Cambered surface burnishing device for machining inner wall of crane hydraulic oil cylinder body

A technology of hydraulic oil cylinder and polishing device, which is applied to grinding/polishing safety device, surface polishing machine tool, grinding drive device, etc., can solve the problems of hydraulic oil cylinder block being unavailable, staff resting, and dust collection being impossible, etc. To achieve the effect of easy polishing operation, reduced labor intensity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

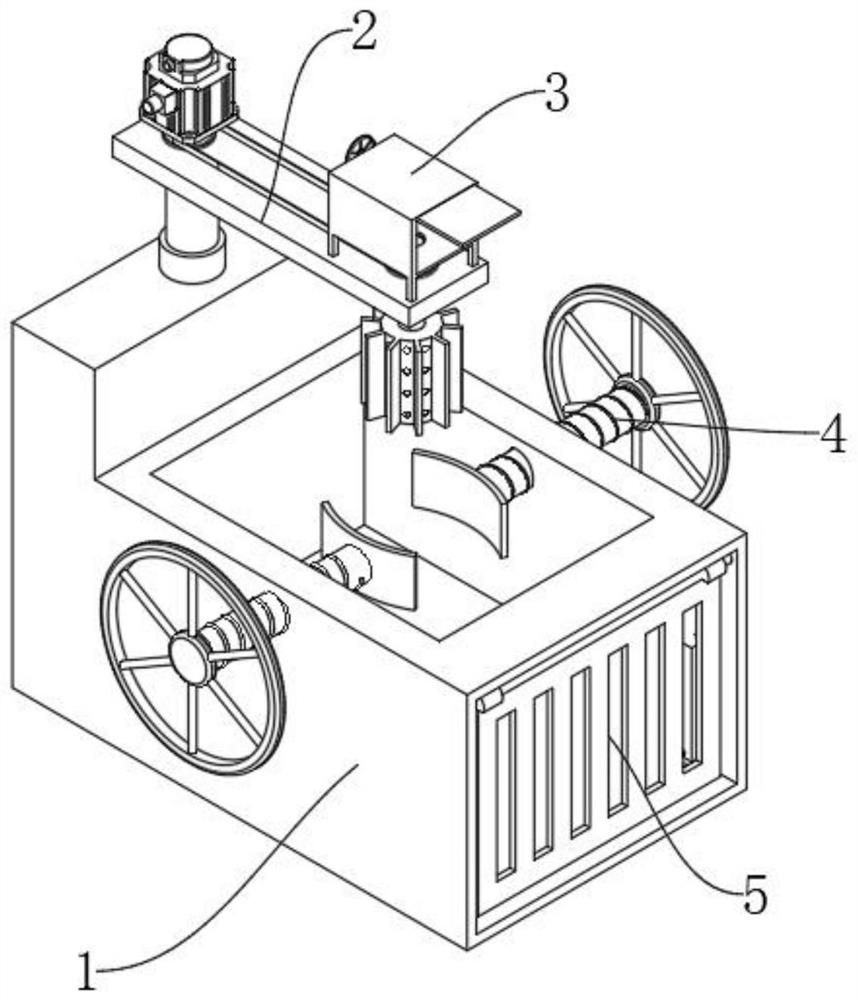

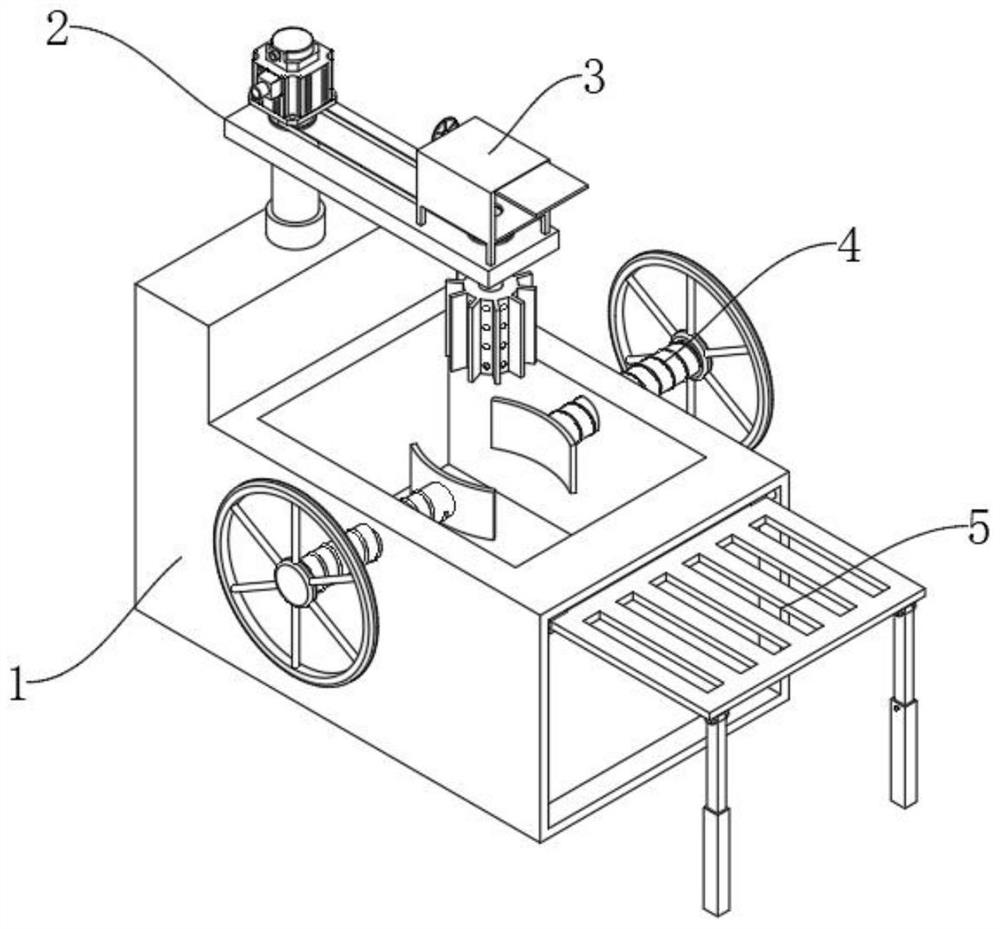

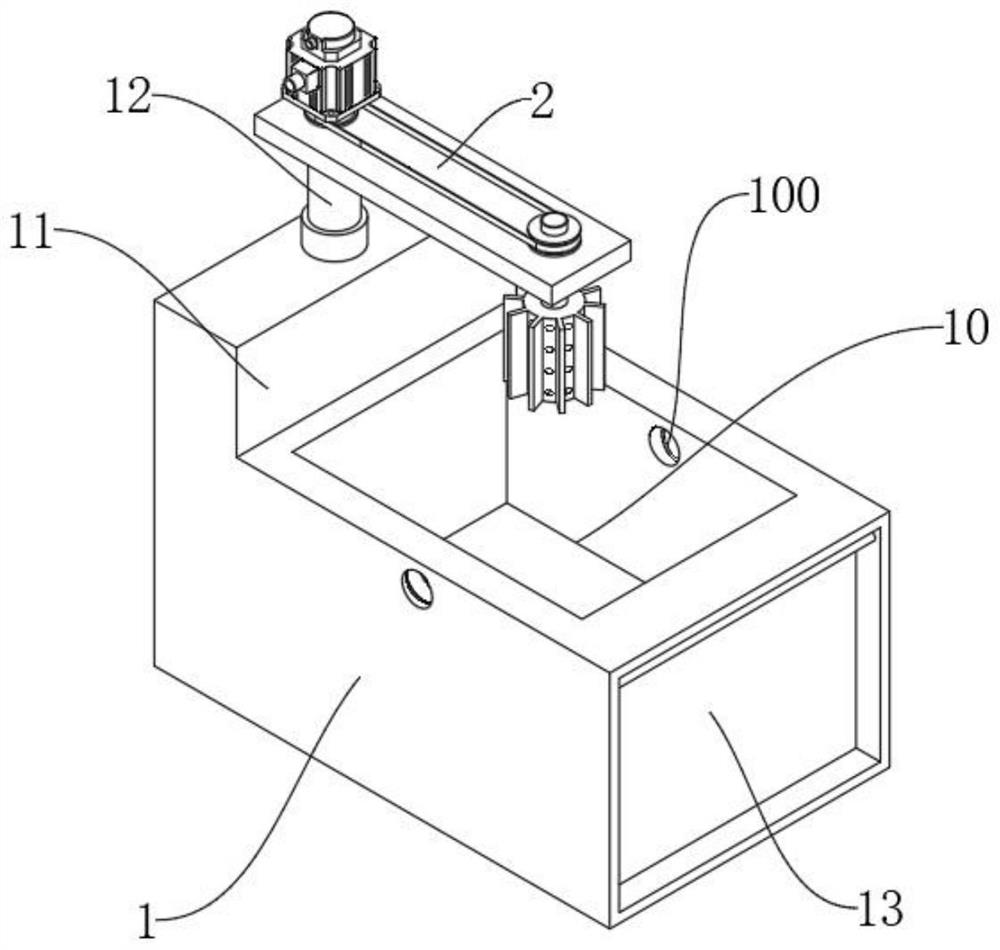

[0035] see Figure 1-Figure 11 As shown, this embodiment provides an arc surface polishing device for processing the inner wall of the hydraulic cylinder of a crane, including a polishing frame 1, a side plate 11 is arranged on the top of the polishing frame 1 near the edge, and an electric push rod 12 is arranged on the top of the side plate 11 , the electric push rod 12 piston rods are provided with a moving plate 2, and the electric push rod 12 piston rods drive the moving plate 2 to move up and down above the polishing frame 1, so as to facilitate adjustment of the distance from the moving plate 2 to the polishing frame 1 and ensure the integrity of the structure.

[0036] Specifically, the working principle of the electric push rod 12 is as well known to those skilled in the art. The rotary motion of the motor drives the worm gear transmission, which is transmitted to the screw rod for rotary motion, and the rotary motion of the screw rod drives the nut to perform linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com