LED lamp string and manufacturing method thereof

A technology for LED light strings and manufacturing methods, which is applied to components of lighting devices, damage prevention measures for lighting devices, semiconductor devices for light-emitting elements, etc., and can solve problems such as difficulty in ensuring connection strength, inconvenient production of light strings, and high cost. Achieve the effects of simple structure, convenient and quick manufacture, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

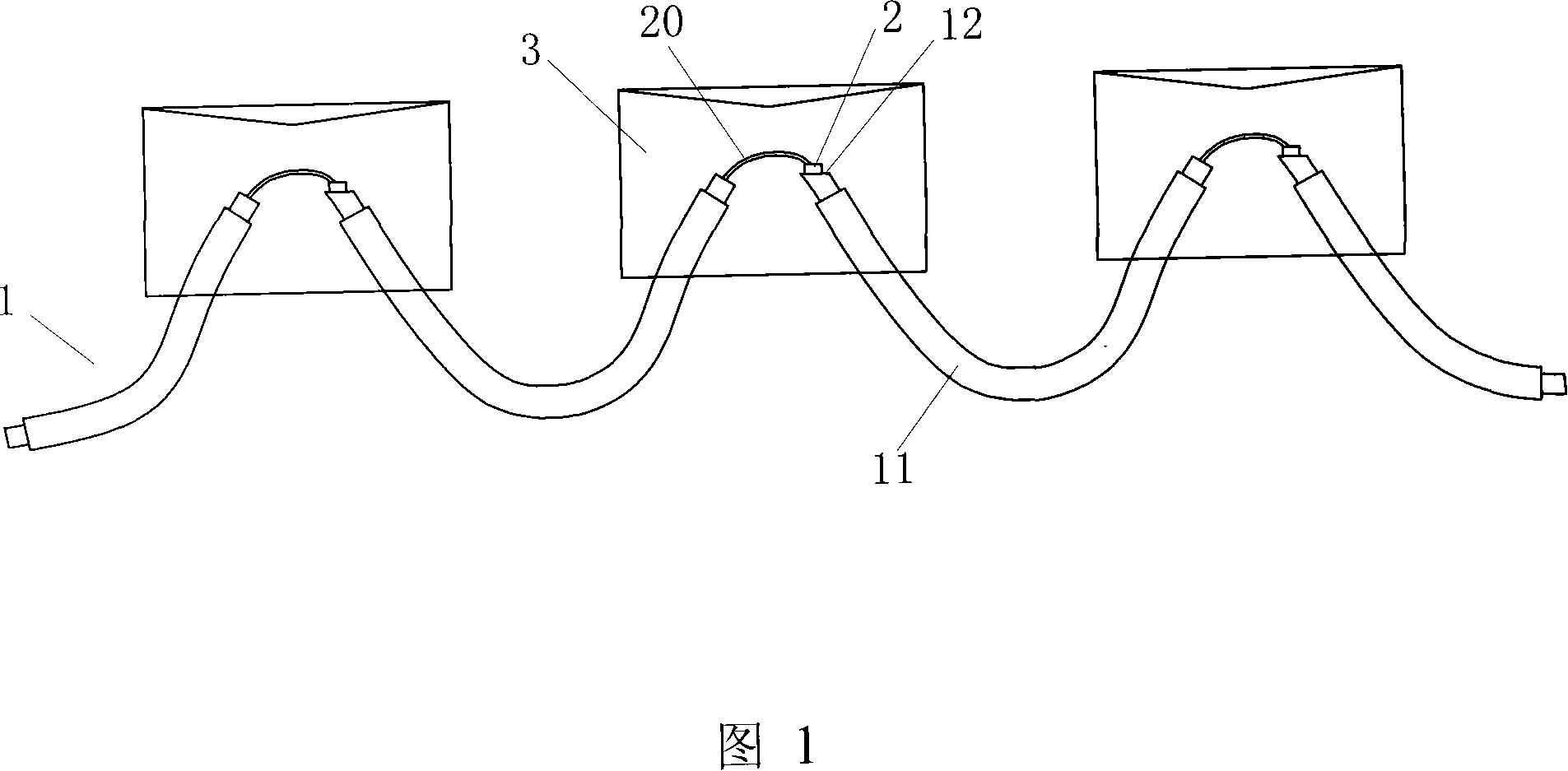

[0017] Referring to Fig. 1, an LED lamp string of the present invention includes a wire 1, a light-emitting chip 2 and an outer covering body 3, the wire 1 is divided into a plurality of connecting wires 11 connected in series, and each connecting wire 11 is divided into two sections. A light-emitting chip 2 is connected, and one end of the connection line 11 is provided with an installation platform 12 electrically connected to it. The light-emitting chip 2 is installed on the installation platform 12 and is electrically connected with the installation platform 12. 20 is electrically connected to the connecting wire 11 adjacent thereto, and the light-emitting chip 2 , the lead wire 20 , and the ends of the two connecting wires 11 electrically connected to the light-emitting chip 2 and the lead wire 20 are packaged together in the encapsulating body 3 .

[0018] According to the structural feature that multiple LEDs need to be connected together to form a string of LED light st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com