Patents

Literature

53results about How to "Improve friction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula and process for powder metallurgy

The invention provides a formula and a process for powder metallurgy. The formula comprises Fe-based powder, machinability improving powder and a free lubricant; the Fe-based powder comprises, by weight, 7 to 14% of copper powder (Cu), 2 to 8% of molybdenum powder (Mo), 0.5 to 3.5% of nickel powder (Ni), 1 to 7% of aluminum powder (Pb), 8 to 16% of graphite (C), 1 to 5.5% of molybdenum disulfide (MoS2), 1.5 to 5% of cast stone, 0.5 to 5% of silicon carbide (SiC) and 4 to 9% of mullite (3Al2O3.2SiO2), with the balance being iron powder, the machinability improving powder is composed of calcium phosphate compounds, and the free lubricant contains at least one selected from the group consisting of thermoplastic resin powder, zinc stearate and lithium stearate.

Owner:王萍

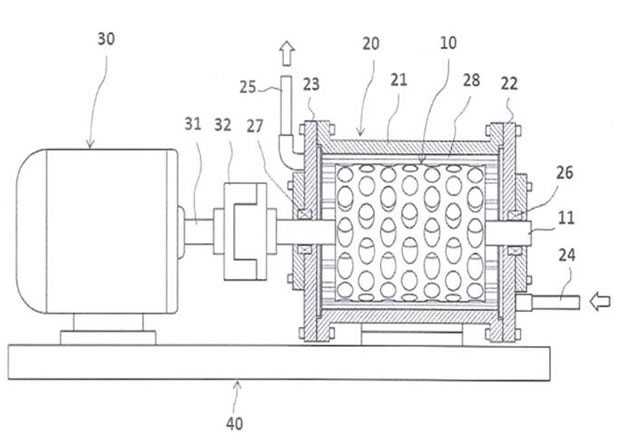

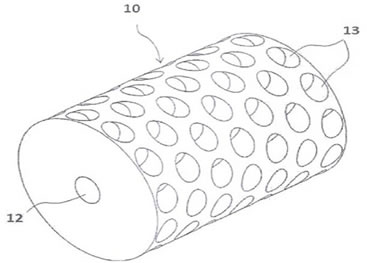

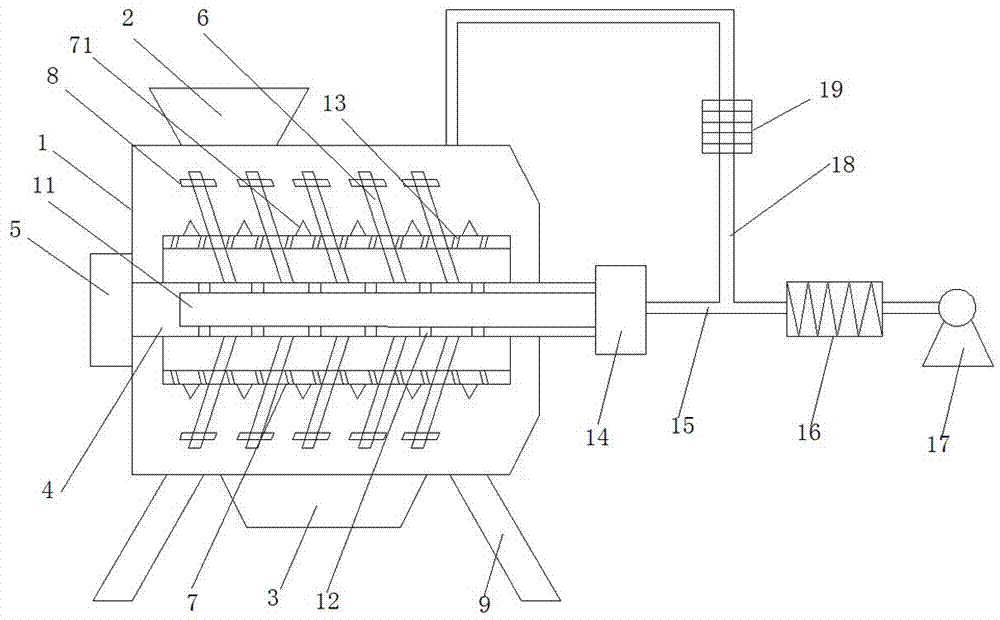

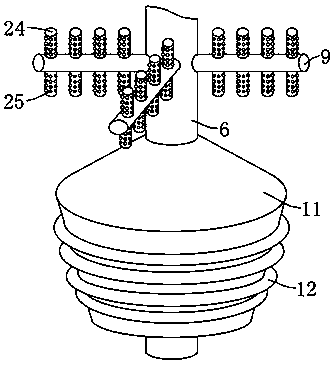

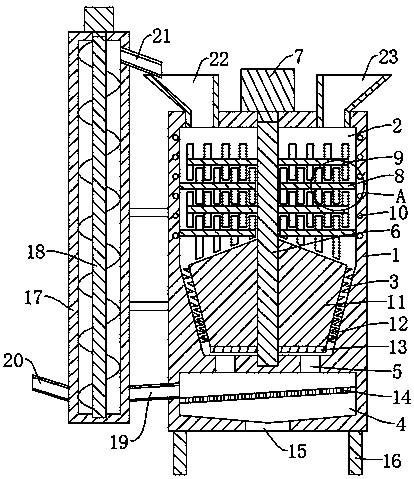

Boiler using rotary force

InactiveCN101893225AIncrease powerIncreased friction distanceSteam generation using mechanical energyOther heat production devicesWater flowEngineering

The present invention relates to a boiler using mechanical rotating power as a rotating force of a rotary body of a driving source to accelerate water molecules to move (friction), and heating water by using frictional heat generated by the movement of the water molecules. The boiler is composed of a rotary body connected to a driving source and a housing accepting and supporting the rotary body, the housing is provided with a water inlet and water outlet, and a water flowpath is formed in the housing. The outer circumferential face of the rotary body is provided with at least two sunken holes sloped to a normal line or a tangent line direction, the inner circumferential face of the housing is provided with at least two grooves apart from by a certain distance in the circumference direction and continuously slopedly or helically arranged in the axis direction. According to the boiler, when the water moves axially along the water flowpath and contacts with the outer circumferential face of the rotary body so as to greatly increase friction distance, and friction efficiency is maximized by the sunken holes. In addition, by means of the grooves, the water is flowed smoothly in the housing, and the water is easy to be sucked, discharged and circulated with an external circulating system by using self suction.

Owner:千庸基

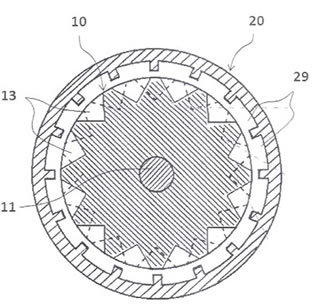

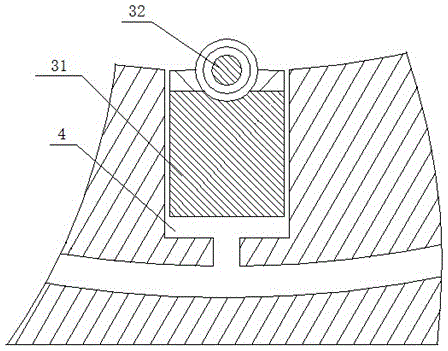

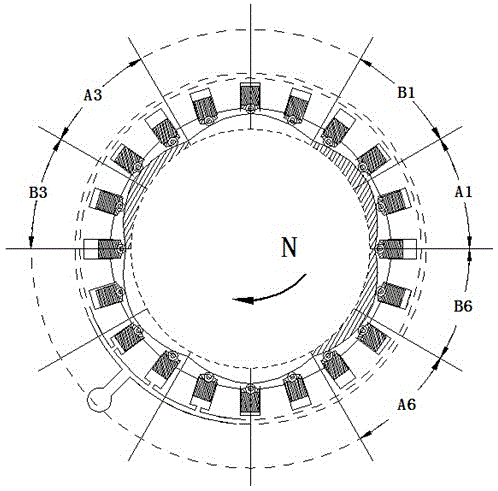

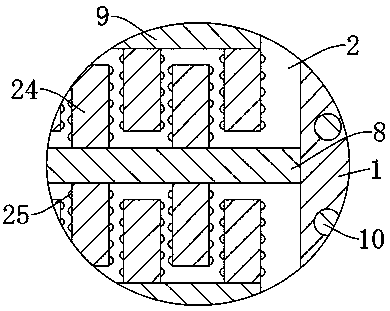

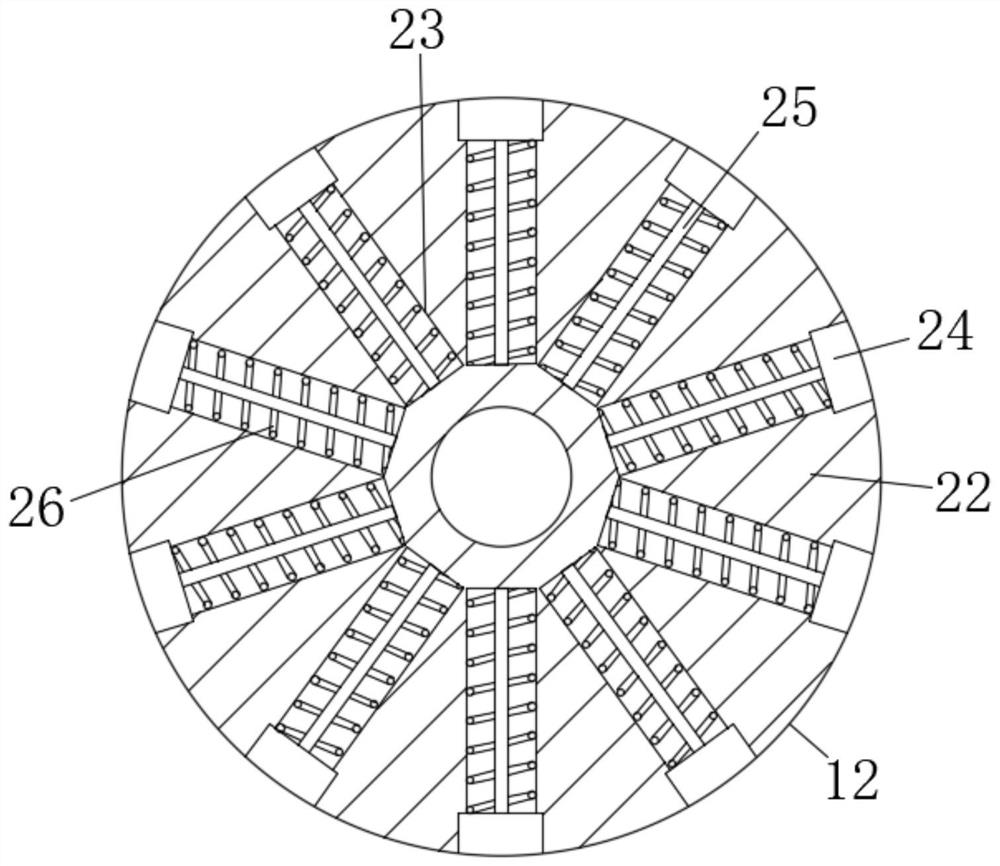

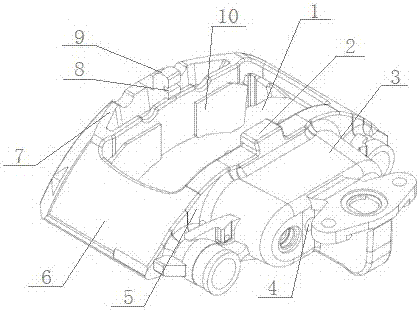

Hydrodynamic retarder

InactiveCN105003569AHigh rolling friction efficiencyDoes not affect workLiquid resistance brakesPhysicsStator

The invention discloses a hydrodynamic retarder which comprises a rotor, a stator and a circle of oscillating teeth. An inner cavity is formed in the stator, the rotor is arranged in the inner cavity of the stator, and the center of the rotor is overlapped with the circle center of the inner cavity of the stator. A circle of oscillating tooth grooves communicated with a high-pressure oil inlet is formed in the wall of the inner cavity of the stator, the oscillating teeth are embedded into the corresponding oscillating tooth grooves one by one, and the outer ends of the oscillating teeth are opposite to the outer wall of the rotor. The outer wall of the rotor is a variable-diameter face, the variable-diameter face is evenly divided into a plurality of equant portions, and the variable diameters and directions of all the equant portions are the same. According to the hydrodynamic retarder, the rotor can freely rotate in the stator in the normal rotating process, and when the oscillating teeth in the stator are in contact with the rotor under the action of high-pressure oil and brake force is generated, high efficiency, large torque and brake buffering can be achieved; meanwhile, the hydrodynamic retarder has the advantages of being balanced in radial power, low in noise, compact in structure, small in size and low in manufacturing cost.

Owner:袁廷华

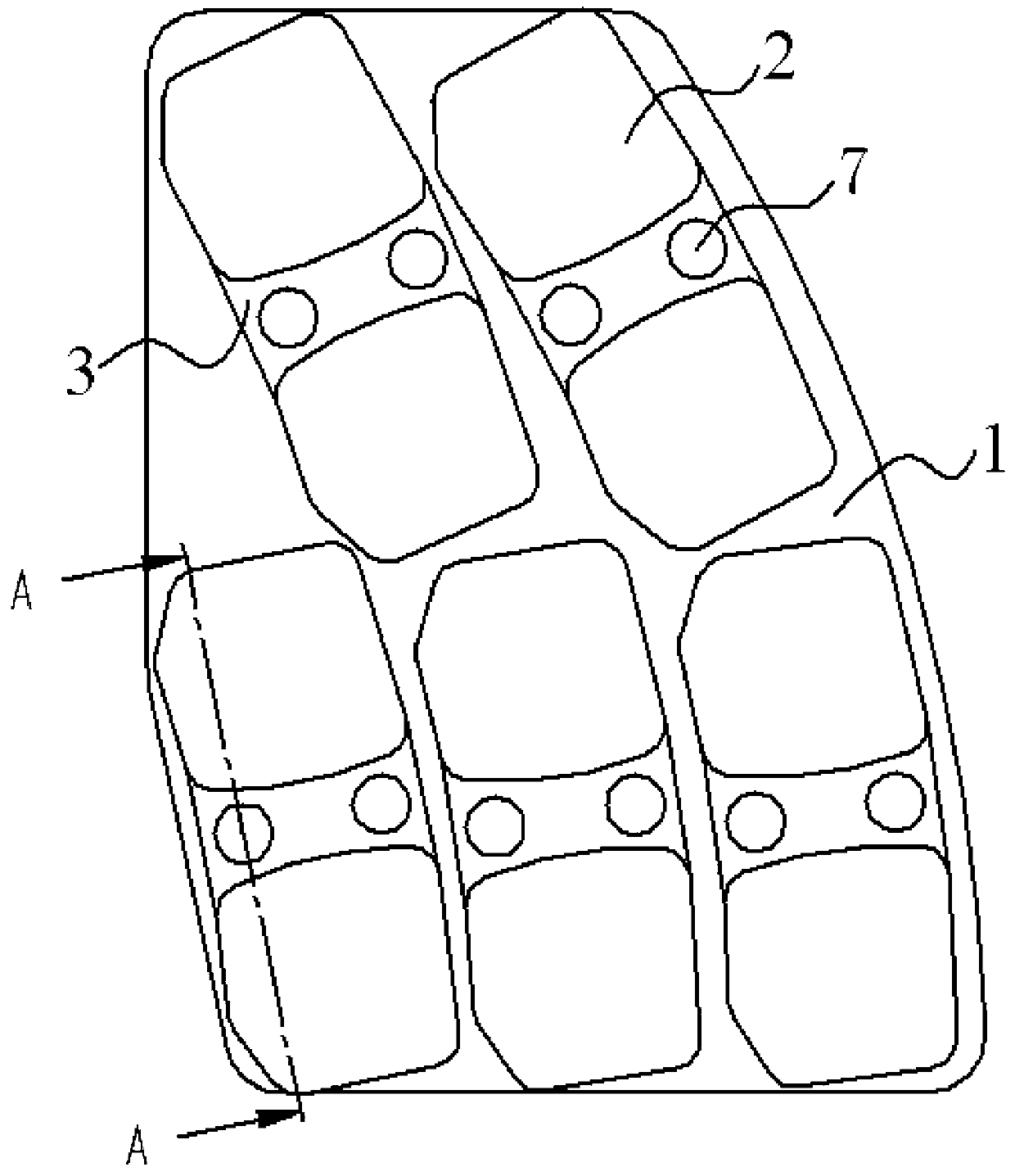

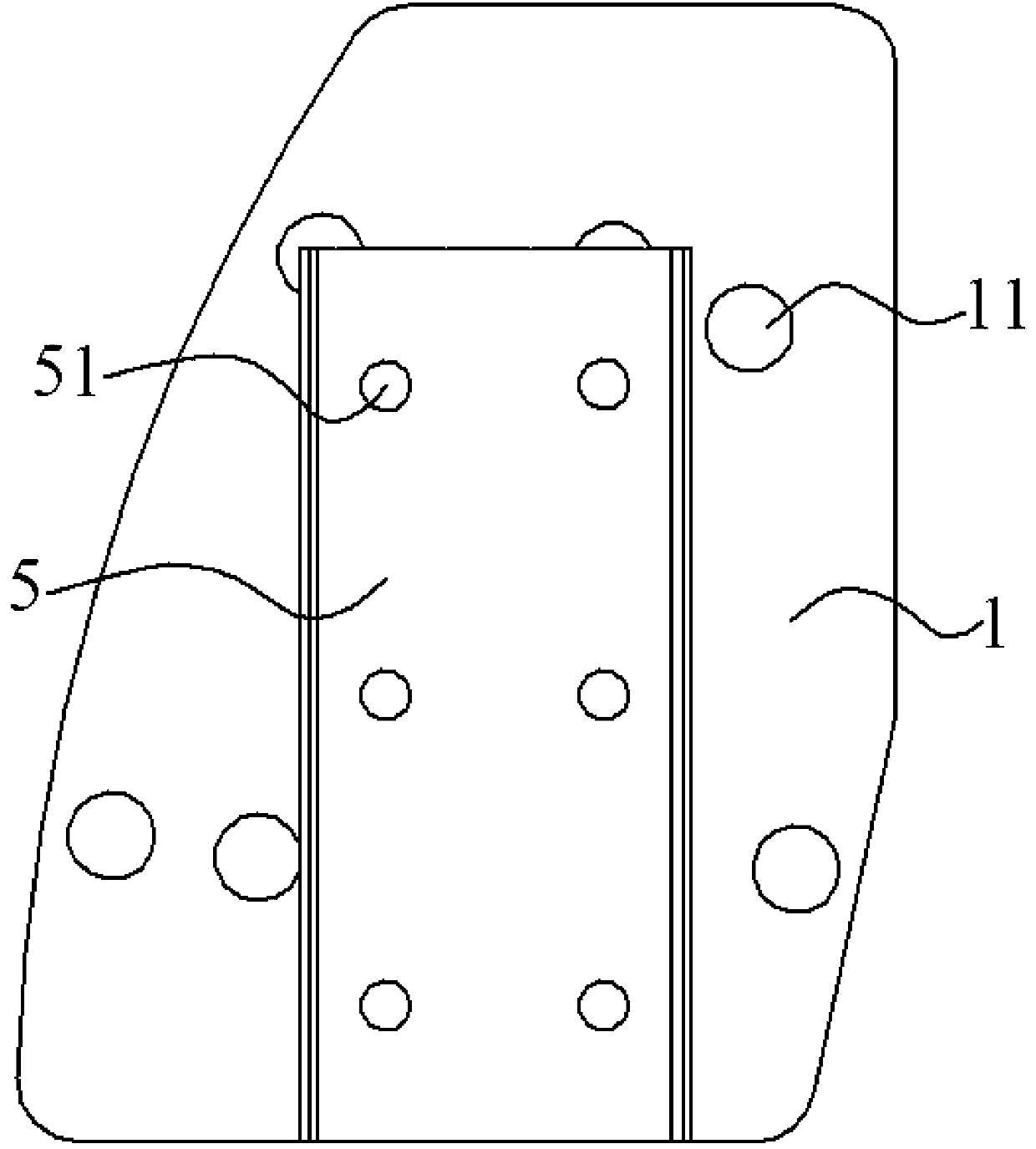

Novel high-speed brake block

InactiveCN102996688AReduce brake temperatureImprove friction efficiencyBraking membersFriction liningWave shapeEngineering

The invention provides a novel high-speed brake pad. Two brake blocks are sintered on a skeleton; a riveting hole is processed in a part, on the skeleton and between the two brake blocks; the sintered brake blocks and the skeleton are riveted on the front of a steel backing through the riveting hole; a space between the two brake blocks is in favor of ventilation, heat dissipation and chip removing during a braking process, the braking temperature of a friction block can be effectively reduced and the friction efficiency can be improved; and a dovetail plate is welded on the back side of the steel backing. In order to solve the problem that the adhering of the brake pad and a brake disc is inadequate, a wave-shaped shrapnel is installed between the steel backing and the skeleton; and in order to prevent excessive abrasion of a rivet, a bush is sleeved over the outer wall of the rivet.

Owner:贵州新安航空机械有限责任公司

Heating mixer for board raw materials

The invention discloses a heating mixer for board raw materials. The heating mixer comprises a machine barrel, a feeding inlet, a discharging outlet, a rotating shaft, a rotating motor and a plurality of stirring shafts. The machine barrel is horizontally arranged. The feeding inlet is formed in the top of the machine barrel, and the discharging outlet is formed in the bottom of the machine barrel. The rotating shaft penetrates into the machine barrel and is further located at the central axis position of the machine barrel. The rotating motor is arranged at the left end of the machine barrel and is further connected with the left end of the rotating shaft. A friction drum is arranged outside the rotating shaft and the axis of the friction drum is consistent with that of the rotating shaft. The multiple stirring shafts are arranged inside the machine barrel, penetrate through the friction drum and are evenly distributed in the circumferential direction of the rotating shaft. Stirring blades are arranged at the ends, far away from the rotating shaft, of the stirring shafts. According to the heating mixer for the board raw materials, stirring efficiency and friction efficiency are improved, and therefore the working efficiency is further improved and energy consumption is reduced.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

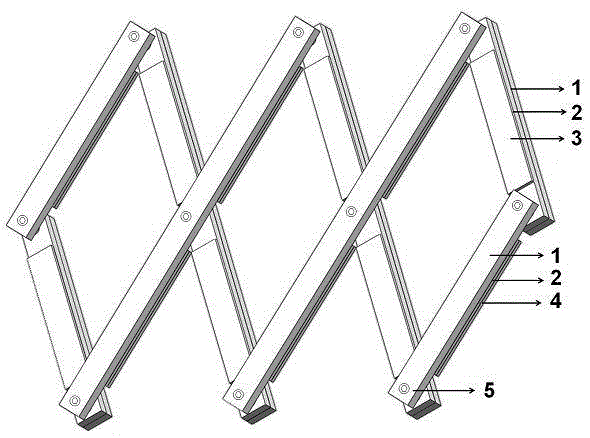

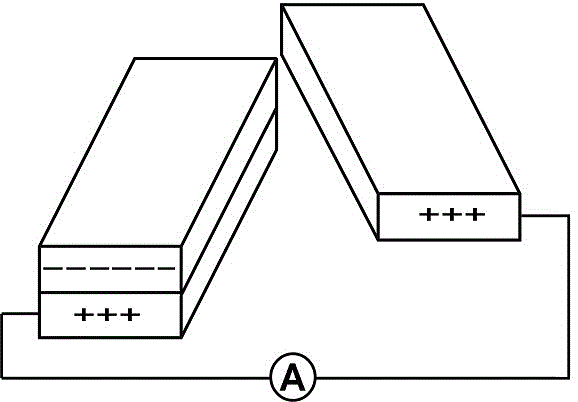

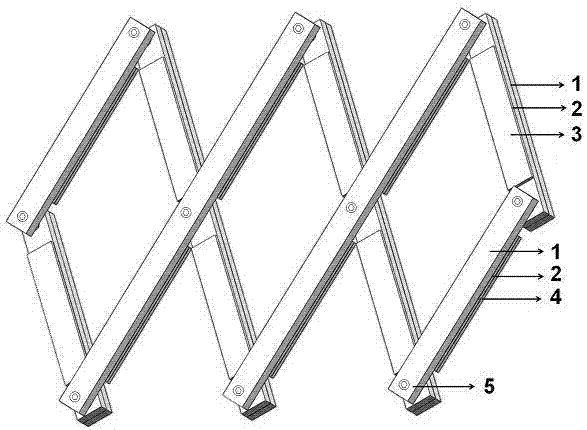

Cross-folding friction generator

InactiveCN105490580ASimple structureLow costFriction generatorsBiochemical engineeringMetal electrodes

The invention discloses a cross-folding friction generator, which comprises at least one friction unit, at least one second friction unit, a rotating shaft and a base plate, wherein the rotating shaft is connected with the first friction unit and the second friction unit; the base plate is arranged on the rotating shaft; the first friction unit comprises a base, a metal electrode plate and a first friction layer; the metal electrode plate is arranged on the base; the first friction layer is filled into the metal electrode plate; the second friction unit comprises a base, a metal electrode plate and a second friction layer; the metal electrode plate is arranged on the base; the second friction layer is filled into the metal electrode plate; the first friction unit and the second friction unit are crossly and oppositely stacked together through the rotating shaft hinged with the centers of the bases to form a power generation unit; and the first friction layer of the first friction unit and the second friction layer of the second friction unit are oppositely arranged. The cross-folding friction generator has the advantages of being simple in structure, low in cost, durable, high in output voltage, high in current, easy to popularize and the like.

