Novel high-speed brake block

A brake pad and high-speed technology, which is applied in the field of high-speed train braking devices, can solve problems such as insufficient bonding of brake pads and brake disc surfaces, and achieve the effect of preventing excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

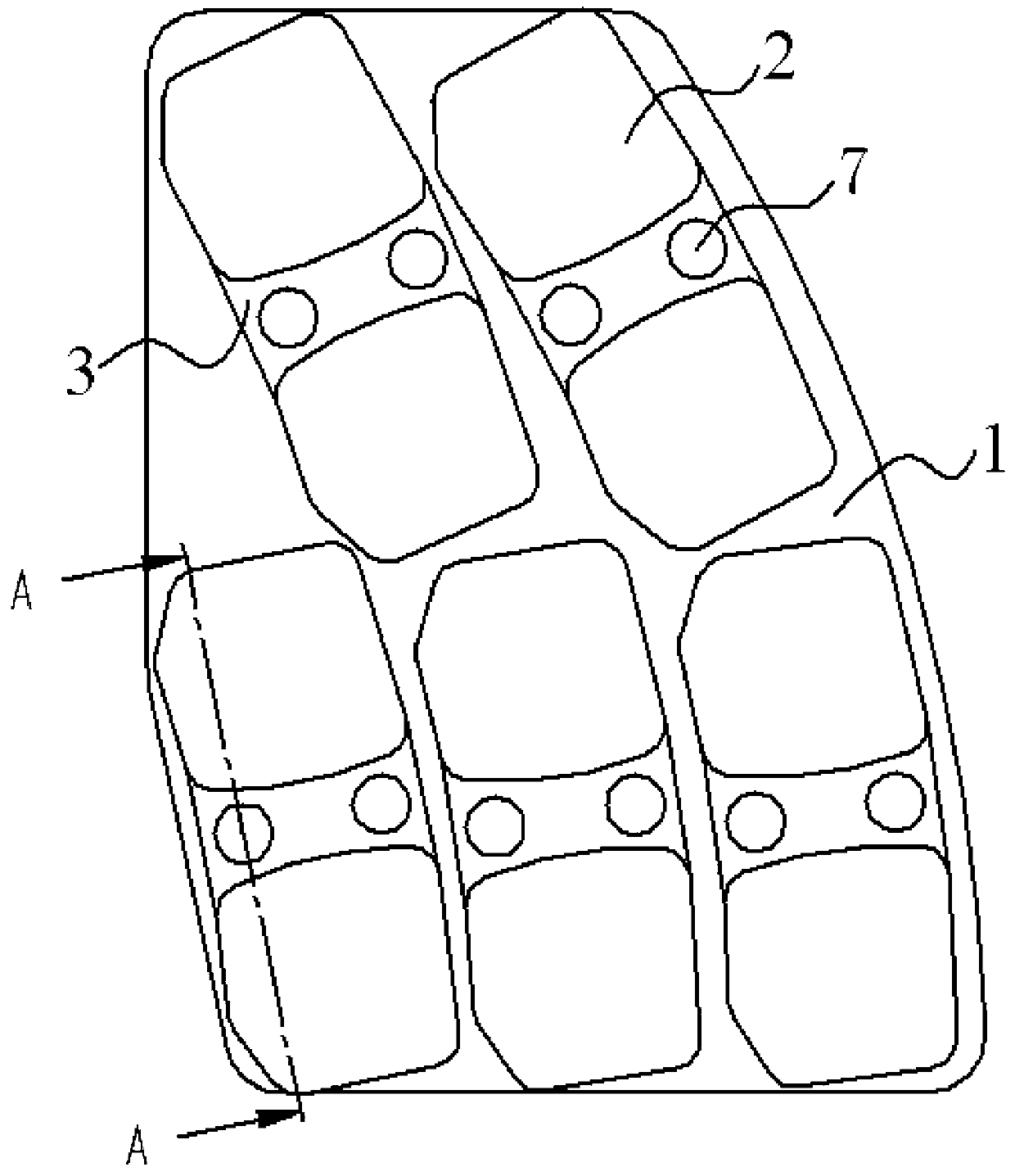

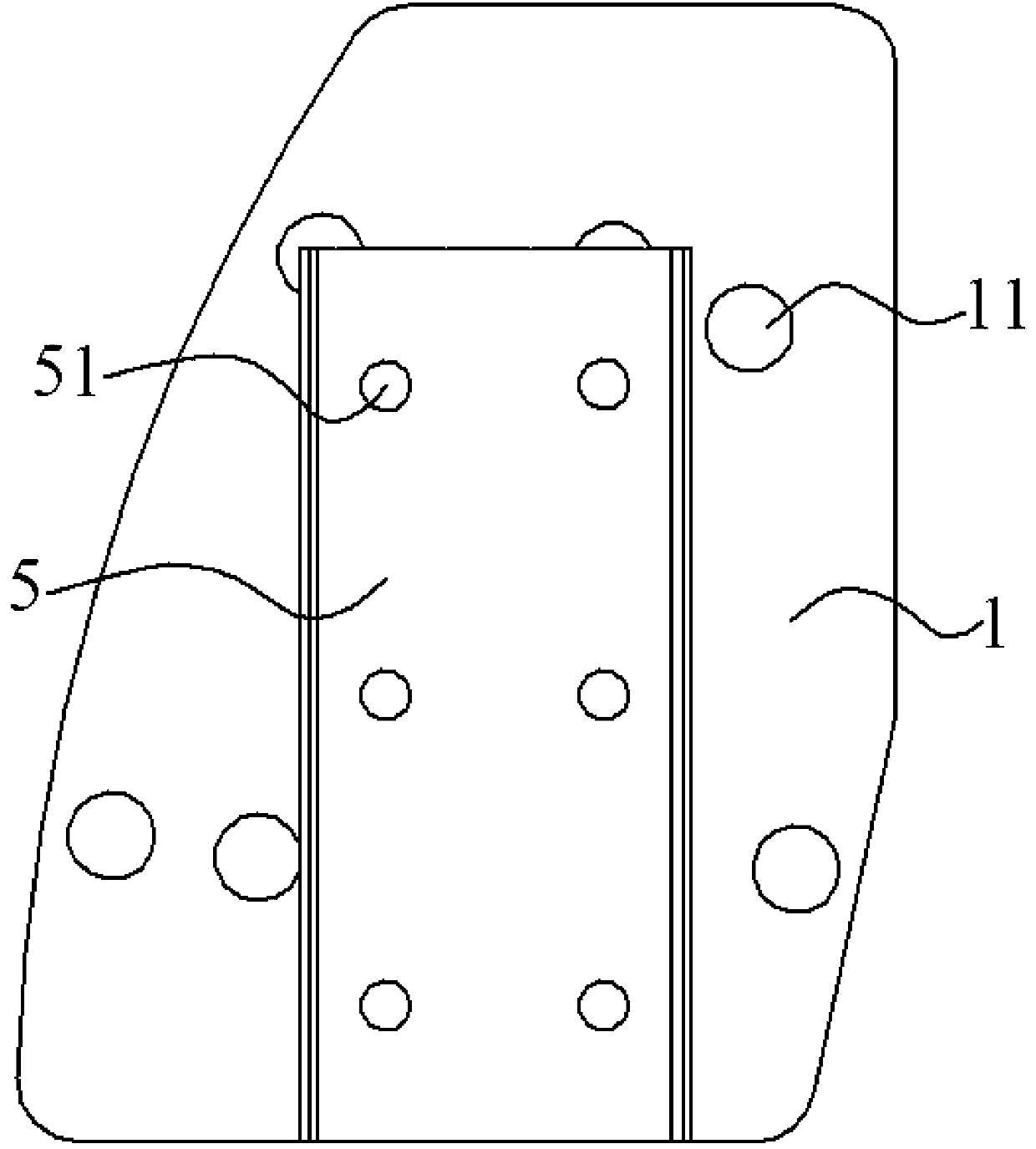

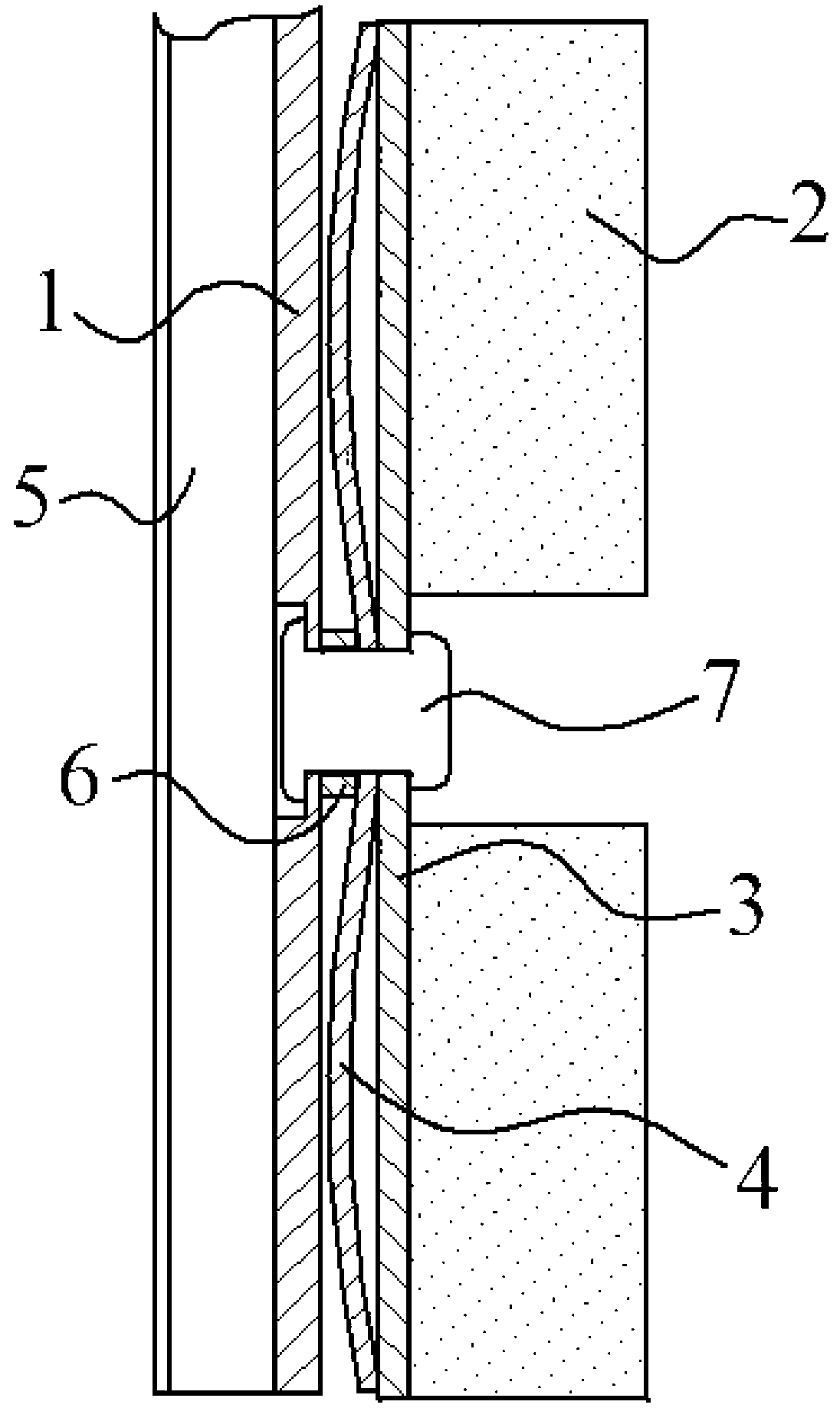

[0022] The invention will be further described below in conjunction with the accompanying drawings, as Figure 1~Figure 7 As shown, the new high-speed brake pad includes a brake block 2, a frame 3, a steel back 1 and a dovetail plate 4. Two brake blocks 2 are sintered on a frame 3, and the part between the two brake blocks 2 on the frame 3 Process the skeleton riveting hole 31, rivet the sintered brake block 2 and the skeleton 3 on the front of the steel back 1 through the rivet 7, set the dovetail plate welding hole 51 on the dovetail plate 5, and weld the dovetail plate 5 through the dovetail plate welding hole 51 On the back side of the steel back 1, in order to realize that the brake block 2 can be adjusted to be close to the brake disc of the high-speed train for braking, a wave shrapnel 4 is installed between the steel back 1 and the frame 3. The front of a steel back 1 is installed with five skeletons 3 including the above-mentioned structure, and ten adjustable brake b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com