Processing technique for forming air nozzle of lighter

A molding process and lighter technology, which is applied in the direction of combustion ignition, lighting and heating equipment, igniters with fuel, etc., can solve the problems of low production efficiency, large loss of raw materials, small size of lighter gas nozzle, etc., and achieve fast processing speed , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

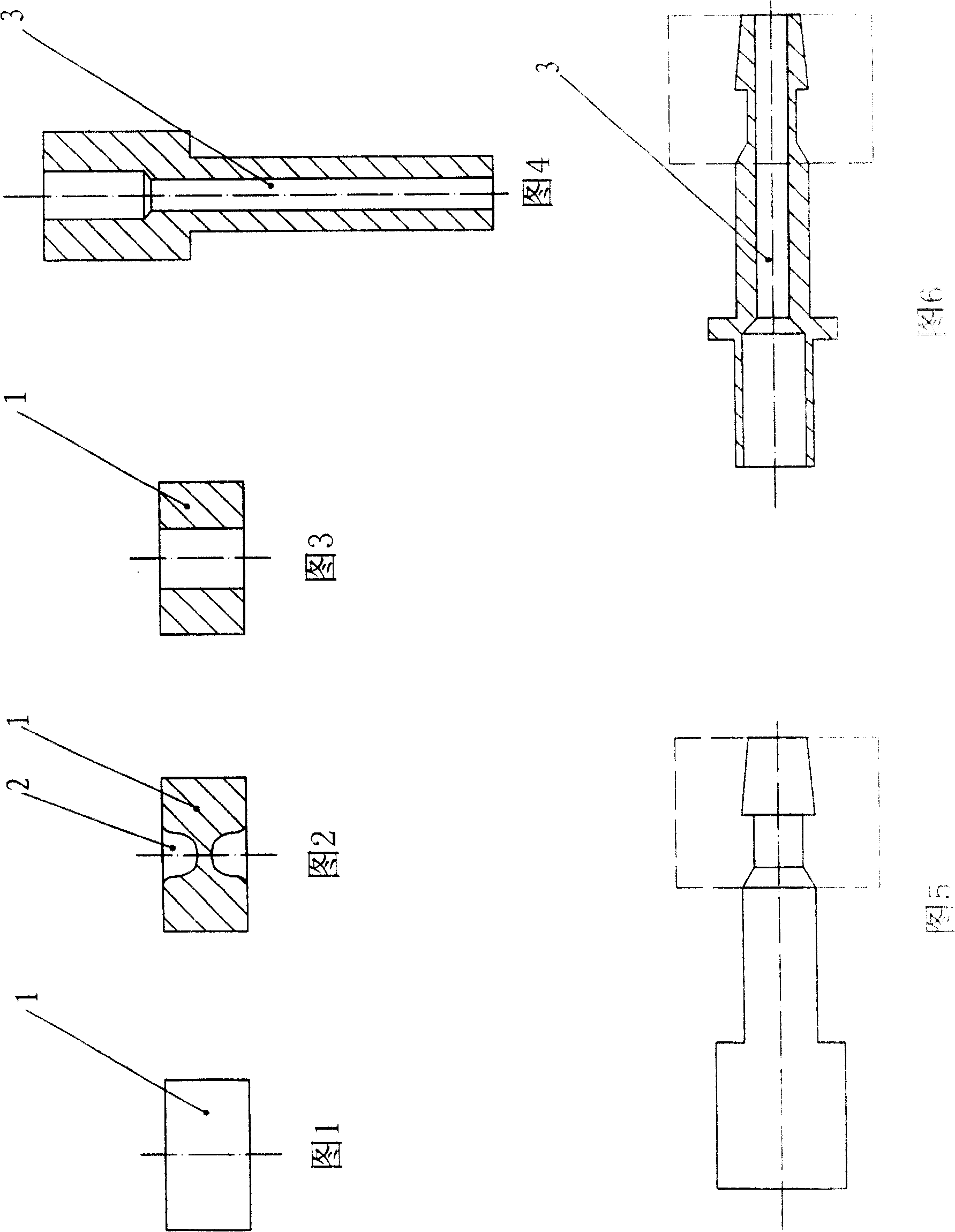

[0018] When this forming process is actually implemented, the blanking, pre-heading, punching and extrusion processes are completed by a general-purpose multi-station cold heading machine, and the raw material is a round strip of cheap metal, such as aluminum, iron, etc., with a diameter smaller than The outer diameter of the air nozzle is slightly larger, preferably between 3-6mm. The blanking is 1.1 to 1.15 times the volume of the air nozzle, and a circular pit 2 is pre-upset at the center of the two ends of the blank 1. The pit 2 The diameter is preferably between 1.2 and 1.25 times the center hole 3 of the air nozzle. The function of pre-upsetting is to facilitate the processing of the next process, that is, the drilling process. The higher the hardness of the selected material, the deeper the pit 2, and then Then carry out the drilling process to get through the pits 2 on both sides. The aperture is between 1.1 and 1.2 times the center hole 3 of the gas nozzle. The extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com