Owner:HENAN NORMAL UNIV

Sand grain friction device for old sand machinery regeneration

PendingCN110076288AEvenly heatedGood removal effectMould handling/dressing devicesPolymer chemistryElectric heating

The invention discloses a sand grain friction device for old sand machinery regeneration. The sand grain friction device comprises a friction box, wherein a coarse grinding cavity and a fine grindingcavity are formed in the upper part of the friction box, a sorting cavity is formed in the lower part of the friction box, a discharging opening is formed between the sorting cavity and the fine grinding cavity, a rotating shaft is in connection between the rough grinding cavity and the fine grinding cavity in a sleeving mode, a motor is installed on the top plate of the friction box, and an output shaft of the motor is connected to a rotating shaft; old sand inlets are formed in the two sides of the motor, a plurality of fixed grinding rods are installed on the inner wall of the rough grinding cavity, and a plurality of stirring rods are installed on the part, at the rough grinding cavity, of the rotating shaft; an electric heating pipe is in connection with the inner wall, at the rough grinding cavity, of the friction box in a sleeving mode; a grinding disc is in connection with the part, at the fine grinding cavity, of the rotating shaft; and friction teeth are installed between theouter wall of the grinding disc and the inner wall of the fine grinding cavity. The electric heating pipe heats the sand material, so that the temperature of an adhesive film is more easily reduced,the rotating shaft drives the stirring rods to rotate, the sand material is stirred so that the sand material is uniformly heated, and coarse grinding is carried out on the sand grains, the coarse grinding sand materials slide up and down along the inner wall of the grinding disc and the inner wall of the fine grinding cavity, the rotating shaft drives the grinding disc to rotate, so that the friction teeth perform strong friction on the sand grains.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

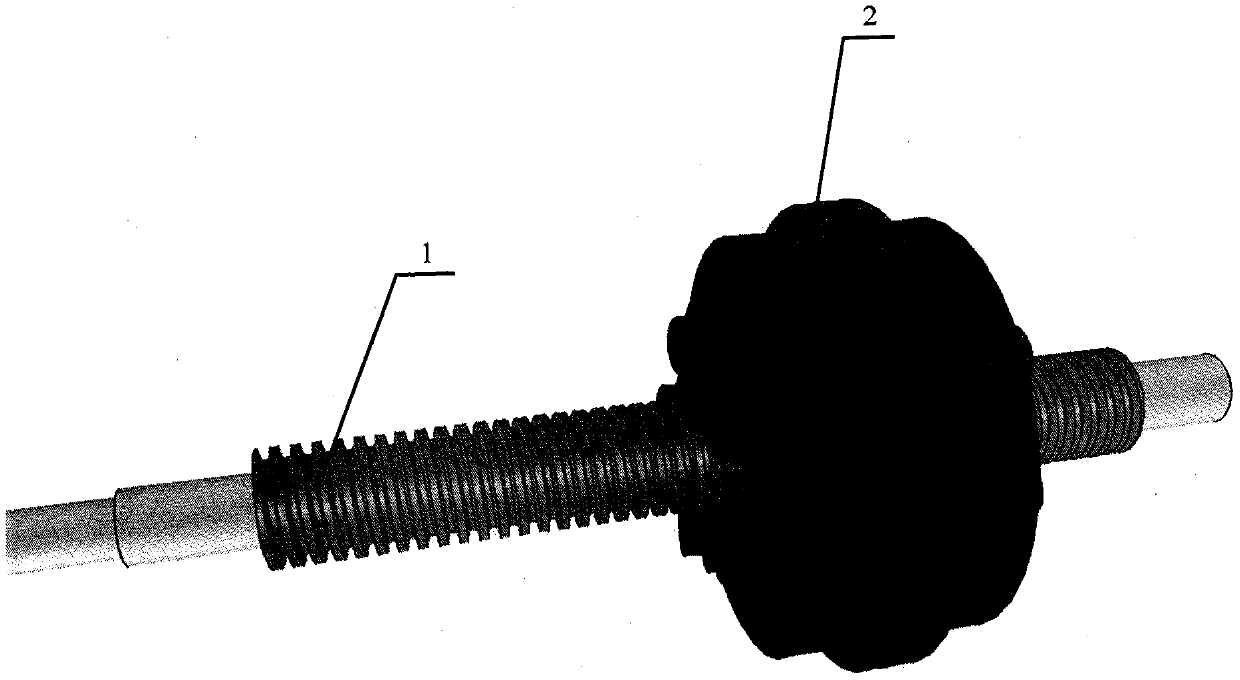

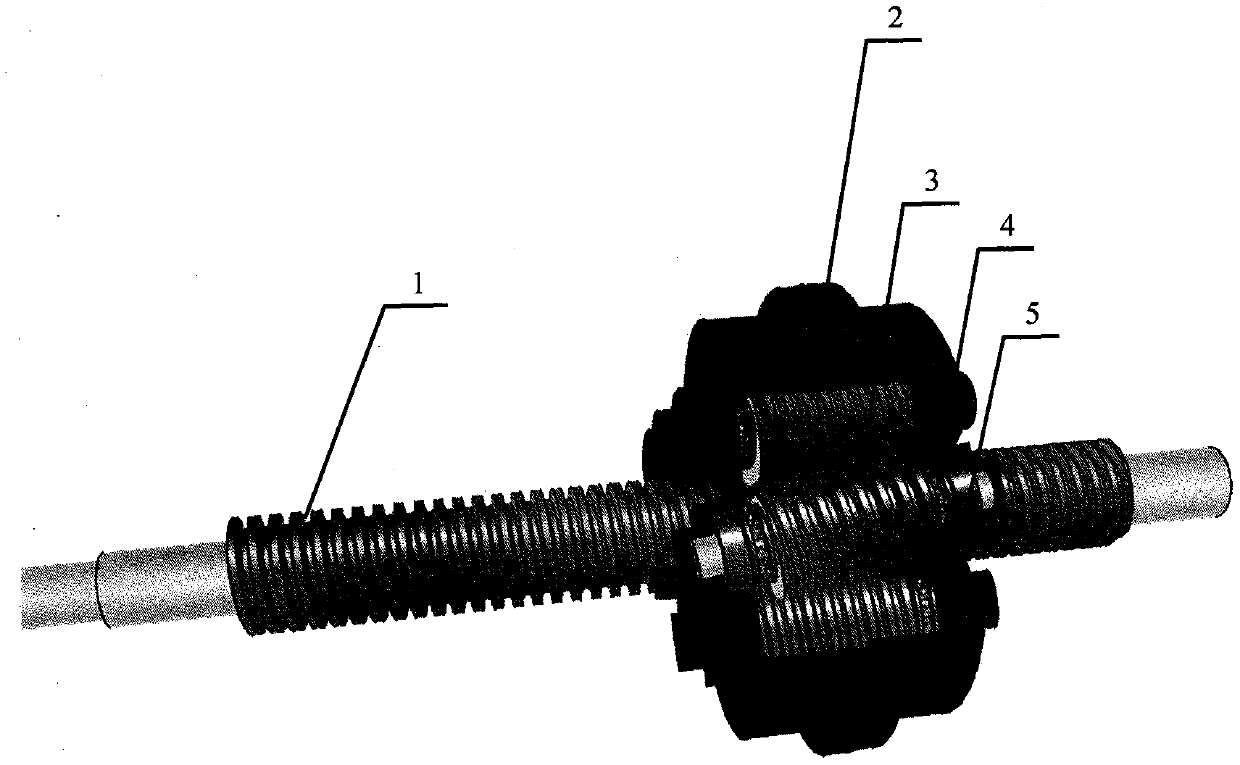

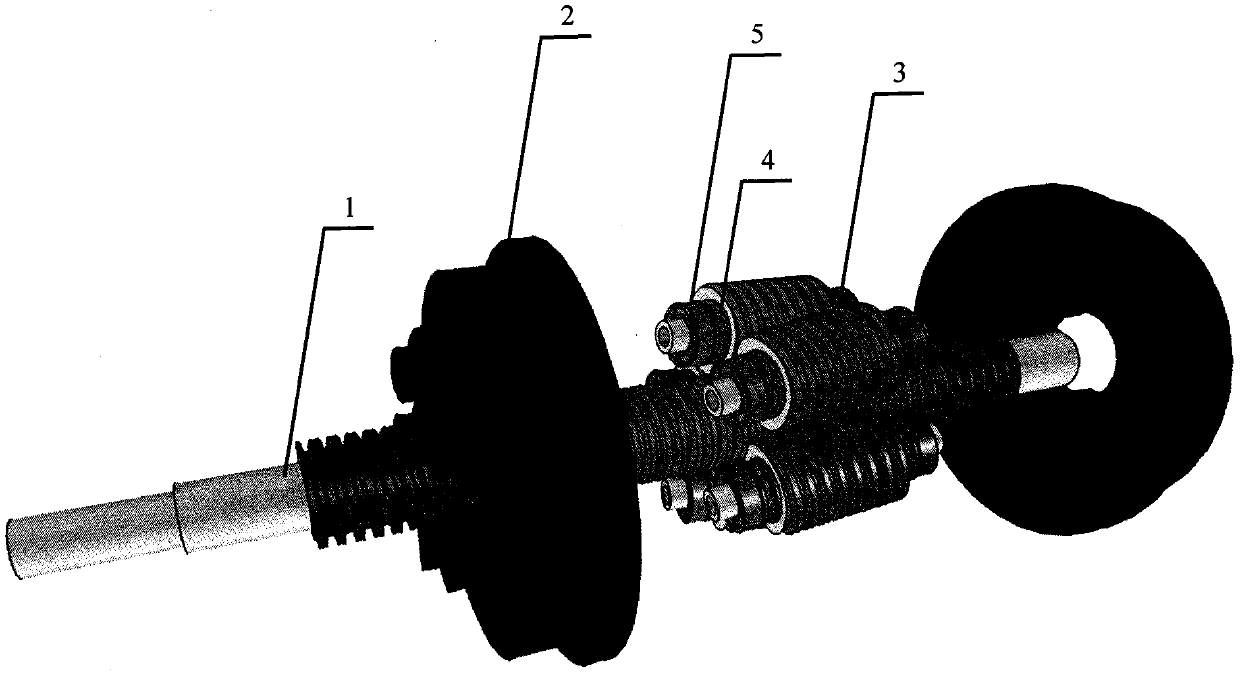

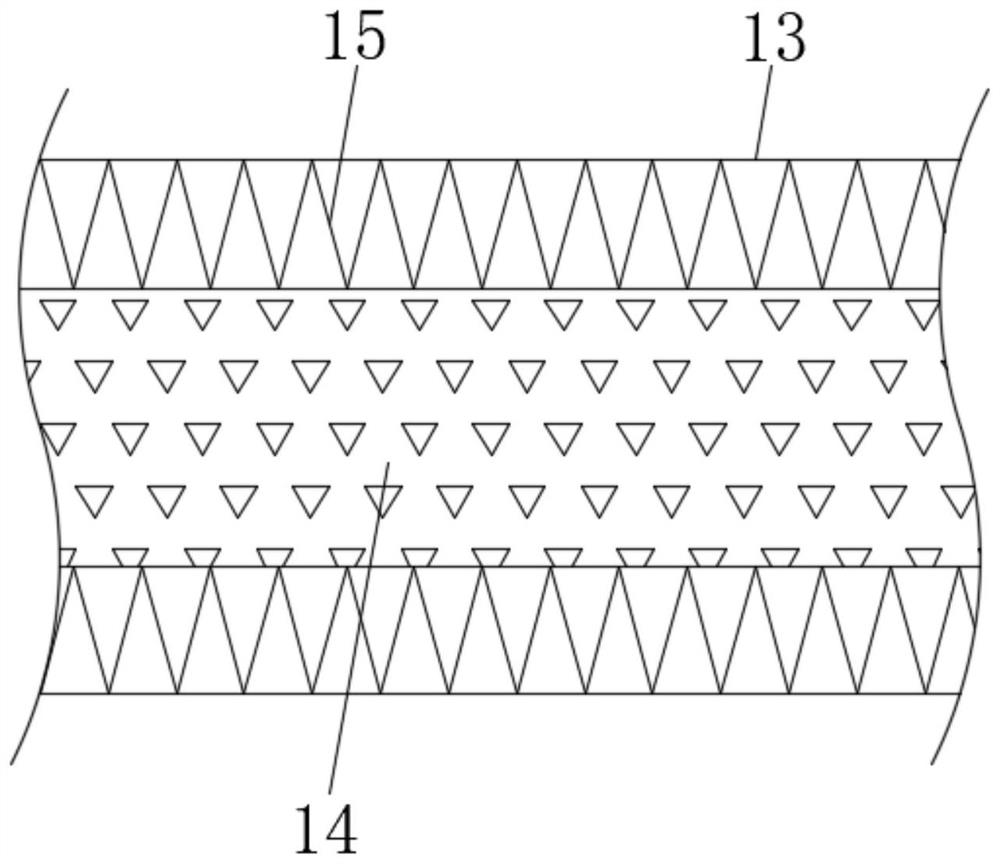

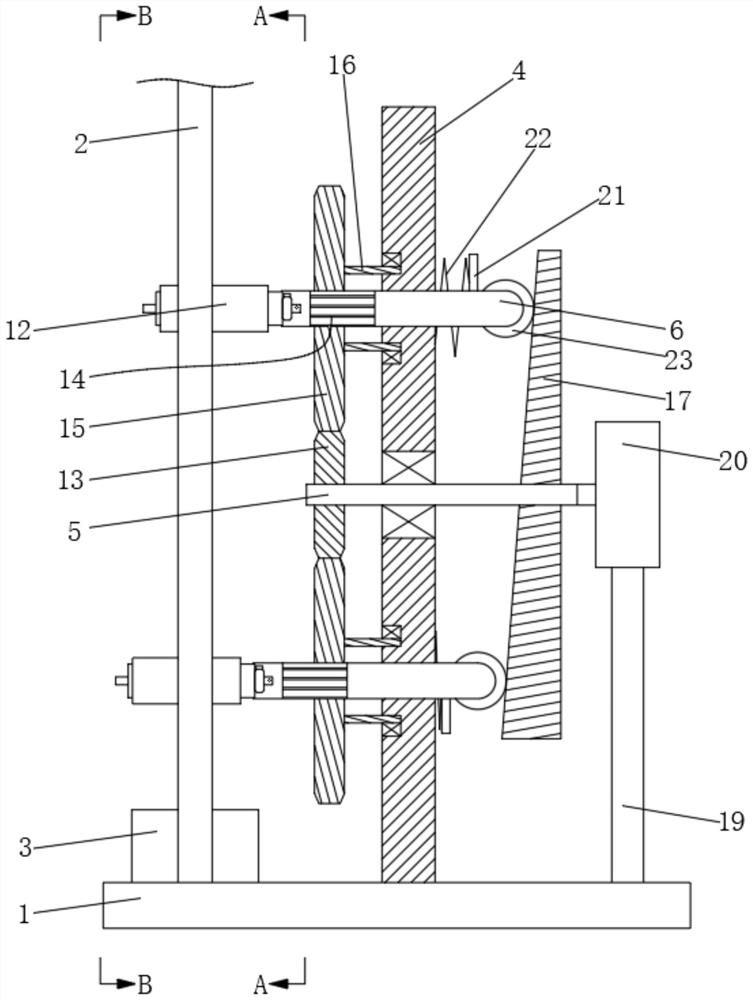

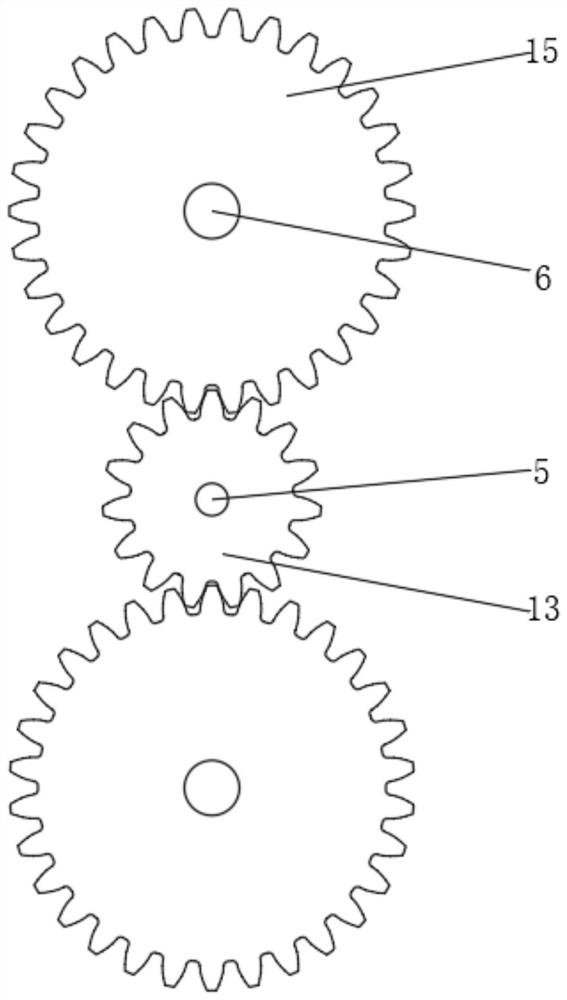

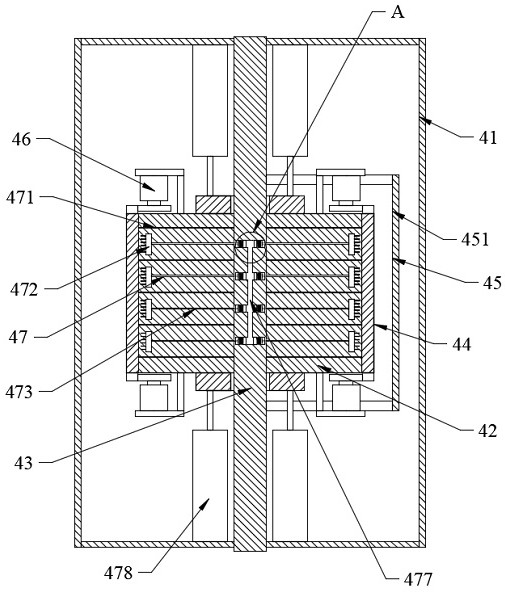

Rolling friction trapezoidal screw rod

PendingCN110043625AReasonable supportImprove friction efficiencyGearingRolling resistanceReciprocating motion

The invention belongs to the field of trapezoidal screw rod driving, and relates to manufacturing of a rolling friction trapezoidal screw rod. The rolling friction trapezoidal screw rod is newly characterized by being formed by two large parts: a trapezoidal screw rod and a rolling friction nut, wherein the rolling friction nut is formed by a nut shell, a trapezoidal screw rolling element and a bearing; the nut shell is connected and fixed with multiple trapezoidal screw pillar rolling elements with screw pitch leads being the same as a screw pitch lead of the trapezoidal screw rod through a bearing; the trapezoidal screw pillar rolling elements are circumferentially distributed in a planet surrounding way in the axial direction of the trapezoidal screw rod and are mutually embedded and enclasped; when the trapezoidal screw rod rotates and the rolling friction nut is fixed, the trapezoidal screw pillar rolling elements self-rotate synchronously along with the trapezoidal screw rod; andmeanwhile, through a screw drive principle, the rotary power of the trapezoidal screw rod is transmitted to the load-carrying nut shell through the bearing, and the rolling friction trapezoidal screwrod is a mechanical product for converting the rotation motion of the trapezoidal screw rod into the straight reciprocating motion of the nut. The rolling friction trapezoidal screw rod provided by the invention becomes a second high-quality type followed in a sliding friction trapezoid screw rod, namely, a common trapezoid screw rod, has a self-locking function, and is reasonable in design and wide in application.

Owner:侯金网

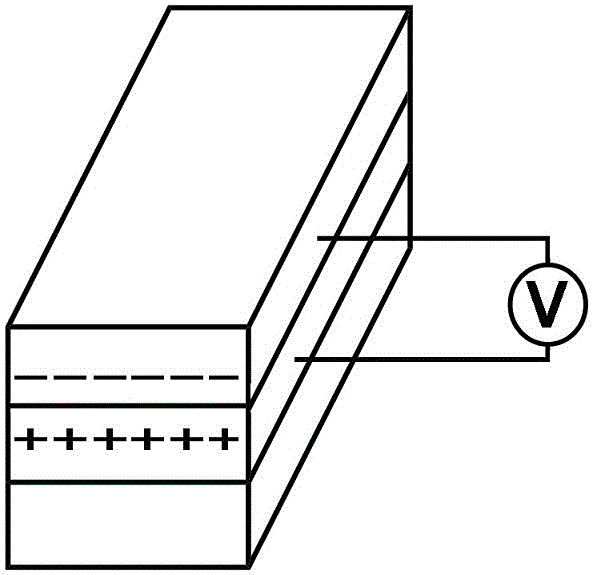

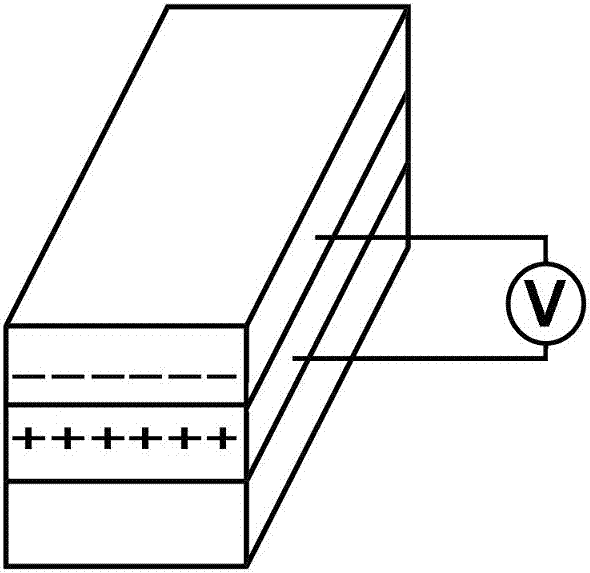

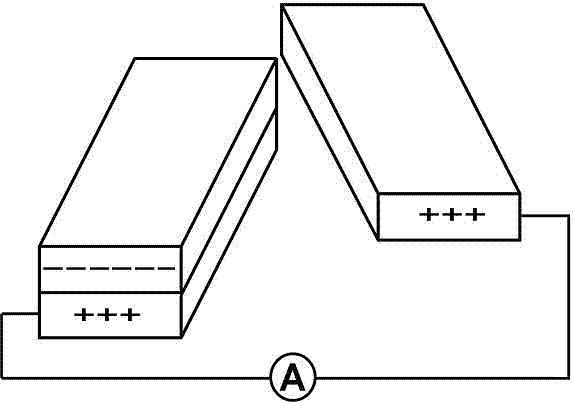

Friction nanogenerator and manufacturing method thereof

ActiveCN108123642AAffect outputSimple manufacturing processFriction generatorsNanogeneratorBiomedical engineering

The invention provides a friction nanogenerator and a manufacturing method thereof. The friction nanogenerator comprises a first friction unit and a second friction unit, wherein the first friction unit comprises a first magnetic part; the second friction unit is arranged oppositely to the first friction unit, the materials on the opposite surfaces of the two have different friction electrode orders, the second friction unit comprises a second magnetic part, the first magnetic part and the second magnetic part are arranged with the same poles corresponding; and relative movement between the first friction unit and the second friction unit is realized through same-pole repulsion. The friction nanogenerator provided in the invention has the advantages of stable output after long-time use, simple structure, safety and reliability, low cost, high output and simple manufacturing process.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Automatic grinding machine

The invention discloses an automatic grinding machine including a support, the lower end surface of the support is fixedly connected with a first sleeve, and the automatic polishing machine is simplein structure; to-be-grinded workpieces are placed below a sanding paper, a motor is started through connecting external power source, forward rotation and backward rotation of a first rotating rod canbe achieved under the action of a first spring through engaging of a rack and a gear, so that a frame can rotate, and further the sanding paper can be rotated while swinging to improve friction efficiency and can transfer power to a second electromagnet; the distance and the acting force between the second electromagnet and a second permanent magnet are changed due to swing of the second permanent magnet, so that a second inserting rod trembles under the action of a second spring, further improving friction of the sanding paper and the workpieces, and the grinding effect is improved.

