An environment sanitation vehicle sweeping disk structure with turnover function

A technology for sanitation vehicles and sweepers, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems that the cornerstones on both sides of the road shoulder cannot be cleaned effectively and cannot meet the needs of high-standard cleaning, and achieve better cleaning results. ,Easy to operate and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

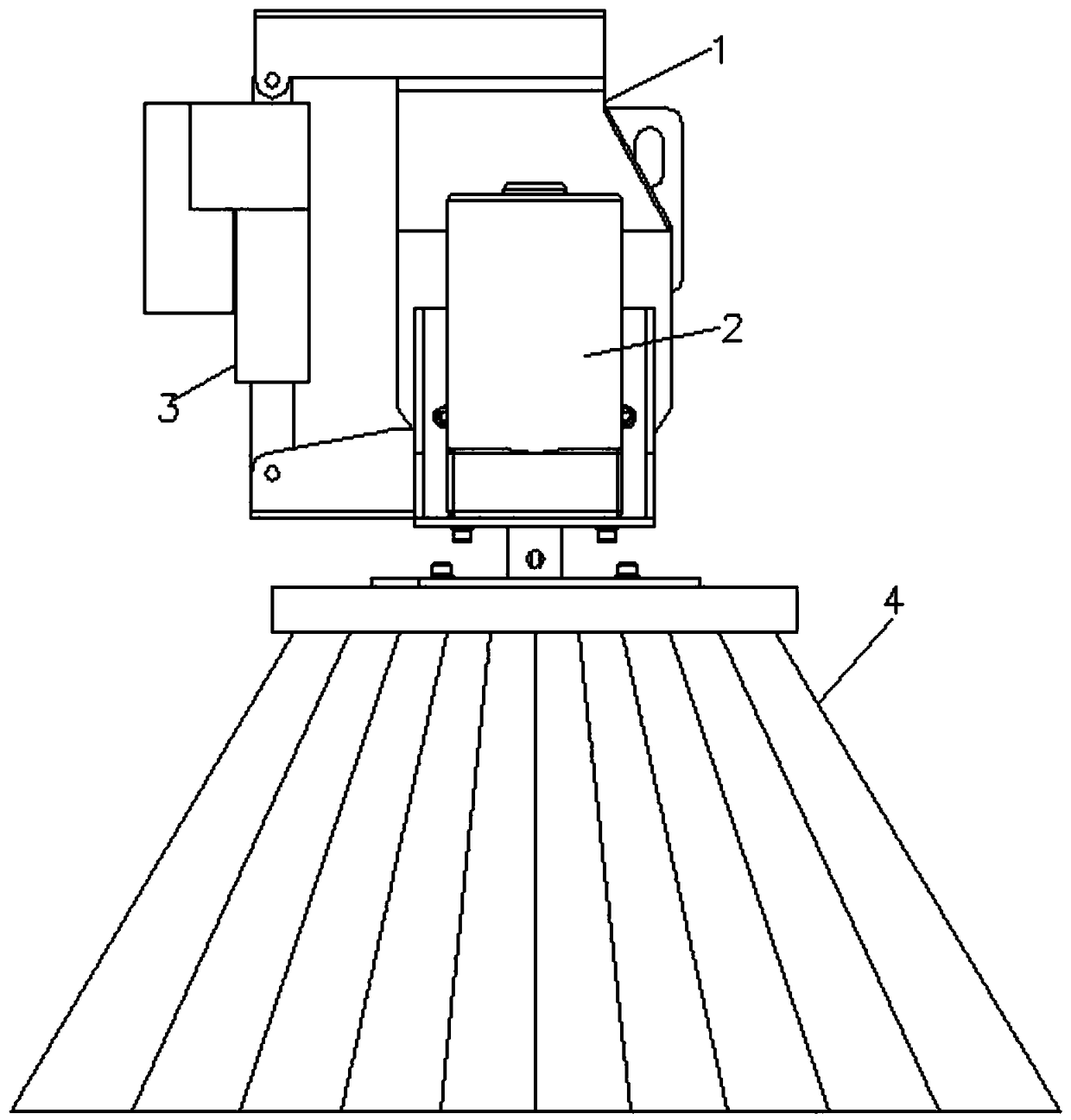

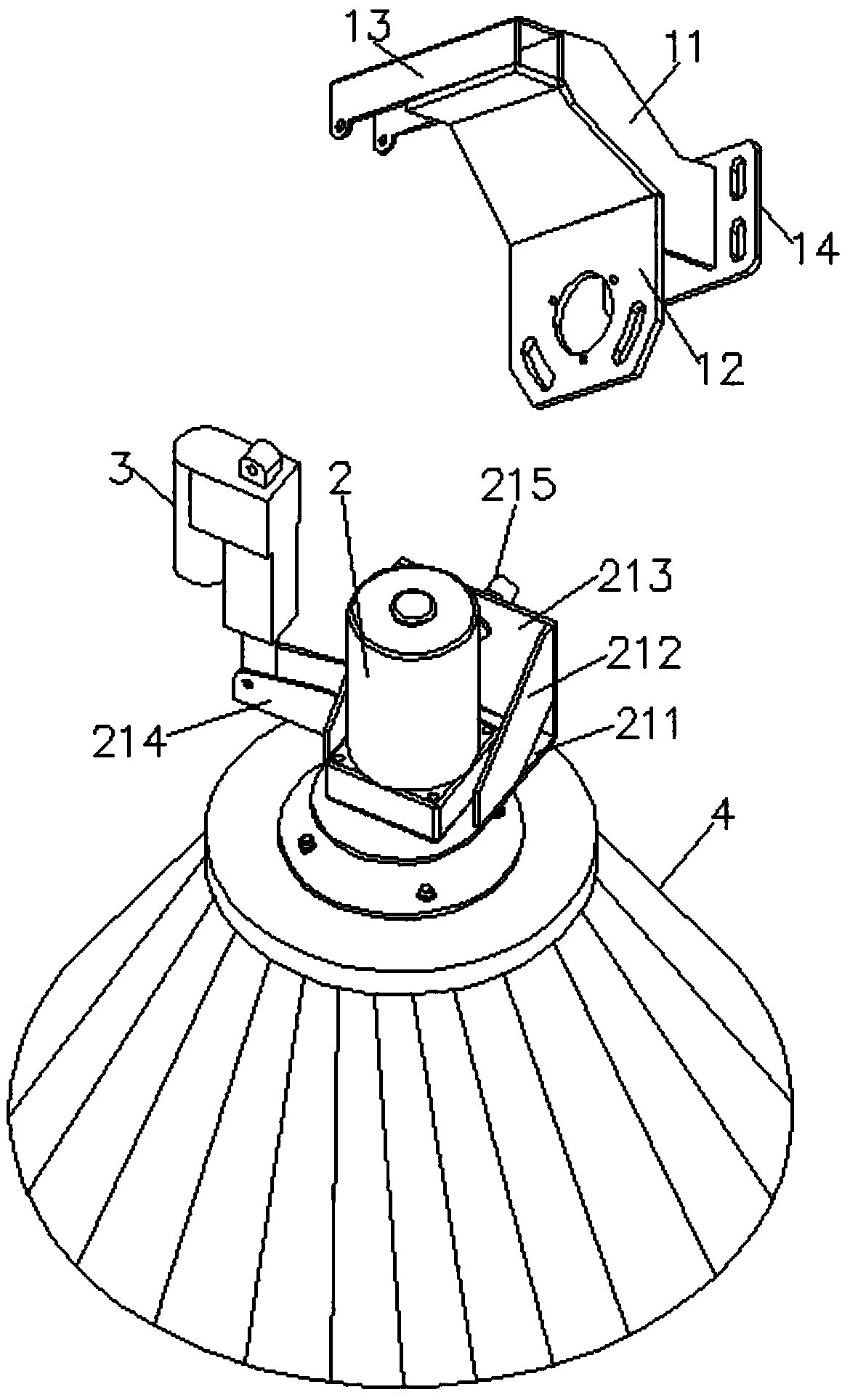

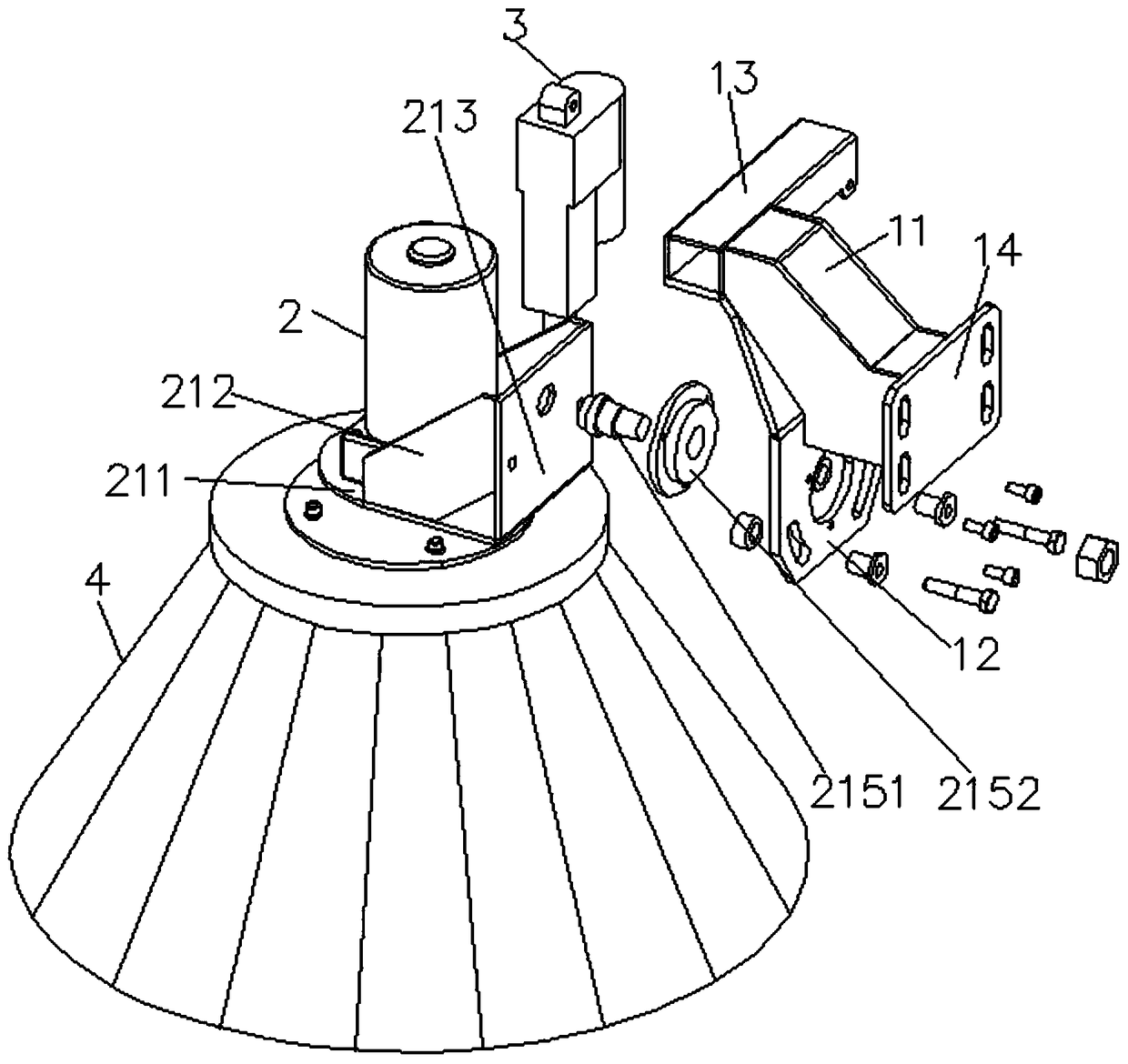

[0038] Embodiment one: if Figures 1 to 5 As shown, the sanitation vehicle sweeping structure with the flip function of this embodiment includes a fixed bracket assembly 1, a rotating drive mechanism 2, a telescopic device 3 and a sweeping assembly 4;

