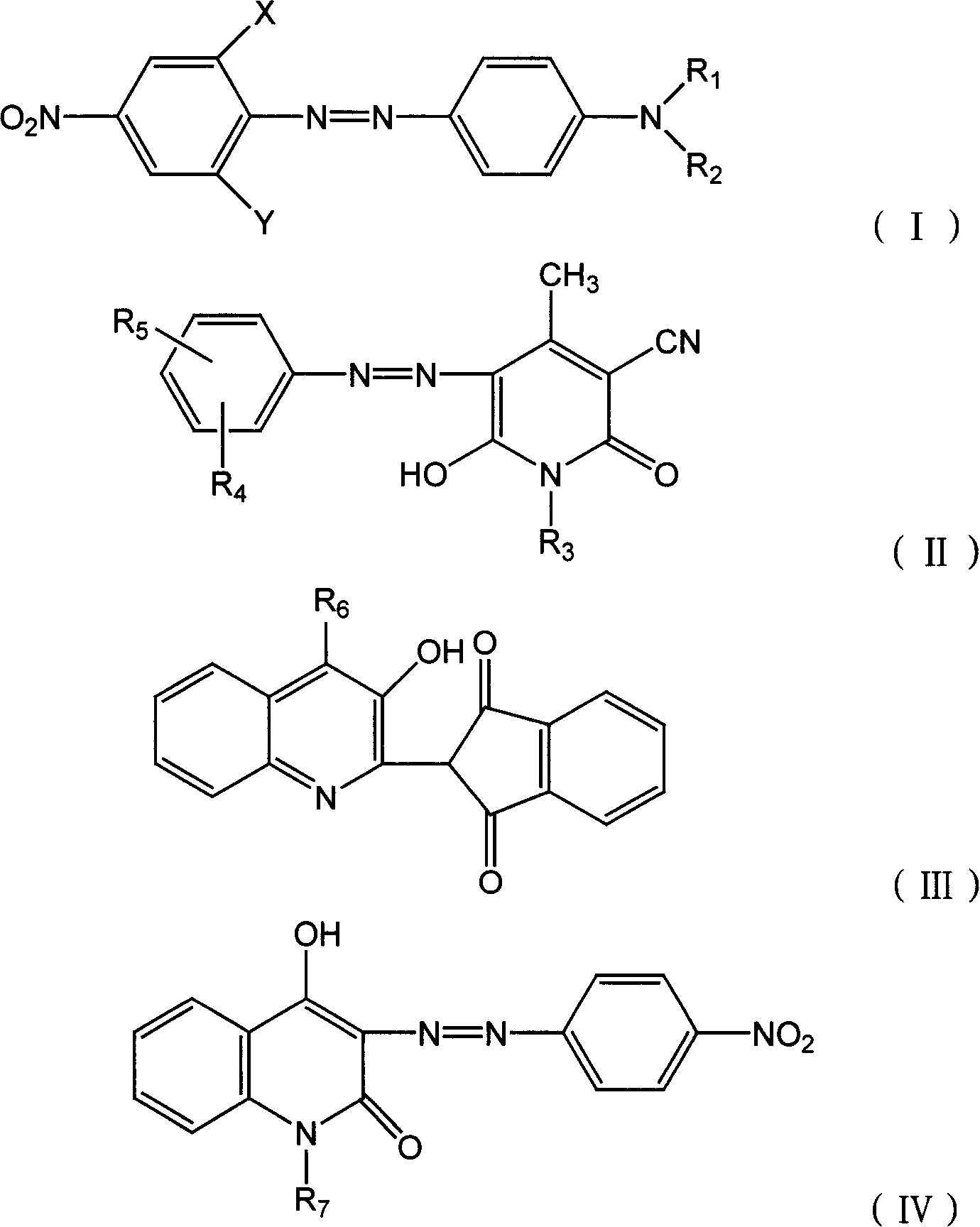

Disperse yellow-brown dye composition and disperse dye

A dye composition, yellow-brown technology, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of poor compatibility and reproducibility of disperse dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