Owner:广东雷诺丽特实业有限公司

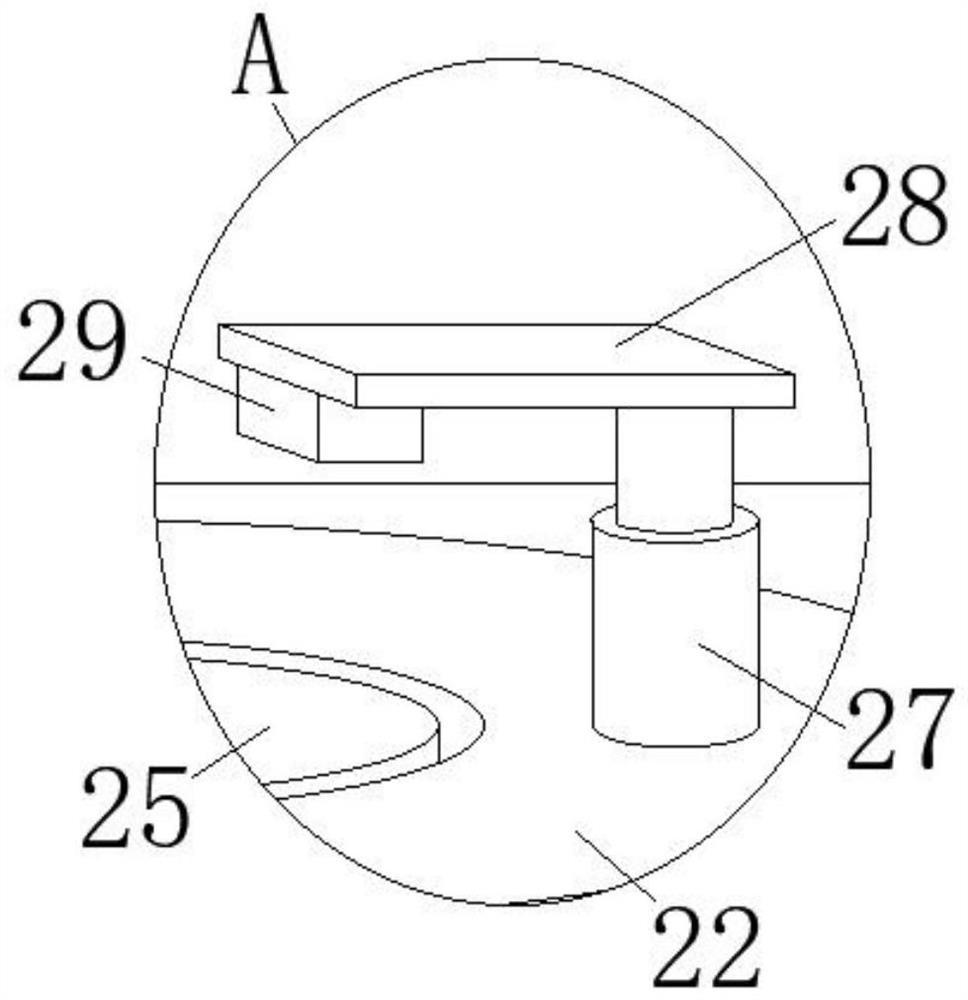

Oval optical lens integrated grinding device

InactiveCN112139906AEasy to moveEnhance friction strengthEdge grinding machinesGrinding feedersEngineeringOptic lens

The invention discloses an oval optical lens integrated polishing device. The oval optical lens integrated polishing device comprises a grinding bin; a shaft I is rotatably connected to the bottom ofthe inner wall of the grinding bin in a limited mode; a clamping plate I is fixedly connected to the top of the shaft I; an oval glass sheet is arranged on the upper surface of the clamping plate I; acover plate is fixedly connected to the inner wall, close to the top, of the grinding bin; a shaft II is rotatably connected to the lower surface of the cover plate in a limited mode; a clamping plate II is fixedly connected to the bottom of the shaft II; the oval glass sheet is located on the opposite faces of the clamping plate I and the clamping plate II; and a supporting frame is arranged onthe right side of the grinding bin. According to the oval optical lens integrated grinding device provided by the invention, through cooperative use of the above structures, the problems that in the actual use process, due to the fact that the actual use effect of a traditional grinding block is poor, it is difficult to conduct complete grinding on the arc-shaped outline of oval glass, the grinding efficiency is low, and complete grinding of the oval glass can be achieved only through multiple times of adjustment are solved, and inconvenience is brought to use.

