Heat mixer for plastic particles

A technology of plastic granules and thermal mixer, applied in the field of sheet metal processing, can solve the problems of high energy consumption, low work efficiency, poor mixing effect, etc., and achieve the effects of saving energy, simple structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

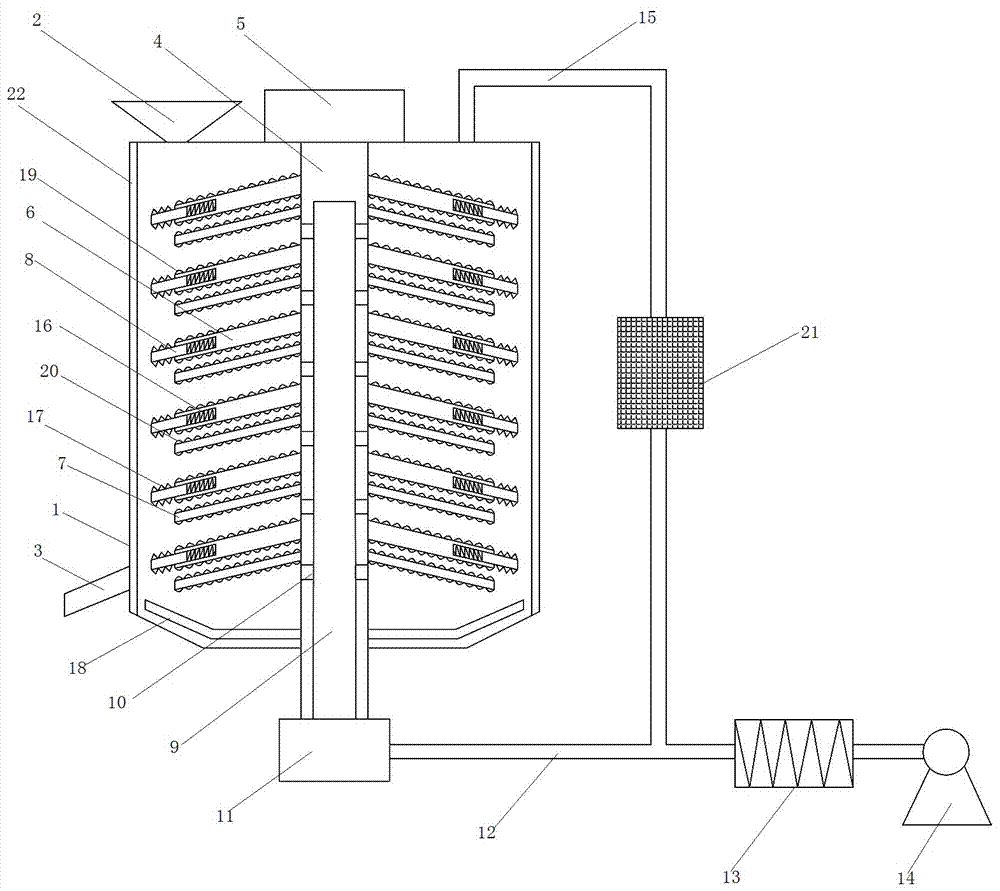

[0021] Such as figure 1 As shown, a plastic granule thermal mixer includes a barrel 1, a feed port 2, a discharge port 3, a rotating shaft 4, a rotating motor 5, a plurality of stirring plates 6, and a plurality of friction plates 7. The mouth 2 is arranged on the top of the barrel 1, and the discharge port 3 is arranged at the lower part of the barrel wall of the barrel 1; the rotating shaft 4 is arranged through the barrel 1 and is located at the central axis of the barrel 1; The rotating motor 5 is arranged on the top of the machine barrel 1 and is connected with the upper end of the rotating shaft 4; the plurality of stirring plates 6 are arranged in the machine barrel 1 and are evenly distributed in the circumferential direction of the rotating shaft 4; the stirring The end of the plate 6 away from the rotating shaft 4 is provided with a groove (because the components have been installed, so it is not shown in the figure), and the stirring head 8 is arranged in the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com