A stable gap device for long-distance polishing

A stable and gap technology, applied in the field of long-range polishing stable gap devices, can solve the problems affecting the polishing quality, the effect of the uniformity of the polishing process, and the change of the distance between the grinding head and the surface of the workpiece, and achieve the effect of improving the polishing quality and stabilizing the polishing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

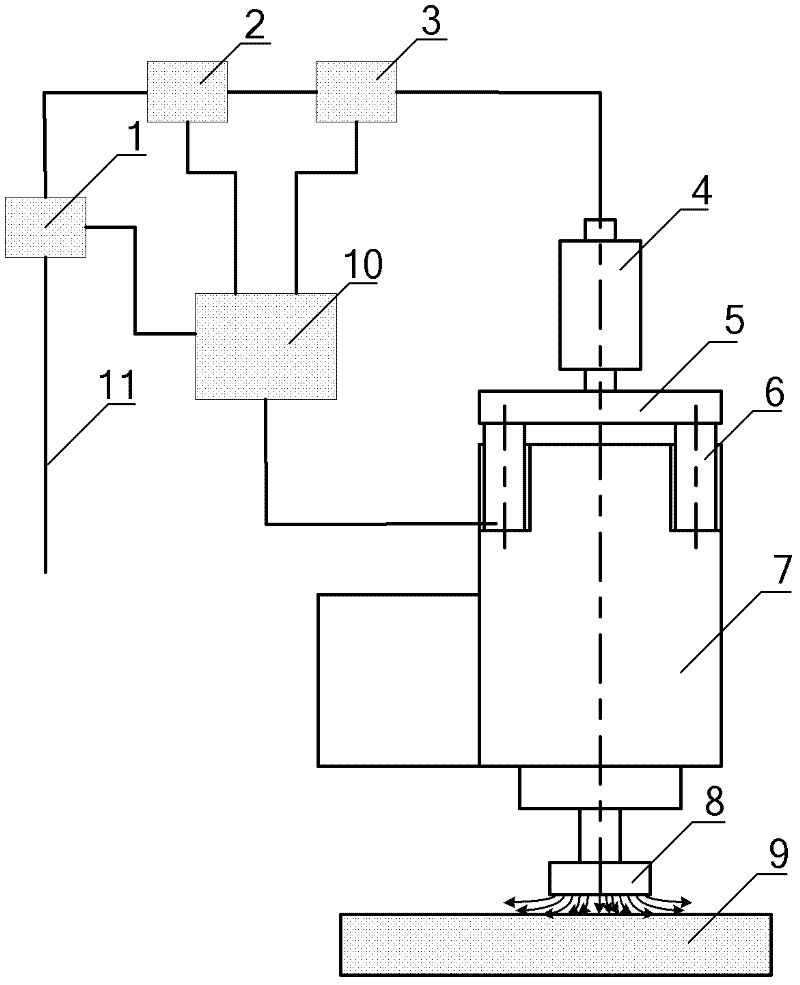

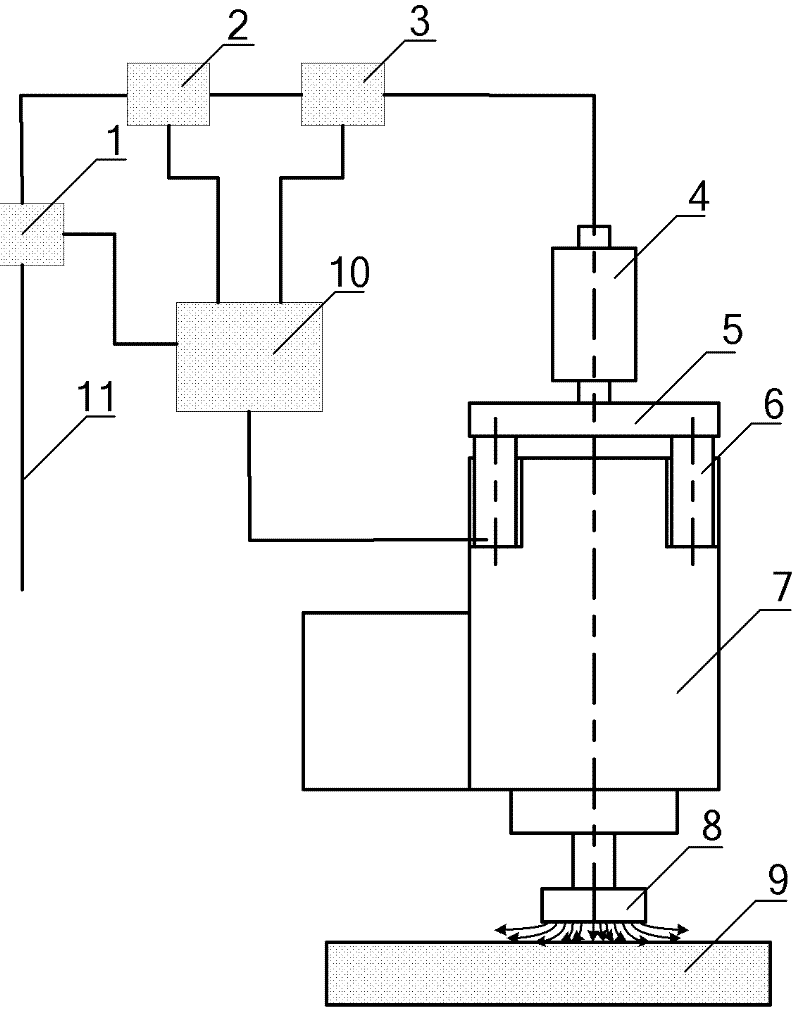

[0009] Depend on figure 1 As shown, the long-distance polishing stable gap device of the present invention includes: a control valve 1, a flow sensor 2, a pressure sensor 3, a rotary connector 4, a main shaft 5, a piezoelectric ceramic stack 6, a frame 7, a liquid jet grinding head 8, and a controller 10; wherein the control valve 1 is connected to the flow sensor 2, the flow sensor 2 is connected to the pressure sensor 3, the pressure sensor 3 is connected to the main shaft 5 through the rotary connector 4, and the piezoelectric ceramic stack 6 and the liquid jet grinding head 8 are connected under the main shaft 5, The piezoelectric ceramic stack 6 is inlaid in the frame 7. The piezoelectric ceramic stack 6 is connected with the frame 7 and the main shaft 5 by threads. The main shaft 5 passes through the frame 7 and is connected with the liquid jet grinding head 8. 1. Flow sensor 2, pressure sensor 3 and piezoelectric ceramic stack 6 are connected.

[0010] The distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com