[0039] The above-mentioned rotary driving mechanism 2 is rotatably installed on the above-mentioned fixed bracket assembly 1 through the sweeping disc turning bracket 21;

[0040] The above-mentioned telescopic device 3 is arranged on one side of the above-mentioned sweeping disk turning bracket 21, and its fixed end is hinged with the above-mentioned fixing bracket assembly 1, and its telescopic end is downward, and is hinged with the above-mentioned sweeping disk turning bracket 21;

[0041] The above-mentioned sweeping disk assembly 4 is vertically arranged below the above-mentioned rotary drive mechanism 2, and its upper end is transmission-connected to the above-mentioned rotary drive mechanism 2;

[0042] The above-menti...

Embodiment 2

[0052] Embodiment two: if Figures 6 to 9 As shown, the road sweeping vehicle of this embodiment includes a car body (not shown in the figure) and the sweeping structure involved in Embodiment 1. The above-mentioned sweeping structure is provided with two, and is symmetrically distributed on the chassis of the above-mentioned car body On both sides below, the mounting plate 14 of the above-mentioned sweeping plate structure is respectively connected with the chassis lower end of the above-mentioned car body through the connecting arm, and the above-mentioned connecting arm (not shown in the figure) is rotatably connected with the chassis of the above-mentioned car body, and can drive the corresponding The above-mentioned sweeping plate structure rotates horizontally to the outside of the two sides of the above-mentioned chassis or the two sides below the chassis. The above-mentioned telescopic device 3 and the rotating drive mechanism 2 are respectively electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com