Automobile injection molding part surface polishing device

A technology for surface polishing and injection molded parts, which is applied in the direction of surface polishing machine tools, grinding/polishing safety devices, grinding/polishing equipment, etc., and can solve problems such as surface scratches on injection molded parts, affecting polishing quality, and poor polishing quality , to avoid damage, ensure polishing quality and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

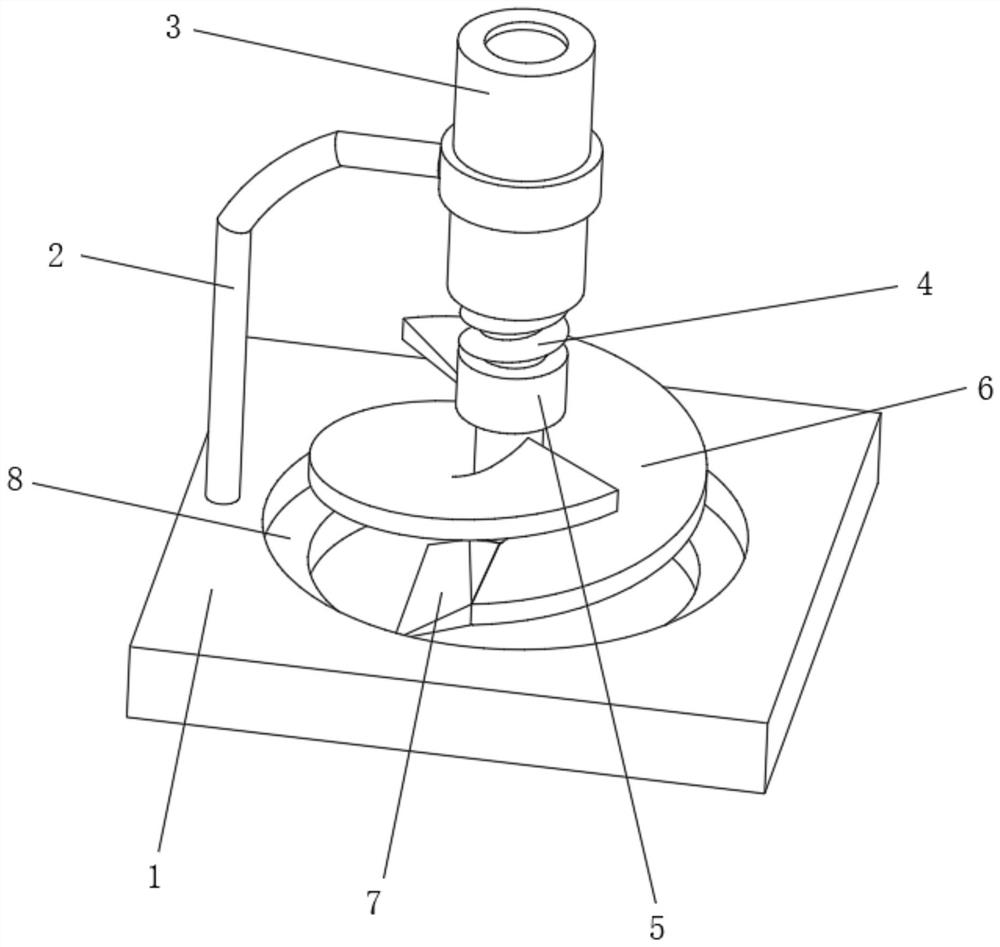

[0041] like figure 1As shown, the present invention provides a technical solution: a surface polishing device for automobile injection molded parts, comprising a support base plate 1, and a mounting frame 2 on the top of the support base plate 1, the mounting frame 2 and the middle of the support base plate 1 are provided with a press The driving rod 3, pressing the lower end of the driving rod 3 is provided with a transmission threaded rod 4, the lower axis of the transmission threaded rod 4 is provided with a walking liquid storage part 5, and the outer surface of the walking liquid storage part 5 is evenly provided with a material guide fan sheet 6, which runs outside the liquid storage portion 5 and is provided with a polished contact portion 7 at the lower end of the guide fan sheet 6;

[0042] There is also a working groove 8 inside the support base plate 1. The upper and lower ends of the working groove 8 are connected, and the diameter of the upper circular hole of the...

