High-precision polishing equipment for automobile parts

A high-precision technology for auto parts, applied in grinding/polishing equipment, metal processing equipment, parts of grinding machine tools, etc., can solve the problem of inability to polish auto parts, and achieve better polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

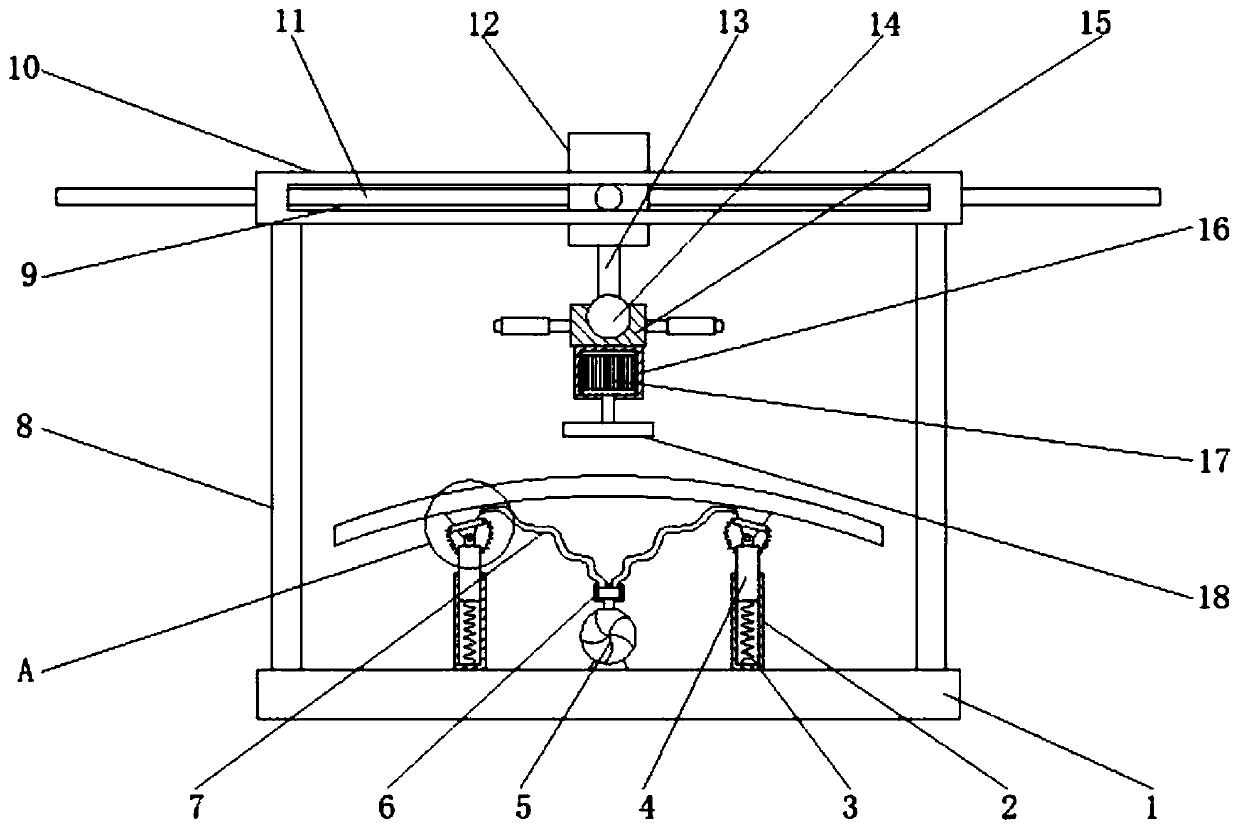

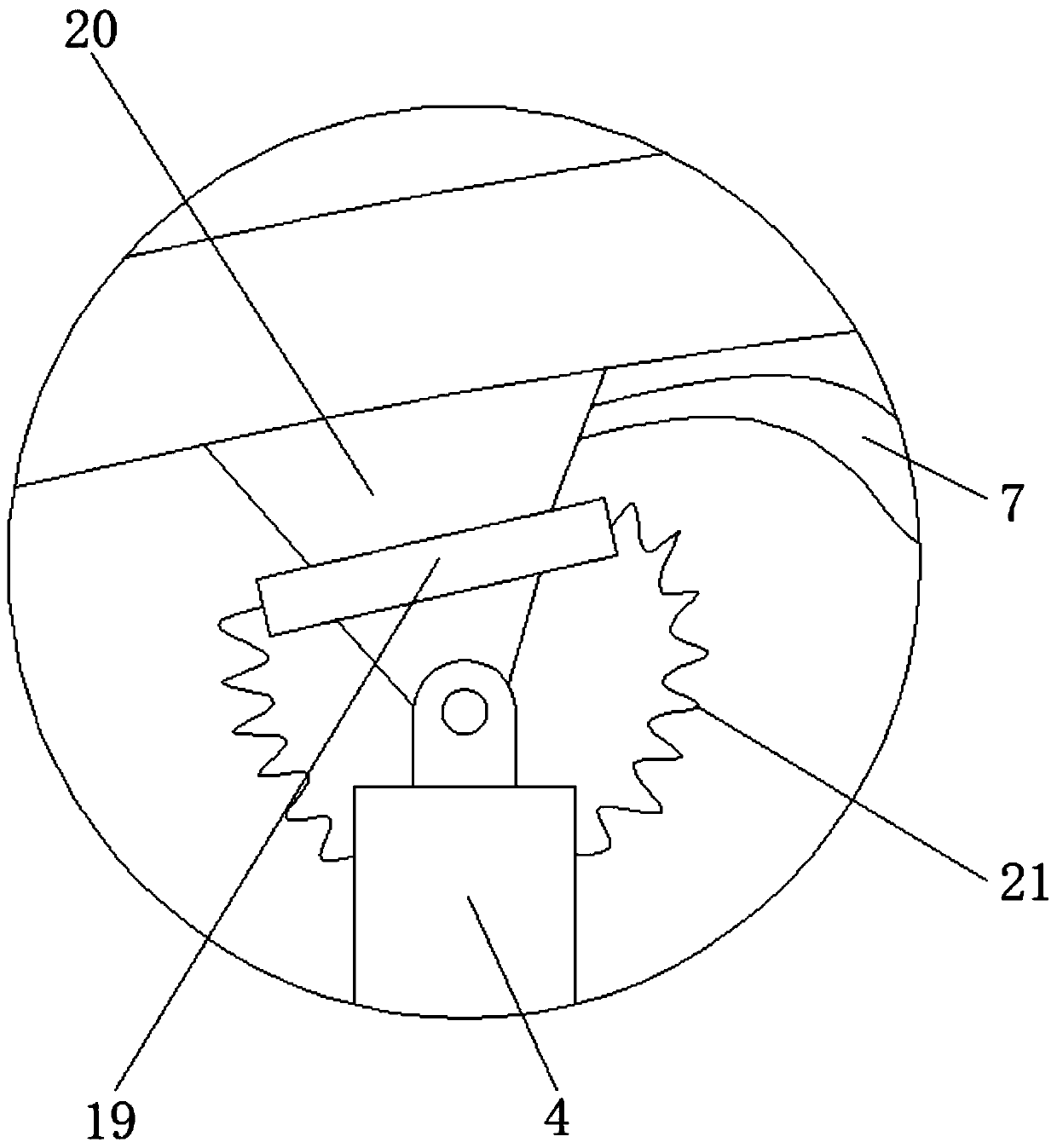

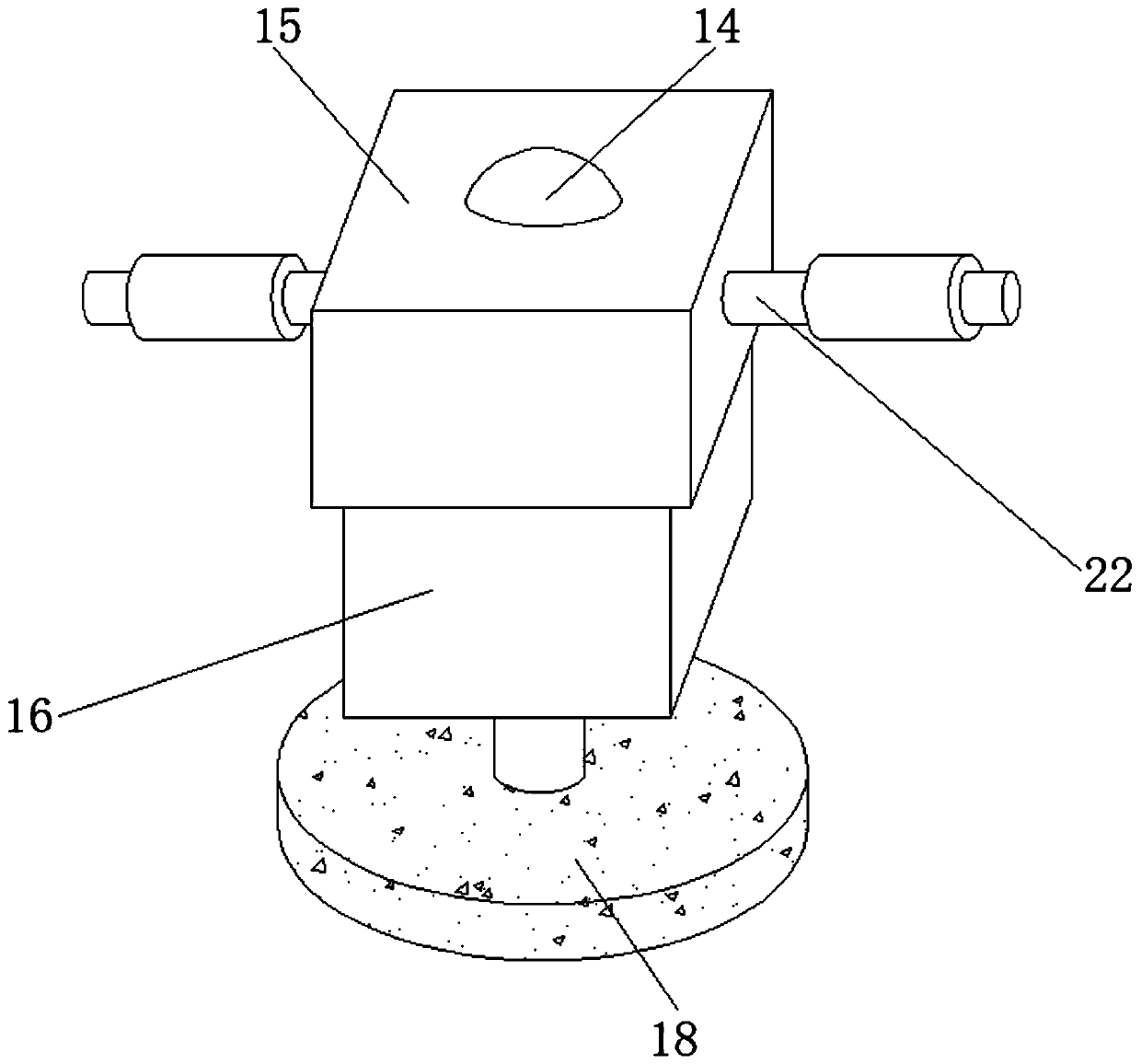

[0032] refer to Figure 1-4 , a kind of high-precision polishing equipment for automobile parts, comprising a bottom plate 1, four corners of the top outer wall of the bottom plate 1 are welded with fixed rods 8, and the top outer wall of the fixed rod 8 is welded with a fixed frame 10, and the outer walls around the fixed frame 10 are Have chute 9, and the inwall of