Polyaluminum ferric chloride-paper mill sludge based polymer composite flocculant and preparation method thereof

A technology of polyaluminum ferric chloride and composite flocculants, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of ineffective removal of low-molecular organic matter and limit large-scale industrial production , high synthetic temperature requirements, etc., to achieve good coagulation effect, reduce infrastructure costs and operating costs, and have a long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

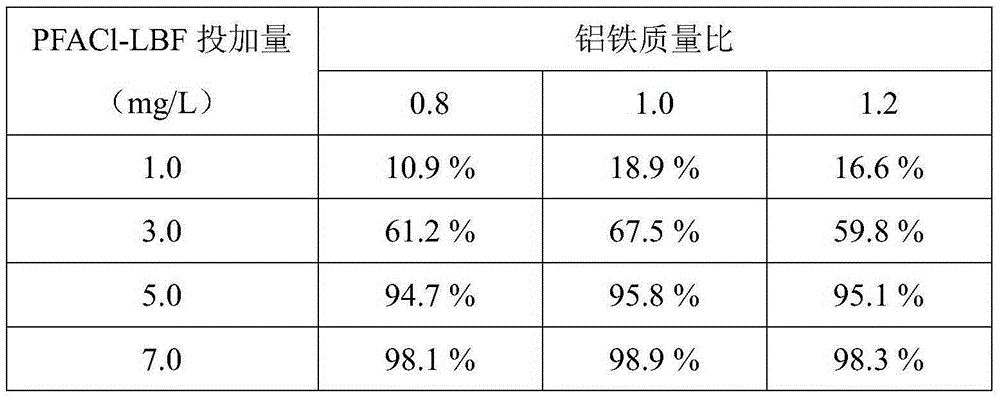

[0054] Embodiment 1. The preparation of the composite flocculant (PFACl-LBF) of different aluminum-iron mass ratios

[0055] (1) Weigh three groups of A1C1 with different mass ratios of aluminum and iron 3 ·6H 2 0 and FeC1 3 ·6H 2 0 solid and dissolved in deionized water, respectively the first group, A1C1 3 ·6H 2 0: 9.9g, FeC1 3 ·6H 2 0: 6.7g; second group, A1C1 3 ·6H 2 0: 11.2g, FeC1 3 ·6H 2 0: 6.0g; the third group, A1C1 3 ·6H 2 0: 12.4g, FeC1 3 ·6H 2 0: 5.3g. Add Na dropwise 2 CO 3 Solution, control alkalinity OH - :(Fe 3+ +Al 3+ ) in a mol ratio of 1.0, until completely dissolved under the effect of a magnetic stirrer. After the foam disappears, add 0.60 g of Na 2 HPO 4 12H 2 0 powder, continue stirring until completely dissolved. Finally dilute and settle to 250ml with distilled water, the mass concentration that makes (Fe+Al) is the polyaluminium ferric chloride solution of 10g / L;

[0056] (2) Weigh 2.0 g of papermaking sludge and dissolve it in...

Embodiment 2

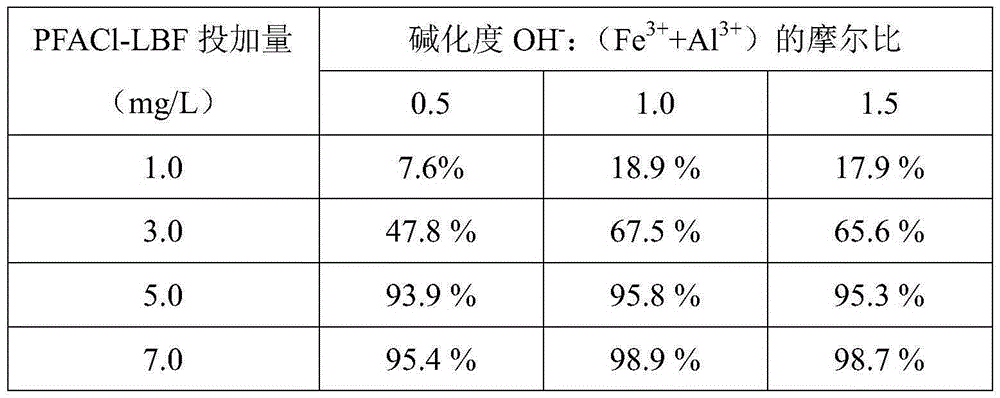

[0060] Embodiment 2. Preparation of the composite flocculant (PFACl-LBF) of different degrees of alkalization

[0061] Same as described in Example 1, the difference is A1C1 3 ·6H 2 0 dosage is 11.2g, FeC1 3 ·6H 2 The dosage of 0 is 6.0g, and the dosage of anhydrous sodium carbonate in step (1) is 7.3g, 14.6g, and 21.9g respectively, so that composite flocculant products with different degrees of alkalization can be obtained.

Embodiment 3

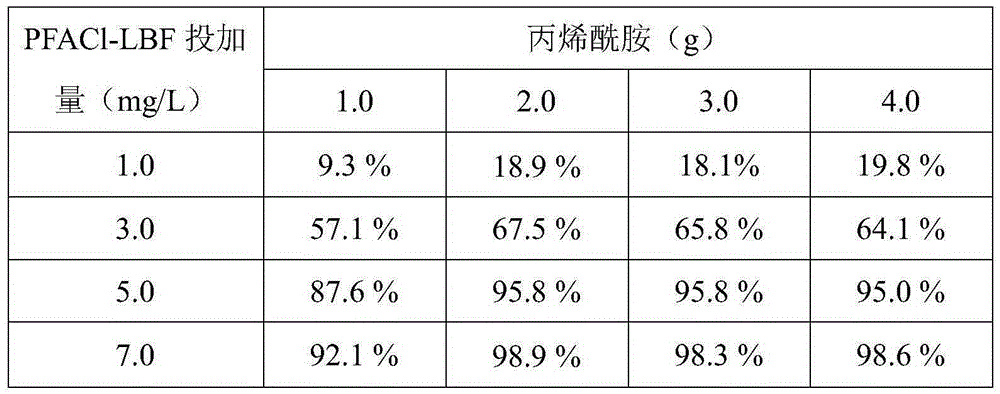

[0062] Embodiment 3. The preparation of the composite flocculant (PFACl-LBF) of different acrylamide addition amount

[0063] Same as described in Example 2, the difference is that the addition of anhydrous sodium carbonate is fixed at 14.6g, and the addition of acrylamide in step (2) is respectively 1.0g, 2.0g, 3.0g, 4.0g, to obtain final product Composite flocculant products with different amounts of acrylamide added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com