Preparation method of thermal barrier coating and thermal barrier coating prepared through preparation method

A technology of thermal barrier coating and spraying equipment, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of low thermal shock resistance and poor interlayer bonding of the coating, and achieve low cost, Effect of suppressing grain growth and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of a thermal barrier coating of the present invention adopts a precursor solution composed of zirconium salt and ytterbium salt as a spraying raw material, and in a liquid plasma plasma spraying equipment, sends the solution into a plasma jet through a two-flow atomizing nozzle, And deposited on the substrate to form a thermal barrier coating with uniform pore distribution and vertical crack structure.

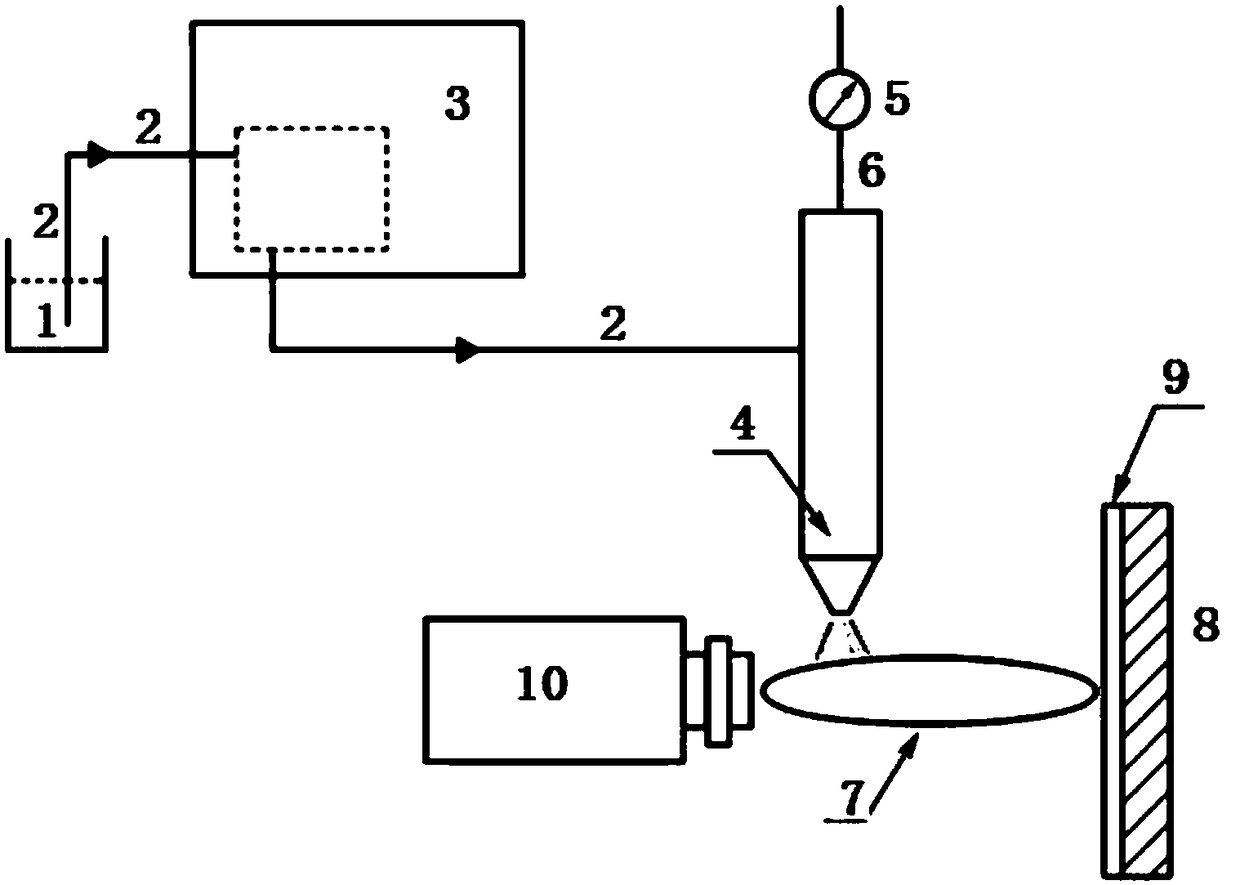

[0038] Such as figure 1 As shown, the liquid plasma spraying equipment includes: a container 1 and a two-flow atomizing nozzle 4, one end is inserted into the container 1, and the other end is connected to the hose 2 of the two-flow atomizing nozzle 4, which is arranged on the soft The pipe 2 is provided with a peristaltic pump 3 for driving the liquid in the container 1 to flow into the two-stream atomizing nozzle 4, and a plasma spray gun 10 is provided on the outlet end side of the two-stream atomizing nozzle 4, and the two-stream spray nozzle T...

Embodiment 1

[0049] Weigh 2.76g of ytterbium oxide into a beaker, add excess (about 10mL) concentrated nitric acid and 10mL of deionized water, heat and stir until complete reaction, and form ytterbium nitrate solution. Weigh 85.8g of zirconium nitrate pentahydrate powder into a beaker, and add deionized water to form zirconium nitrate aqueous solution. Add the formed ytterbium nitrate solution to the zirconium nitrate aqueous solution, add deionized water to adjust the concentration, and stir at room temperature to fully mix the two solutions to obtain a precursor solution with a solute concentration of 0.8 mol / L.

