Prefabricated assembled tunnel and construction method thereof

A prefabricated assembly and tunnel technology, which is applied in tunnels, tunnel linings, bolt installation, etc., can solve the problems of high noise in cast-in-place construction, large impact on residents and buildings, and long construction time, so as to reduce construction conditions and reduce social costs , the effect of small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

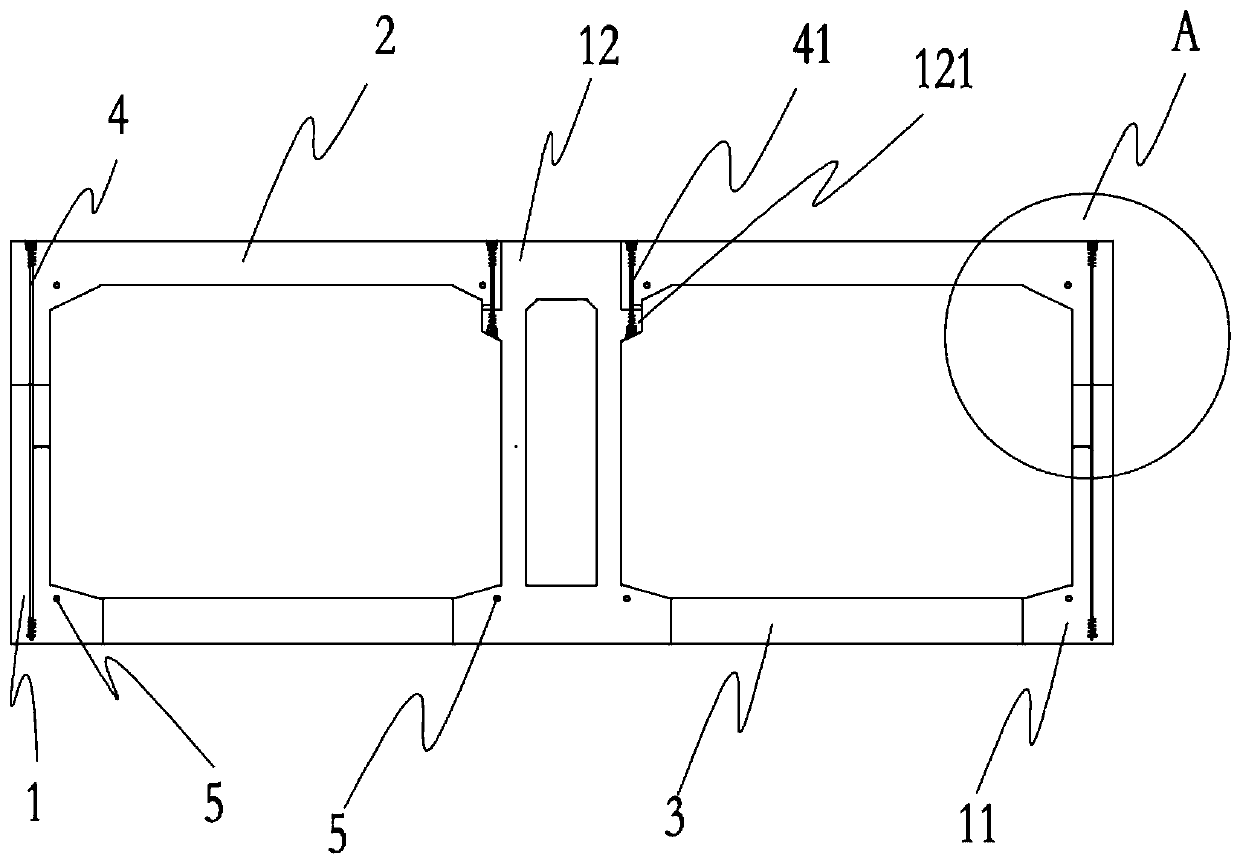

