Preparation method and application of composite microspheres

A technology of composite microspheres and grapefruit peel, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to avoid secondary pollution, strong adsorption and regeneration ability, and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

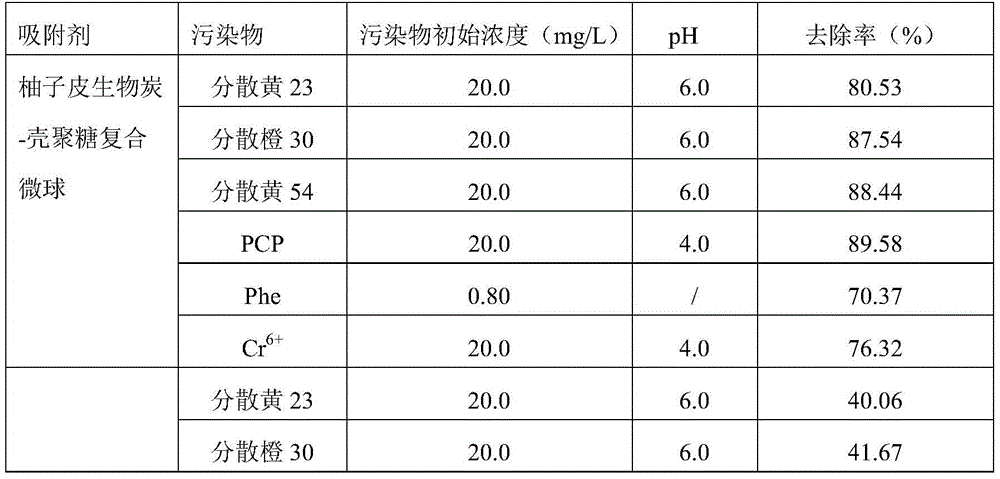

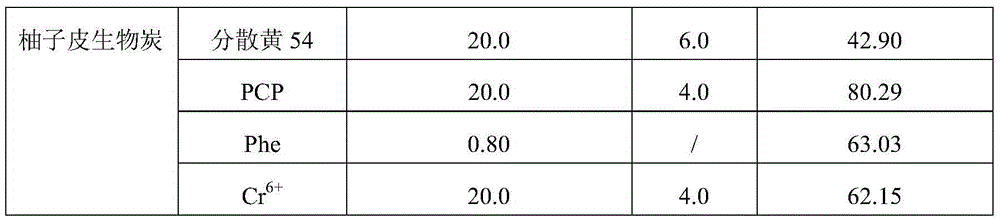

Examples

Embodiment 1

[0019] Recover the waste pomelo peel, wash it with deionized water, air-dry it to constant weight, crush it with a plant grinder, weigh 30.0-60.0g of pomelo peel powder in a bottle filled with N 2 Pyrolysis in a muffle furnace with a heating rate of 15°C / min and a pyrolysis temperature of 500°C. After pyrolysis for 2 hours, cool to room temperature and take it out. Pass through a 100-mesh sieve to obtain carbonized pomelo peel powder.

[0020] Take 10.0-20.0g of carbonized pomelo peel powder, soak it in 1mol / L hydrochloric acid (V:m=20:1), place it at 25°C and 180rpm and shake it at a constant temperature for 12h, filter it, discard the filtrate, and use The ionized water was washed repeatedly until the pH value of the filtrate was 7.0, and then dried at 60°C to obtain pomelo peel biochar.

[0021] Weigh 4.0g chitosan powder and add it to 100mL volume fraction of 1% acetic acid solution to dissolve, then add 4.0g pomelo peel biochar into the chitosan solution and stir it in a ...

Embodiment 2

[0031] Adsorbed disperse dyes, PCP, Phe and Cr in embodiment 1 6+ The grapefruit peel biochar-chitosan composite microspheres were washed with deionized water until there was no residue on the surface, and then desorbed in 0.05mol / L NaOH solution for 3 times. After the desorption was complete, the microspheres were washed with deionized water until medium The regenerated pomelo peel biochar-chitosan composite microspheres were obtained and used repeatedly for the adsorption experiments of corresponding pollutants. Disperse dyes, PCP and Cr during regeneration adsorption 6+ The initial concentration used is 20 mg / L, Phe is 0.8 mg / L, and the rest of the experimental conditions are consistent with Example 1. When the regeneration times are up to 4 times, it still maintains a good removal effect on pollutants. Disperse Yellow 23, Disperse Orange 30 and Disperse Yellow 54, PCP, Phe and Cr 6+ The removal rates were 65.63%, 68.11%, 71.47%, 60.45%, 57.42% and 61.38%, respectively. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com