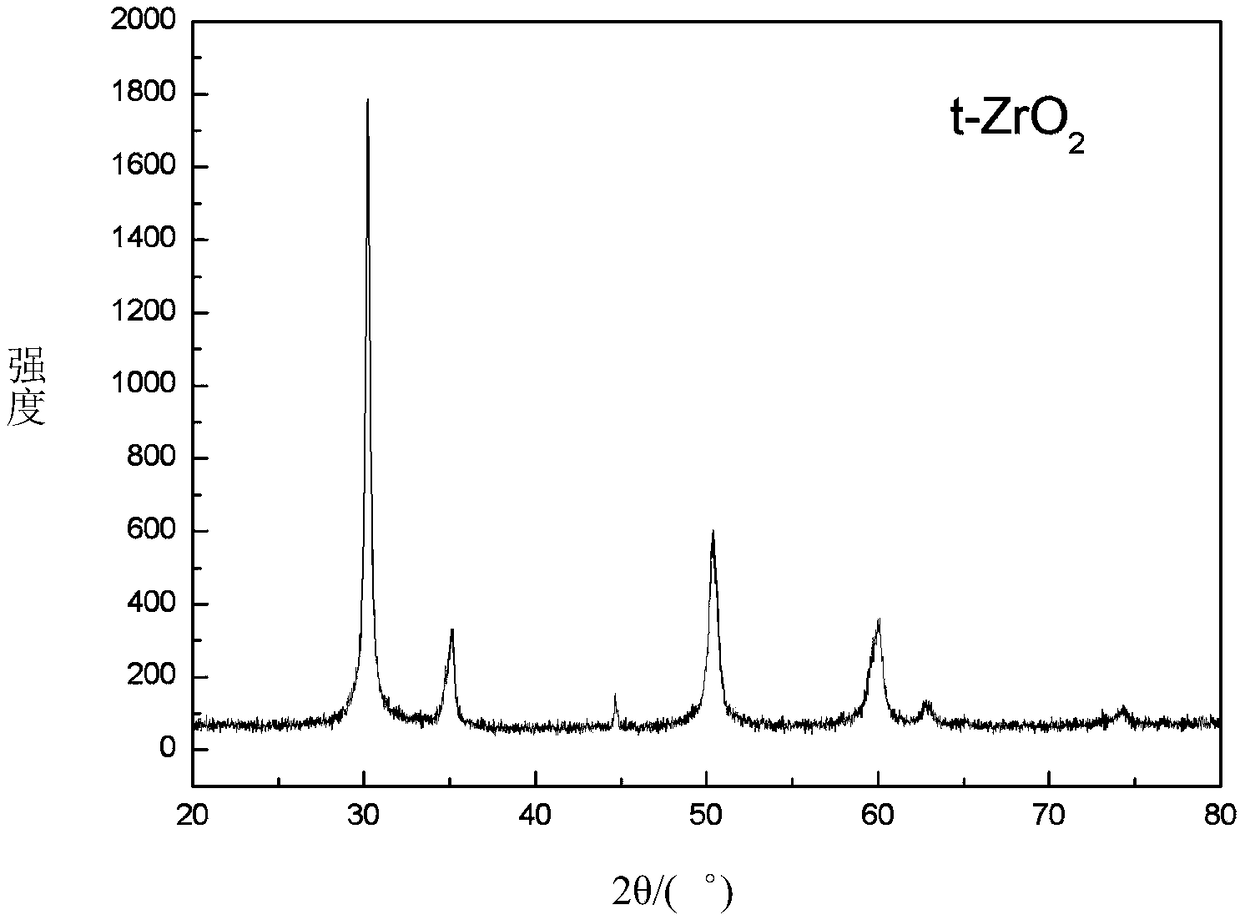

[0050] The prepared precursor solution was atomized through a two-flow atomization nozzle at a flow rate of 24 mL / min and then sent into the plasma jet with an atomization gas pressure of 0.2 MPa, and finally a thermal barrier coating was formed on the stainless steel substrate. The spraying distance is 80mm, the current is 600A, and the spraying pressure is 60V. The crystal ...

Embodiment 2

[0052] Weigh 2.76g of ytterbium oxide into a beaker, add excess (about 8mL) concentrated nitric acid and 8mL of deionized water, heat and stir until complete reaction, and form ytterbium nitrate solution. Weigh 85.8g of zirconium nitrate pentahydrate powder into a beaker, and add deionized water to form zirconium nitrate aqueous solution. Add the formed ytterbium nitrate solution to the zirconium nitrate aqueous solution, add deionized water to adjust the concentration, and stir at room temperature to fully mix the two solutions to obtain a precursor solution with a solute concentration of 1.0 mol / L.

[0053] The prepared precursor solution was atomized through a two-flow atomization nozzle at a flow rate of 24 mL / min and then sent into the plasma jet with an atomization gas pressure of 0.2 MPa, and finally a thermal barrier coating was formed on the stainless steel substrate. The spraying distance is 80mm, the current is 600A, and the spraying pressure is 60V. The crystal st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com