Owner:冀敏敏

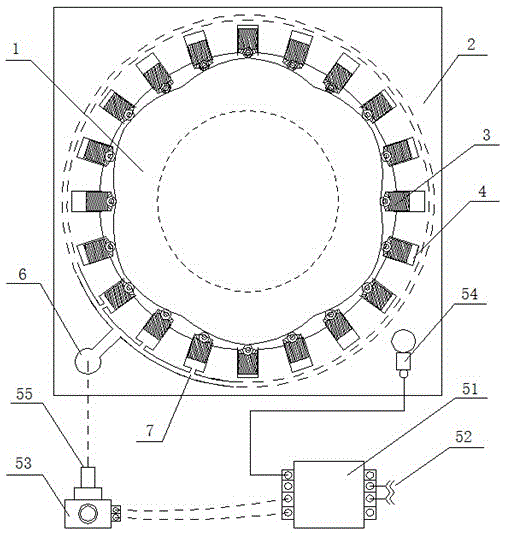

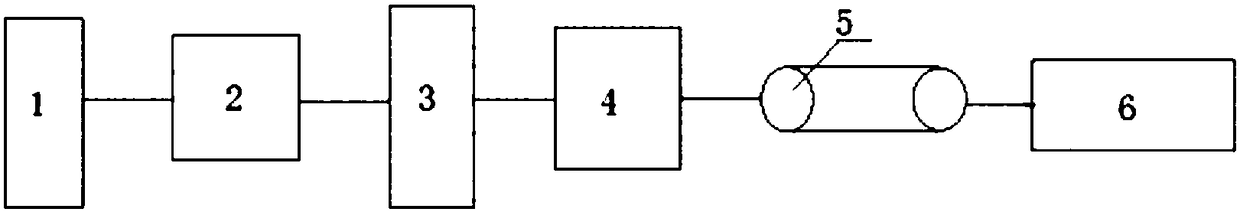

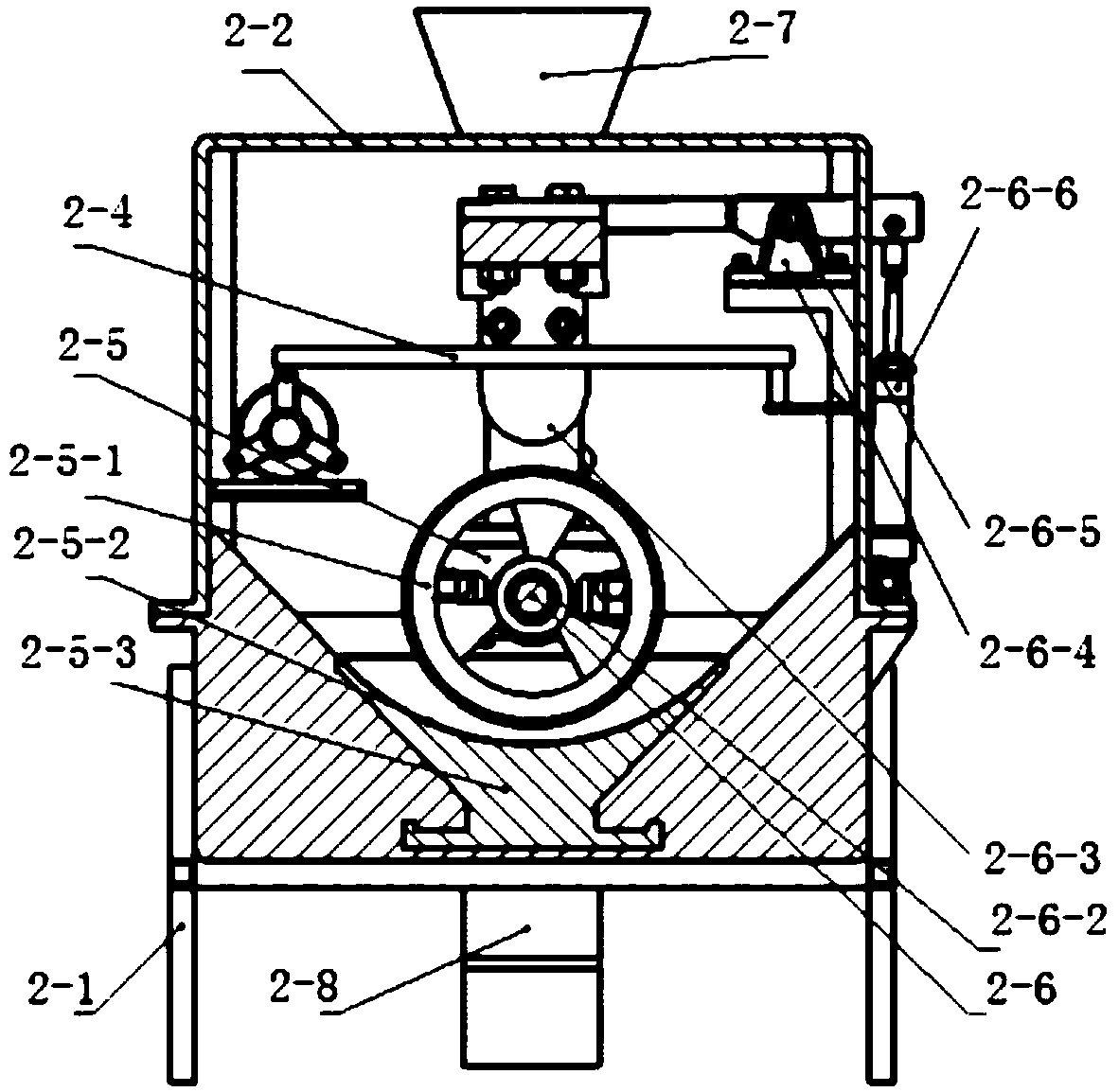

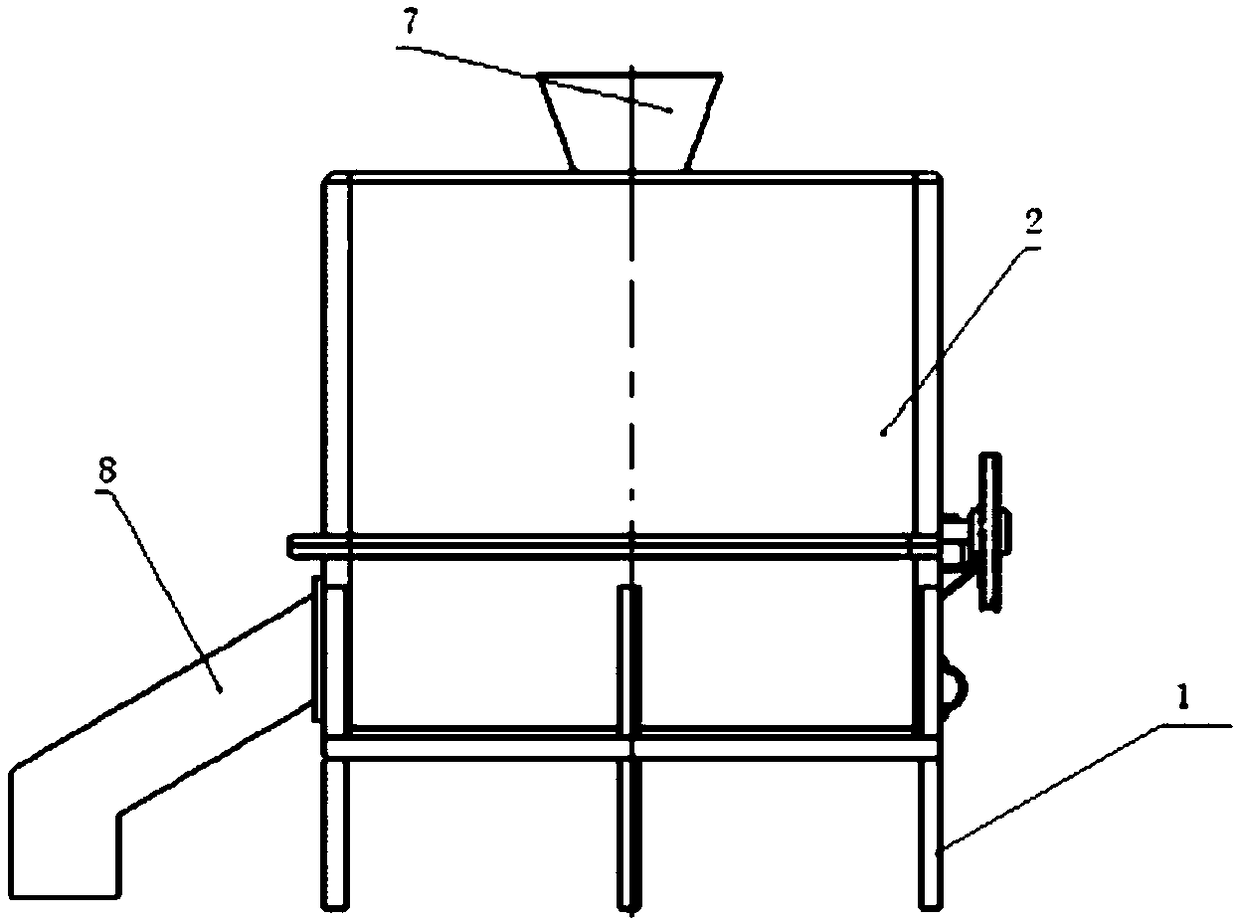

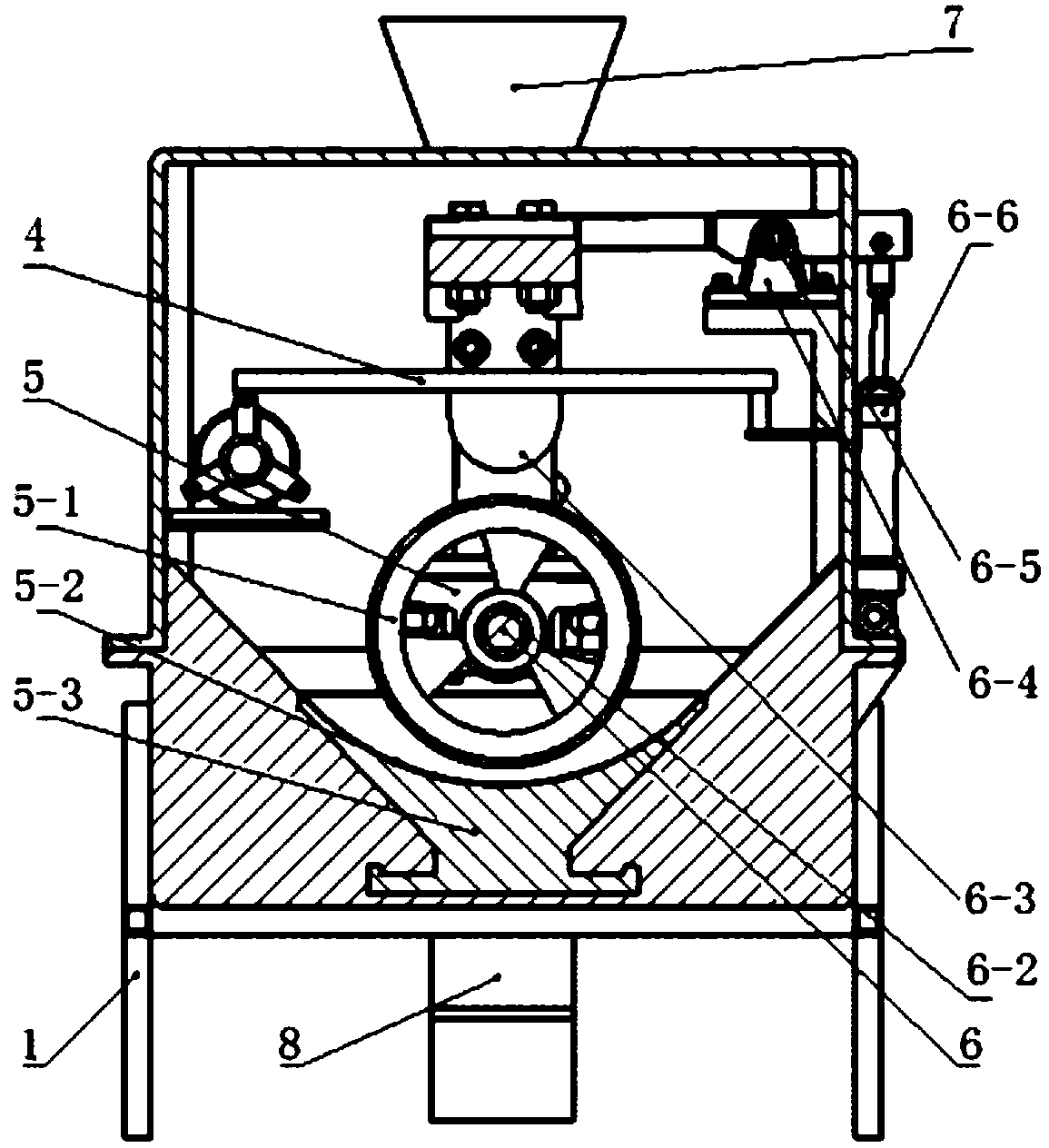

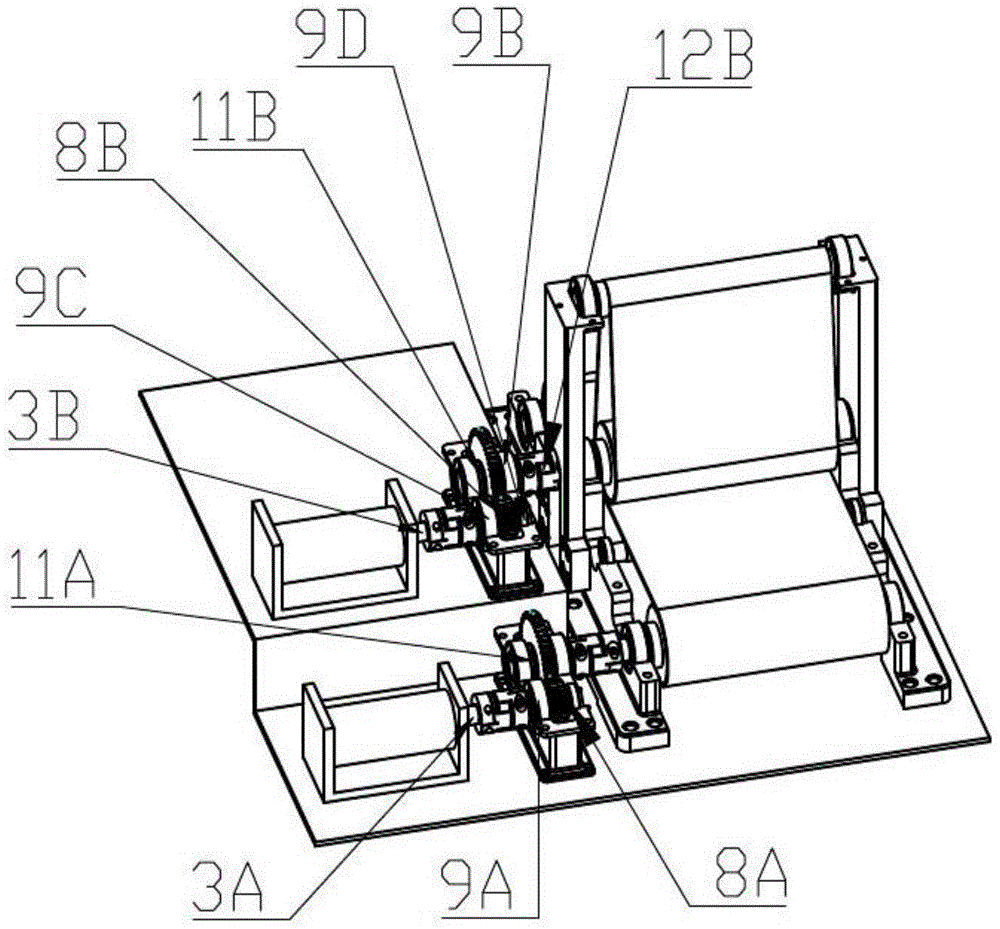

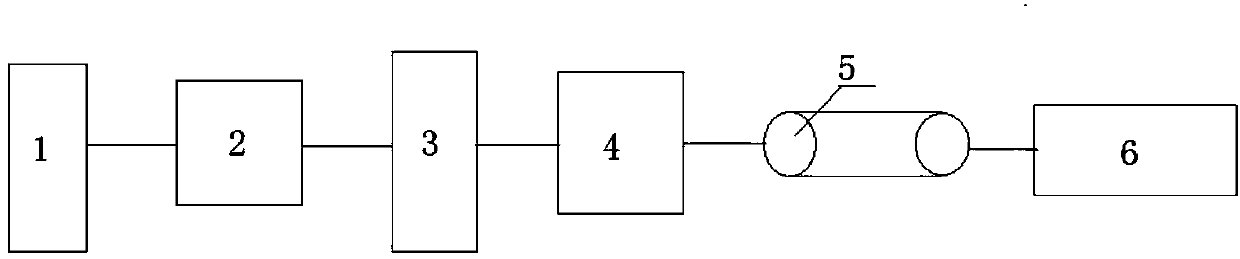

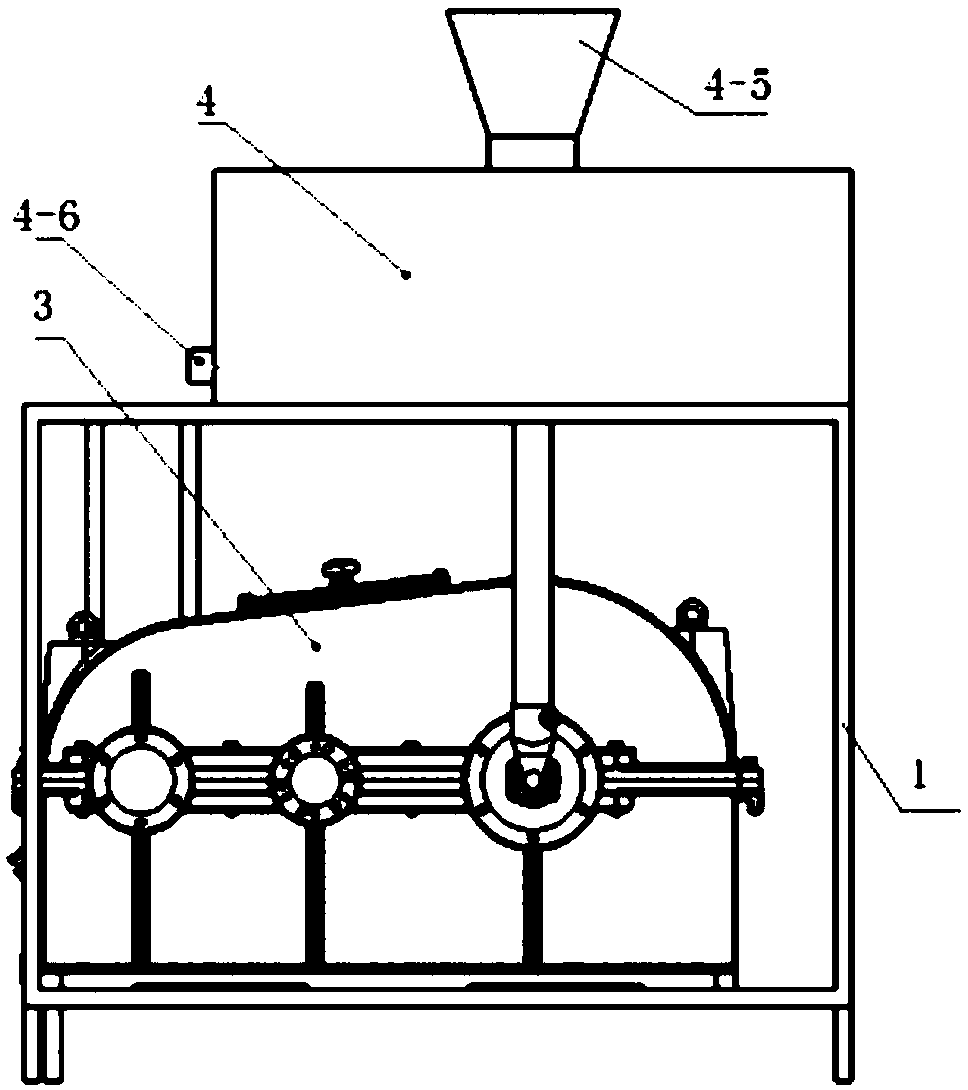

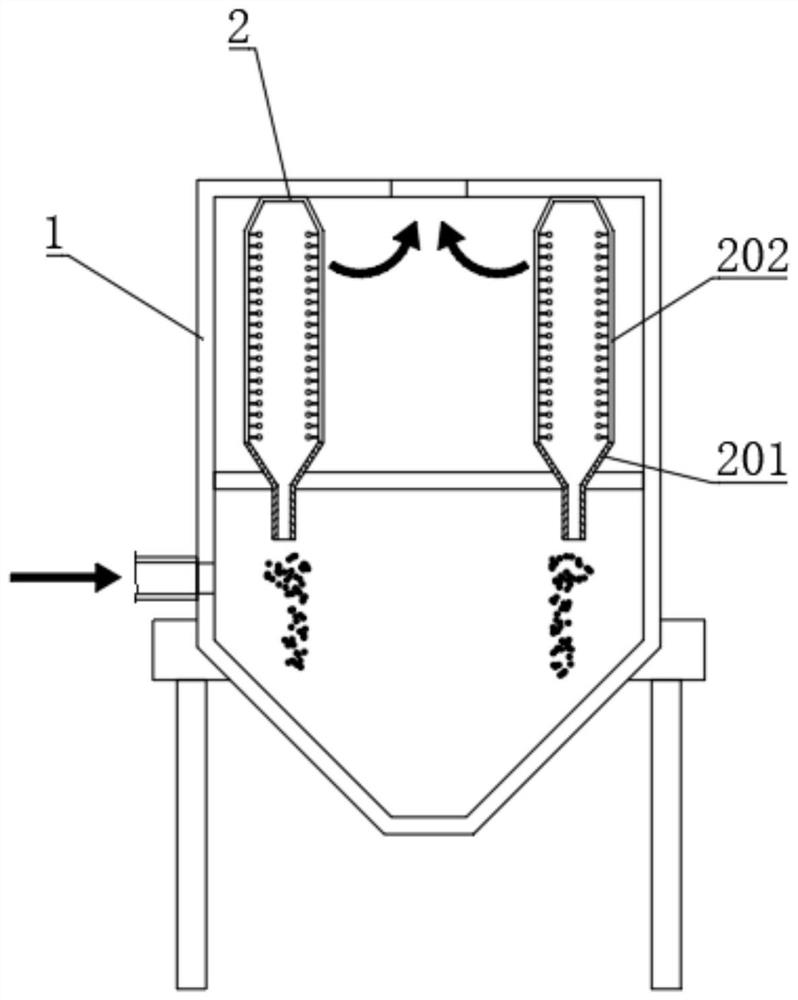

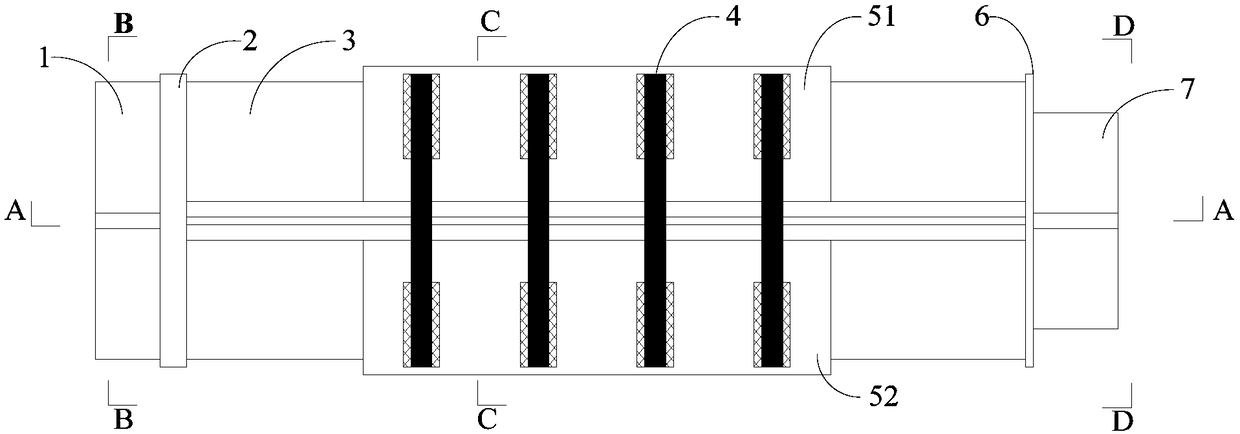

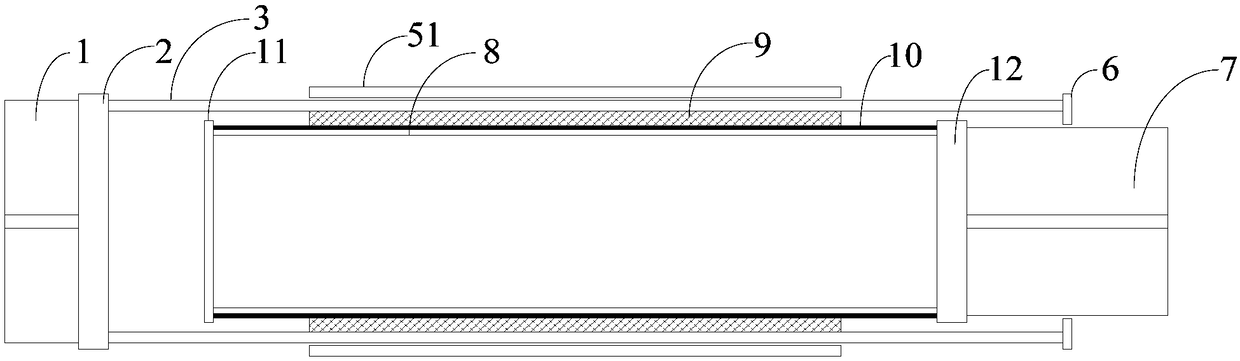

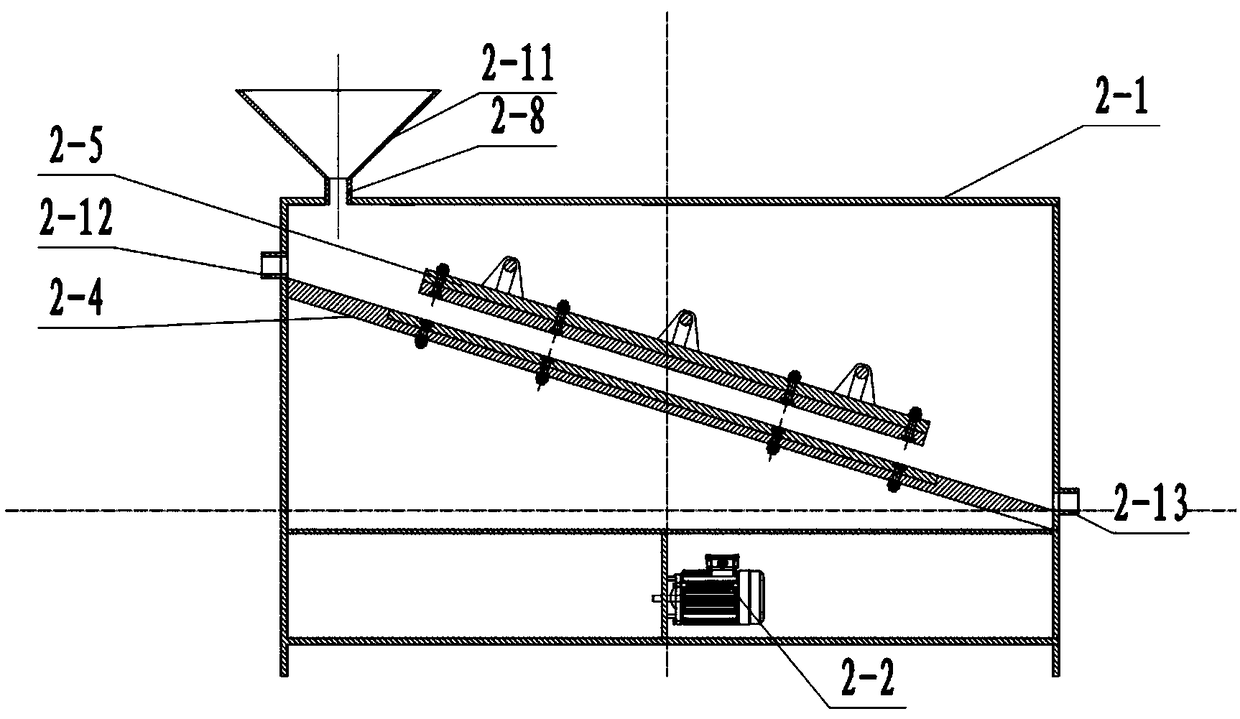

Drum-type hard seed dormancy breaking production system

InactiveCN108966732AImprove the efficiency of breaking upIncrease productionSeed and root treatmentSeed dormancyFiltration

The invention discloses a drum-type hard seed dormancy breaking production system. The system comprises a dormancy breaking agent box (1), a grinding device (2), a seed filtration device (3), a drum-type drying device (4), a transport device (5) and a constant temperature incubator (6) which are connected in sequence. the drum-type hard seed dormancy breaking production system provided by the invention has the advantages of reasonable structure design, convenient operation, high degree of automation and good complete set of equipment, the combination of chemical and mechanical dormancy breaking is adopted, and the filtration device, the drying device and the constant temperature incubator are combined, the hard seeds of alfalfa and the like can be broken with high efficiency, the cultivated seeds can be planted directly after being taken out, the seeds germinate more easily, the germination rate of the hard seeds is increased and the yield of the alfalfa is increased.

Owner:GANSU AGRI UNIV

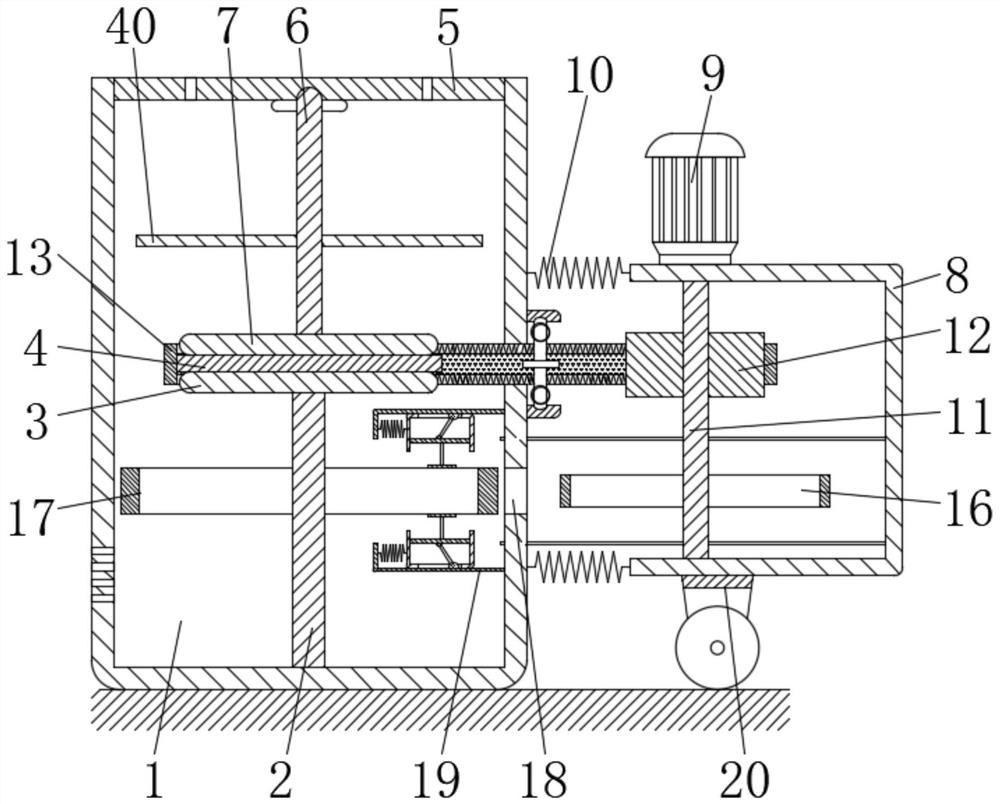

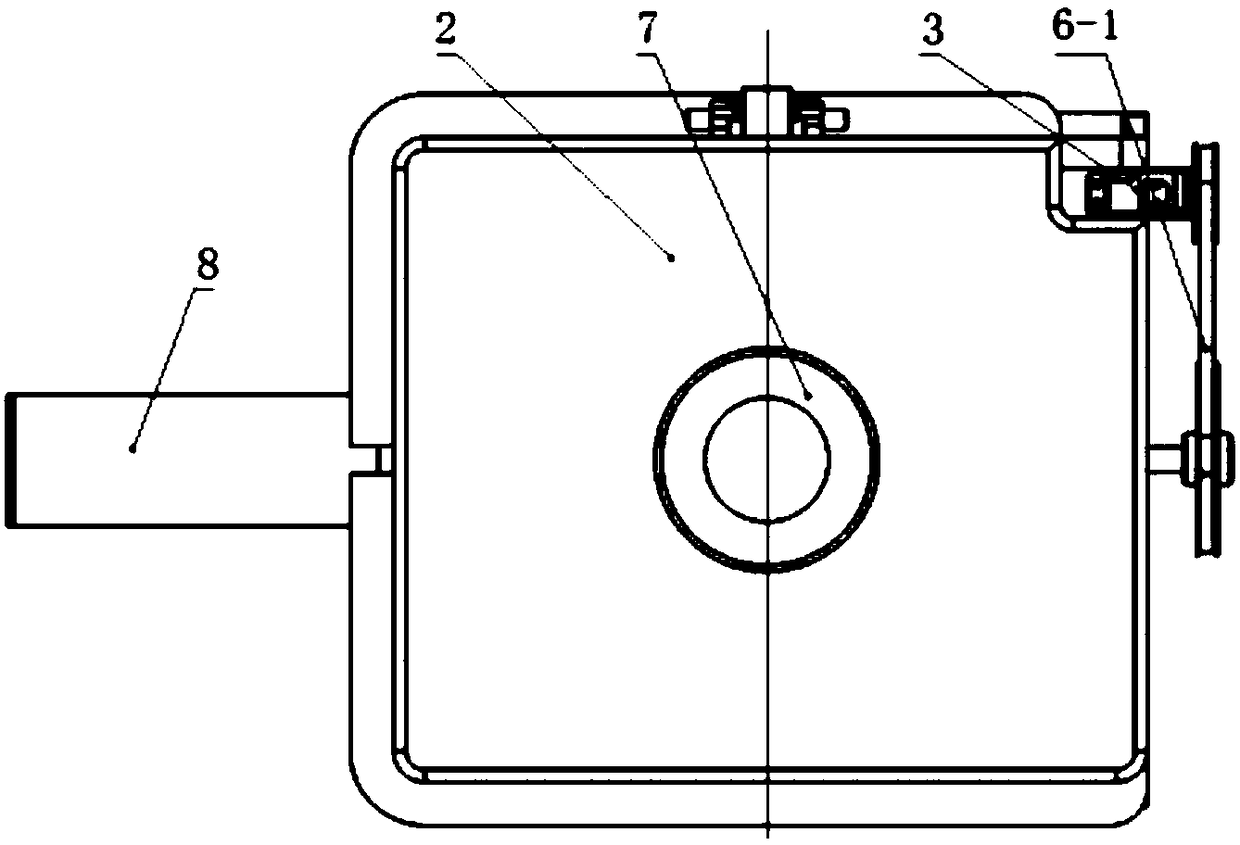

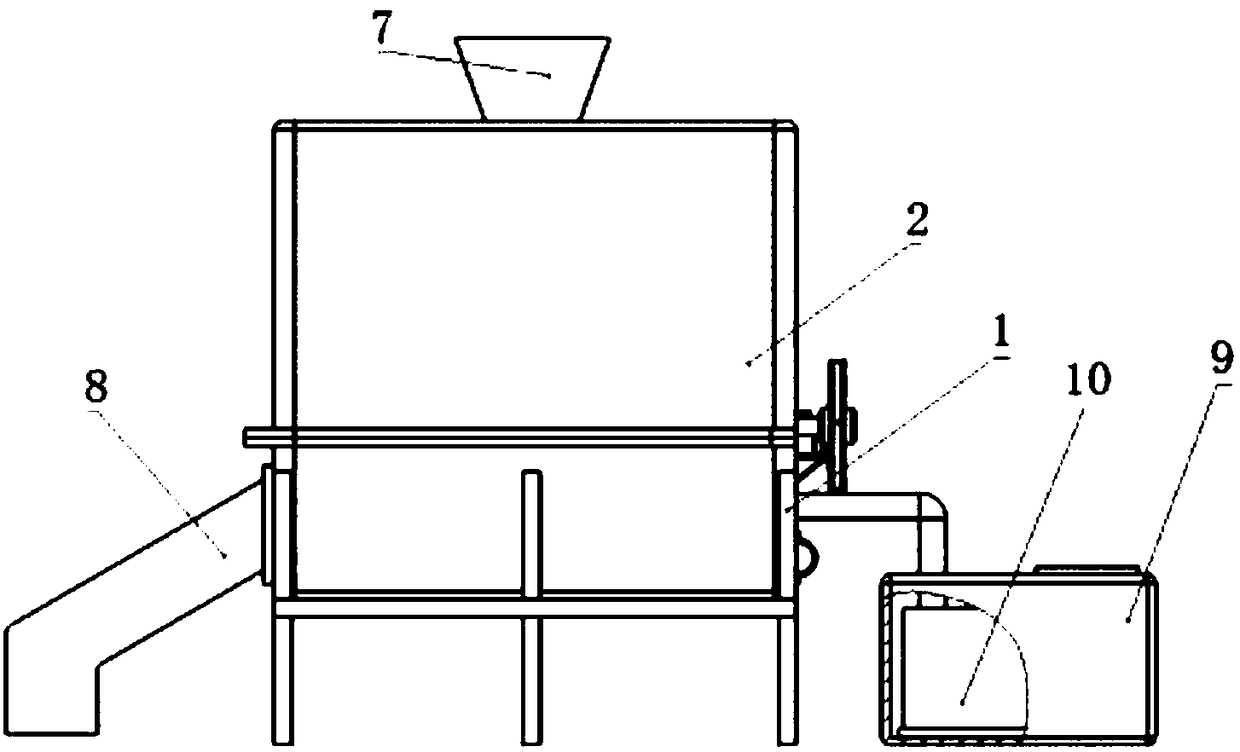

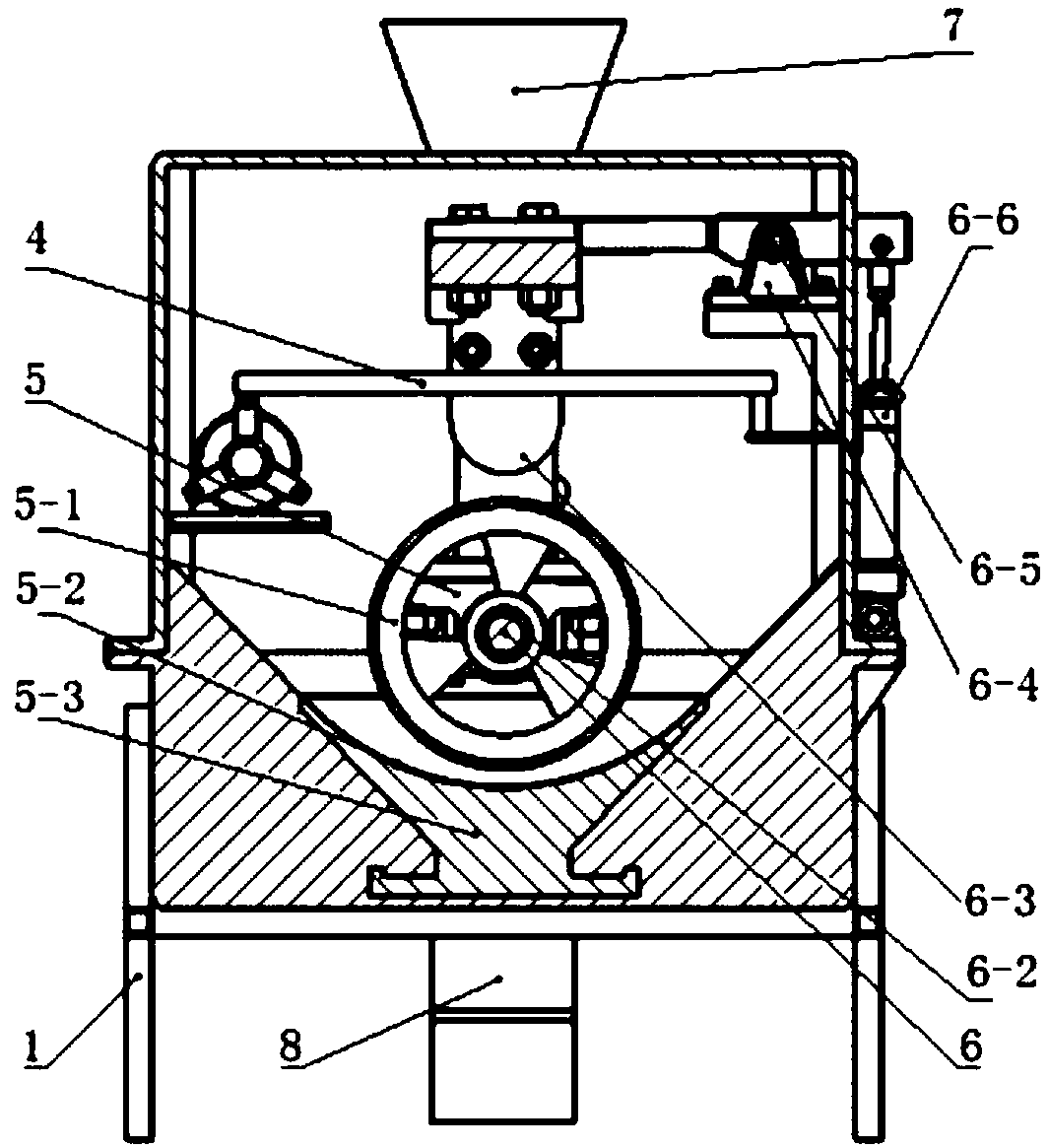

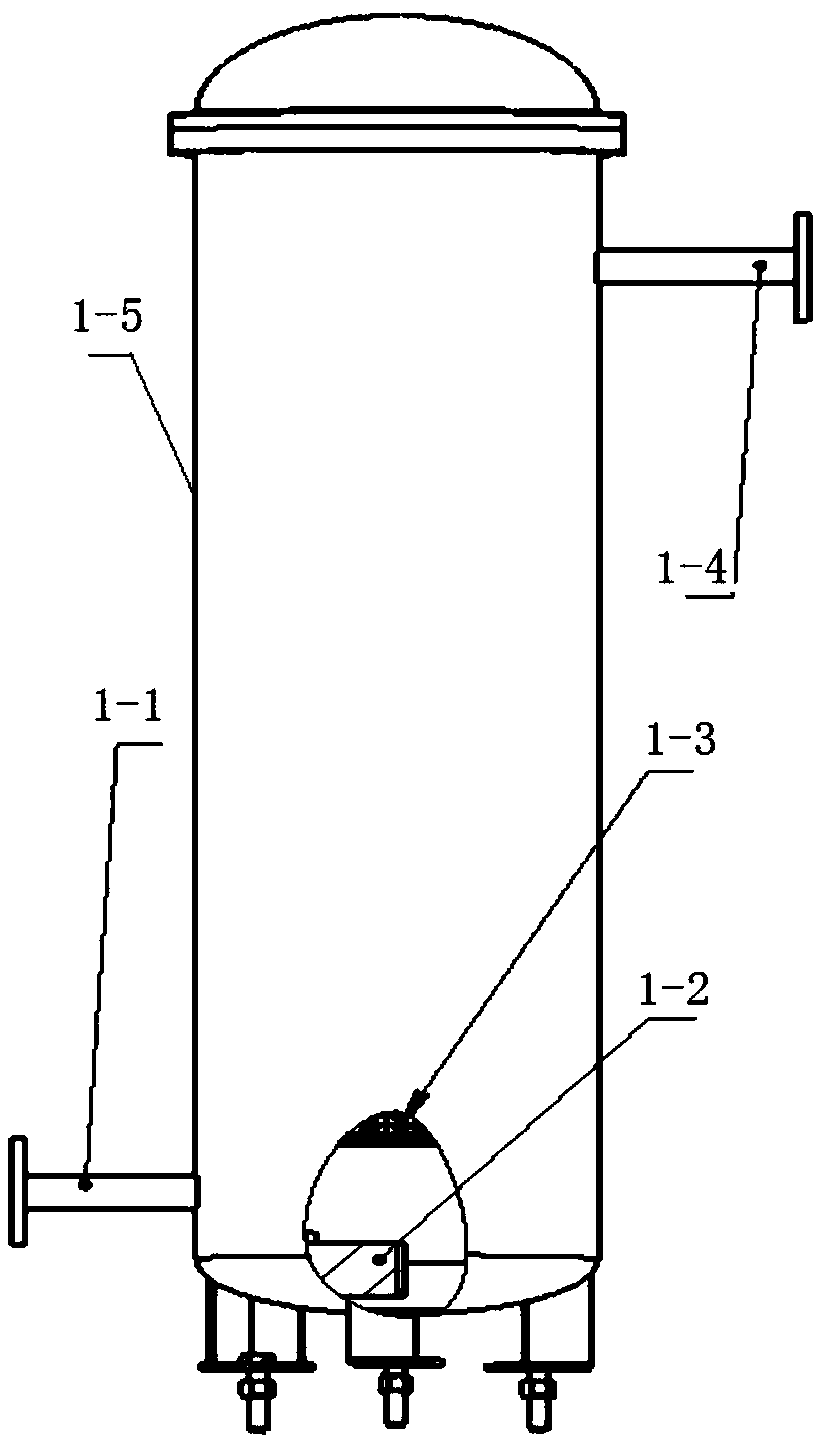

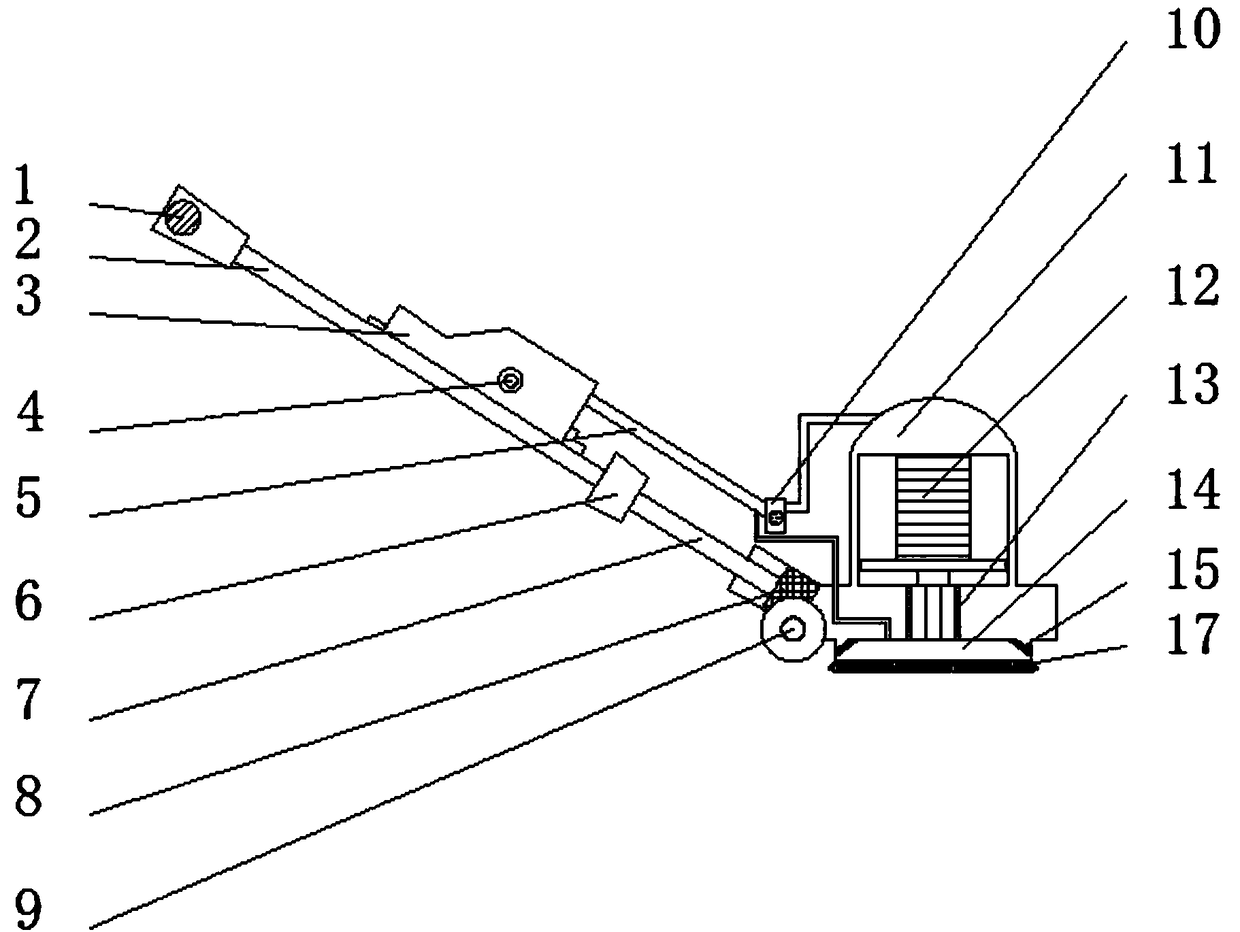

Drum type mechanical shell breaking machine for hard seeds

InactiveCN109005731AIncrease productionImprove the efficiency of breaking upGerminating apparatusEngineeringMechanical engineering

The invention discloses a drum type mechanical shell breaking machine for hard seeds. The drum type mechanical shell breaking machine for hard seeds comprises a frame (1), an outer shell (2), a motor(3), a vibrating screen (4) and a grinding mechanism (5); the outer shell (2) is fixedly mounted on the frame (1), the motor (3) is mounted at one side of the outer shell (2), the vibrating screen (4)is mounted at the upper side of the internal of the outer shell (2), and the grinding mechanism (5) is located below the vibrating screen (4); and the top of the outer shell (2) is provided with a feeding opening (7), and the lower part of the outer shell (2) is provided with a discharging opening (8). The drum type mechanical shell breaking machine for hard seeds has the advantages of reasonablestructural design, convenience in operation, high shell breaking efficiency for alfalfa and other hard seeds, improvement of the germination rate of the hard seeds, increase of the yield of alfalfa,and strong practicability.

