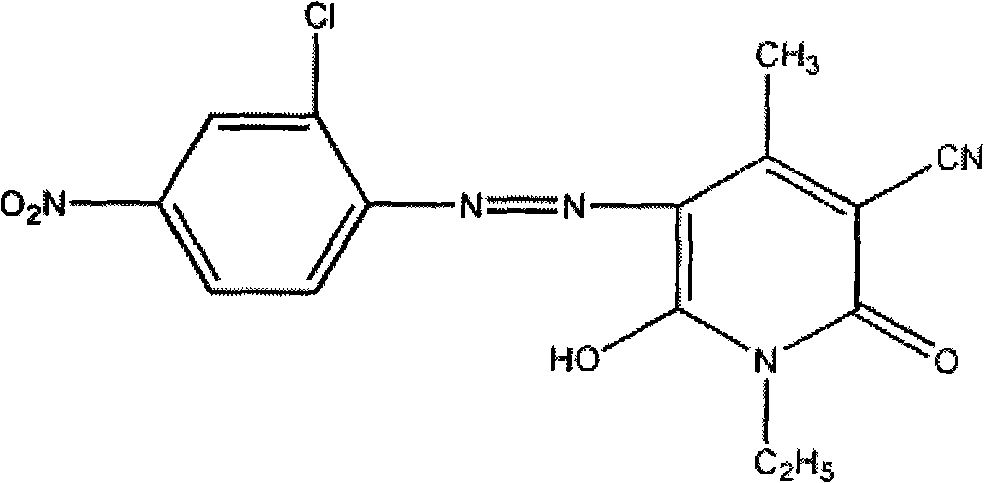

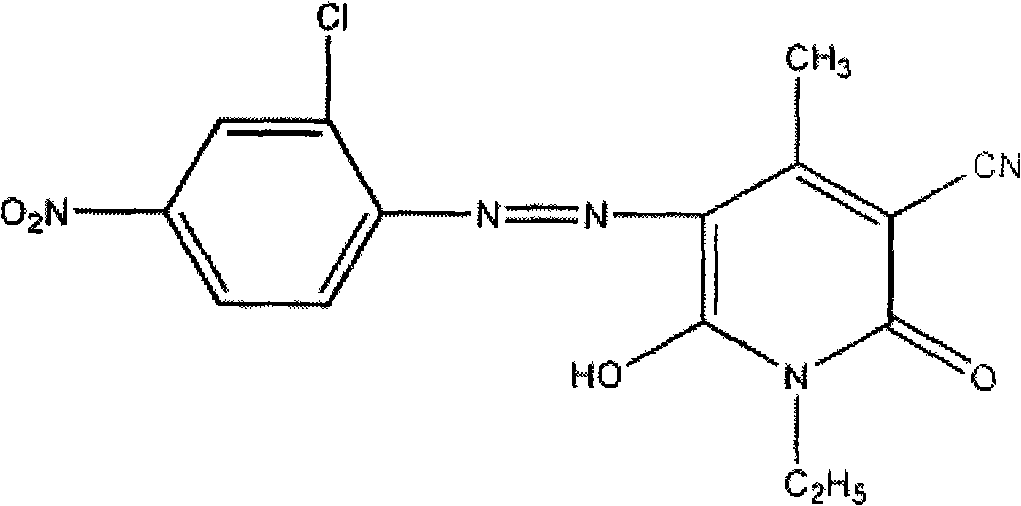

Monoazo type composition dye

A composition, monoazo technology, applied in the direction of organic dyes, dyeing, textiles and papermaking, etc., can solve the problems that have not been seen, and achieve the effect of strong color development power, good heat setting ability, and uniform color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

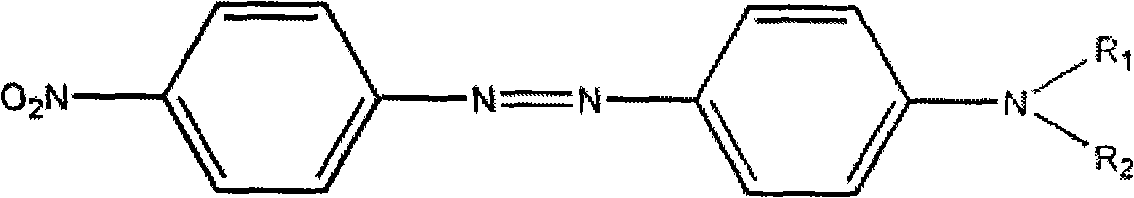

Method used

Image

Examples

Embodiment 31

[0037] Weigh respectively 0.500g of the finished dyes prepared in Examples 1-30, add 100mL of water to the beaker, stir on a magnetic stirrer for 10 minutes, and after all disperse into a uniform suspension, move to a 500mL volumetric flask, and use distilled water Dilute to volume and shake well. Draw 20.0mL of the prepared dye solution, add 80.0mL of water, adjust the pH to 4.0-5.0 with 1% HAc-NaCl solution, add 2.0g of polyester fabric, make a sample in a dyeing proofer, and raise it to 130°C in 45 minutes. And keep at 130 DEG C for 45 minutes, cool to room temperature, take out the fabric, and fully wash with water to obtain bright yellow or golden yellow fabric.

[0038]Taking the dispersed golden yellow E-3RL100% sample as a standard, the color light and intensity are compared, and the intensity of the monoazo type composition dye of the present invention increases with the decrease of the amount of diffusing agent, up to more than 300%, and the color light is between ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com