Heterogeneous white polyimide functional film and preparing method of functional film

A polyimide film and polyimide technology are applied in the field of non-homogeneous white polyimide functional film and its preparation, which can solve the requirement of thickness of the part, the limitation of the scope of application, and the influence of the comprehensive performance of the target part. and other problems, to achieve the effects of excellent performance, improved compactness, excellent and controllable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

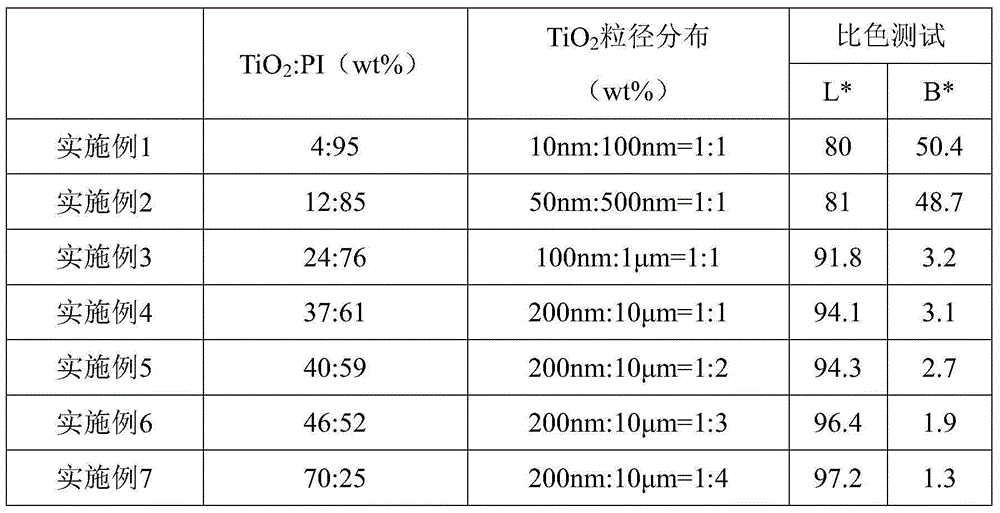

Examples

Embodiment 1

[0038] Take TiO with a particle size of 10nm 2 0.158g and 100nmTiO 2 Put 0.158g into 140g of absolute ethanol, stir ultrasonically at 20°C for 60min, the ultrasonic frequency is 100KHz, the TiO after reaction 2 The particles are washed, ground, dried and ready for use.

[0039] Weigh 3.5897g ODA, dissolve it in a reactor with 30g DMAc polar solvent, stir it ultrasonically at 20°C, the ultrasonic frequency is 100KHz, after it is completely dissolved, add the dianhydride monomer PMDA in an equimolar amount to ODA in 3 batches A total of 3.9103g, continue to stir ultrasonically at 20°C, and the ultrasonic frequency is 100KHz. With the continuous dissolution of the dianhydride monomer, the viscosity of the polymer is also increasing. After the monomer is completely dissolved, continue to react for 3.5h, and the obtained solid content is 20 % PAA solution 37.5g. The above TiO to be used 2 Add to the PAA solution, add 0.08g KH560 coupling agent at the same time, stir ultrasonica...

Embodiment 2

[0042] Take TiO with a particle size of 50nm 2 0.8g and 500nmTiO 2 Put 0.8g into 100g of absolute ethanol, stir ultrasonically at 15°C for 60min, the ultrasonic frequency is 100KHz, the TiO after reaction 2 The particles are washed, ground, dried and ready for use.

[0043] Weigh 4.8307g of DDS, dissolve it in a reactor containing 63.6106g of NMP polar solvent, stir it ultrasonically at 15°C, the ultrasonic frequency is 100KHz, after it is completely dissolved, add it in 3 batches, the molar mass ratio of DDS is 1.02:1 The total amount of dianhydride monomer BTDA is 6.3947g, continue to stir ultrasonically at 15°C, and the ultrasonic frequency is 100KHz. With the continuous dissolution of the dianhydride monomer, the viscosity of the polymer is also increasing. After the monomer is completely dissolved, continue to react for 3 hours to prepare 74.836 g of PAA solution with a solid content of 15% was obtained. The above TiO to be used 2 Add the PAA solution, add 0.4g KH550 ...

Embodiment 3

[0046] Take TiO with a particle size of 100nm 2 3.8g and 1μm TiO 2 Put 3.8g into 60g of absolute ethanol, stir ultrasonically for 30min at 25°C, the ultrasonic frequency is 20KHz, the TiO after reaction 2 The particles are washed, ground, dried and ready for use.

[0047] Weigh 12.0697g of BAPB, dissolve it in a reactor containing 58.5356g of DMAc polar solvent, and stir it ultrasonically at 25°C with an ultrasonic frequency of 20KHz. A total of 13.0170g of dianhydride monomer 6FDA, continued to stir ultrasonically at 25°C, with an ultrasonic frequency of 20KHz, as the dianhydride monomers continued to dissolve, the viscosity of the polymer also continued to increase. After the monomers were completely dissolved, the reaction was continued for 4 hours to obtain 83.6223g of PAA solution with a solid content of 30%. The above TiO to be used 2 Add to the PAA solution, add 0.015g KH550 coupling agent at the same time, stir ultrasonically at 25°C for 1h, and the ultrasonic freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com