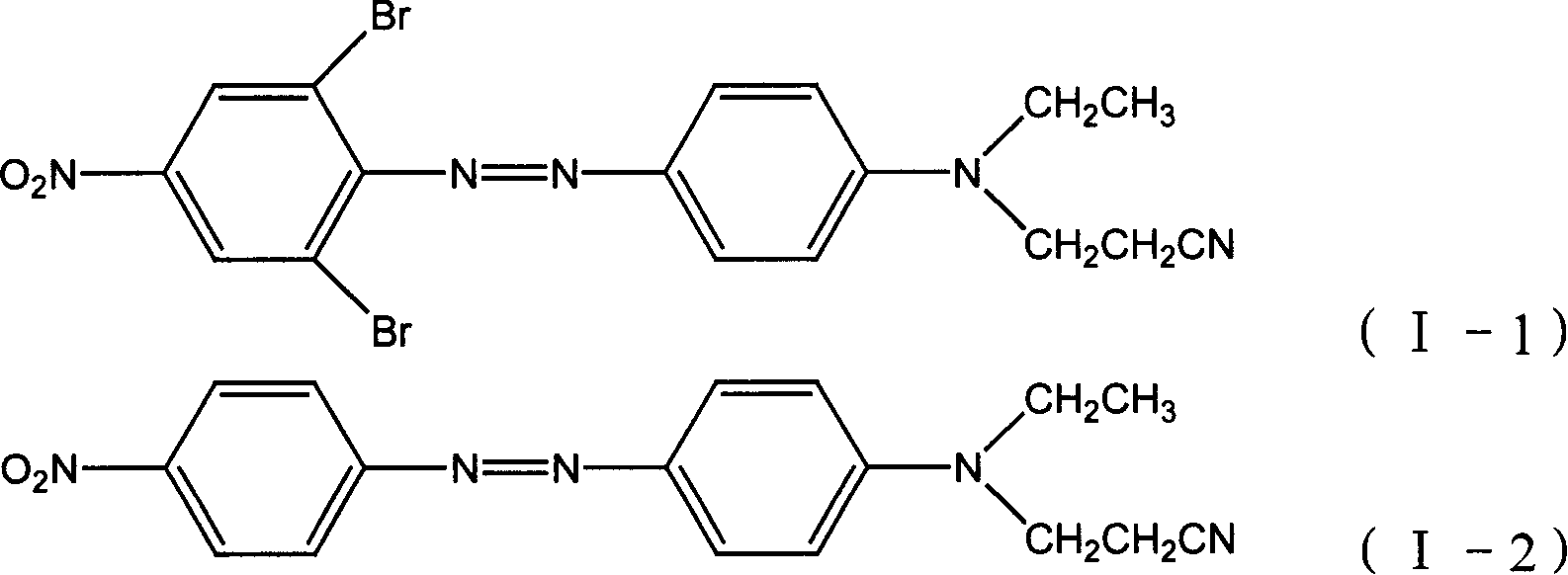

Embodiment 1

[0039] Component A of 84 grams of formula (I-1), component A of 5 grams of formula (I-2), component B of 11 grams of formula (II-1), sodium lignosulfonate of 195 grams, add water After blending, use a grinder to grind and disperse, and spray dry to obtain the finished product. The dye can provide uniform orange color to the fabric with good fastness.

[0040]

[0041]

Embodiment 2

[0043] Component A of 84 grams of formula (I-1), component A of 5 grams of formula (I-2), component B of 11 grams of formula (II-2), sodium lignosulfonate of 195 grams, add water After blending, use a grinder to grind and disperse, and spray dry to obtain the finished product. The dye can provide uniform orange color to the fabric with good fastness.

[0044]

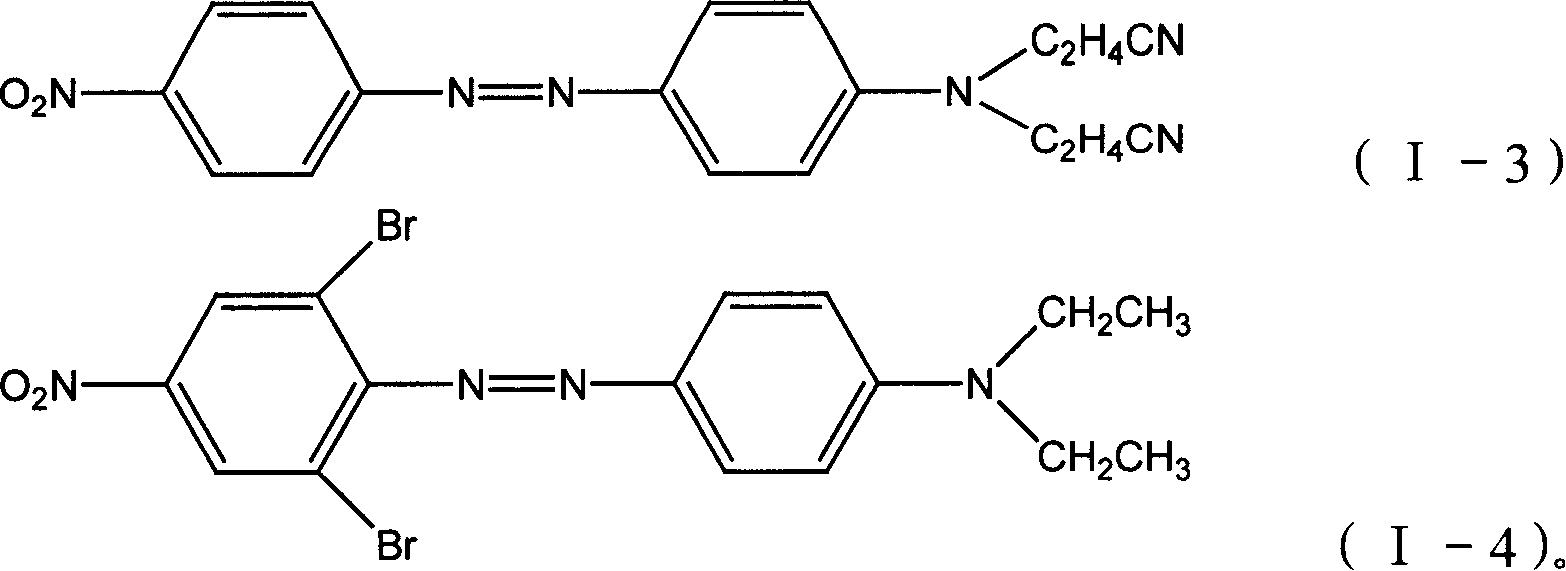

Embodiment 3~6

[0046] According to the data shown in Table 1, component A, component B, 195 grams of additives, and water were blended, ground and dispersed with a grinder, and then spray-dried to obtain a finished product.

[0047] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com