Owner:GANSU AGRI UNIV

Mechanical and chemical combined hard seed dormancy breaking treatment machine

InactiveCN108966735AIncrease productionImprove the efficiency of breaking upGerminating apparatusSeed dormancyEngineering

The invention discloses a mechanical and chemical combined hard seed dormancy breaking treatment machine, which comprises a rack (1), a shell (2), a motor (3), a vibrating screen (4), a grinding mechanism (5) and a dormancy breaking medicament box (9), wherein the shell (2) is fixedly arranged on the rack (1), and the motor (3) is arranged at one side of the shell (2); a vibrating screen (4) is arranged at the upper side of the inside of the shell (2), and a grinding mechanism (5) is positioned below the vibrating screen (4); the top of the shell (2) is provided with a feed port (7), and the lower part of the shell (2) is provided with a discharge port (8); one end of the shell (2) is provided with a water inlet, and the dormancy breaking medicament box (9) is connected with the water inlet through a pipeline. The mechanical and chemical combined hard seed dormancy breaking treatment machine disclosed by the invention has the advantages of reasonable structural design and convenient operation, combination of mechanical dormancy breaking and chemical dormancy breaking to improve the germination rate of hard seeds, improvement in yield, and high practicability.

Owner:GANSU AGRI UNIV

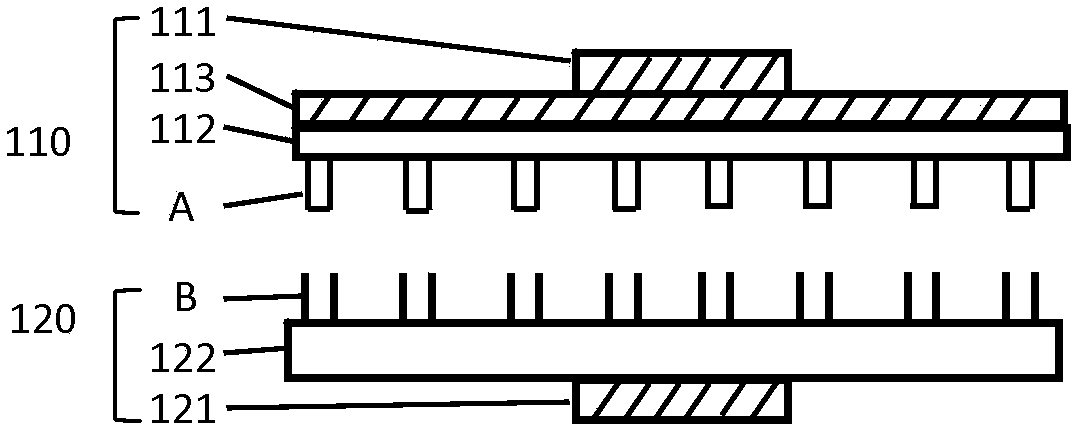

A cross-folding friction generator

The invention discloses a cross-folding friction generator, which comprises at least one friction unit, at least one second friction unit, a rotating shaft and a base plate, wherein the rotating shaft is connected with the first friction unit and the second friction unit; the base plate is arranged on the rotating shaft; the first friction unit comprises a base, a metal electrode plate and a first friction layer; the metal electrode plate is arranged on the base; the first friction layer is filled into the metal electrode plate; the second friction unit comprises a base, a metal electrode plate and a second friction layer; the metal electrode plate is arranged on the base; the second friction layer is filled into the metal electrode plate; the first friction unit and the second friction unit are crossly and oppositely stacked together through the rotating shaft hinged with the centers of the bases to form a power generation unit; and the first friction layer of the first friction unit and the second friction layer of the second friction unit are oppositely arranged. The cross-folding friction generator has the advantages of being simple in structure, low in cost, durable, high in output voltage, high in current, easy to popularize and the like.

Owner:HENAN NORMAL UNIV

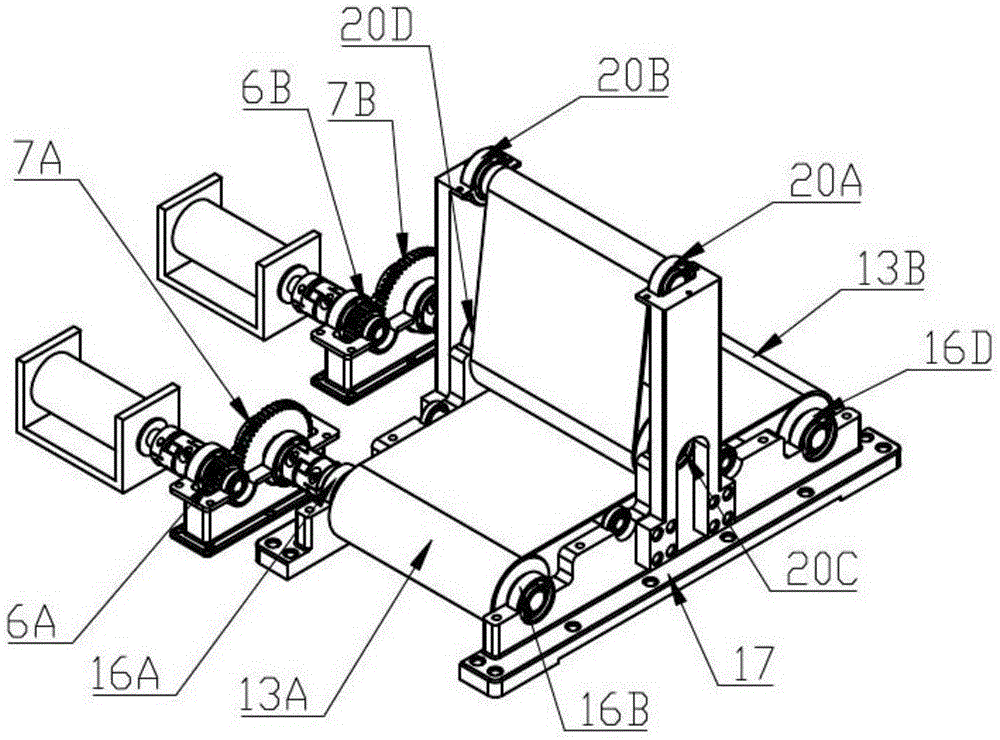

Mechanical printing paper ink removal method and mechanical printing paper ink removal device

ActiveCN104827372AReduce manufacturing costReduce work costsGrinding drivesBelt grinding machinesPulp and paper industryDrive motor

The invention discloses a mechanical printing paper ink removal method and a mechanical printing paper ink removal device. A set of drive mechanism which comprises a driving motor and a speed reducer drives a transfer mechanism to act, so that paper is driven to move forward. At the same time, another set of drive mechanism which comprises a driving motor and a speed reducer drives an abrasive belt grinding mechanism to act, a grinding abrasive belt is in contact with the paper, the principle of friction is utilized to remove the ink of the paper, consequently, the effect of paper ink removal is achieved, the paper can be recycled, energy is saved, and the cost of waste paper recovery and pollution are reduced.

Owner:枣庄华亿矿业集团有限公司

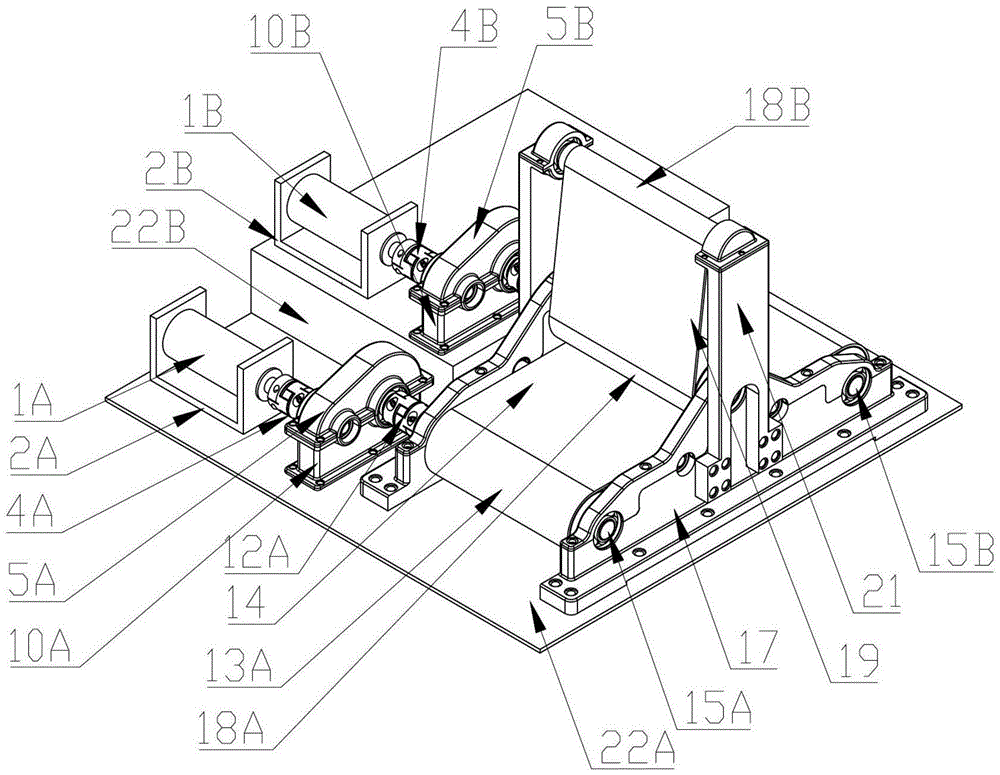

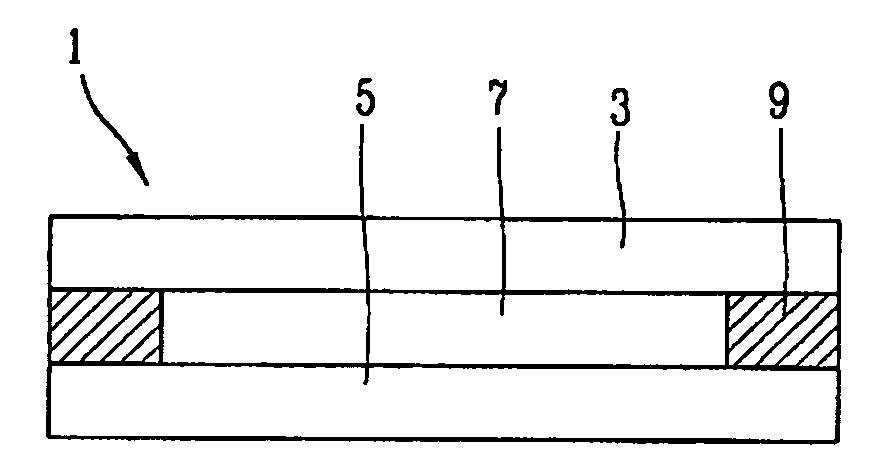

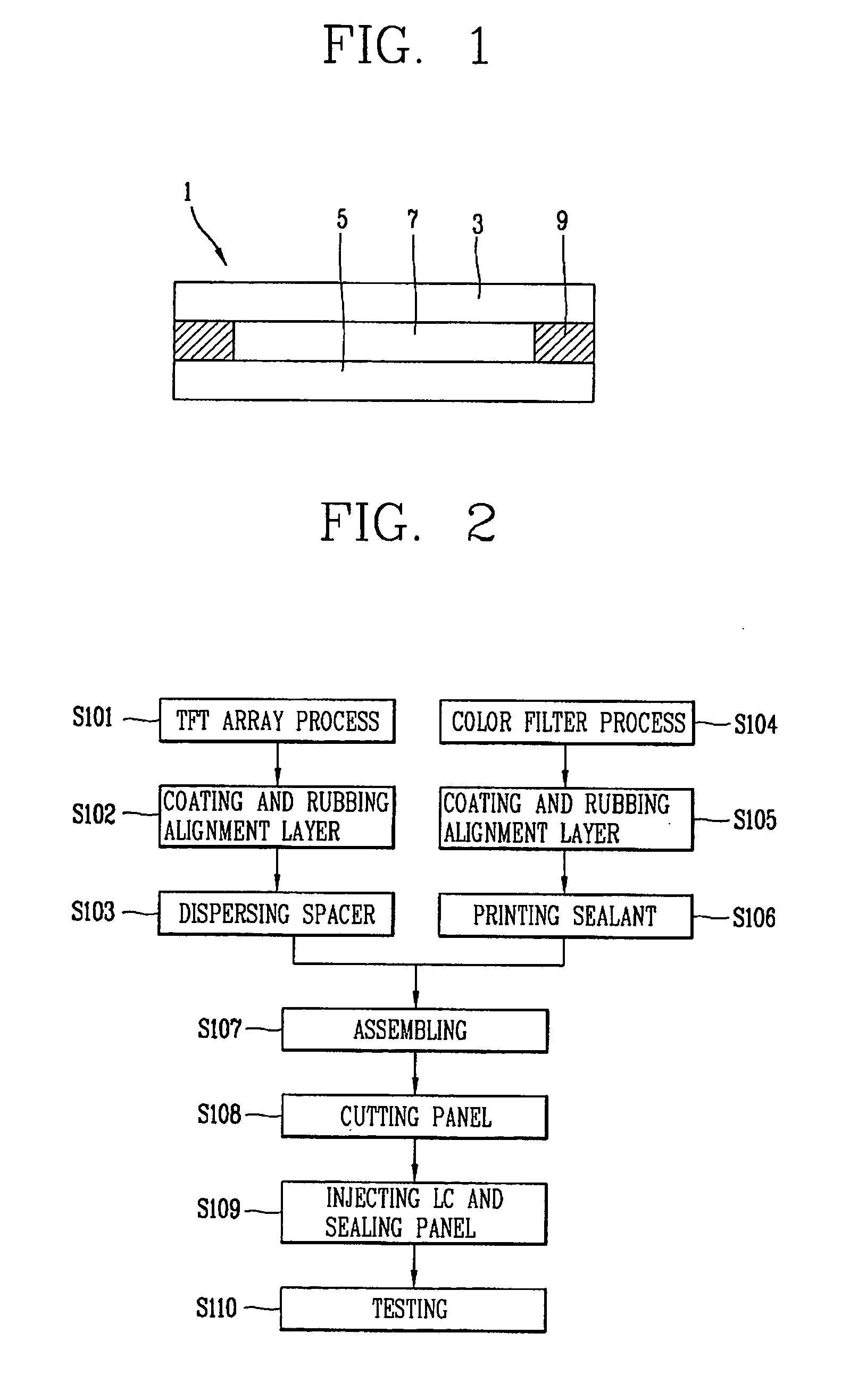

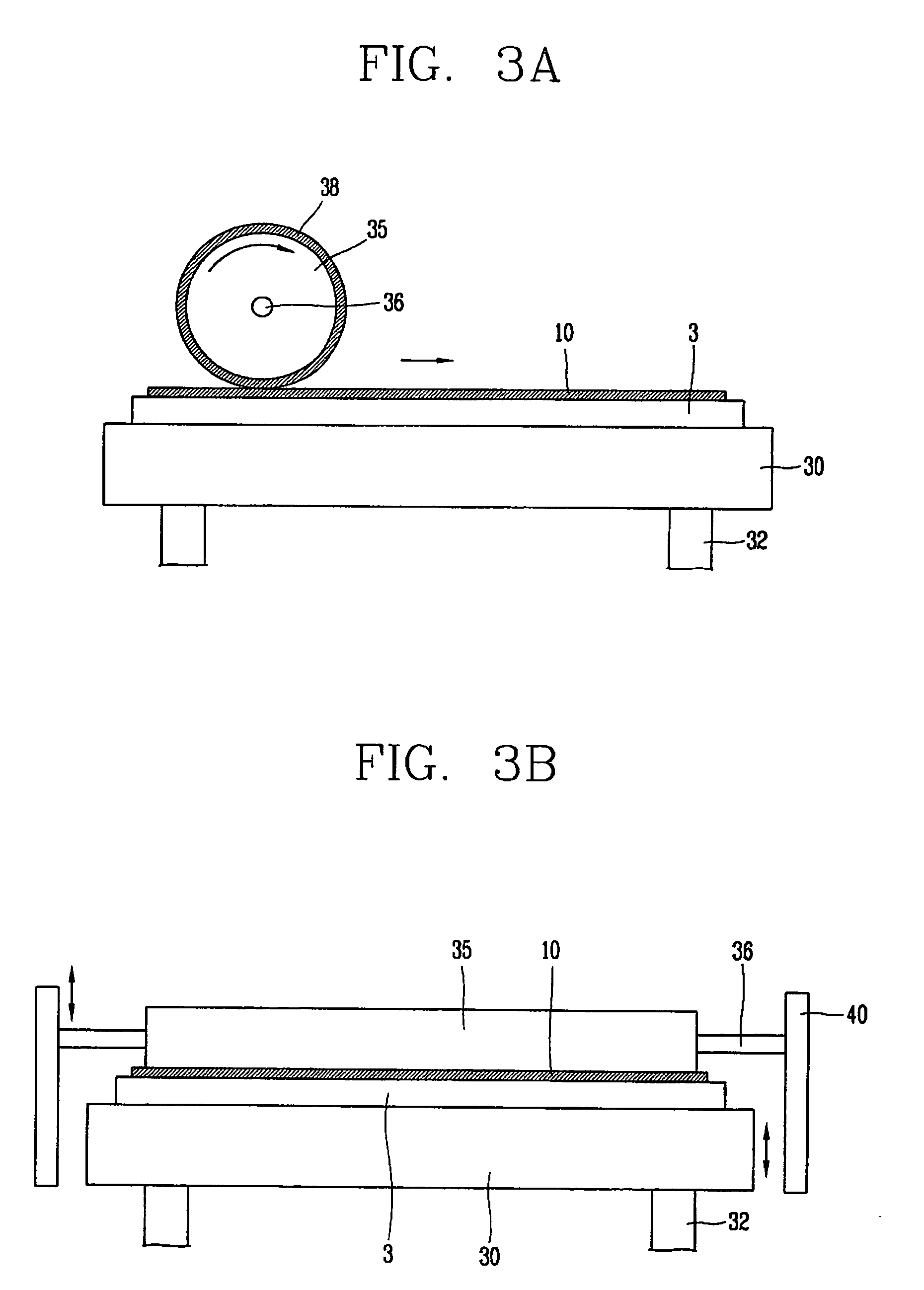

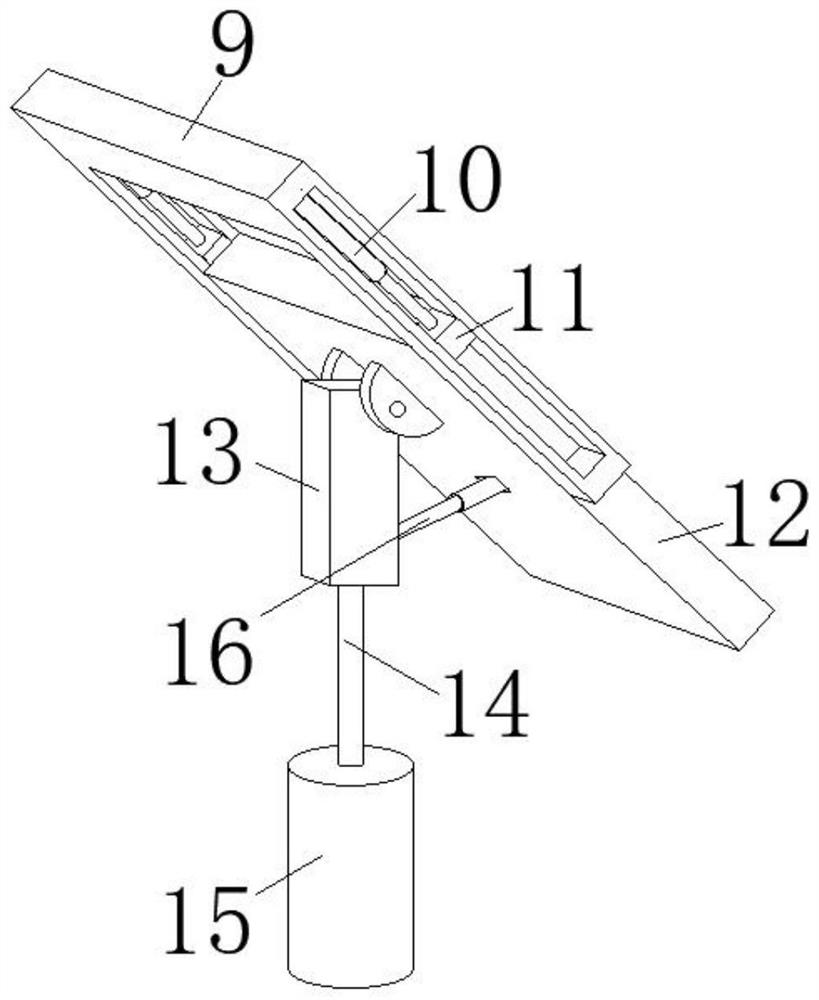

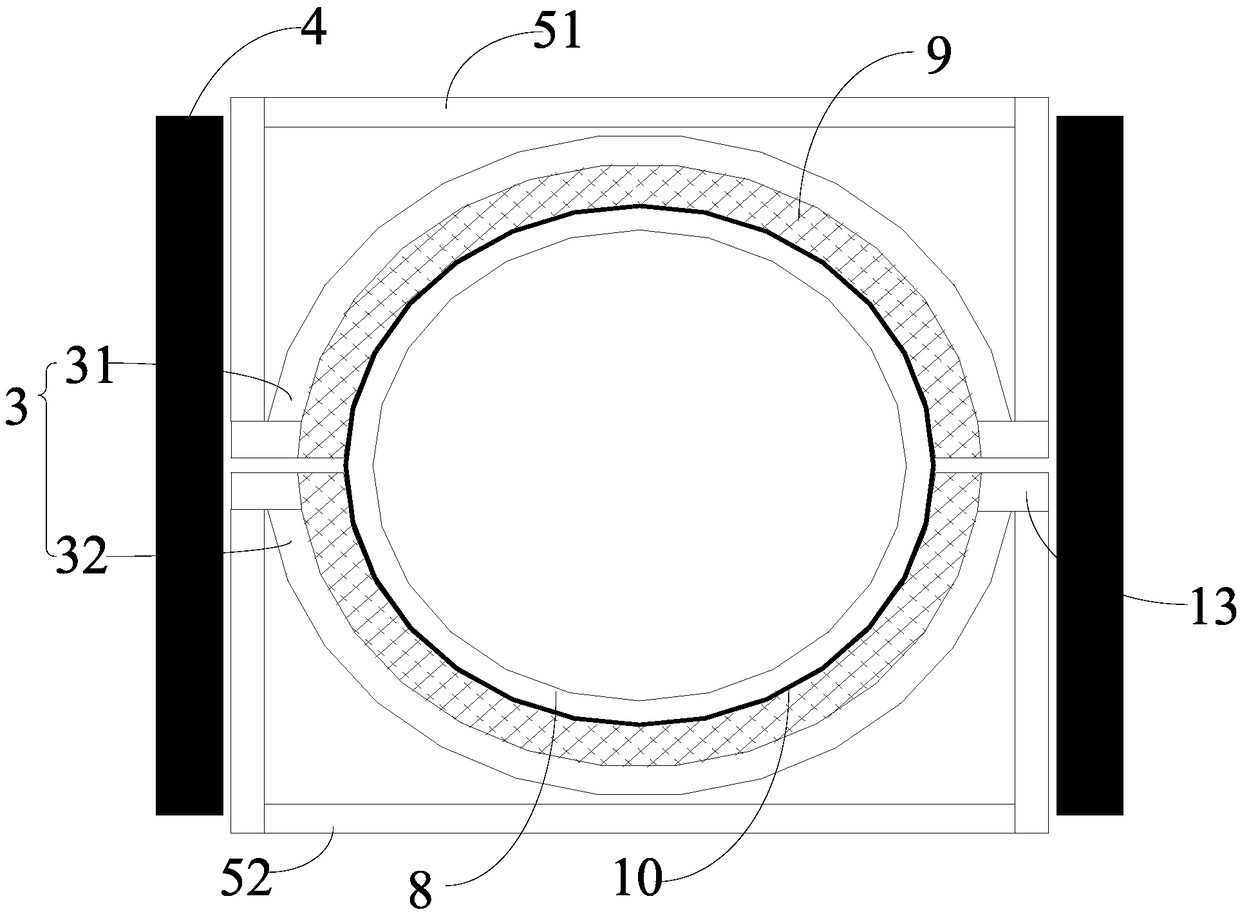

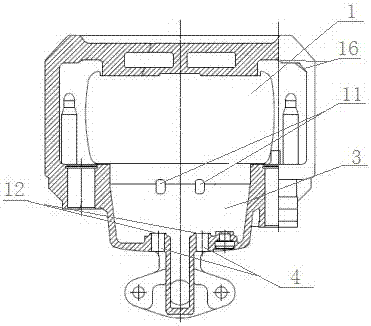

Rubbing system for alignment layer of LCD and method thereof

ActiveUS20070166857A1Maintaining gapImprove friction efficiencySemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

A rubbing system for an alignment layer of a liquid crystal display (LCD) device, comprises: a rubbing table on which a substrate having an alignment layer thereon is positioned; a rubbing roll on which a rubbing material is wound, substantially positioned on the rubbing table thus to substantially contact the alignment layer, for rubbing the alignment layer by rotation of the rubbing roll; and a controlling unit for controlling the alignment layer to be rubbed by substantially contacting the rubbing roll onto the alignment layer by simultaneously lifting and lowering a rubbing table and the rubbing roll according to an alignment controlling force to be applied to the alignment layer.

