Complex dye composition, complex disperse dyes and preparation methods of composition and dyes

A dye composition and composite dispersion technology, which is applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of low cost and urgent need, and achieve low cost, high compatibility and good level dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

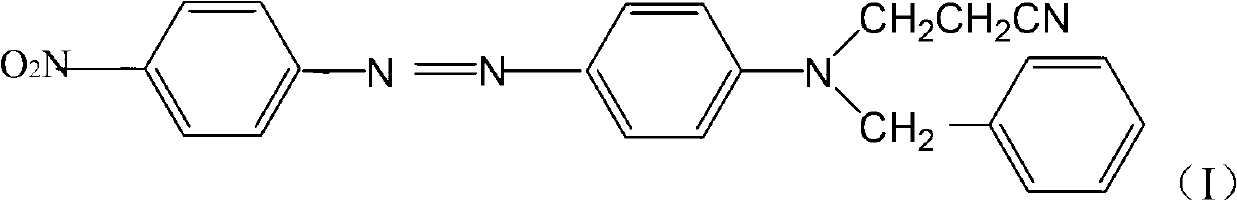

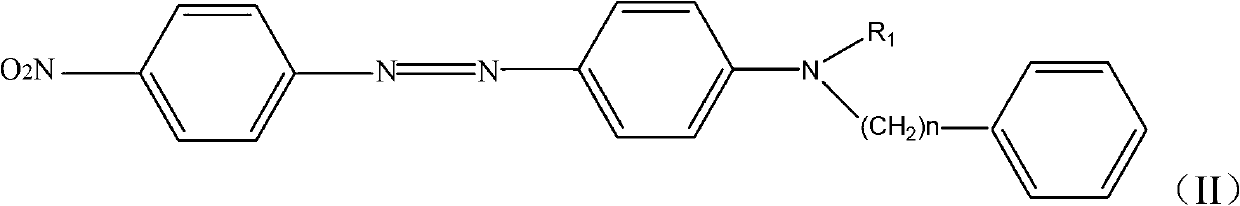

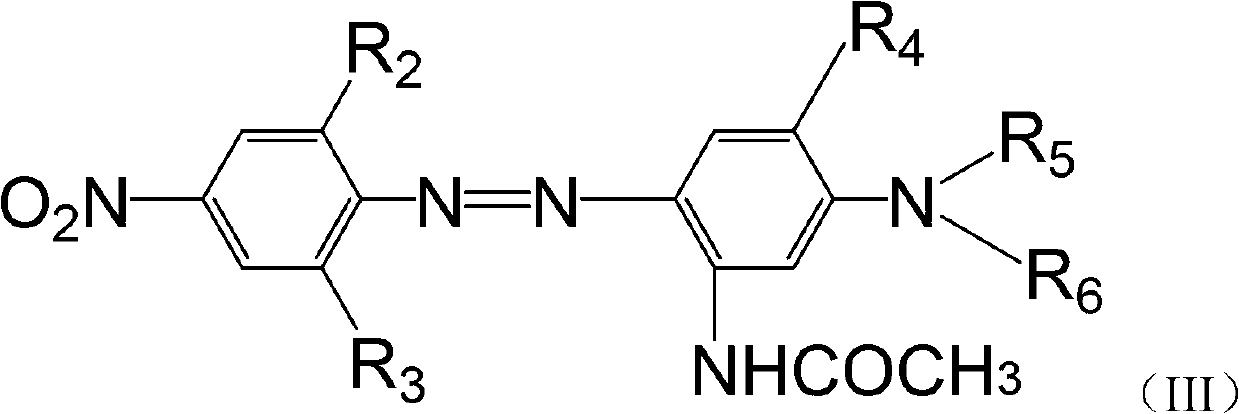

Image

Examples

Embodiment 1-6

[0033] According to the components and contents shown in Table 1, the prepared composite dye composition, auxiliary agent and water were mixed, ground, and spray-dried to obtain a composite disperse dye.

[0034] Table 1

[0035]

[0036] Use 0.1 g of the composite disperse dyes prepared in Examples 1-6, together with 10 g of polyester fabric and water, adjust the pH of the dyeing bath to 5~5.5 with acetic acid, heat up to 130 ° C within 35 minutes, and keep the temperature for 30 Minutes, cooled to 80°C and sampled to obtain a yellow to orange textile material. According to the standards of GB / T2397-2003 and GB / T2043-2006, the lifting force and pH adaptation were tested, and the results are shown in Table 2.

[0037] Table 2

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com