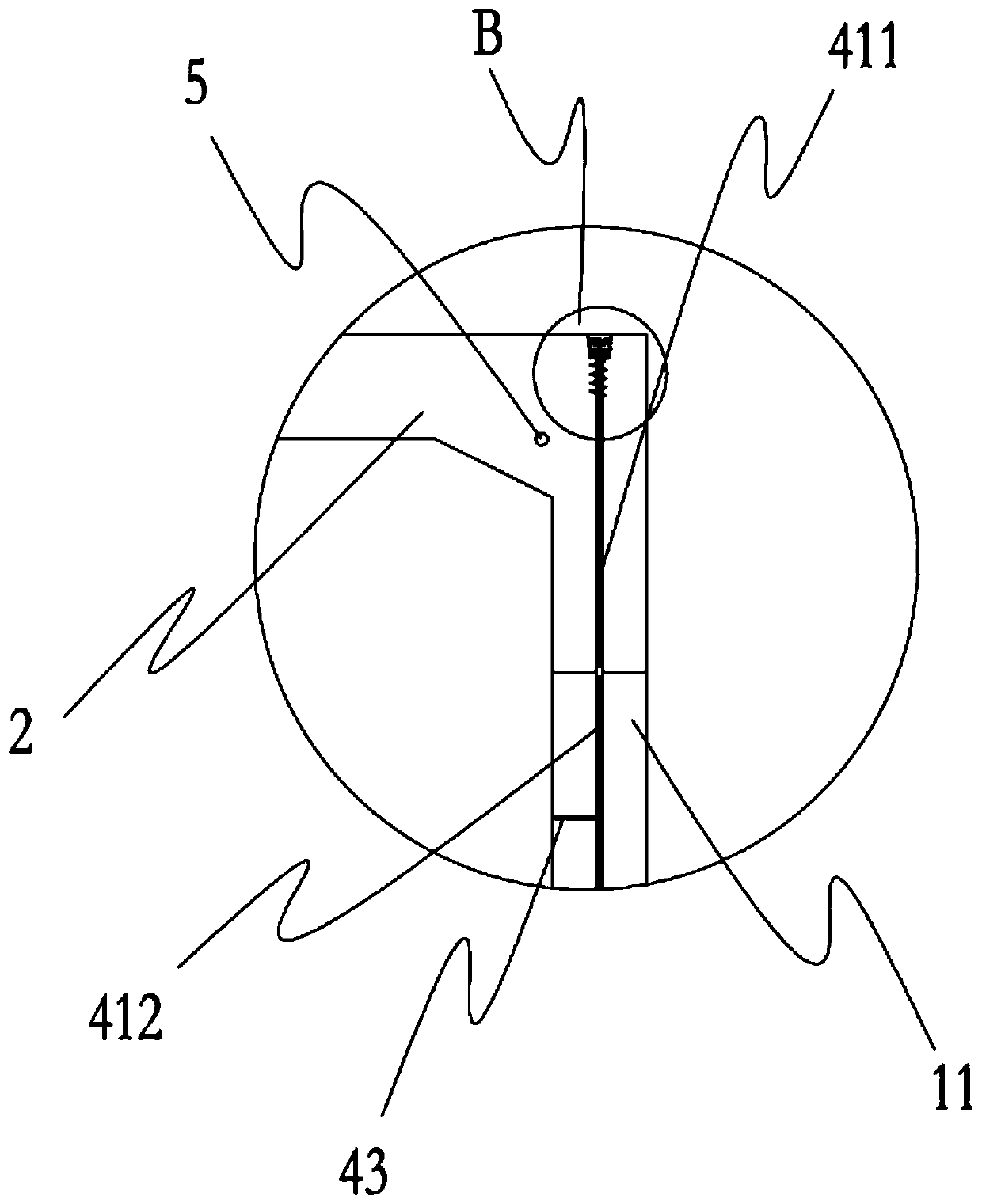

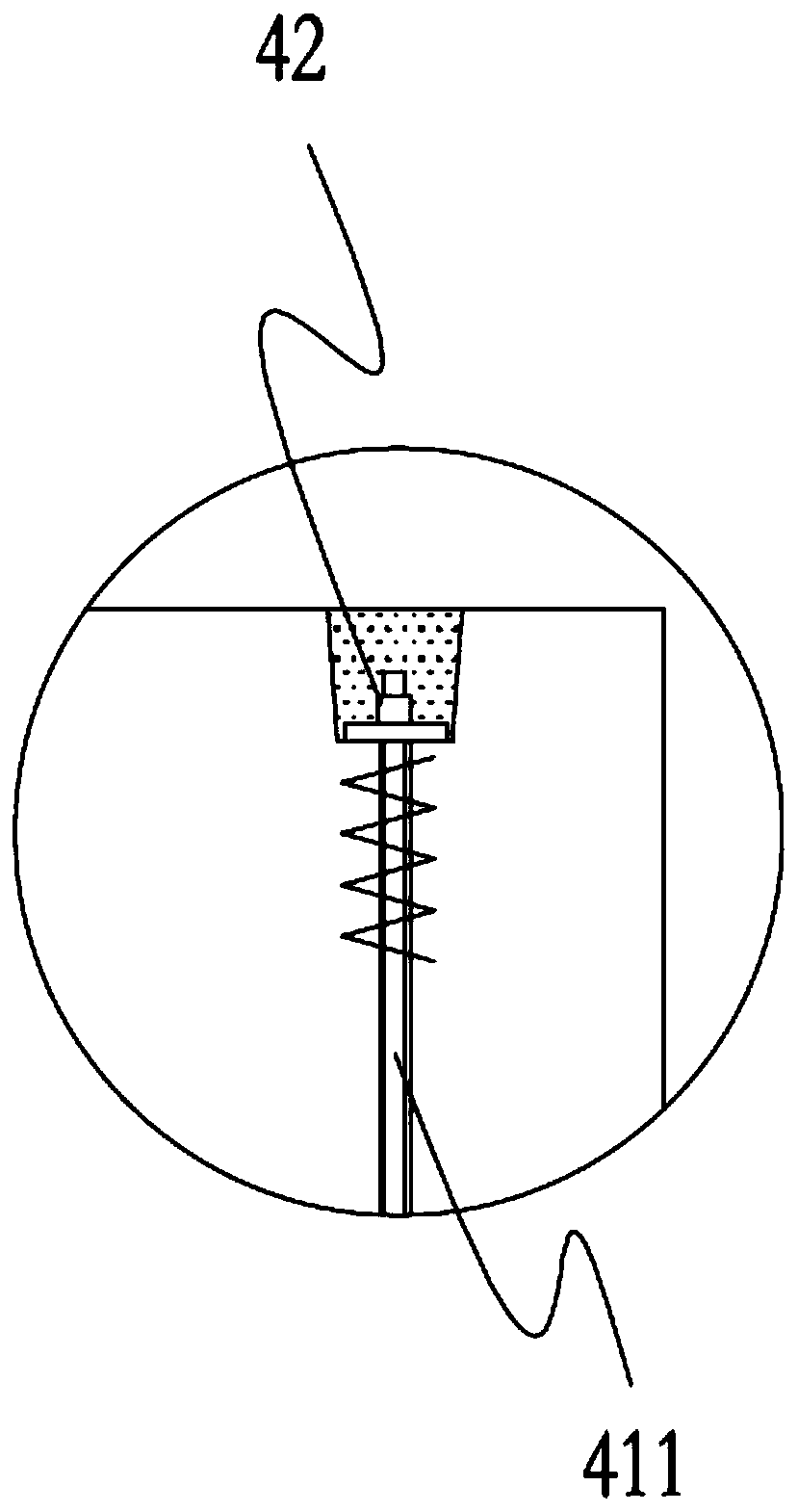

[0037] refer to Figure 1-6 , a prefabricated assembly tunnel, including a plurality of prefabricated panels, the prefabricated panels include an upper cover plate 2, a vertical support plate 1, at least two of the vertical support plates 1 and at least one of the upper cover plate 2 In a section warehouse, a base plate 3 is provided between the lower ends of two adjacent vertical support plates 2; in one section warehouse, the upper end of the vertical support plate 1 Support the upper cover plate 2, a vertical fastener 4 is connected between the upper cover plate 2 and the vertical support plate 1, between each upper cover plate 2 and each vertical support plate 4, They are all connected by a plurality of vertical fasteners 4, and the plurality of vertical fasteners 4 are evenly arranged in the longitudinal direction; a plurality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com