Owner:LG DISPLAY CO LTD

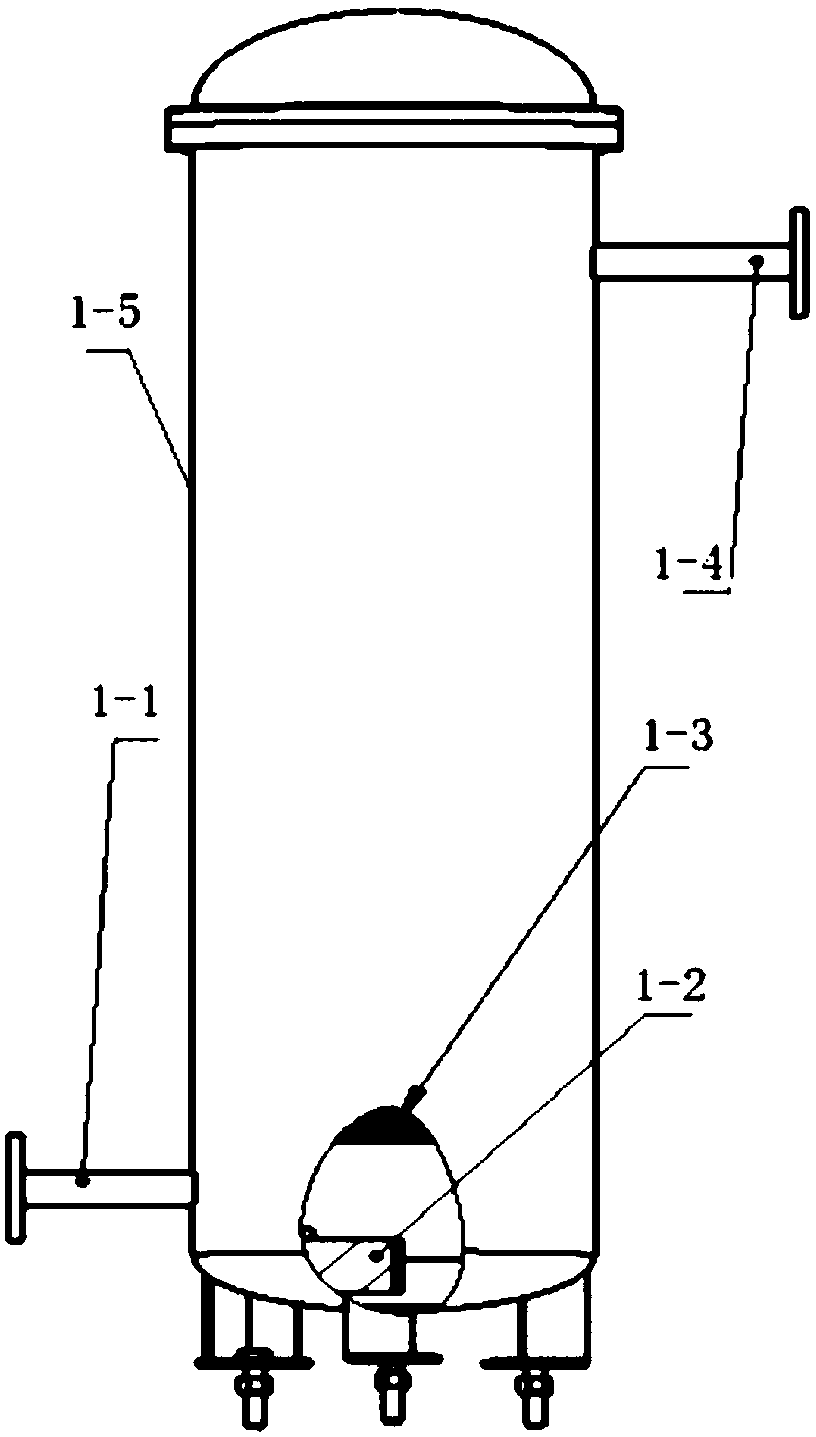

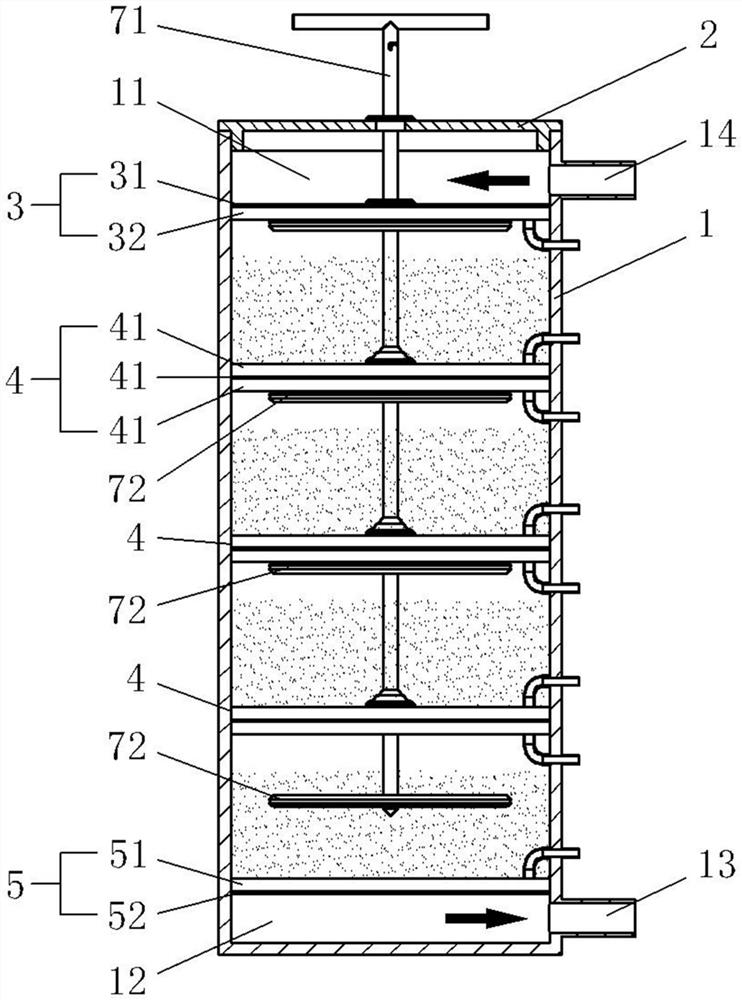

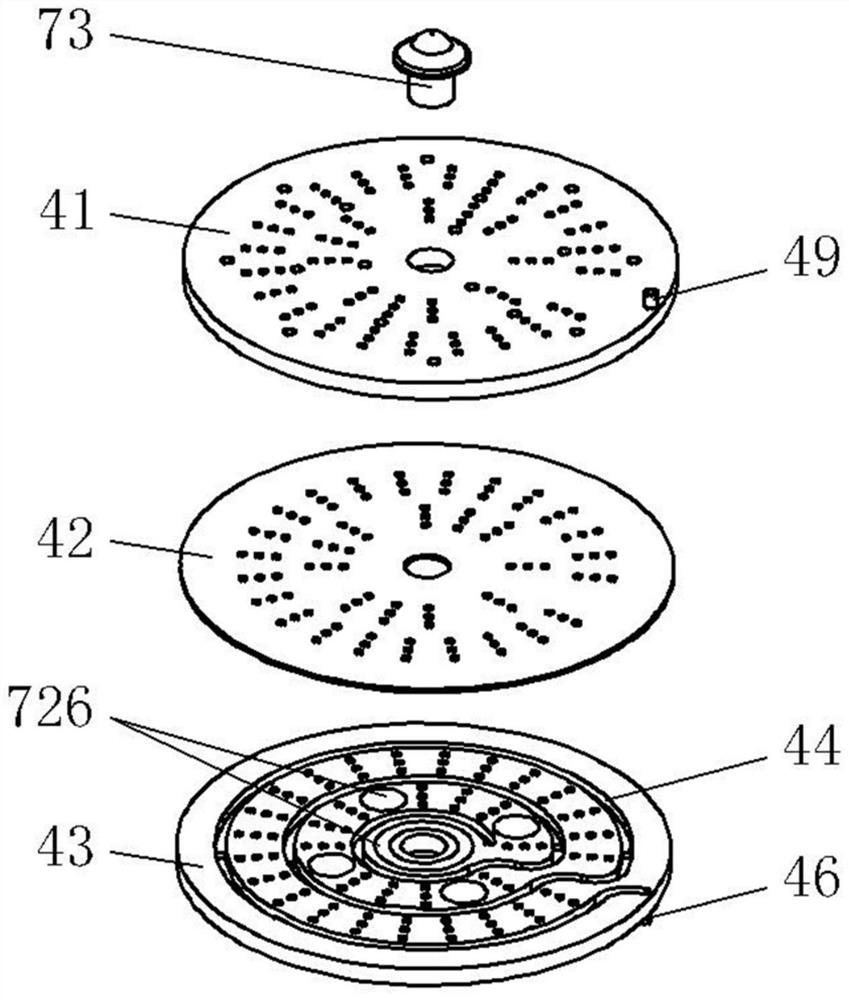

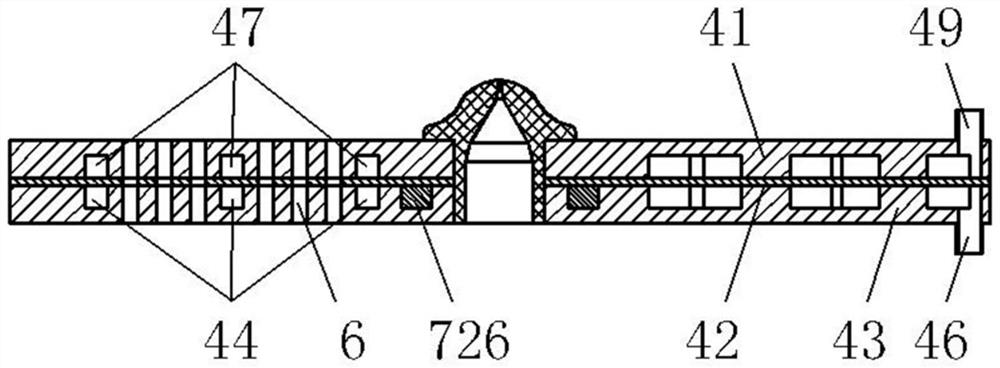

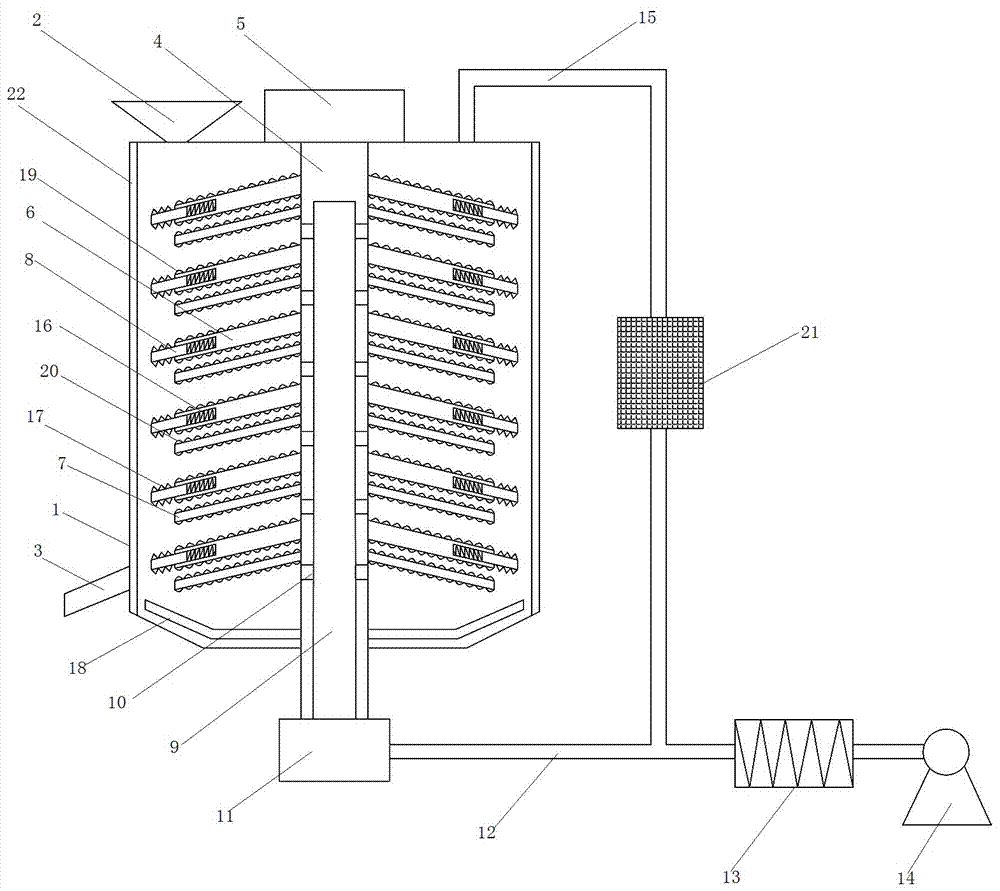

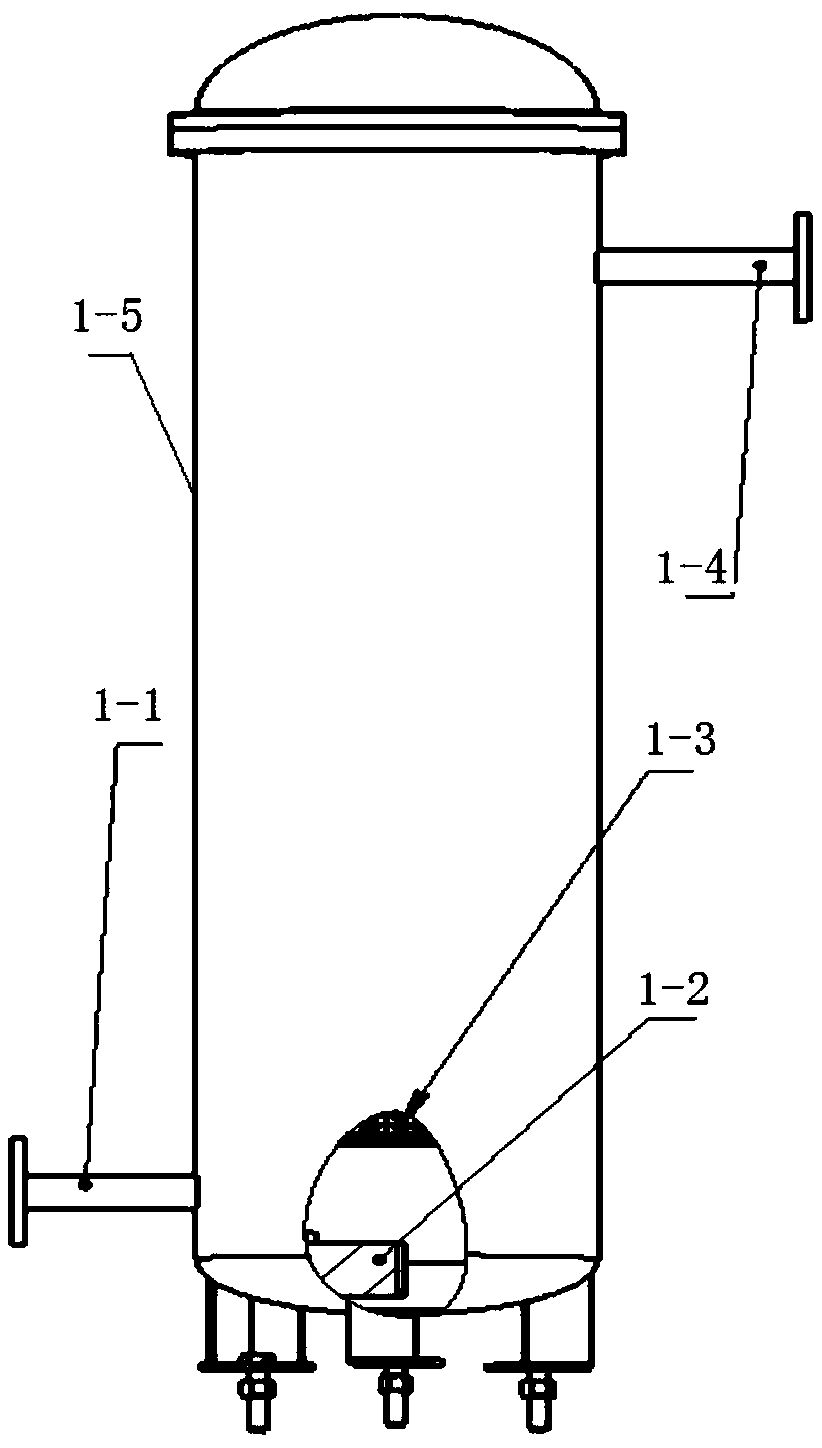

Multi-medium filter for filtering tap water

ActiveCN112915600AImprove friction efficiencyEasy to cleanLoose filtering material filtersGravity filtersTap waterStructural engineering

The invention discloses a multi-medium filter for filtering tap water, and belongs to the technical field of tap water filtering equipment. The multi-medium filter comprises a shell and a cover plate, an upper partition plate assembly, a plurality of middle partition plate assemblies and a lower partition plate assembly are arranged in the shell, a water inlet channel is formed between the upper partition plate assembly and the cover plate, and a water outlet channel is formed between the lower partition plate assembly and the bottom of the shell; a space capable of accommodating a filter material is formed between the upper partition plate assembly and the lower partition plate assembly, and the space is divided into a plurality of small spaces by the plurality of middle partition plate assemblies; the bottom of the upper partition plate assembly, the top and the bottom of the middle partition plate assemblies and the top of the lower partition plate assembly are all provided with cleaning mechanisms capable of performing independent water vapor scrubbing on the filter materials in the corresponding small spaces; a stirring mechanism is arranged in the shell and can be used for independently stirring the filter materials in different small spaces. The invention aims to provide the multi-medium filter for filtering tap water. The function of stirring and cleaning the filter material in the filter is realized.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Heat mixer for plastic particles

The invention discloses a heat mixer for plastic particles. The heat mixer comprises a machine barrel, a charge hole, a discharge hole, a rotary shaft, a rotary motor, a plurality of mixing plates and a plurality of friction plates, wherein the charge hole is formed in the top of the machine barrel; the discharge hole is formed in the lower part of the barrel wall of the machine barrel; the rotary shaft is arranged in the machine barrel in a penetrating mode; the rotary motor is connected with the upper end of the rotary shaft; the mixing plates are arranged in the machine barrel and are uniformly distributed in the peripheral direction of the rotary shaft; one end, away from the rotary shaft, of each mixing plate is equipped with a groove, and a mixing head is arranged in the groove; and the friction plates are arranged in the machine barrel and are uniformly distributed in the peripheral direction of the rotary shaft. The heat mixer improves mixing efficiency and improves friction efficiency, further improves working efficiency and reduces energy consumption.

