Polishing equipment for instrument and meter manufacturing

An instrumentation and equipment technology, applied in the field of polishing equipment for instrumentation manufacturing, can solve problems such as poor polishing uniformity, inability to meet workpiece size requirements, changes, etc., to prevent scattering, stable and reliable polishing, and good polishing uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

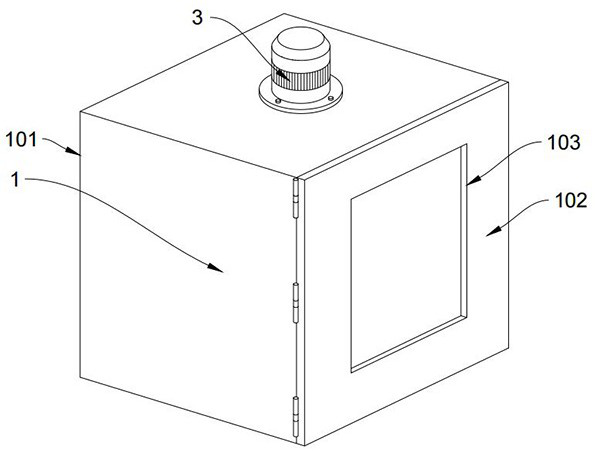

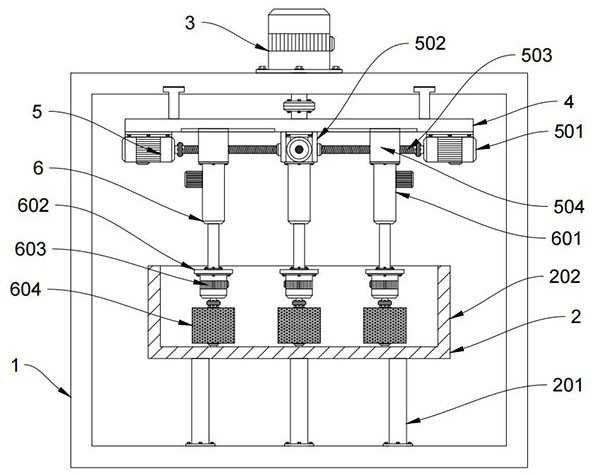

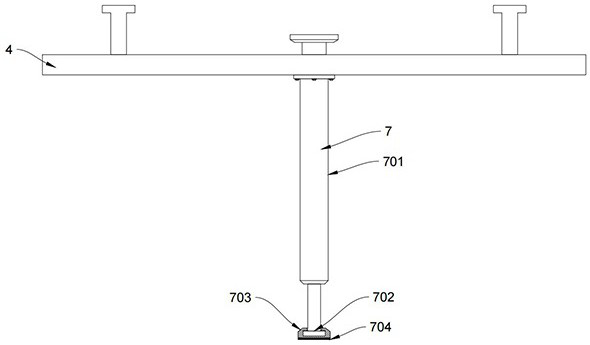

[0019] combined with figure 1 To attach image 3 , a kind of polishing equipment for the manufacture of instruments and meters, comprising a working box 1, a workpiece placement structure 2 is fixed on the inner bottom surface of the working box 1 by bolts, a rotating motor 3 is fixed on the middle of the upper surface of the working box 1 by bolts, and the output end of the rotating motor 3 extends One end in the working box 1 is connected with a turntable 4, several groups of polishing size adjustment assemblies 5 are evenly installed under the turntable 4, and telescopic polishing assemblies 6 are fixedly installed under the polishing size adjustment assemblies 5, and the telescopic polishing assemblies 6 extend into the The workpiece is placed in the structure 2 to move, and the middle of the bottom of the turntable 4 is fixedly equipped with a telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com