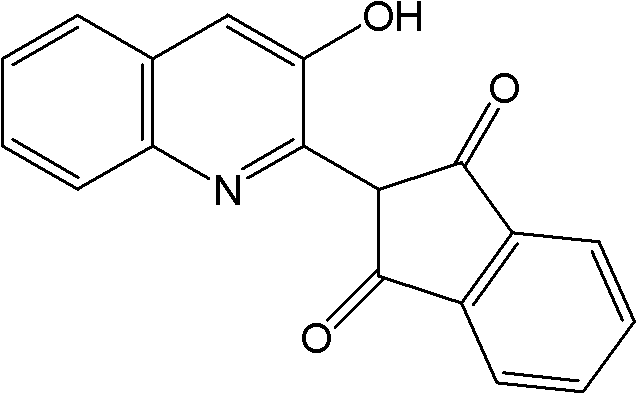

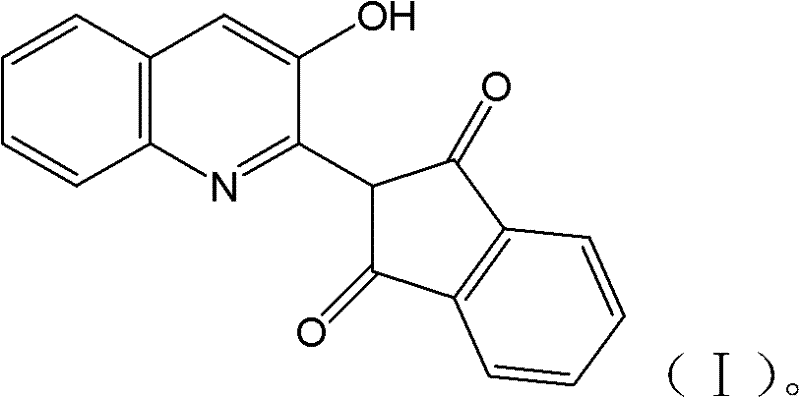

A kind of preparation method of disperse yellow dye

A technology for disperse yellow and dyes, which is applied in the field of preparation of quinoline disperse yellow dyes, can solve the problems of large amount of high-boiling point organic solvents, large amount of raw material phthalic anhydride, increased recovery of solvents, etc., to achieve reduced raw material consumption, convenient operation, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

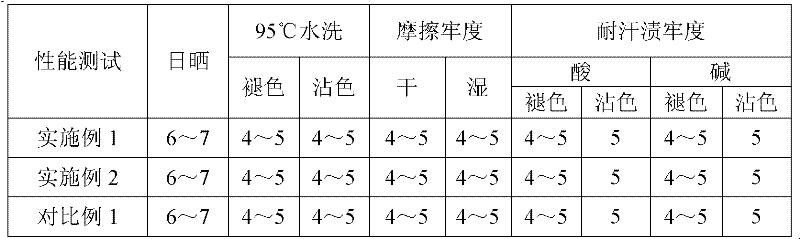

Embodiment 1

[0017] Put 812g of dry 4-carboxylic acid and 769.6g of phthalic anhydride into a 4L kneader, start stirring, slowly raise the temperature, control the temperature of the material at 180-190°C, keep it warm for 2 hours, and cool down to 55°C until no bubbles are generated. °C, after the material is cooled, transfer the material to 4.8L of water, raise the temperature to 90-95 °C, keep it warm for 1-2 hours, filter, and wash the filter cake with hot water at 80 °C to pH 6.5.

Embodiment 2

[0019] Put 609g of dry 4-carboxylic acid and 666g of phthalic anhydride into a 4L kneader, start stirring, slowly raise the temperature, control the temperature of the material at 190-200°C, keep it warm for 2 hours until no bubbles are generated, then cool to room temperature, Transfer this material to 3L of water, heat up to 90-95°C, keep warm for 1-2h, filter, and wash the filter cake with hot water at 75°C to pH 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com