Owner:江苏冠春新材料科技有限公司

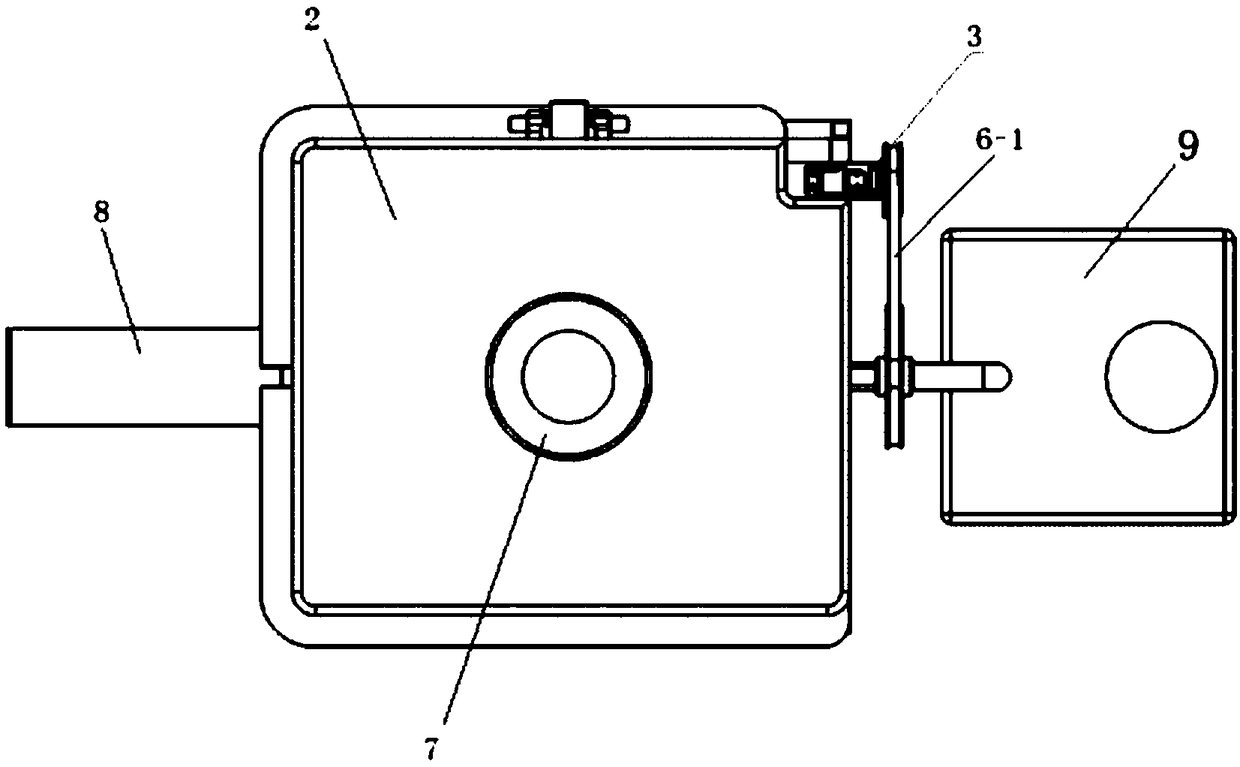

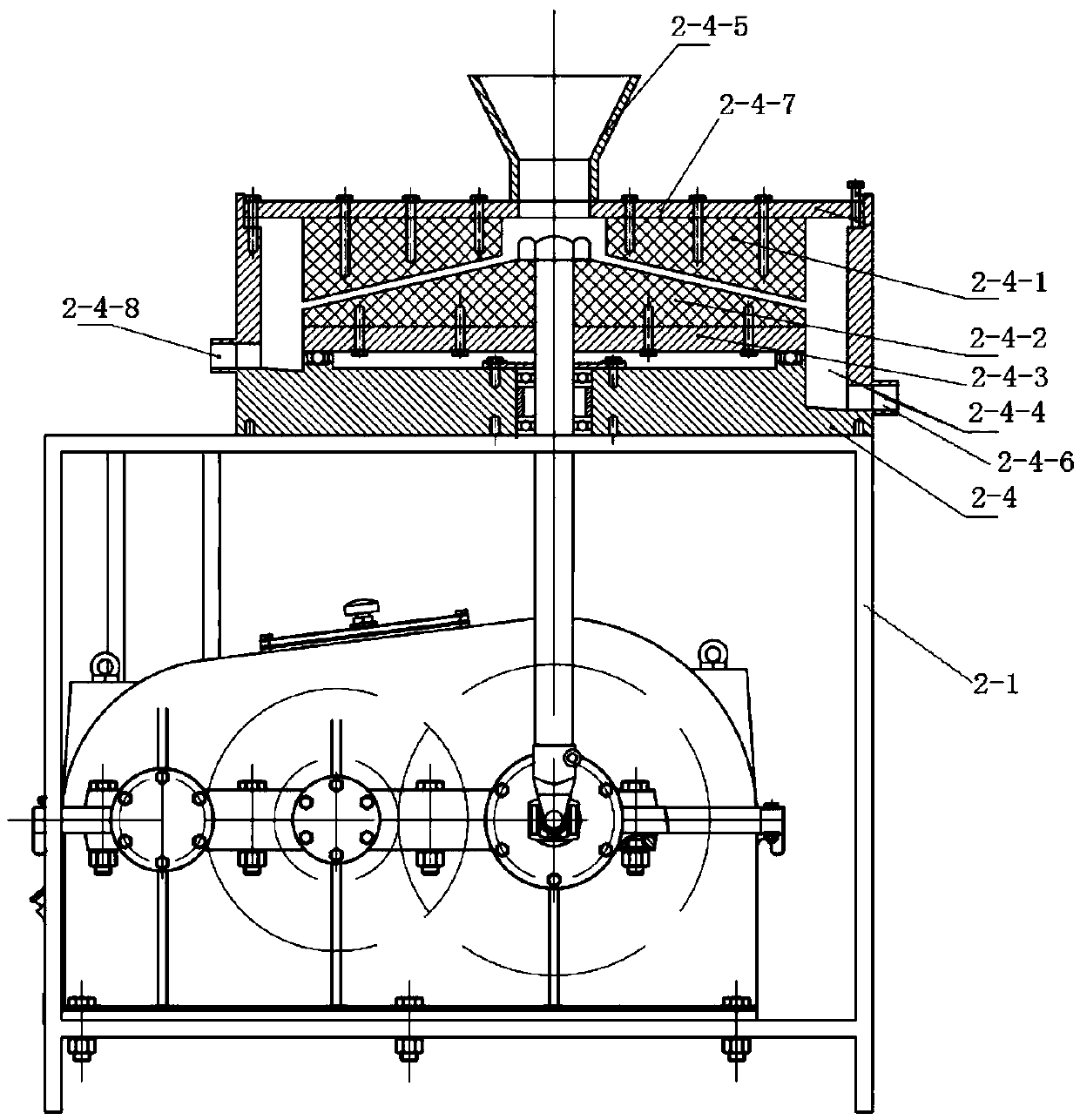

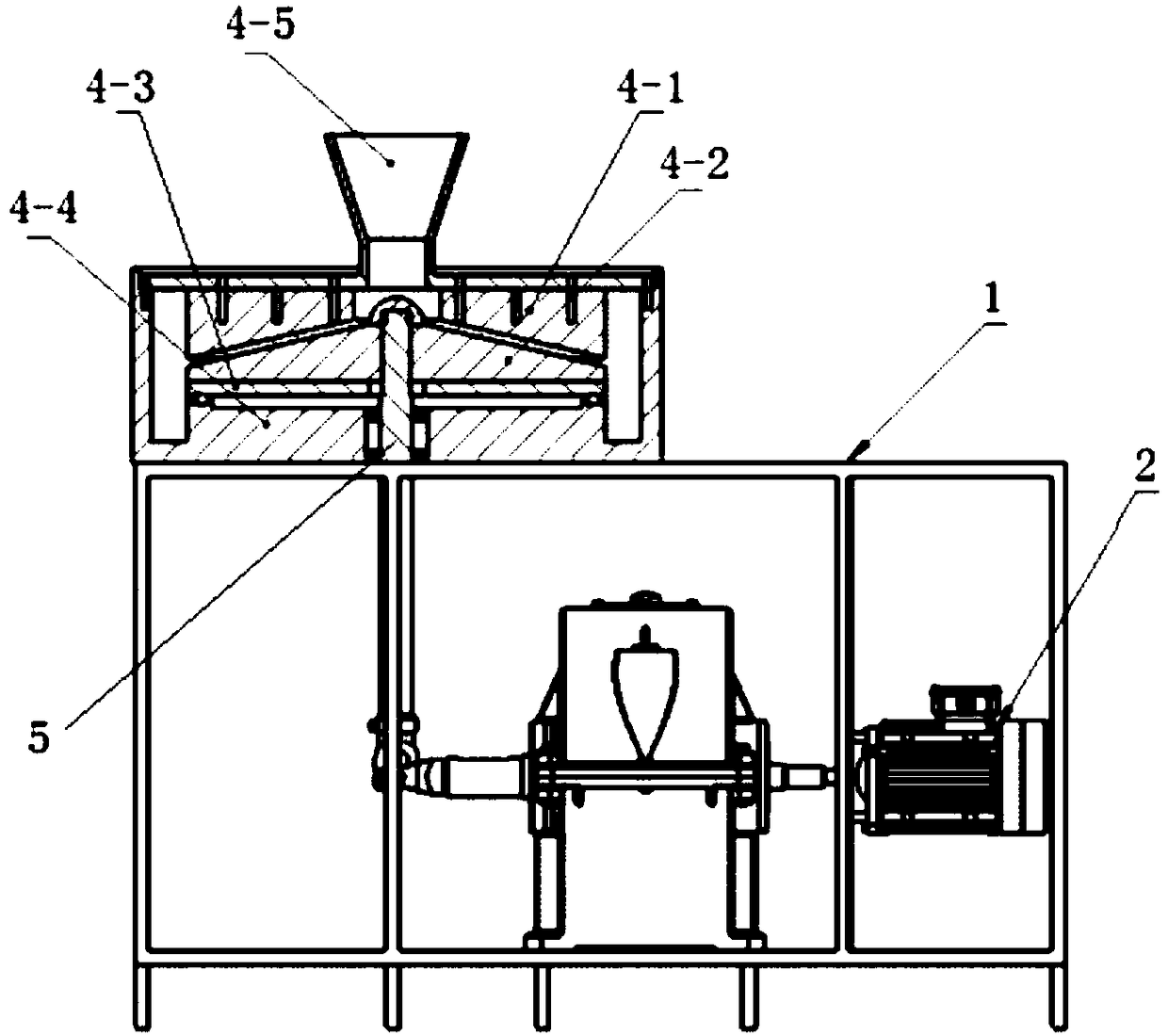

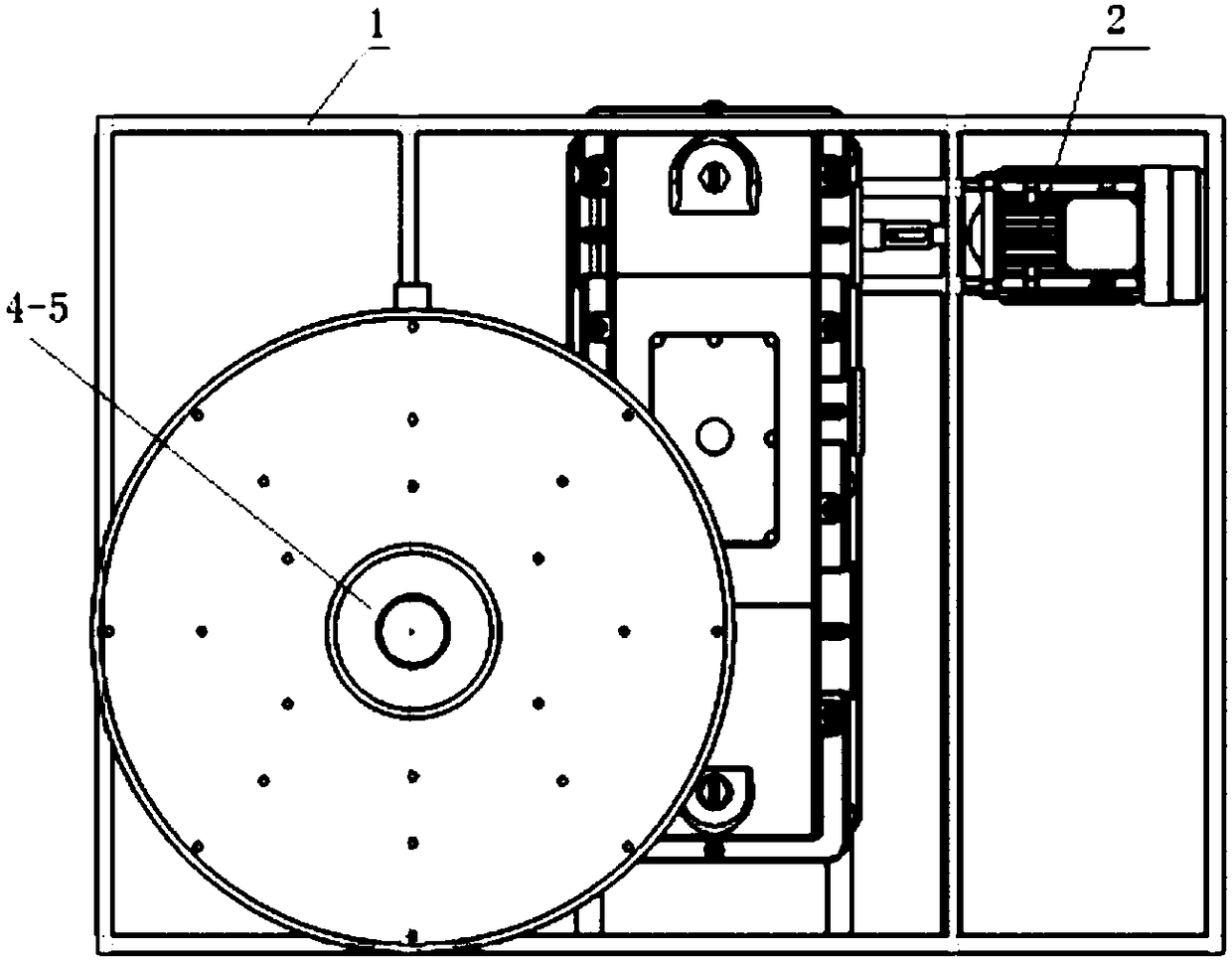

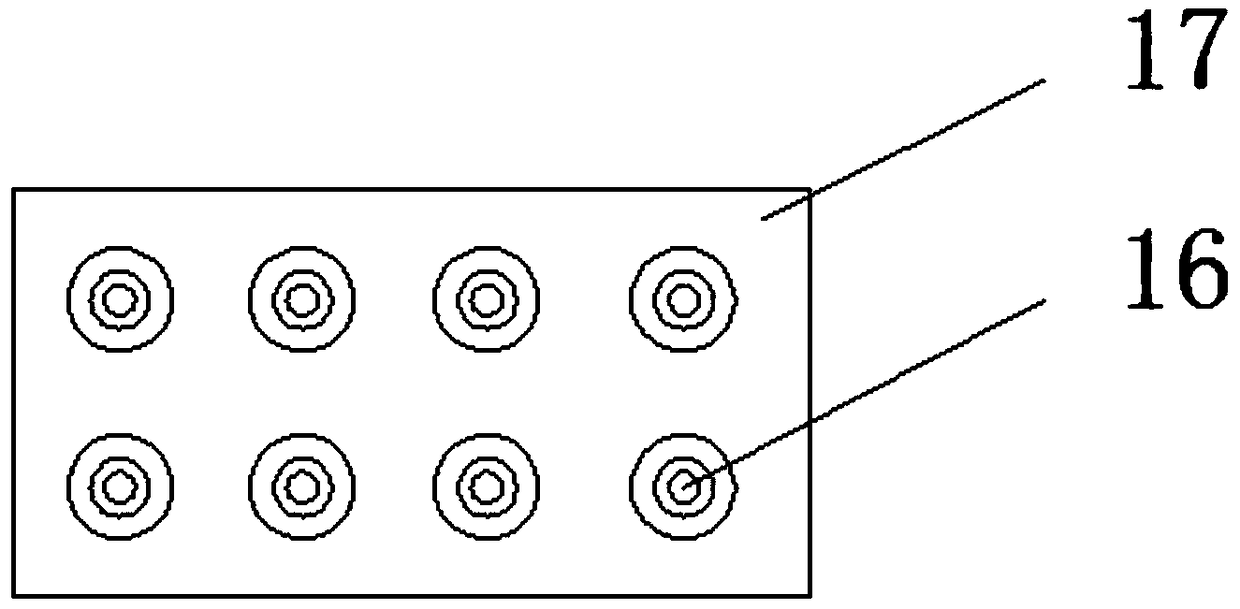

Grinding disc type hard seed dormancy breaking production system

InactiveCN109089464ATo achieve the effect of breaking the shellIncrease chance of germinationSeed and root treatmentEngineeringDormancy

The invention discloses a grinding disc type hard seed dormancy breaking production system. The grinding disc type hard seed dormancy breaking production system comprises a dormancy breaking agent box(1), a grinding disc type hard seed mechanical-breaking machine (2), a seed filtering device (3), a grinding disc type drying device (4), a conveying device (5) and a constant temperature incubator (6) which are connected in sequence. The grinding disc type hard seed dormancy breaking production system is reasonable in structure design, convenient to operate, high in automation degree and good incomplete set nature. By adopting the chemical dormancy breaking and mechanical dormancy breaking joint mode and integrating the filtering device, the drying device and the constant temperature incubator, the efficiency of breaking shells of hard seeds such as alfalfa seeds is high, cultured seeds can be directly planted after being taken out, the seeds are easier to sprout, the germination rate of the hard seeds is greatly improved, and the grinding disc type hard seed dormancy breaking production system has an important application value.

Owner:GANSU AGRI UNIV

Grinding disc type hard solid seed mechanical shell breaking machine

InactiveCN108966733AAvoid damageSolve operational difficultiesGerminating apparatusCouplingDrive shaft

The invention discloses a grinding disc type hard solid seed mechanical shell breaking machine, comprising a frame (1), a motor (2) and a grinding mechanism (4) mounted on the frame (1), and a speed reducer (3) connected with the motor (2), wherein the speed reducer (3) is connected with one end of a transmission shaft (5) through a universal coupling, and the other end of the transmission shaft (5) fixes a lower grinding surface (4-2) in the grinding mechanism (4) on a grinding surface support plate (4-3) by a nut; the bottom of the grinding surface support plate (4-3) and the bottom of a shell of the grinding mechanism (4) are respectively provided with a groove, and the grooves are internally provided with balls, and the grinding surface support plate and the grinding mechanism can rotate relative to each other. The grinding disc type hard solid seed mechanical shell breaking machine has the advantages of reasonable structure design, convenience in operation, high work efficiency and high practicability, can prevent damage to germs during alfalfa seed planting shell breaking, and can solve the problem of difficult operation when treating alfalfa seeds in mass.

Owner:GANSU AGRI UNIV

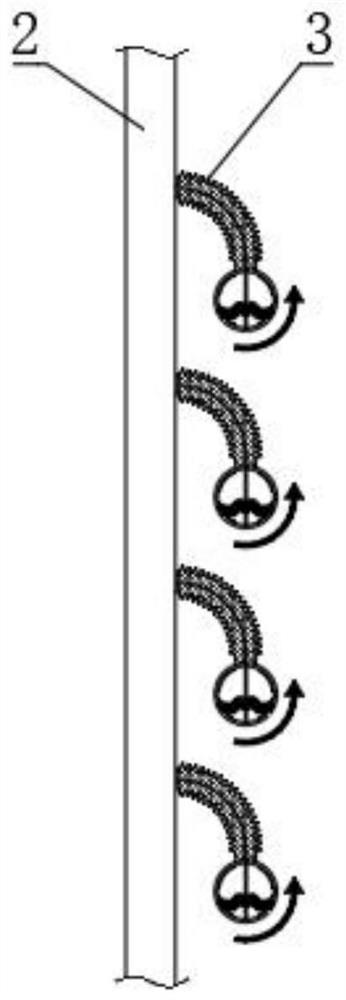

Machine for machining automobile swing arm and using method of machine

ActiveCN112223017AAchieve grinding and polishing efficiencyImprove friction efficiencyGrinding carriagesGrinding drivesDrive shaftGear wheel

The invention discloses a machine for machining an automobile swing arm and a using method of the machine. The machine comprises a bottom plate, a first gear is fixedly connected with a grinding pipe,a rack plate is further fixedly connected to the surface of a driven shaft, the rack plate is meshed with the first gear, and abrasive cloth is fixedly connected to the surface of the grinding pipe.The machine has the advantages that firstly, the abrasive cloth revolves with a driving shaft as the circle center, through elastic restoring force of a first spring in the direction away from the driving shaft, the abrasive cloth revolving with the driving shaft as the circle center can be always attached to a triangular through groove wall and a rectangular through groove wall on the automobileswing arm, and therefore, the abrasive cloth can adapt to grinding and polishing of groove walls in various sizes and various shapes; and secondly, the abrasive cloth revolves while rotating and reciprocates, so that rolling friction force and rotating friction force are generated between the abrasive cloth and the through groove wall on the automobile swing arm, the friction efficiency between the abrasive cloth and the triangular through groove wall and the rectangular through groove wall on the automobile swing arm is further improved, and the grinding and polishing efficiency is further improved.

Owner:江苏塑光汽车部件有限公司

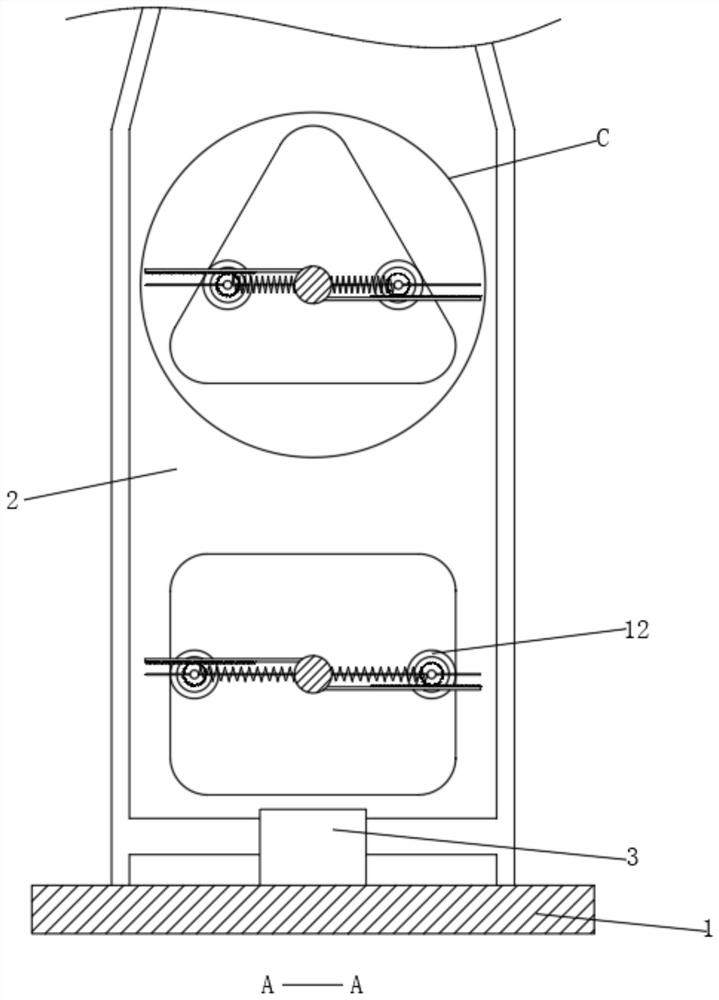

Bag-type dust collector capable of continuously operating

InactiveCN112246030AReduce the possibility of static electricityPromote escapeDispersed particle filtrationThermodynamicsMechanical engineering

The invention discloses a bag-type dust collector capable of continuously operating, which belongs to the technical field of dust collection, and adopts the scheme that dust-containing gas is introduced into a dust collection rack through a gas inlet guide pipe on the outer side of the dust collection rack, wherein the carbon dioxide gas in a carbon dioxide aqueous solution can escape by virtue ofgas flow and collision of dust to a dust pendulum, so that the dust pendulum is in a level status overall; therefore, on one hand, the possibility that dust is attached to the inner wall of the built-in dust removal cloth bag can be reduced by means of deformation swing of the dust pendulum, and on the other hand, heat generated when the dust collides with one another is absorbed by means of a carbon dioxide aqueous solution; thus, the possibility of explosion caused by over-high temperature in the dust is reduced, and the thermal change traction wire can be promoted to deform to a high-temperature phase state by means of heat; by means of repeated change of the corrugated storage bag, the air purification efficiency can be improved, and the possibility that the dust is attached to the inner wall of the built-in dust removal cloth bag can also be reduced.

Owner:夏汝心

A kind of edging equipment for forklift parts finishing

ActiveCN111993196BIncrease friction speedImprove friction efficiencyEdge grinding machinesGrinding carriagesStructural engineeringGrinding wheel

The invention discloses an edging device for forklift parts finishing, which comprises a base, a guide frame is fixedly connected to the top surface of the base, and a motor 1 is installed on the top surface of the base, and the output end of the motor 1 is fixedly connected to There is a screw rod, and the other end of the screw rod is engaged with a moving block, and the moving block is slidably connected with the side wall of the guide frame, and the side wall of the moving block is fixedly connected with a slider one, and the slider one It is slidingly socketed with the guide frame, and the other side of the slider one is rotationally connected with a moving plate, the other end of the moving plate is fixedly connected with a slide bar, and the other end of the slide bar is slidingly socketed with the guide frame; the present invention The grinding wheel can be adjusted at multiple angles, making the edging angle of the grinding wheel changeable, so as to adapt to the edging of various forklift accessories, improve the scope of application of the equipment, improve the edging efficiency, and improve the friction efficiency, shorten the friction time, reduce Reduce the cost consumption, avoid the waste of resources, and at the same time can completely grind the edge, improve the product quality.

