Method for deep oxidation treatment of industrial wastewater by ozone

A technology for deep oxidation of industrial wastewater, applied in oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as insufficient mixing effect, avoid secondary pollution, and have large treatment capacity , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

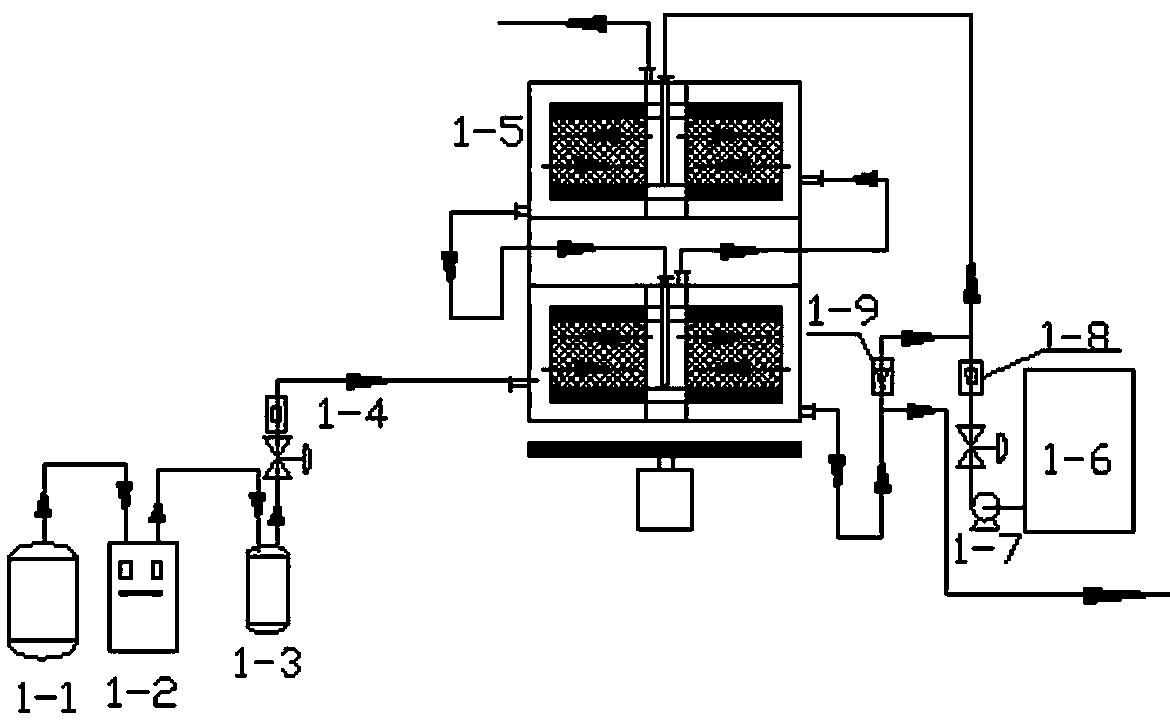

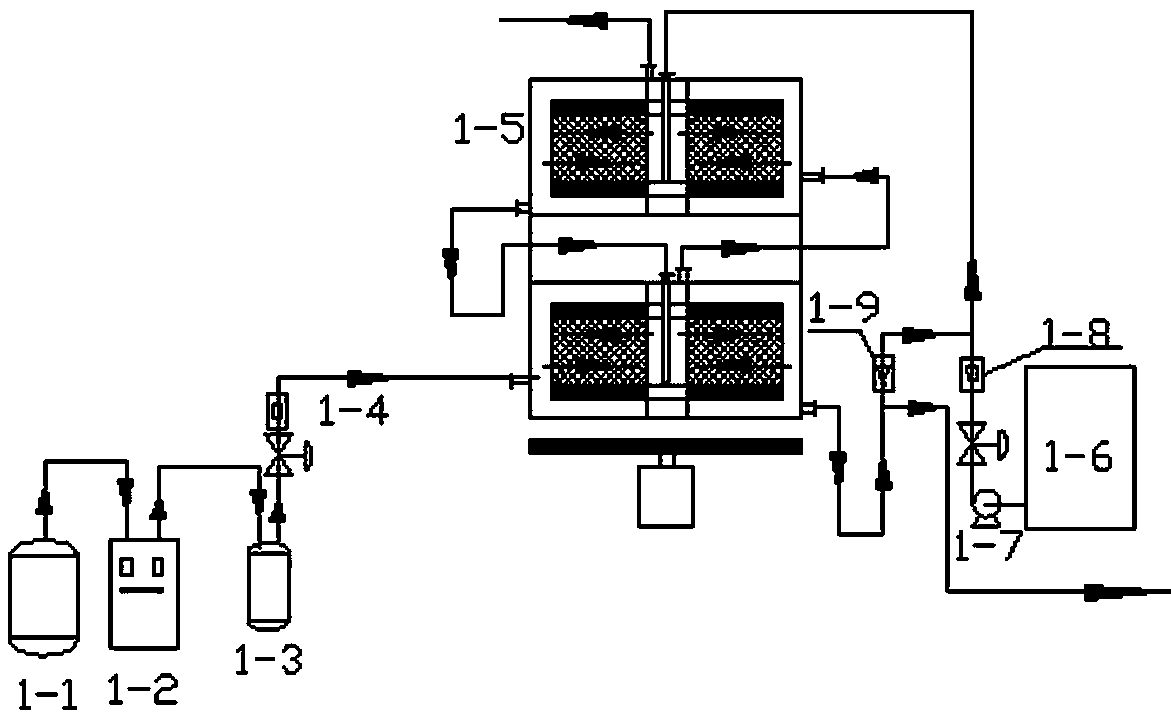

Image

Examples

Embodiment 1

[0031]Put the waste water to be treated in the waste water tank, the COD of the original waste water is 75.8mg / L, open the second-stage micro-mixing reactor 1-5, and control the speed at 900r / min, after the operation is stable, open the centrifugal pump 1-7 to adjust the liquid flow Calculate 1-8 as 120L / h, and continuously add 120g / h of catalyst from the catalyst inlet, the catalyst composition is metatitanic acid, metaboric acid, hydrochloric acid (concentration 30%) and water with a mass ratio of 1:0.8:1.5: 20. Adjust the return flow meter to full return flow. Turn on the ozone generator 1-2, adjust the gas flow meter 1-4 to 4.5ml / min, and take the ozone content of the exhaust gas outlet and the COD value of the wastewater outlet water every 10 minutes. After 20 minutes, the COD of the wastewater from the sampling port is 30.5mg / L. Turn off the reflux flowmeter, and start to produce the treated waste water that meets the requirements, and the COD degradation efficiency is 5...

Embodiment 2

[0033] Put waste water to be treated in the waste water tank, the waste water COD is 360mg / L, open the second-stage micro-mixing reactor 1-5, and control the speed at 900r / min, after the operation is stable, open the centrifugal pump 1-7, and adjust the liquid flow meter 