Suspension polishing device with adjustable pressure

A polishing device and float-off technology, which is applied in the field of ultra-precision polishing, can solve the problems of unstable pressure on the workpiece surface and low polishing efficiency, and achieve the effects of continuous polishing, accelerated polishing rate, and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

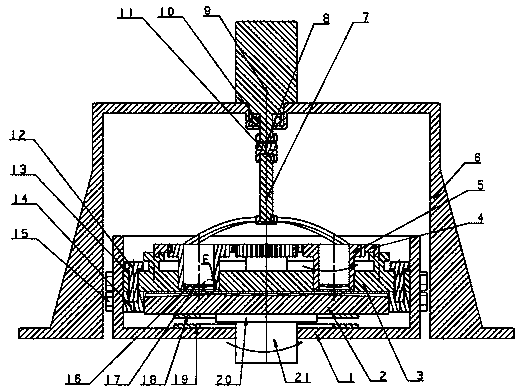

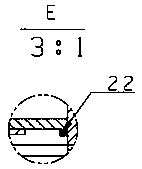

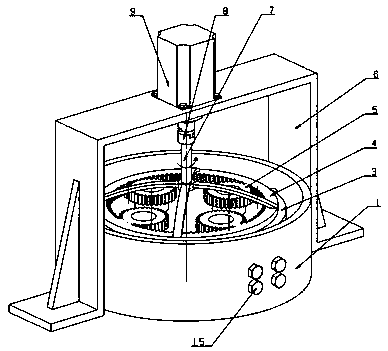

[0032] Embodiment 1: as Figure 1-8As shown, a floating-off polishing device with adjustable pressure includes a polishing container 1, a support frame 6, a magnetic floating micro-displacement mechanism, a polishing disc mechanism, a clamp holding platform mechanism, and a motor transmission mechanism. The support frame 6 is located outside the polishing container 1. The magnetic floating micro-displacement mechanism, the polishing disc mechanism, and the clamp holding platform mechanism are all located inside the polishing container 1. The magnetic floating micro-displacement mechanism includes a first electromagnet 18, a second electromagnet 19, an electromagnet control system, and a pressure sensor 22; the polishing disc mechanism includes The polishing disc 2, the polishing tray 20, the second main shaft 21; the jig holding platform mechanism includes a rotating jig 5, the jig holding platform 3, and the workpiece holding disc 16; the motor transmission mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com