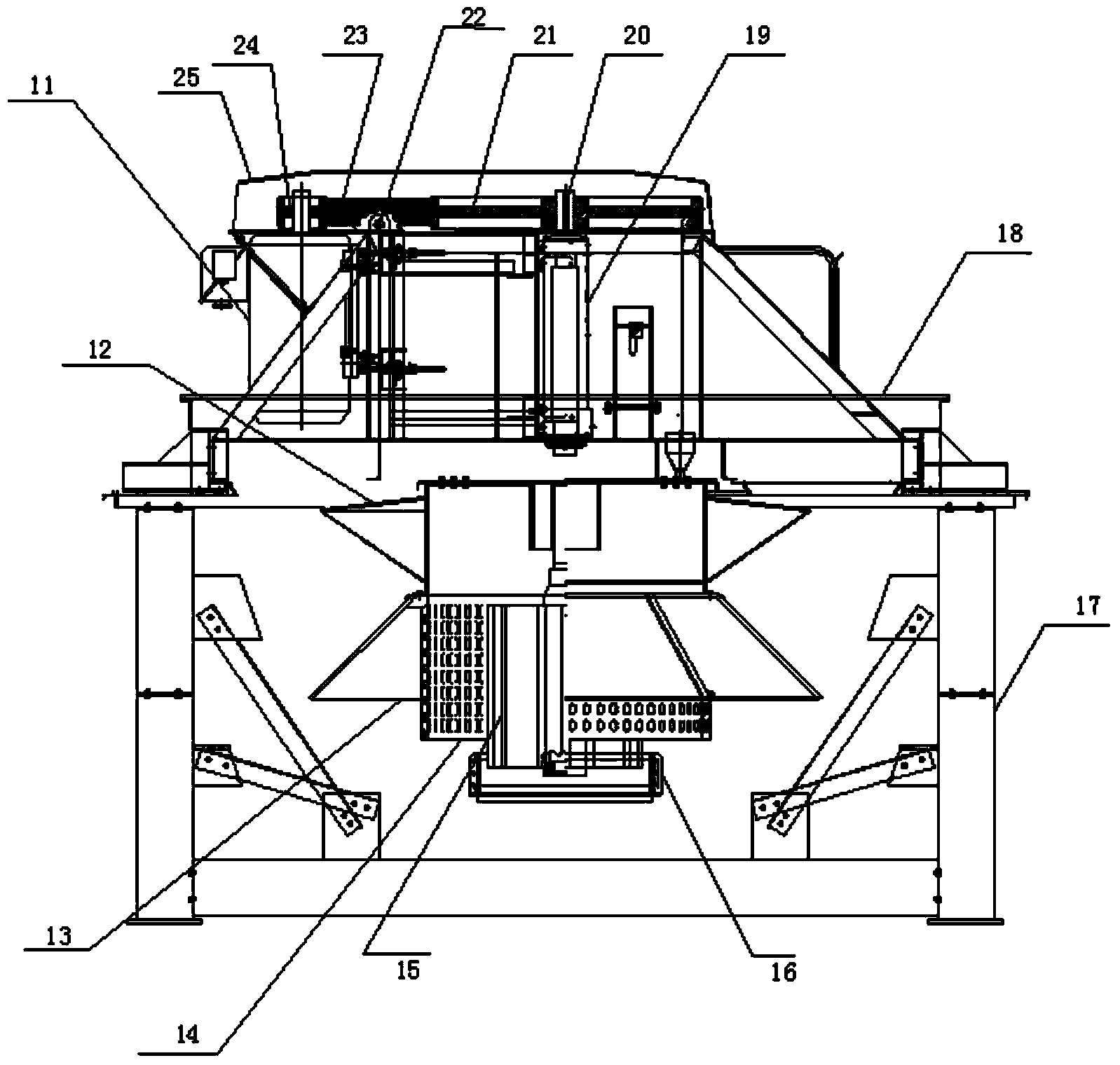

[0017] ⑴. Make a special support device: including four columns, two bottom beams 5, and four main diagonal braces. The four columns are arranged at the four corners of the rectangle. The main diagonal braces 9 and 10 are set between the two uprights, and each upright is composed of a bottom upright 1 and an extended upright 2, the bottom upright and the upright are fixed by connecting bolts 8, and the bottom upright and the bottom beam are installed There are bottom reinforced diagonal braces 6, lengthened diagonal braces 7 are installed between the extended column and the bottom beam, a rotor support surface 3 is arranged on the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com