Boiler using rotary force

A rotating force and boiler technology, applied in the field of boilers, can solve the problems of increasing boiler volume, short friction distance, and increased power consumption, and achieve the effects of increasing hot water capacity, increasing friction distance, and increasing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the invention is shown in the drawings. The drawings are only preferred state diagrams for easy understanding of the present invention, and part of the structure is either enlarged or omitted, so it is different from the actual structure. And, there are many more embodiments than the structures shown in the drawings.

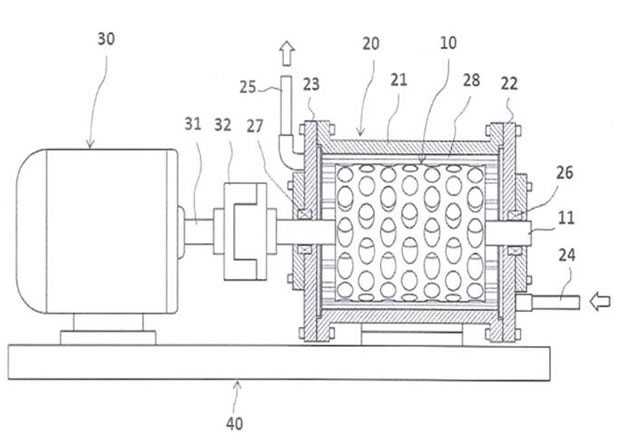

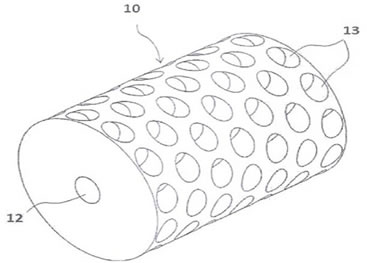

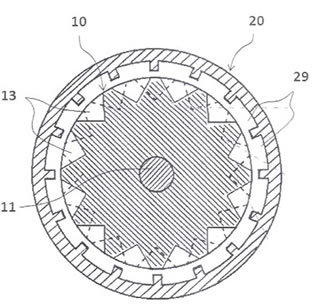

[0028] Such as figure 1 As shown, the boiler utilizing rotational force of the present invention is composed of a rotating body 10 and a housing 20 , and a rotating shaft 11 penetrating through the rotating body 10 is connected to an external drive source motor 30 .

[0029] The rotating shaft 11 of the rotating body 10 and the driving shaft 31 of the motor 30 can be connected in series through a coupling ring 32 , or can be connected in a transmission manner by a transmission belt or a gear not shown in the figure. Where there is no electricity, a gasoline engine or a diesel engine (not shown) may be used instead of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com