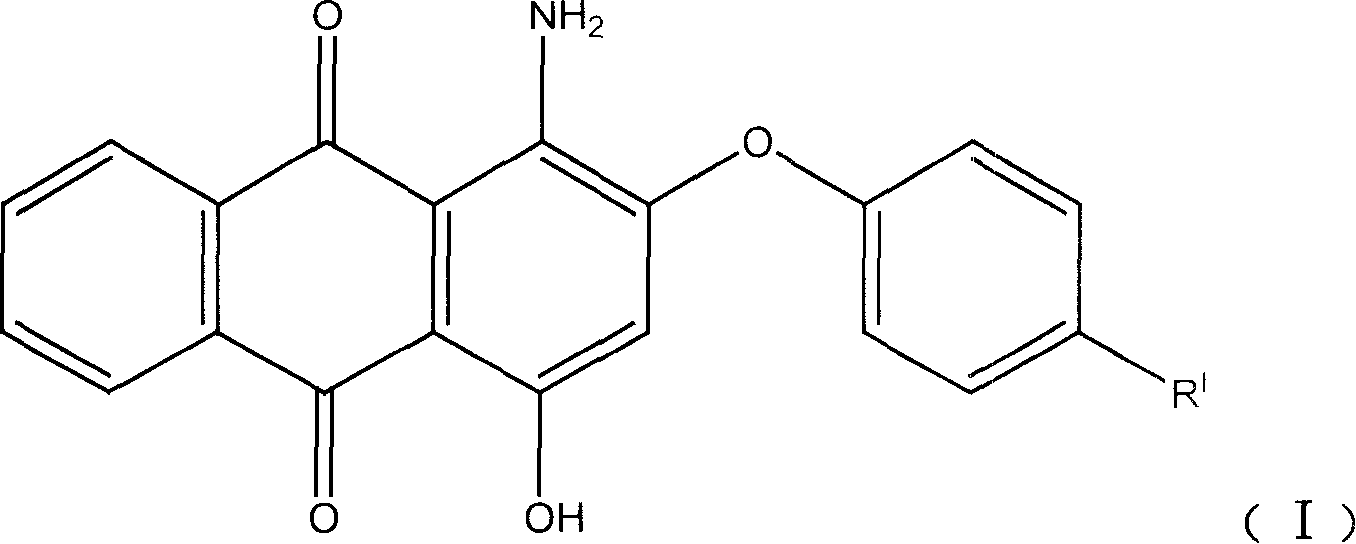

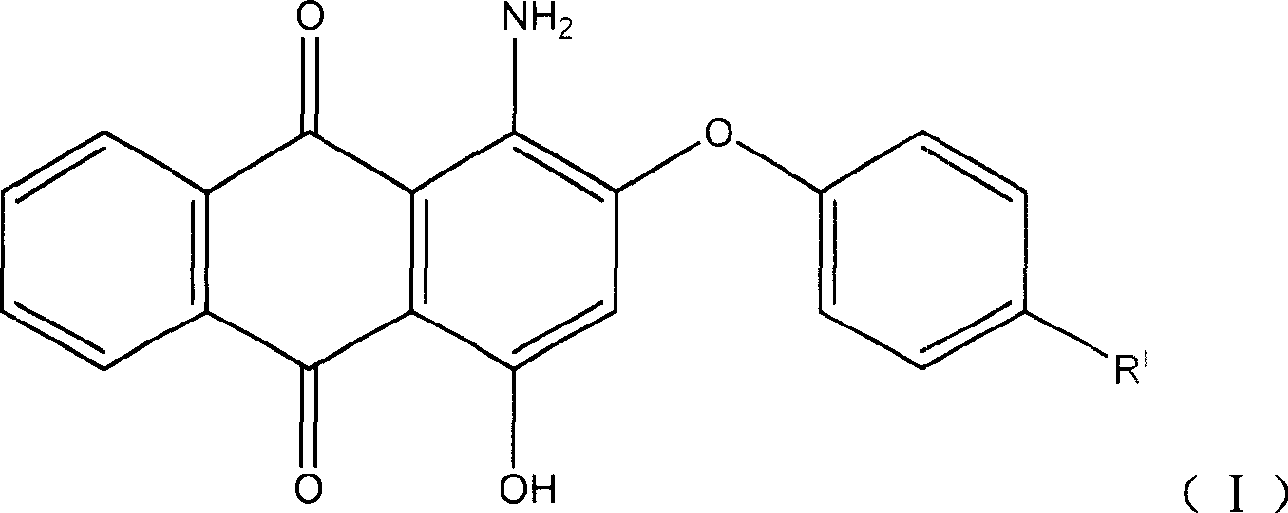

Sublimation fastness improved dispersion red dyes mixture

A dye mixture, sublimation fastness technology, applied in the direction of organic dyes, etc., can solve the problems of color change, sublimation inconsistency, etc., to achieve the effect of improving color change and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one: a kind of disperse red dye mixture

[0015] 1. Formula

[0016] Composition Content

[0017] Meet the C.I. disperse red 60 dyestuff of general chemical formula (IV) 52%;

[0018] C.I. Disperse Red 343 dye 10%;

[0019] Auxiliary balance.

[0020] 2. Preparation

[0021] The wet filter cake of the above dye and the auxiliary agent are sanded together according to the above ratio to process the finished product of the dye mixture.

Embodiment 2

[0022] Embodiment two: a kind of disperse red dye mixture

[0023] 1. Formula

[0024] Composition Content

[0025] Meet the C.I. disperse red 60 dyestuff of general chemical formula (IV) 50%;

[0026] C.I. Disperse Red 92 dye 16%;

[0027] Auxiliary balance.

[0028] 2, the preparation is the same as in Example 1.

Embodiment 3

[0029] Embodiment three: a kind of disperse red dye mixture

[0030] 1. Formula

[0031] Composition Content

[0032] Meet the C.I. disperse red 60 dyestuff of general chemical formula (IV) 60%;

[0033] C.I. Disperse Red 146 dye 26%;

[0034] Auxiliary balance.

[0035] 2, the preparation is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com