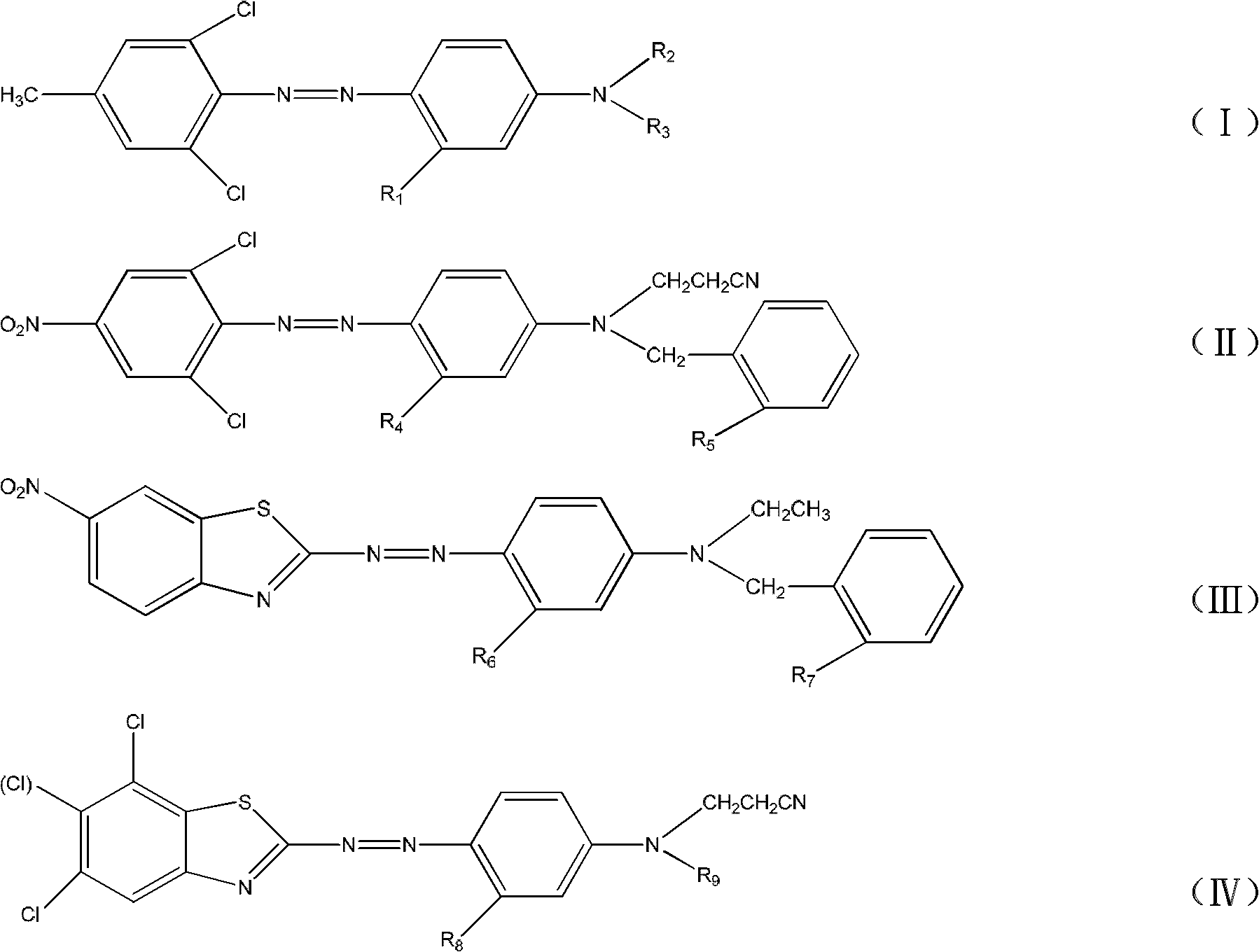

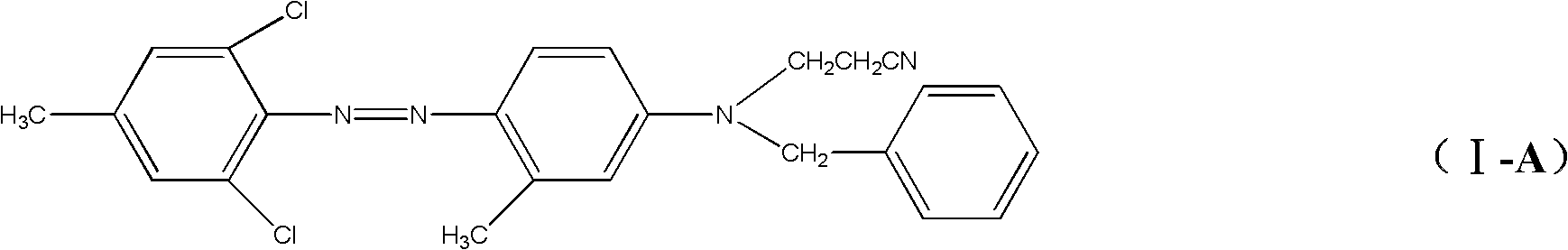

Disperse dye composition for disperse/reactive dye combination printing, and preparation and application thereof

