Formula of foam disperse dyeing system and preparation method thereof

A dyeing system and technology of disperse dyes, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of white edges, uneven dyeing, etc., and achieve high fastness, uniform dyeing cloth surface, and high color yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

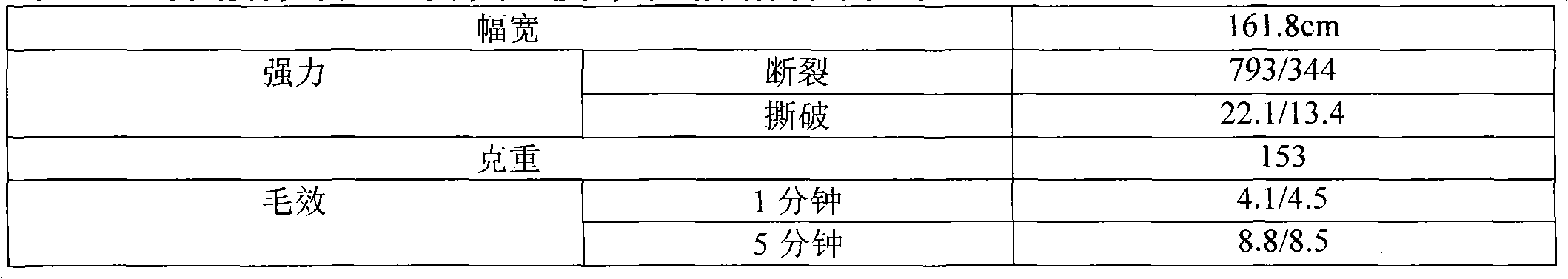

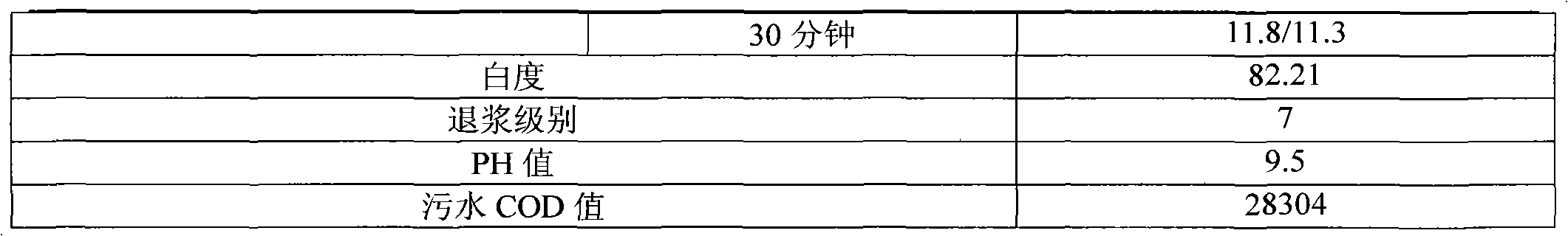

Embodiment 1

[0047] The formula of the foam dyeing system: foaming agent 4g / L, thickener ACRACONC 2C 4g / L, dispersant CM-5 1ml / L and high temperature disperse dye 20g / L.

[0048] Foaming agent is sodium dodecylsulfonate;

