High-light fastness yellow disperse dye mixture and application thereof

A technology of disperse dyes and mixtures, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of not being able to make bright yellow, poor lifting, and poor level dyeing, and achieve excellent light fastness, good Dye tolerance, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15 and comparative example 1-6

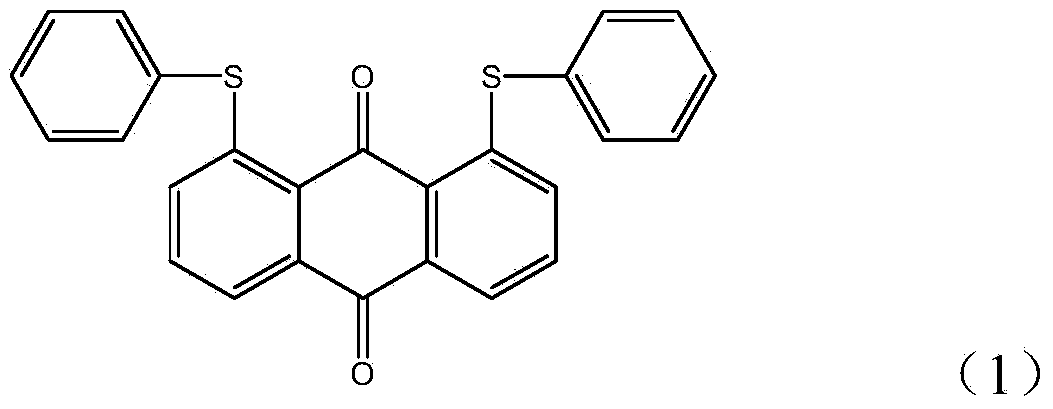

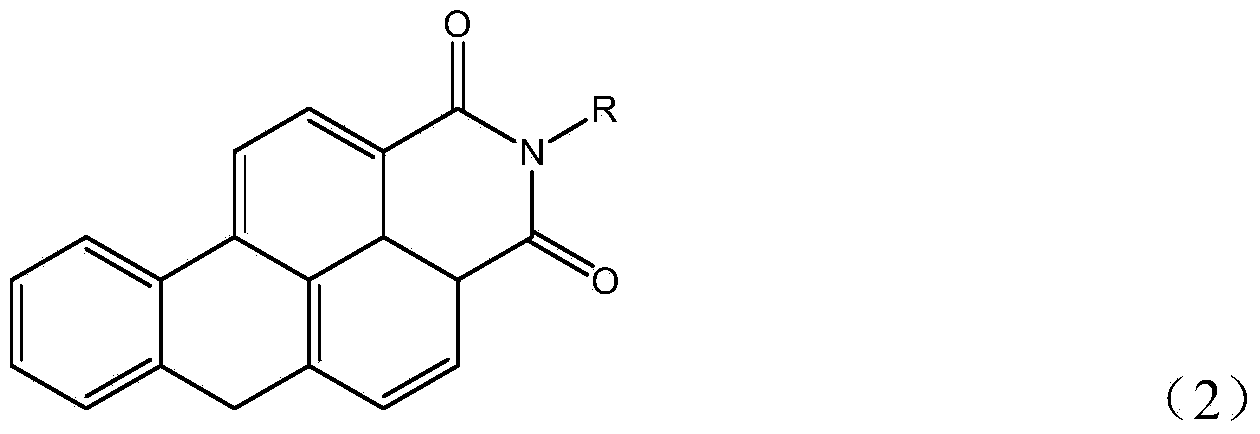

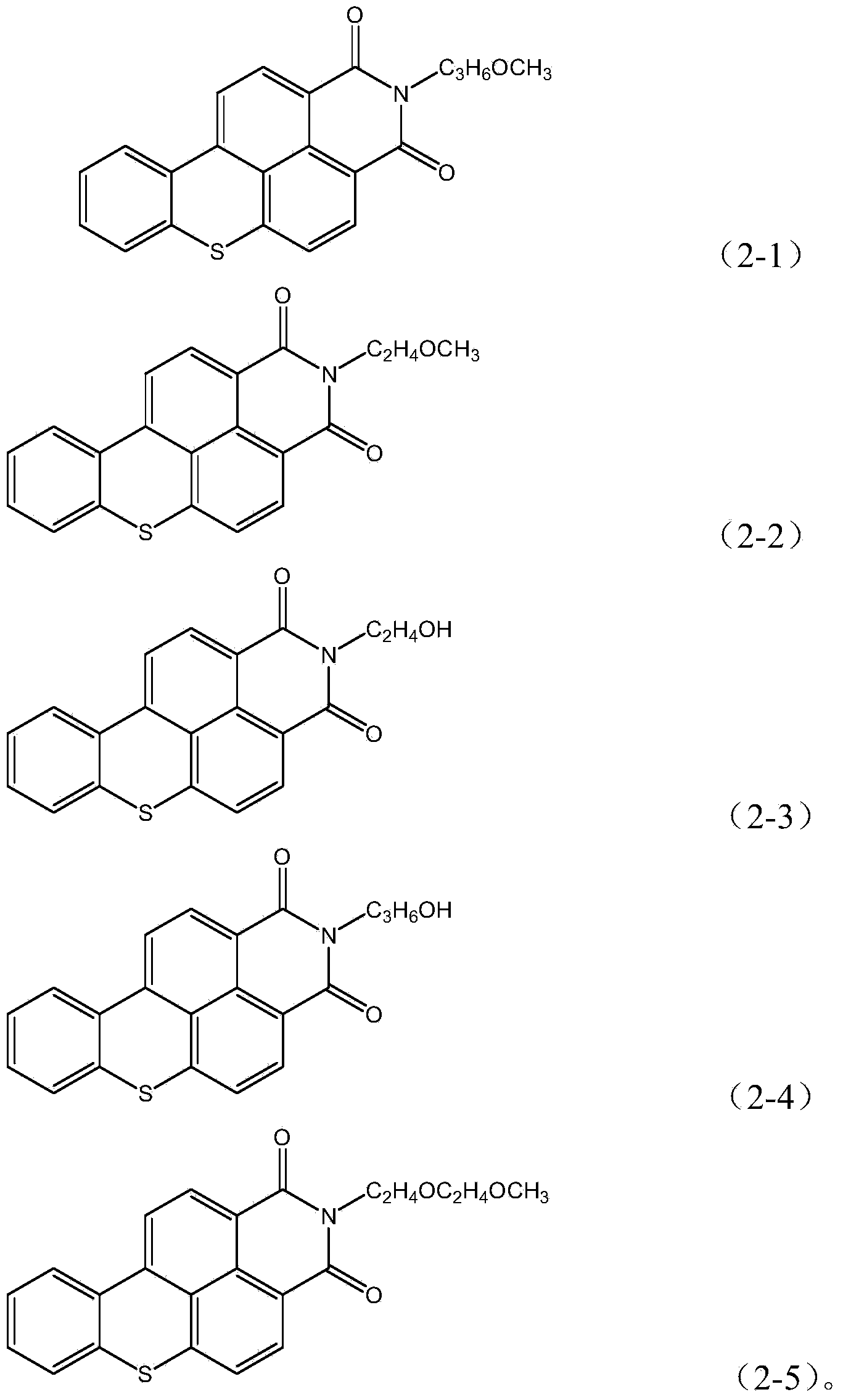

[0021] The dyes with the structure of Formula 1 and the dyes with the structures of Formula 2-1 to Formula 2-5 are mixed according to the ratio shown in Table 1, and 16 mg of the mixture is mixed with 49 mg of dispersant (using methylnaphthalenesulfonic acid formaldehyde condensate as the dispersant) After grinding and dispersing, add distilled water to make the volume to 100ml, add acetic acid / sodium acetate buffer solution to adjust the pH of the solution to 4.5, add 5g of polyester knitted fabric, heat up to 130°C and dye for 30 minutes, then take out the fabric sample for reduction cleaning, and fully rinse with water Dry to obtain yellow dyed fabric.

[0022] The light fastness test adopts the light fastness test method of Toyota Motor Corporation of Japan, using high-energy xenon lamps, and the irradiation density is 150W / m 2 (300-400nm), black panel temperature 73±3°C, 38 cycles of irradiation, each cycle including 3.8 hours of irradiation time and 1 hour of non-irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com