Owner:HEFEI DONGLU MACHINERY MFG

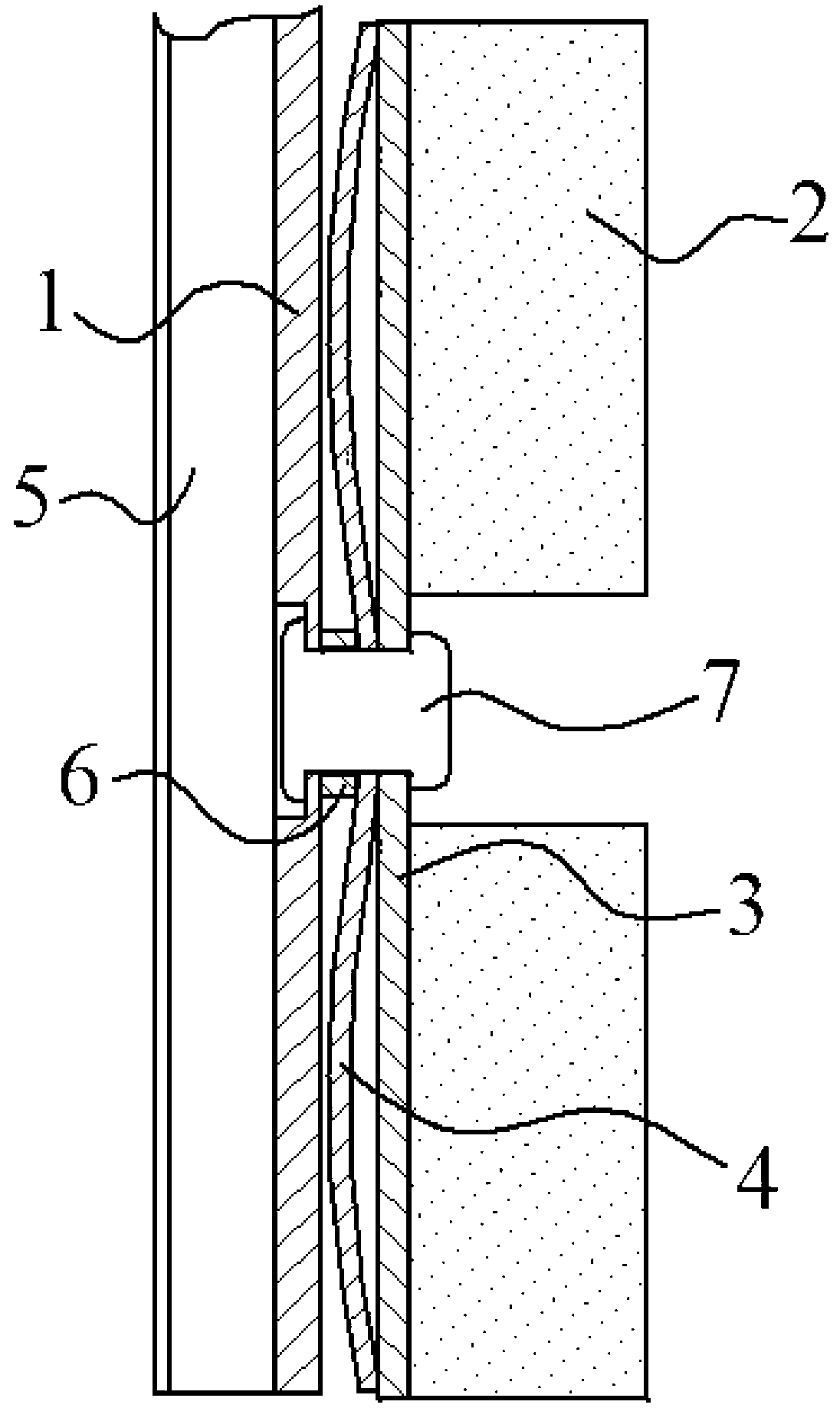

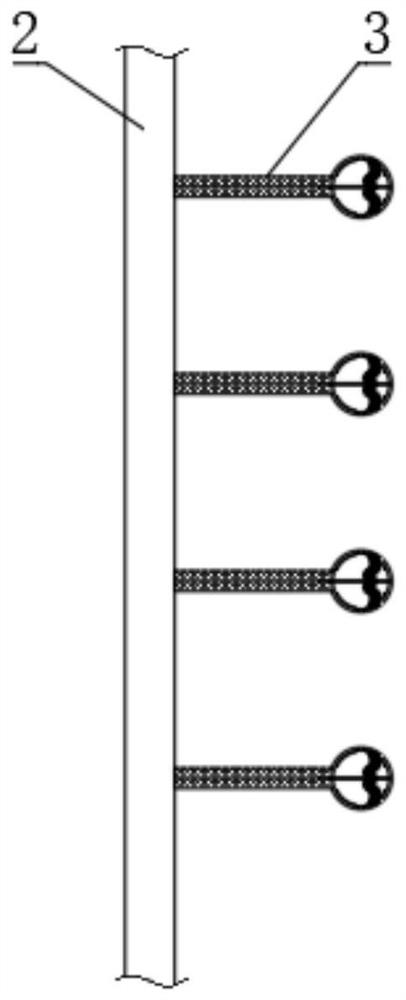

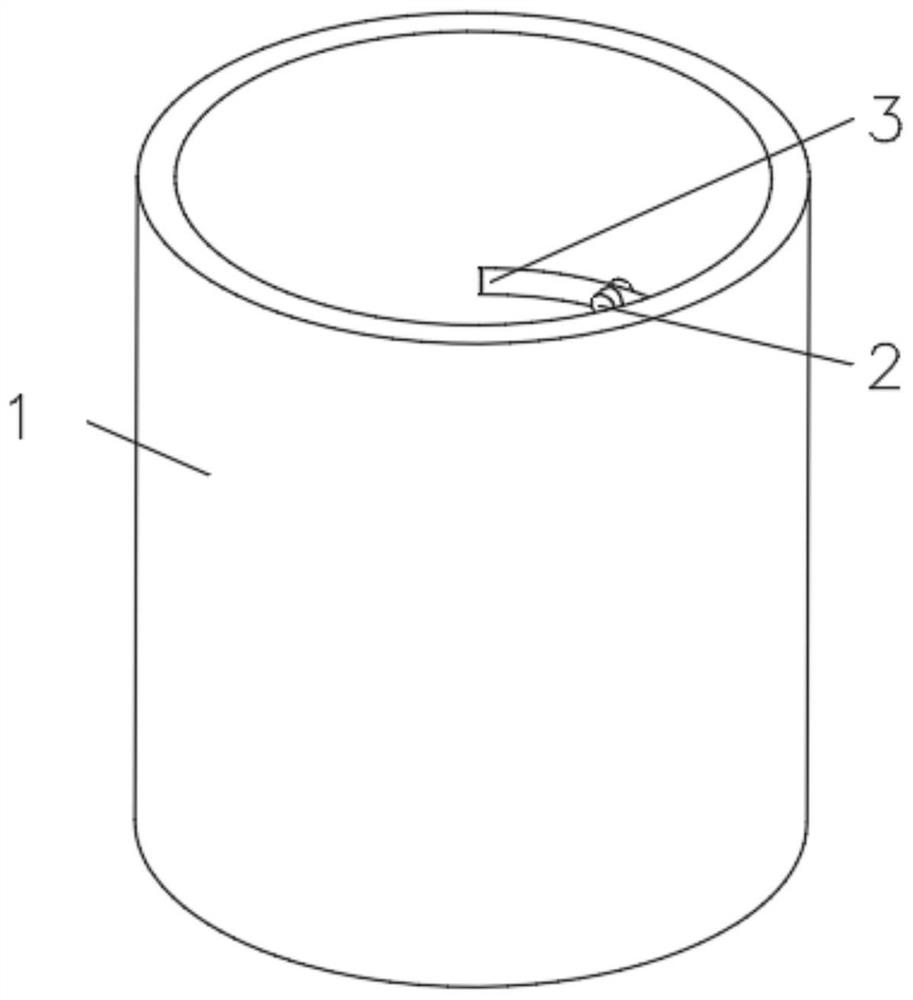

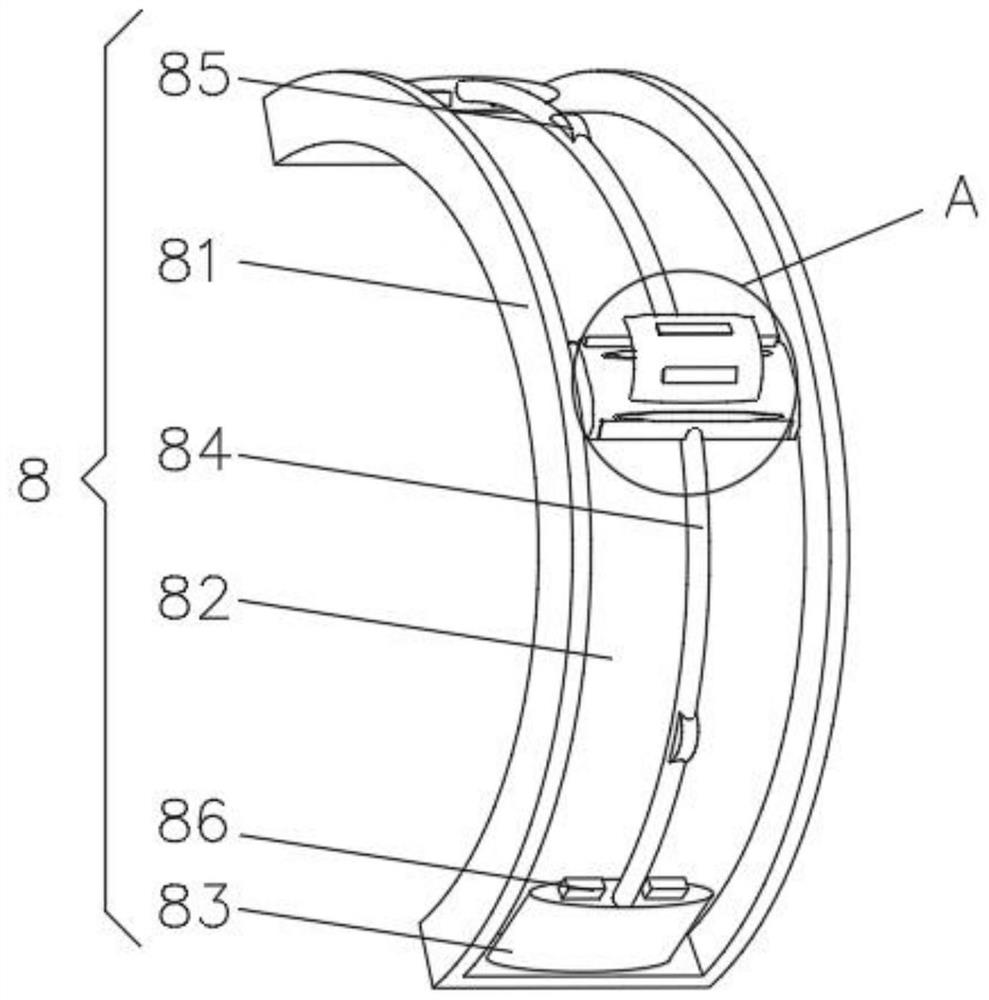

A barrel type friction damper and its loading method

ActiveCN106245971BSimple structureEasy to get materialsProtective buildings/sheltersShock proofingEngineeringShock absorber

The invention provides a cylindrical friction damper and a loading method thereof. The cylindrical friction damper comprises a constraint inner cylinder, a hoop outer cylinder and a tensioning device, wherein the constraint inner cylinder is connected with a first main body structure; the hoop outer cylinder is connected with a second main body structure, and comprises a first hoop body and a second hoop body outside the constraint inner cylinder; and the tensioning device comprises a first clamping piece arranged outside the first hoop body, a second clamping piece arranged outside the second hoop body, and a fastening piece fixed between the first clamping piece and the second clamping piece. A friction damping layer is hooped by the hoop outer cylinder, and force is uniformly applied to the hoop outer cylinder via the first clamping piece and the second clamping piece, so that the force of the fastening piece is relatively uniformly transferred to the end of the hoop outer cylinder and the friction damping layer; the cylindrical friction damper is simple in structure, convenient in material acquisition, high in frictional efficiency and strong in stability and durability.

Owner:SHANGHAI KUNYI SEISMIC DAMPING ENG TECH CO LTD

an oil pipeline

ActiveCN112944091BLow viscosityIncrease frictionPipe heating/coolingPipe elementsEngineeringOil transportation

The invention discloses an oil pipeline, comprising a pipeline, an inner wall of the pipeline is fixedly connected with a fixing column, one end of the fixing column away from the pipeline is connected with an arc-shaped plate, and the side of the arc-shaped plate away from the fixing column is evenly installed There is an elastic telescopic rod, an arc-shaped groove is symmetrically opened inside the pipe near the fixed column, the end of the fixed column away from the arc-shaped plate extends through the pipeline to the inside of the arc-shaped groove, and the fixed column is close to the arc-shaped groove. An arc-shaped rubber block is fixedly connected at one end, a limiting column is symmetrically installed on the inner wall of the pipe near the fixed column, a friction device is symmetrically installed on one side of the elastic telescopic rod, and a contact device is installed inside the friction device, A shaking device is installed at one end of the limiting column away from the pipeline, and the invention relates to the technical field of oil transportation. The oil pipeline utilizes frictional heat to achieve the purpose of heating the fixed area, so as to reduce the viscosity of the oil and make it fluid.

Owner:山东美生热能科技有限公司

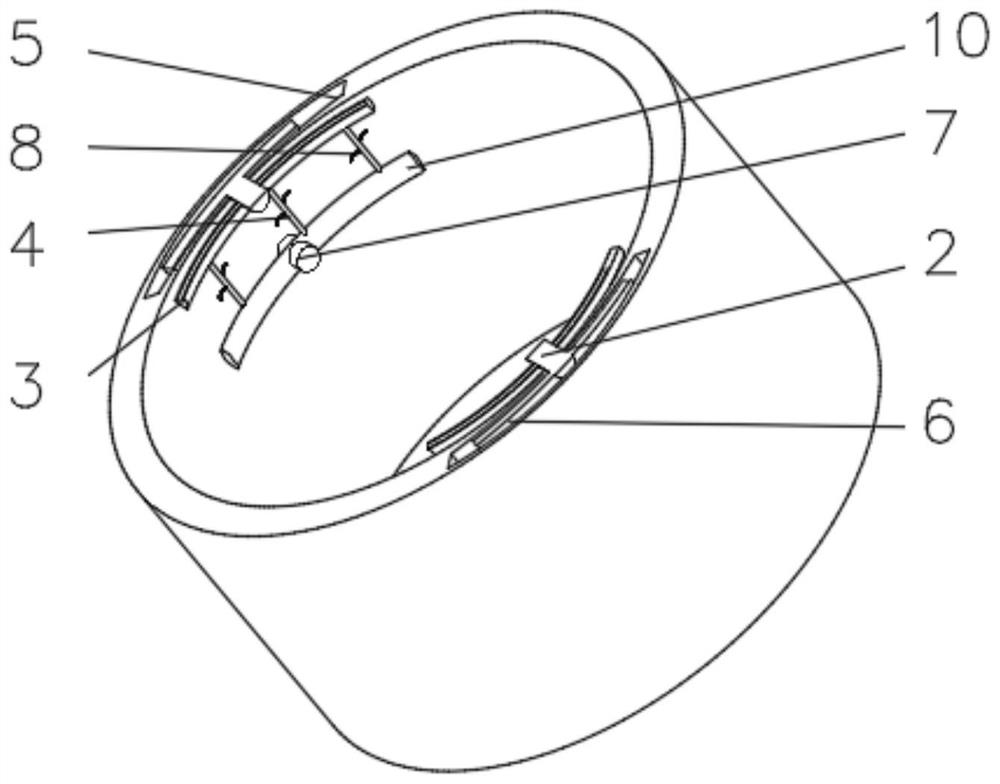

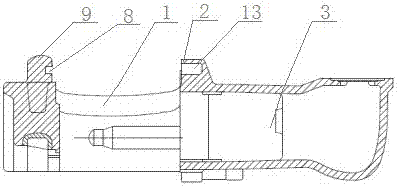

Integrated radial air chamber disk brake calipers

The invention provides integrated radial air chamber disk brake calipers. The integrated radial air chamber disk brake calipers comprise a calipers body which is integrally formed. The calipers body comprises a first cavity for containing a brake disk and a second cavity for containing a rotating shaft mechanism, the first cavity communicates with the second cavity, and benchmark base guiding faces are symmetrically arranged on the upper surface and the lower surface in the second cavity. The integrated radial air chamber disk brake calipers are of an integrated structure, bolt connection between the arc back part and a containing cavity of an existing split calipers body is removed, assembling and machining between the arc back part and the containing cavity are avoided, and the rigidity and strength of the whole calipers body are improved; and meanwhile, the four benchmark base guide faces are machined in the second cavity containing the rotating shaft mechanism in a disk cutter machining manner, machining is easy and stable, the function of limiting a benchmark base in the rotating shaft mechanism is achieved, deflection of the benchmark base is limited, brake force is stable and consistent, the service life of the rotating shaft mechanism is prolonged, and the friction efficiency is improved.

Owner:WUHAN YOUFIN AUTOPARTS

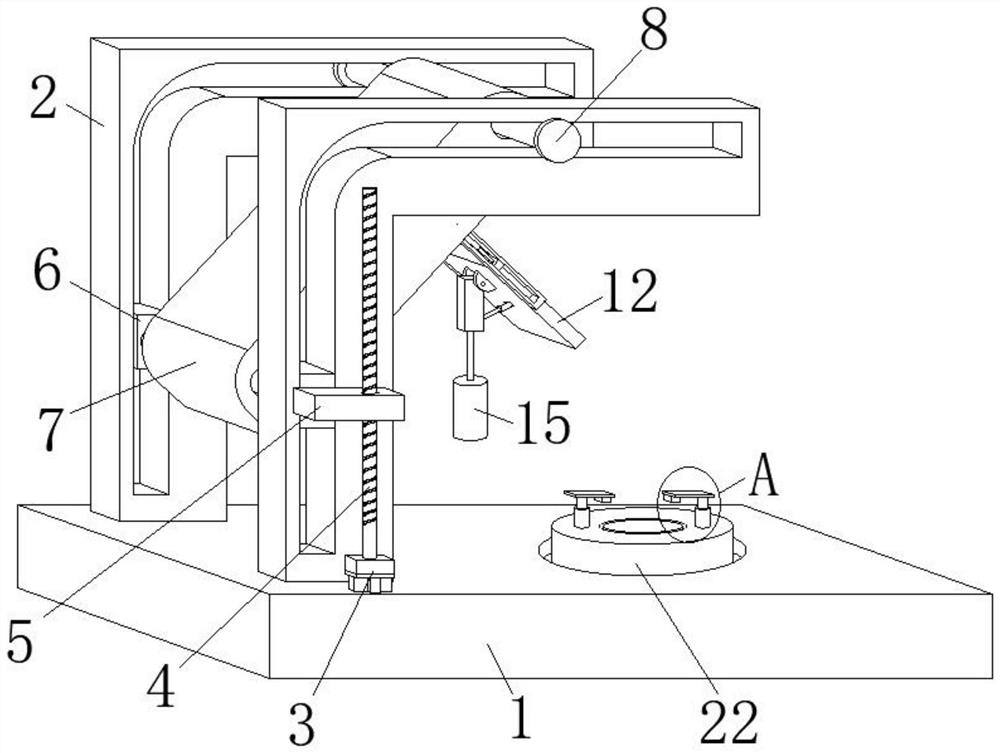

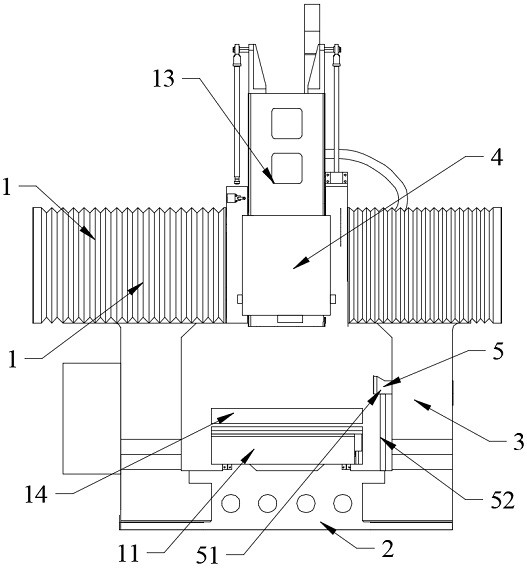

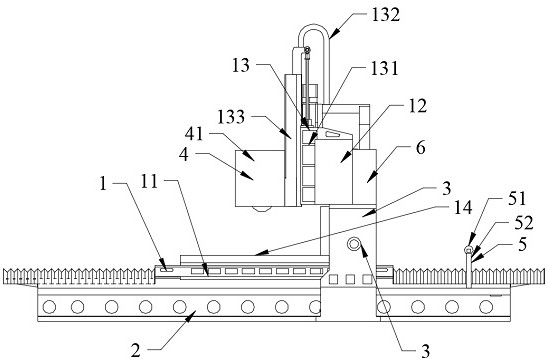

High-precision grinding machine device with workpiece surface precision detection function

ActiveCN114523403AAvoid wasteful situationsImprove balanceGrinding carriagesGrinding feed controlEngineeringDisplacement control

The invention discloses a high-precision grinding machine device with a workpiece surface precision detection function, and relates to the technical field of workpiece surface grinding, the high-precision grinding machine device comprises a displacement control assembly, a base, a gantry support, a grinding assembly, a detection assembly and a connecting plate, the bottom of the gantry support is fixedly connected with the base, and the connecting plate is fixedly connected with the bottom of the gantry support; one end of the displacement control assembly is fixedly connected with the base, the other end of the displacement control assembly is fixedly connected with the connecting plate, the grinding assembly is fixedly connected with the displacement control assembly, and the detection assembly is arranged on one side of the displacement control assembly and fixedly connected with the base. The adjusting component can accurately control the local use amount of the coolant, the situation of coolant waste is avoided, on the other hand, axial friction is carried out when the local temperature difference reaches the limit, and the balance of the local area of the annular grinding sleeve is greatly improved.

Owner:恒迈新材料科技南通有限公司

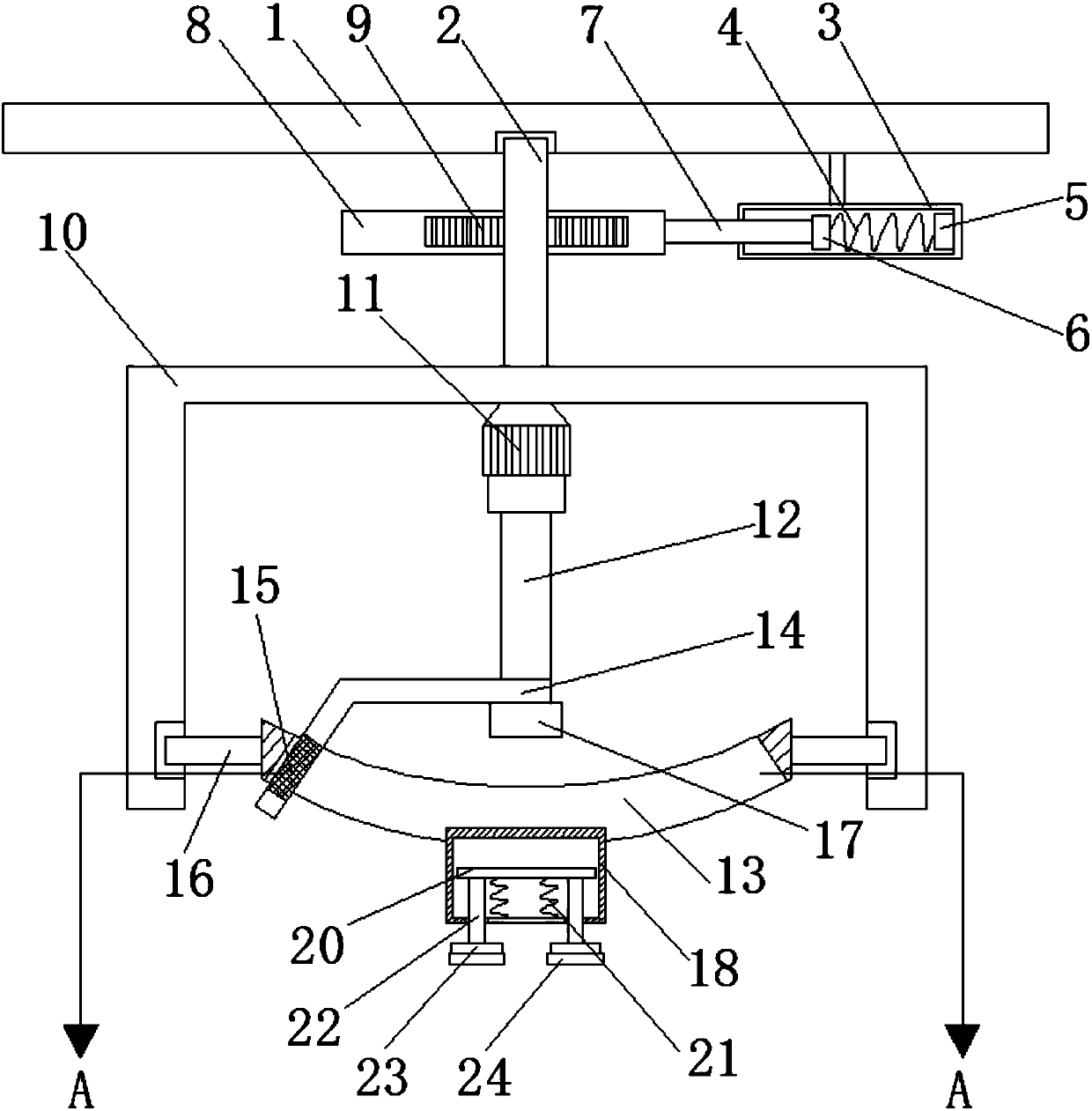

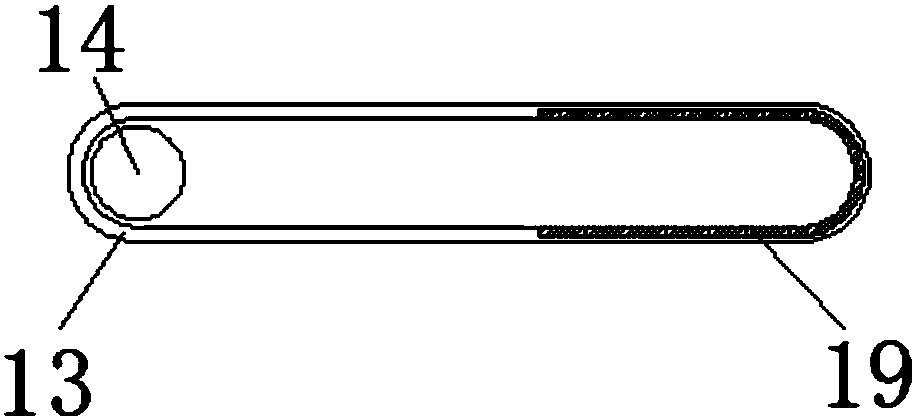

An indoor cleaning device

ActiveCN106073645BControl rotational frictionImprove cleaning efficiencyCarpet cleanersFloor cleanersAgricultural engineeringWater pipe

The invention discloses an indoor cleaning device. The indoor cleaning device comprises a handheld handle and a fed-liquid filtering device. A connecting rod is installed below the handheld handle, a clean-water storage trough is installed on the connecting rod, a water adding opening is formed in the clean-water storage trough, a fixing sleeve is installed below the connecting rod, a stretchable rod is installed below the fixing sleeve, the clean-water storage trough is connected with a cleaning-liquid buffering trough through a water pipe, a cleaning-liquid mixing preparing device is installed on the water pipe, a cleaning device body is installed below a motor, a friction face plate is installed at the bottom of the cleaning device body, and clean-water spraying openings are formed in the friction face plate. According to the indoor cleaning device, cleaning liquid is prepared and enters water absorption cloth of the friction face plate through the cleaning-liquid buffering trough, the clean-water spraying openings are connected with the clean-water storage trough, cleaning is carried out through clean water and the cleaning liquid at the same time, and cleaning efficiency is greatly improved.

Owner:中高后勤服务(云南)有限公司

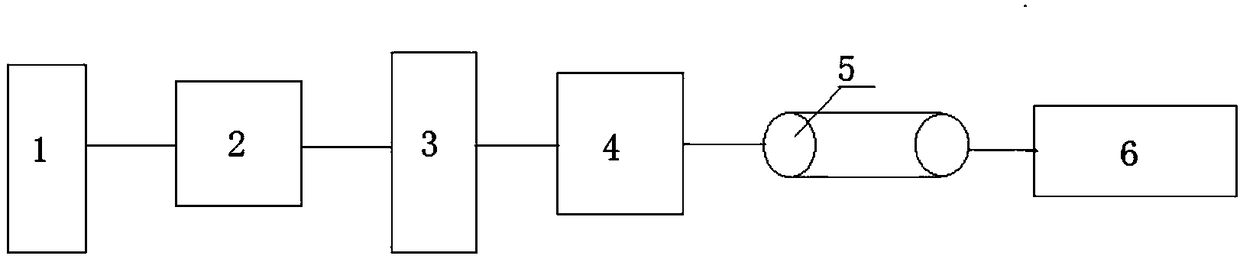

Reciprocating type hard seed dormancy breaking production system

InactiveCN109121557ATo achieve the effect of breaking the shellIncrease frictionGerminating apparatusSeed dormancyAutomation

The invention discloses a reciprocating type hard seed dormancy breaking production system which comprises a dormancy breaking agent tank (1), a reciprocating type hard seed mechanical case breaking machine (2), a seed filter device (3), a reciprocating type drying device (4), a conveying device (5) and a constant-temperature cultivation tank (6). The dormancy breaking agent tank (1), the reciprocating type hard seed mechanical case breaking machine (2), the seed filter device (3), the reciprocating type drying device (4), the conveying device (5) and the constant-temperature cultivation tank(6) are sequentially connected with one another. The reciprocating type hard seed dormancy breaking production system has the advantages that the reciprocating type hard seed dormancy breaking production system is reasonable in structural design, convenient to operate, high in automation degree and good in equipment complete-set property; hard seeds can be jointly treated by chemical dormancy breaking and the reciprocating type hard seed mechanical case breaking machine, the filter device, the drying device and the constant-temperature cultivation tank are integrated with one another, accordingly, the reciprocating type hard seed dormancy breaking production system is high in hard seed case breaking efficiency, cultivated seeds can be directly planted after being taken out and are easy togerminate, the germination rate of the hard seeds can be greatly increased, and the reciprocating type hard seed dormancy breaking production system has an important application value.

Owner:GANSU AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com