chute 9 is slidably connected with slide bar 11, and the outer wall of one end of slide bar 11 is welded with movable case 12, and the top inner wall of movable case 12 is welded with the 3rd spring 23, the third spring 23 The bottom outer wall is welded with lifting plate 24, and the bottom outer wall of lifting plate 24 is welded with connecting rod 13, and the bottom outer wall of connecting rod 13 is welded with universal ball 14, and the outer wall of universal ball 14 is rotatably connected with movable seat 15, movable seat The bottom outer wall of 15 is welded with motor cover 16, and the inwall of motor c...

Embodiment 2

[0036] refer to Figure 5-7, a kind of high-precision polishing equipment for automobile parts. Compared with Embodiment 1, this embodiment also includes circular grooves 25 on the bottom outer wall of the polishing disc 18, and circular grooves 25 arranged on the inner wall of the circular groove 25. Groove 26, polishing disk 18 top outer walls are all provided with installation groove near the position of both sides, and the inwall of installation groove is provided with air guide pipe 27, and one end outer wall of air guide pipe 27 is connected with circular groove 25, and the air guide pipe 27 An air collecting pipe 28 is welded on the outer wall of the other end.

[0037] Working principle: when in use, when the polishing disc 18 rotates and polishes, the polishing debris generated by polishing will enter the chip removal groove 26, and the wind will enter the air guide pipe 27 through the air collecting pipe 28, and then blow through the air guide pipe 27. Enter the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com