Laser sintering synthesis method of ceramic-particle-reinforced nickel-aluminum-based composite

A composite material and laser sintering technology, applied in the field of material processing, can solve the problems of difficulty in adding reinforcements, poor interface bonding, and easy segregation of reinforcements, and achieve the effects of small size, improved comprehensive performance, and firm bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix nickel powder and aluminum powder according to the atomic ratio Ni:Al=3:1, and add 0.5wt% tungsten concentrate ore powder of the total mass of nickel-aluminum mixed powder, then put it into a ball mill tank and place it on a ball mill for 4 hours , the ball milling speed is 100rpm, and the mixed powder is obtained after ball milling;

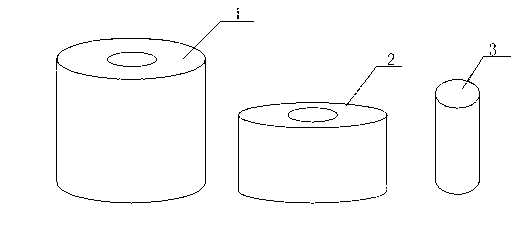

[0032] (2) using such as figure 1 As shown, the compact mold with a cylindrical cavity is composed of a stripping seat and a female mold. The mixed powder is placed in the cavity, and the cylindrical compact is pressed by a pressure rod under a pressure of 60KN. The height of the compact is 12mm, the relative density is 88%;

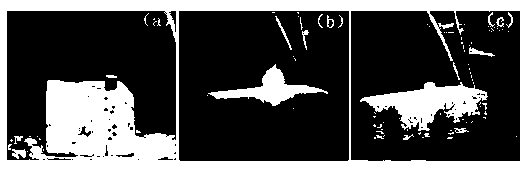

[0033] (3) Place the compact on the CNC machine tool, the CNC machine tool and CO 2Connect the laser processing machine, adjust the spindle of the CNC machine tool so that the diameter of the spot is the same as the diameter of the compact when the laser beam is irradiated vertically, and start the CO 2 L...

Embodiment 2

[0037] (1) Mix nickel powder and aluminum powder according to the atomic ratio Ni:Al=3:1, and add tungsten concentrate ore powder with a total mass of nickel-aluminum mixed powder of 1wt%, and then put it in a ball mill tank and place it on a ball mill for 5 hours. The ball milling speed is 150rpm, and a uniformly mixed powder is obtained after ball milling;

[0038] (2) using such as figure 1 As shown, the compact mold with a cylindrical cavity includes a knockout seat and a female mold. The mixed powder is placed in the cavity and pressed into a cylindrical compact with a pressure rod under a pressure of 70KN. The height of the compact is 15mm, the relative density is 88%;

[0039] (3) Place the compact on the CNC machine tool, the CNC machine tool and CO 2 Connect the laser processing machine, adjust the spindle of the CNC machine tool so that the diameter of the spot is the same as the diameter of the compact when the laser beam is irradiated vertically, and start the CO...

Embodiment 3

[0043] (1) Mix nickel powder and aluminum powder according to the atomic ratio Ni:Al=3:1, and add tungsten concentrate ore powder with a total mass of nickel-aluminum mixed powder of 2wt%, and then put it in a ball mill tank and place it on a ball mill for 6 hours. The ball milling speed is 200rpm, and a uniformly mixed powder is obtained after ball milling;

[0044] (2) using such as figure 1 As shown, the compact mold with a cylindrical cavity includes a knockout seat and a female mold. The mixed powder is placed in the cavity and pressed into a cylindrical compact with a pressure rod under a pressure of 80KN. The height of the compact is 18mm, the relative density is 88%;

[0045] (3) Place the compact on the CNC machine tool, the CNC machine tool and CO 2 Connect the laser processing machine, adjust the spindle of the CNC machine tool so that the diameter of the spot is the same as the diameter of the compact when the laser beam is irradiated vertically, and start the CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com