Buried garbage can facilitating garbage collection and garbage collection vehicle

A buried type and garbage bin technology, which is applied in garbage collection, garbage cans, garbage containers, etc., can solve the problems of not being applicable to a large municipal area, inconvenient and quick cleaning of garbage, etc., and achieve a small overall operation area and use scenarios The effect of small limitations and fast collection of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

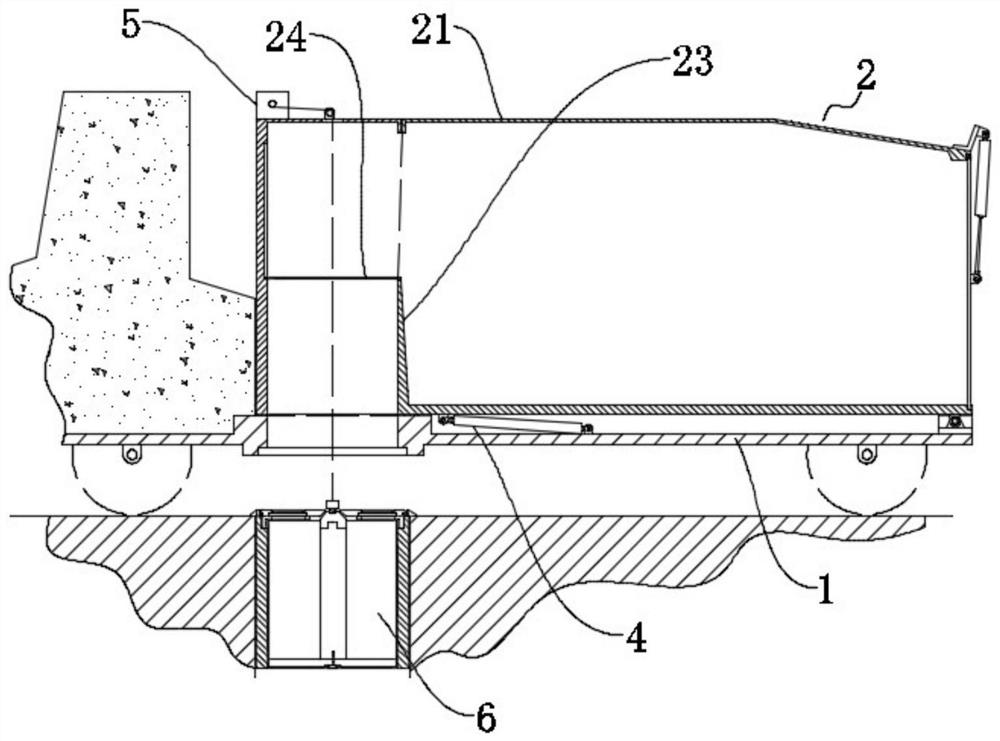

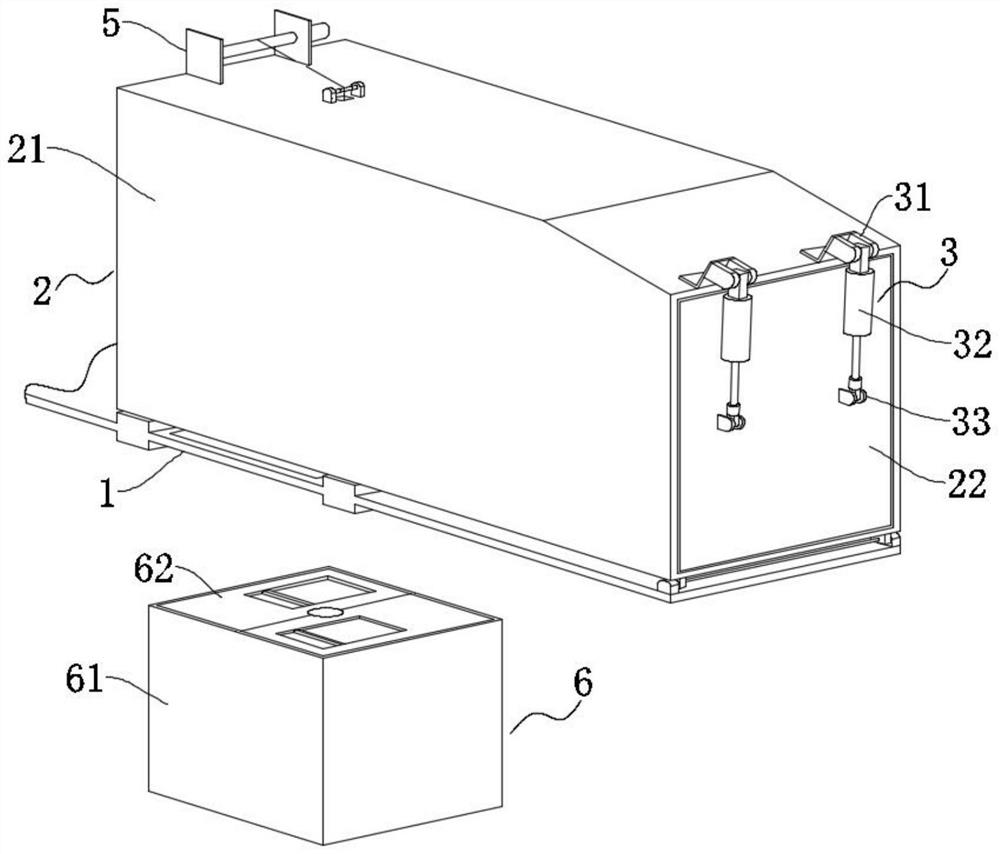

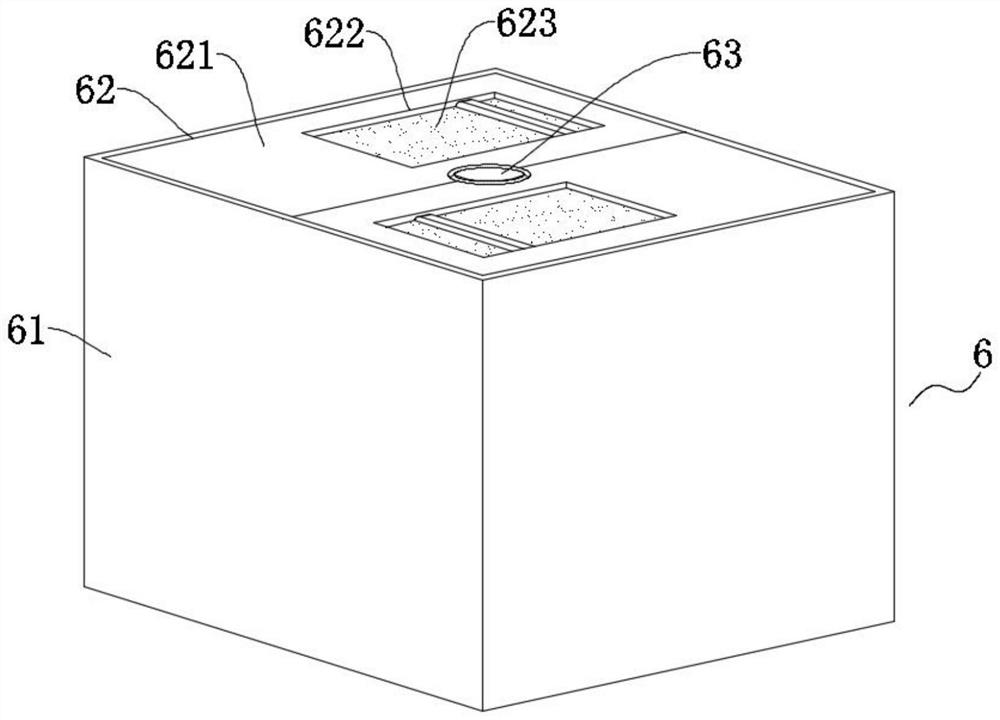

[0034] An underground garbage bin and a garbage collection truck for collecting garbage, comprising a vehicle frame 1 and an underground garbage bin 6, the underground garbage bin 6 is buried on the ground, and the top of the underground garbage bin 6 is exposed to the ground, The bottom of the frame 1 is provided with a through opening, and a garbage hopper 2 is movably assembled on the frame 1. The garbage hopper 2 includes a first box body 21, and a partition plate 23 is fixed inside the first box body 21. The partition plate 23 Divide the first box body 21 into a garbage storage cavity and a garbage throwing cavity, such as figure 1 As shown, the left side of the partition 23 is the garbage throwing cavity, and the right side is the garbage storage cavity.

[0035] The lower surface of the first box body 21 is provided with a garbage inlet, one end of the garbage inlet is opposite to the through opening, the other end of the garbage inlet is communicated with the garbage t...

Embodiment 2

[0049] Embodiment 2, on the basis of Embodiment 1, the difference between Embodiment 2 is that, such as Figure 1-8 As shown in the figure, the side of the first box 21 protrudes outward, the garbage throwing cavity is located in the protruding part, and there is a sloping plate in the garbage throwing cavity of the protruding part to guide the garbage into the garbage storage cavity, and the frame 1 cooperates with the first box. The side of 21 protrudes outward. With this shape design, the vehicle does not need to drive above the buried garbage bin 6, and the buried garbage bin 6 laid on the sidewalk can also easily collect garbage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com