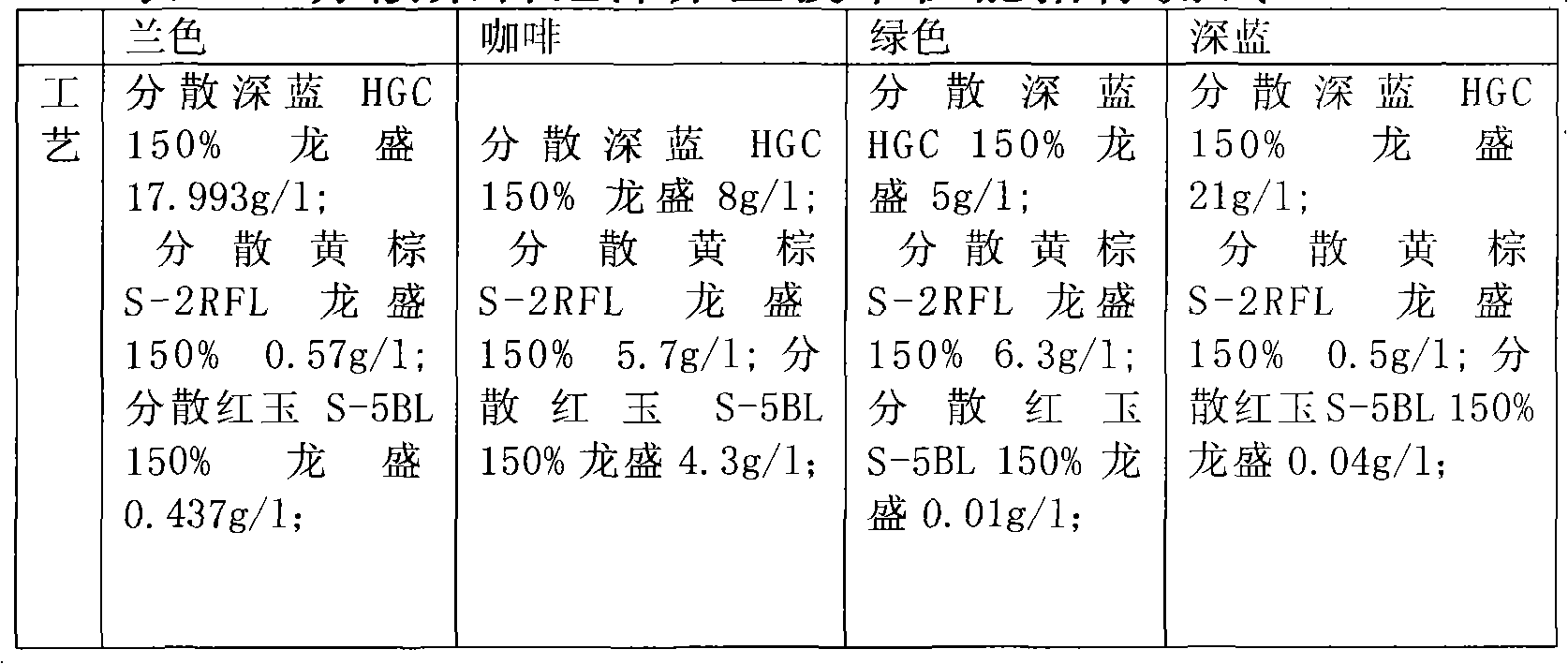

[0049] The disperse dye is a mixture of high temperature disperse dark blue, disperse yellow brown and disperse ruby.

[0050] Preparation of thickener: Weigh a certain amount of thickener according to Xie’s formula, add distilled water according to the ratio of thickener to distilled water 1:5, stir slightly, and place it for 24 hours for later use.

[0051] Preparation of dispersant: take a certain amount of dispersant according to the formula, add distilled water according to the ratio of 1:5 of dispersant to distilled water, stir to make it fully dissolve, and set aside.

[0052] A new method for foam dyeing, the detailed steps of the new method for foam dyeing are:

[0053]a. According to the formula of the above-mentioned foam dyeing system, put the prepared foam...

Embodiment 2

[0057] The formula of the foam dyeing system: foaming agent 6g / L, thickener ACRACONC 2C 6g / L, dispersant CM-5 5ml / L and high temperature disperse dye 45g / L.

[0058] The foaming agent is sodium dodecylsulfonate; the disperse dye is high-temperature disperse dark blue.

[0059] Preparation of thickener: Weigh a certain amount of thickener according to Xie’s recipe, add distilled water according to the ratio of thickener to distilled water 1:8, stir slightly, and place it for 24 hours for use.

[0060] Preparation of dispersant: take a certain amount of dispersant according to the recipe, add distilled water according to the ratio of 1:8 of dispersant to distilled water, stir to make it fully dissolved, and set aside.

[0061] A new method for foam dyeing, the detailed steps of the new method for foam dyeing are:

[0062] a. According to the formula of the above-mentioned foam dyeing system, put the prepared foaming agent, thickener, dispersant and high-temperature disperse dye...

Embodiment 3

[0066] The formula of the foam dyeing system: foaming agent 5g / L, thickener ACRACONC 2C 5g / L, dispersant CM-5 3ml / L and high temperature disperse dye 60g / L.

[0067] The foaming agent is sodium dodecylsulfonate; the disperse dye is high-temperature disperse dark blue.

[0068] Preparation of thickener: Weigh a certain amount of thickener according to Xie’s formula, add distilled water according to the ratio of thickener to distilled water 1:10, stir slightly, and place it for 24 hours for later use.

[0069] Preparation of dispersant: take a certain amount of dispersant according to the recipe, add distilled water according to the ratio of 1:10 of dispersant to distilled water, stir to make it fully dissolved, and set aside.

[0070] A new method for foam dyeing, the detailed steps of the new method for foam dyeing are:

[0071] a. According to the formula of the above-mentioned foam dyeing system, put the prepared foaming agent, thickener, dispersant and high-temperature dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com