REY molecular sieve containing phosphor and amorphous silica, preparation method and application

A molecular sieve and silicon oxide technology, which is applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of long preparation process, complicated preparation method, low equilibrium unit cell, etc., and shorten the preparation process and preparation method Ease of use, balanced reaction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

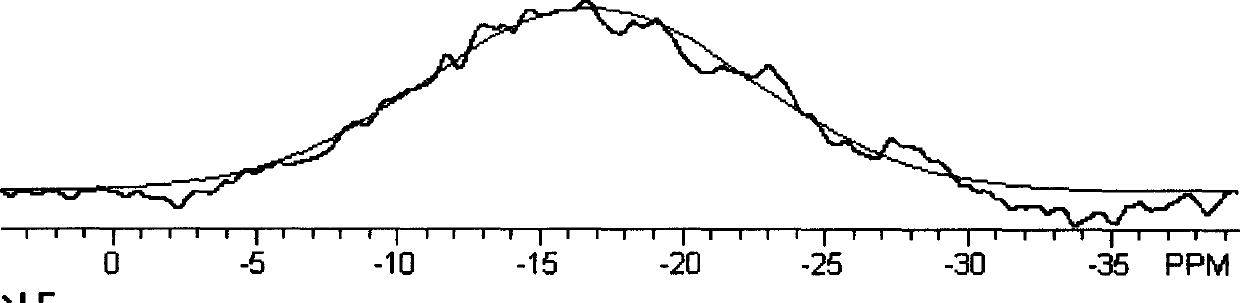

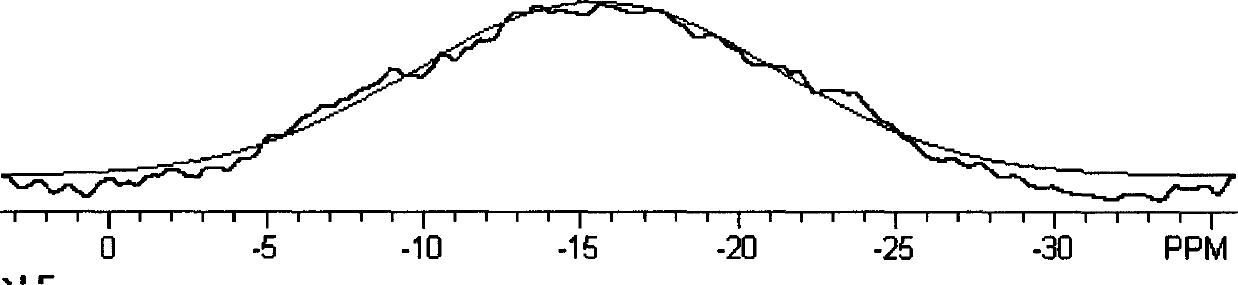

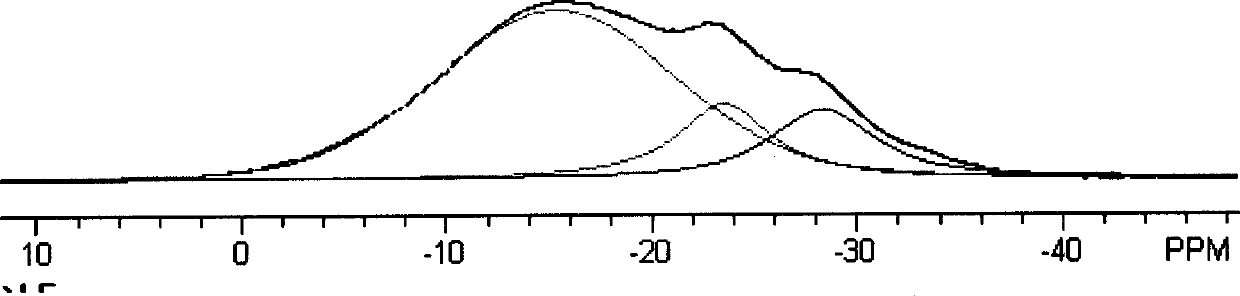

Image

Examples

Embodiment 1

[0040] Get 1000 grams of NaY molecular sieves (dry basis weight, produced by Qilu Catalyst Factory, silicon-aluminum ratio 4.96, the same below), after beating with 8 liters of deionized water, add RECl with a concentration of 157g / l 3 Solution (mixed rare earth chloride solution, in which La is calculated as oxide 2 o 3 36 wt%, CeO 2 Account for 64% by weight) 1250 milliliters, exchange 0.5 hour at 85 ℃, then add 200 milliliters of water glass solution (modulus 3.2, produced by Qilu Catalyst Factory) with a silicon oxide concentration of 250 g / l, stir at constant temperature for 0.5 hours, filter and rinse , and then roast the filter cake at 580° C. in a 100% water vapor atmosphere for 2 hours to obtain dry molecular sieve powder. Take 1000 grams of this molecular sieve dry powder (dry basis weight), beat with 4 liters of deionized water, add 500 grams of ammonium chloride solid, 35 grams of ammonium dihydrogen phosphate solid, exchange at 85 ° C for 0.5 hours, filter and r...

Embodiment 2

[0044] Take 1000 grams of NaY molecular sieves, after beating with 8 liters of deionized water, add RECl with a concentration of 157g / l 3 1875 ml of solution, exchanged at 90°C for 1 hour, then added 400 ml of water glass solution with a concentration of 250g / l, stirred at constant temperature for 0.25 hours, filtered and rinsed, and then roasted the filter cake at 600°C in a 100% water vapor atmosphere After 2 hours, a molecular sieve dry powder was obtained. Take 1000 grams of this molecular sieve dry powder, beat with 10 liters of deionized water, add 500 grams of ammonium sulfate solid, 35 grams of diammonium hydrogen phosphate solid, exchange at 85°C for 0.5 hour, filter and rinse, and dry the filter cake to obtain the present invention. Molecular sieve, the sample is marked as A2.

[0045] Rare earth content in A2 is expressed as RE 2 o 3 Calculated as 16.6% by weight, the phosphorus content is expressed as P 2 o 5 Calculated as 1.8% by weight, silicon to aluminum r...

Embodiment 3

[0048] Take 1000 grams of NaY molecular sieves, after beating with 10 liters of deionized water, add RECl with a concentration of 157g / l 3 1060 ml of solution, exchanged at 90°C for 1 hour, then added 200 ml of water glass solution with a concentration of 250g / l, stirred at constant temperature for 1 hour, filtered and rinsed, and then roasted the filter cake at 600°C in a 100% water vapor atmosphere After 2 hours, a molecular sieve dry powder was obtained. Take 1000 grams of this molecular sieve dry powder, beat with 10 liters of deionized water, add 500 grams of ammonium chloride solid, exchange at 75 ° C for 1 hour, filter and rinse, add 660 grams of 10% by weight ammonium dihydrogen phosphate aqueous solution to the filter cake, and beat After 1 hour, put it into a tray and dry it in an oven to obtain the molecular sieve of the present invention, which is denoted as A3.

[0049] Rare earth content in A3 is expressed as RE 2 o 3 Calculated as 12.9% by weight, the phosphoru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com