Graphene-coated variable phase nano magnetic composite material and preparation method thereof

A graphene-coated, nano-magnetic technology, applied in the direction of magnetic materials, inductors/transformers/magnets, magnetic objects, etc., can solve the problems affecting the development, application and preparation of graphene/carbon-coated iron and iron-nitrogen compound powders Strict conditions, complex test equipment, etc., to achieve the effect of mass production, short preparation process, and reduction of toxicity and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the ink olefin-coated variable-phase nano magnetic composite material provided by the present invention includes the following steps:

[0035] (1) After cleaning the reaction chamber of the plasma generator with inert gas continuously and several times, fill the entire reaction chamber with inert gas to isolate the air;

[0036] (2) After a stable inert gas plasma flow is obtained by excitation by the plasma power supply, a mixed plasma flow is formed by inputting a reactive gas source, and then the ferrocene powder is thermally evaporated, and the ferrocene vapor is sent into the plasma in the form of carrier gas Body center area

[0037] (3) Using the high plasma enthalpy and chemical activation effect, ferrocene is rapidly pyrolyzed and chemically reacted, and nano-magnetic particles are obtained through nucleation and growth at the tail of the plasma flame, and the surface of the particles is coated with graphene;

[0038] (4) The reaction chamber ...

Embodiment 1

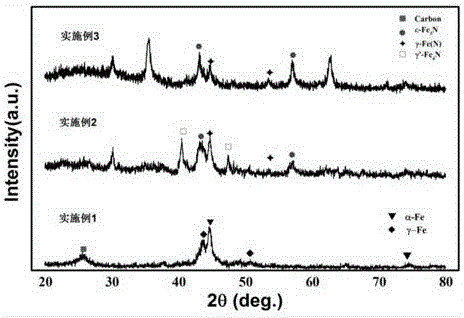

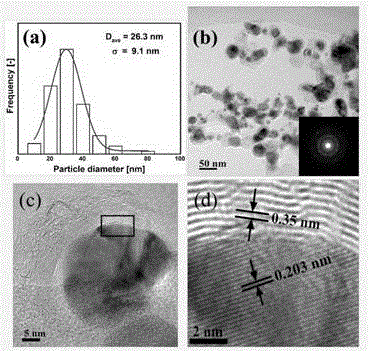

[0043] Using commercially available ferrocene powder as the raw material, after cleaning the reaction chamber with argon several times, argon is used as the plasma forming gas to establish a stable operating argon plasma. The argon flow rate is 5 slpm and the side shielding argon flow rate is 5slpm. The temperature of the constant-temperature fluidized bed is set to 120°C, and the ferrocene vapor is sent into the plasma flame through argon with a flow rate of 3 slpm. After the plasma high temperature decomposition and activation reaction, the graphene-coated variable phase nano magnetic particles are obtained. The XRD graph is as figure 1 As shown, the TEM image and particle size distribution are as figure 2 Shown.

[0044] by figure 1 It can be seen that the phase composition of Example 1 is α-Fe, γ-Fe and C. by figure 2 It can be seen that the particle size distribution of the obtained graphene-coated variable-phase nanomagnetic composite material is between 10 and 90 nm, an...

Embodiment 2

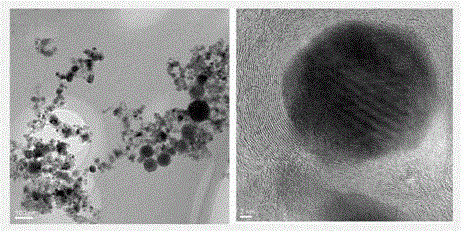

[0046] Using commercially available ferrocene powder as raw material, after cleaning the reaction chamber with argon for many times, argon and nitrogen are used as plasma forming gases to establish a stable operation of argon-nitrogen plasma. The flow of argon is 5slpm and the flow of nitrogen is 1slpm, the side shielding gas argon flow rate is 10slpm. The constant temperature fluidized bed was set to 160°C, and the carrier gas flow rate was 1 slpm of argon. The other operations were the same as in Example 1. The XRD pattern of graphene-coated iron nitride nano magnetic particles is obtained as figure 1 As shown, the TEM image is image 3 Shown.

[0047] by figure 1 It can be seen that the phase composition of the product prepared in Example 2 is γ-Fe(N), γ’-Fe 4 N, ε-Fe 3 N. by image 3 It can be seen that the obtained graphene-coated variable-phase nanomagnetic composite material has a particle size distribution between 10 nm and 90 nm, and has an obvious core-shell structure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com