Embodiment 2

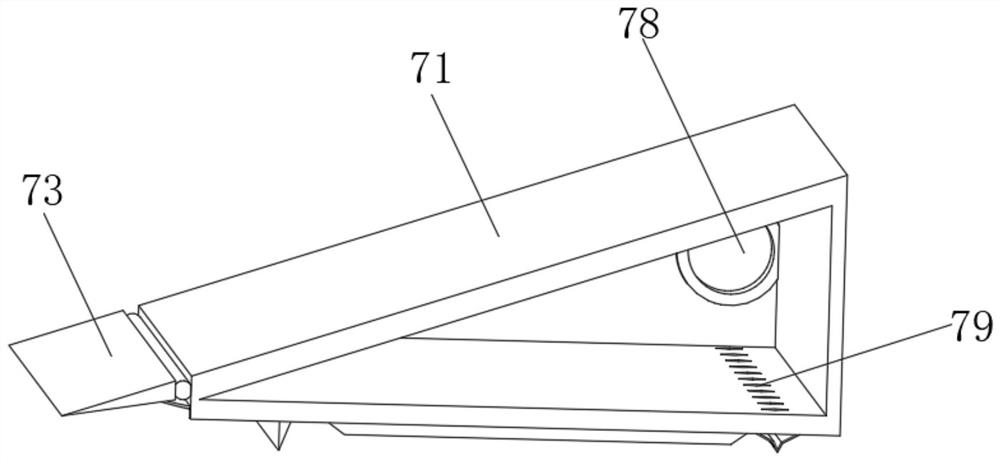

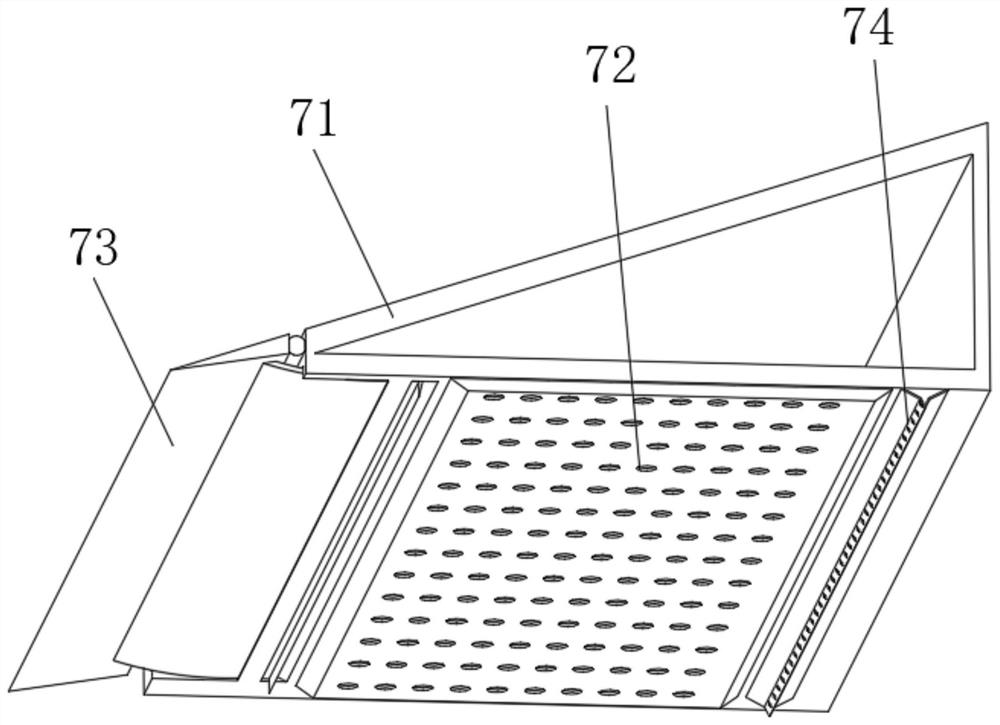

[0046] like Figure 2-5 As shown, on the basis of the first embodiment, the present invention provides a technical solution: a surface polishing device for automobile injection molded parts, the polishing contact part 7 includes a material guide inclined plate 71, and a polishing and polishing sheet at the lower part of the material guide inclined plate 71 72. The upper inclined surface of the material guide inclined plate 71 is correspondingly connected with the surface of the material guide fan piece 6, an auxiliary blade 73 is provided on the front end of the material guide inclined plate 71, and a scrap cleaning mechanism is provided on the back of the lower part of the material guide inclined plate 71 74. The dust on the machined surface is removed to prevent the dust from participating in the next polishing work and reduce the abrasion of the polishing dust on the surface of the injection molded parts. The elastic arc plate 76 is fixedly connected with a resistance-incr...

Embodiment 3

[0052] like Figure 6-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a surface polishing device for automobile injection molded parts, the scrap cleaning mechanism 74 includes a liquid-conducting inner groove 741, A scraping cone 742 is fixedly connected to the bottom, and an abrasive groove 743 is provided under the front surface of the scraping cone 742 .

[0053] A supply hole 744 is evenly provided below the front of the scraper cone 742 and at the top of the abrasive groove 743 , and an abrasive rod 745 is rotatably connected inside the abrasive groove 743 . The sharp parts of the dust particles are initially rubbed to avoid damage to the surface of the injection molded parts by the sharp parts.

[0054] A discharge restricting plate 746 is evenly disposed on the inner side of the supply hole 744 , and the back surface of the scraper cone 742 is evenly and fixedly connected to a limited amount guide rod 747...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com