Method for preparing transparent conducting electrode based on 3D (three-dimensional) printing technique

A transparent conductive electrode, 3D printing technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of limitation, poor physical adhesion, and high requirements for growth environment, improve the quality rate and accuracy, and reduce production costs. , the effect of simplifying the tedious process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

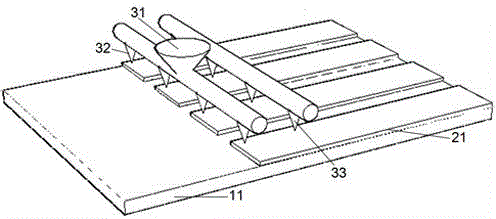

[0032] refer to figure 1 and figure 2 . This embodiment is illustrated by taking a tin-doped indium oxide transparent conductive electrode prepared by 3D printing technology, that is, an indium tin oxide (ITO) transparent conductive electrode as an example.

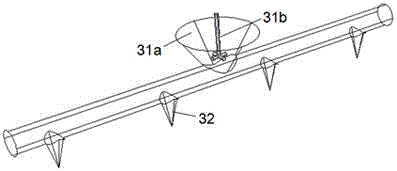

[0033] The ITO transparent conductive electrode includes 11 glass substrates and 21 ITO films. The 3D printing device includes 31 sol generating chambers, 32 3D printing heads and 33 laser printing heads, and the specific 31 sol generating chambers include 31a sol generating chambers and 31b stirring rods.

[0034] The specific configuration method of the sol used to generate the ITO film is: adding indium chloride, tin chloride and ethanol in proportion to the 31a sol generation chamber, and then using the 31b stirring rod in the sol chamber to stir the solution evenly, A sol is formed. It is characterized in that the molar concentration of indium chloride is 0.15mol / L, and the concentration ratio of indium chloride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com