1 -8 is 160L / h, continuously add 110g / h of catalyst from the catalyst inlet, the catalyst composition is metatitanic acid, metaboric acid, hydrochloric acid (30% concentration) and water with a mass ratio of 1:1.5:1.5:10 , adjust the reflux flow meter to full reflux. Turn on the ozone generator 1-2, adjust the gas flow meter 1-4 to 4.5ml / min, and take the ozone content of the exhaust gas outlet and the COD value of the wastewater outlet water every 10 minutes. After 25 minutes, the COD of the wastewater from the sampling port is 97.2mg / L. Turn off the reflux flow meter and begin to produce the treated waste water that meets the requirements. The COD degradation efficiency is 73%.

Embodiment 3

[0035] Put waste water to be treated in the waste water tank, the waste water COD is 1740mg / L, open the second-stage micro-mixing reactor 1-5, and control the speed at 900r / min, after the operation is stable, open the centrifugal pump 1-7, and adjust the liquid flow meter 1- 8 is 240L / h, and 160g / h of catalyst is continuously added from the catalyst inlet. The catalyst composition is metatitanic acid, metaboric acid, hydrochloric acid (concentration: 30%) and water with a mass ratio of 1:1:2:15. Adjust the return flow meter to full return flow. Turn on the ozone generator 1-2, adjust the gas flow meter 1-4 to 4.5ml / min, and take the ozone content of the exhaust gas outlet and the COD value of the wastewater outlet water every 10 minutes. After 30 minutes, the COD of the wastewater from the sampling port is 307.06mg / L. Turn off the reflux flow meter and start to produce the treated waste water that meets the requirements. The COD degradation efficiency is 82.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com