Rapid greening protection slope for oligotrophic soil slope as well as construction method thereof

A slope and barren technology, applied in the field of slope greening, can solve the problems of poor stability, difficult vegetation root system to form a barren soil slope as a whole, and achieve the effects of good durability, rapid development, and simple and reliable construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

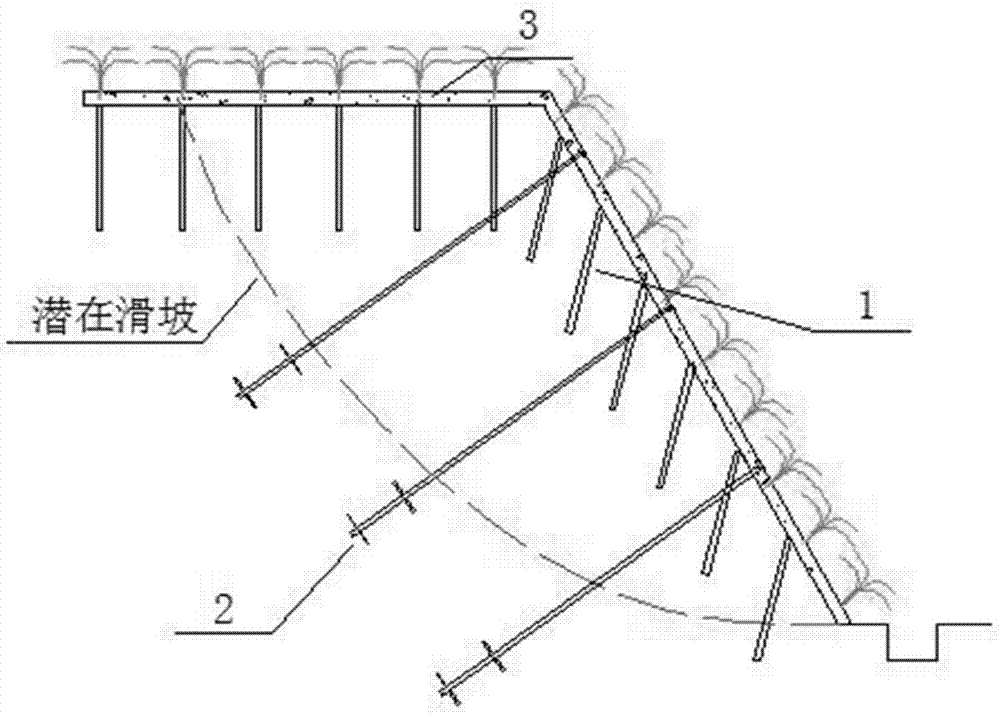

[0036] A rapid greening slope protection for barren soil slopes, including a three-dimensional geonet, a nutrient soil column 1, a spiral steel pile 2 and a base material layer 3, and the nutrient soil column 1 and the spiral steel pile 2 are drilled under the three-dimensional geonet In the soil, the substrate layer 3 is set on the three-dimensional geonet. The three-dimensional geonet is connected to the spiral steel pile 2 by hooking, and the joint is protected by a concrete pile head, and the three-dimensional geonet is embedded in the lower part of the concrete pile head. The spiral steel pile 2 is a blade-type spiral steel pile. The outer diameter of the spiral steel pile 2 is 50mm, the wall thickness is 0.1 times of the outer diameter, and the blade diameter is 2.5 times of the outer diameter. The surface of the spiral steel pile 2 has a zinc coating. The nutrient soil columns 1 are evenly distributed in the form of vertical and horizontal rows, the distance between th...

Embodiment 2

[0039]A rapid greening slope protection for barren soil slopes, including a three-dimensional geonet, a nutrient soil column 1, a spiral steel pile 2 and a base material layer 3, and the nutrient soil column 1 and the spiral steel pile 2 are drilled under the three-dimensional geonet In the soil, the substrate layer 3 is set on the three-dimensional geonet. The three-dimensional geonet is connected to the spiral steel pile 2 by hooking, and the joint is protected by a concrete pile head, and the three-dimensional geonet is embedded in the lower part of the concrete pile head. The spiral steel pile 2 is a blade-type spiral steel pile. The outer diameter of the spiral steel pile 2 is 80mm, the wall thickness is 0.1 times of the outer diameter, and the blade diameter is 3.0 times of the outer diameter. The surface of the spiral steel pile 2 has a zinc coating. The nutrient soil columns 1 are evenly distributed in the form of vertical and horizontal rows, the distance between the...

Embodiment 1 and Embodiment 2

[0041] Both embodiment 1 and embodiment 2 are constructed by the following method:

[0042] [1] Carry out geological survey to determine the setting depth of the nutrient soil column 1, and the setting of the depth of the nutrient soil column 1 needs to be able to provide water and nutrients that can satisfy the survival of the grown vegetation;

[0043] [2] Clean up the slope to make the surface of the slope smooth, so as to facilitate the subsequent laying of the three-dimensional geonet and the construction of the substrate layer 3;

[0044] [3] The spiral steel pile 2 is drilled. When the slope has a potential sliding surface, the spiral steel pile 2 needs to pass through the potential sliding surface;

[0045] [4] Nutrient soil column 1 is drilled;

[0046] [5] Use the three-dimensional geonet to lay the entire surface of the slope, and connect the spiral steel pile 2 with the three-dimensional geonet;

[0047] [6] Carry out base material layer 3 construction, use the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com