A technology of disperse dyes and compositions, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of poor printing fastness, poor quality, white staining of printing, etc., reduce production costs, improve production efficiency, The effect of printing waste water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

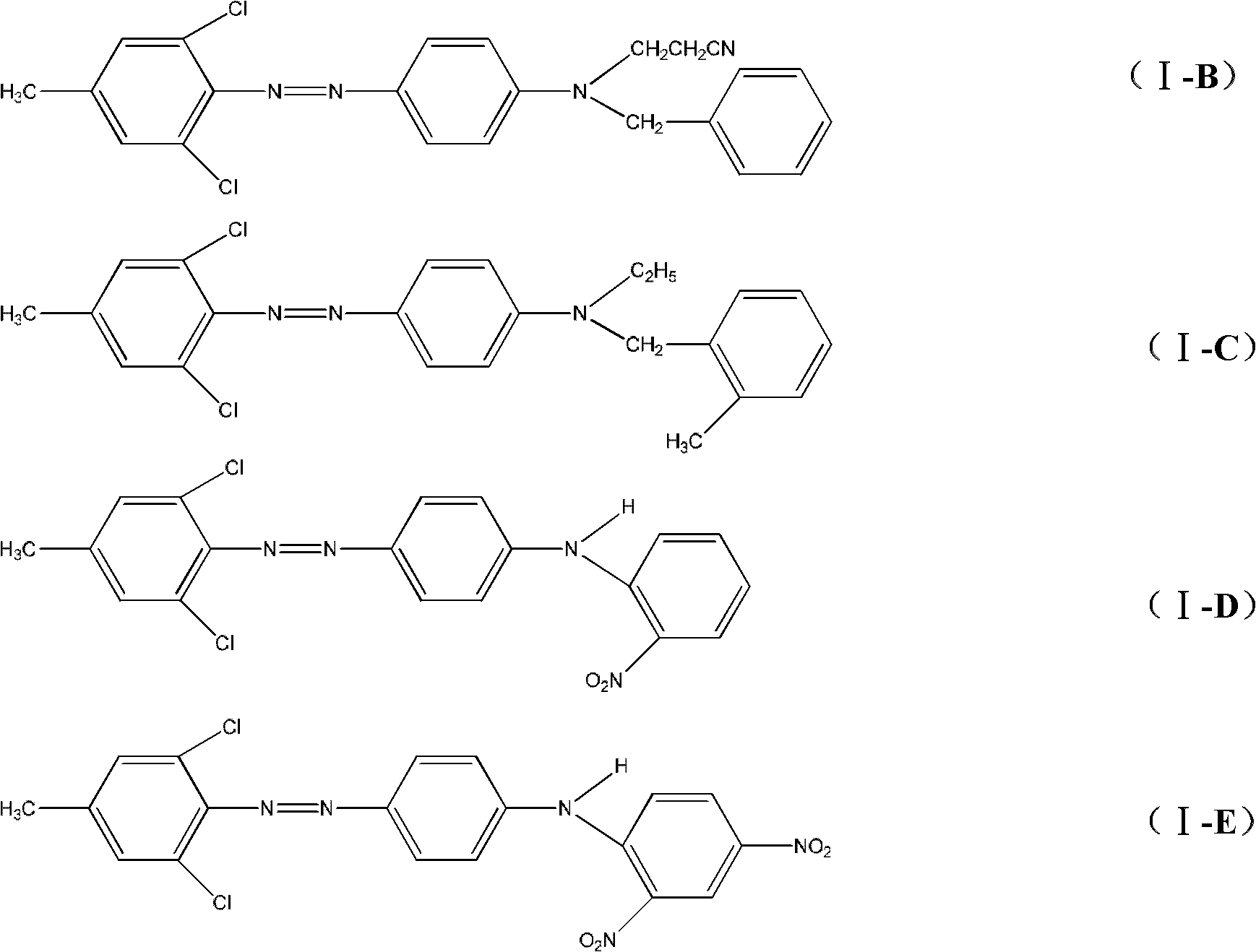

[0057] Mix 100kg formula (II-B) and 98kg formula (II-C) of the original disperse dye, 250kg dispersant MF, 50kg dicyandiamide, 25kg sodium bicarbonate and water, grind and disperse with a grinder, spray Dry to get the finished product. The dye is suitable for the new process of disperse / reactive one-size printing, and can provide orange hues with excellent fastness properties for fabrics.

Embodiment 2

[0059] After mixing 98kg formula (II-B) and 100kg formula (II-C) of the original disperse dye, 200kg dispersant MF, 25kg dicyandiamide, 30kg sodium bicarbonate and water, grind and disperse with a grinder, spray Dry to get the finished product. The dye is suitable for the new process of disperse / reactive one-size printing, and can provide orange hues with excellent fastness properties for fabrics.

Embodiment 3

[0061] Mix 50kg formula (II-B), 150kg formula (II-C) of the original disperse dye, 200kg dispersant MF, 25kg nicotinic acid, 30kg sodium bicarbonate and water, grind and disperse with a grinder, and spray dry , the finished product is obtained. The dye is suitable for the new process of disperse / reactive one-size printing, and can provide orange hues with excellent fastness properties for fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com