Drum brake lining and drum brake

A technology of drum brakes and brake linings, which is applied in the direction of brake parts, friction linings, mechanical equipment, etc., can solve the problems of uneven pressing of drum brake linings and potential safety hazards, and improve the uneven pressing Uniform, conducive to discharge, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

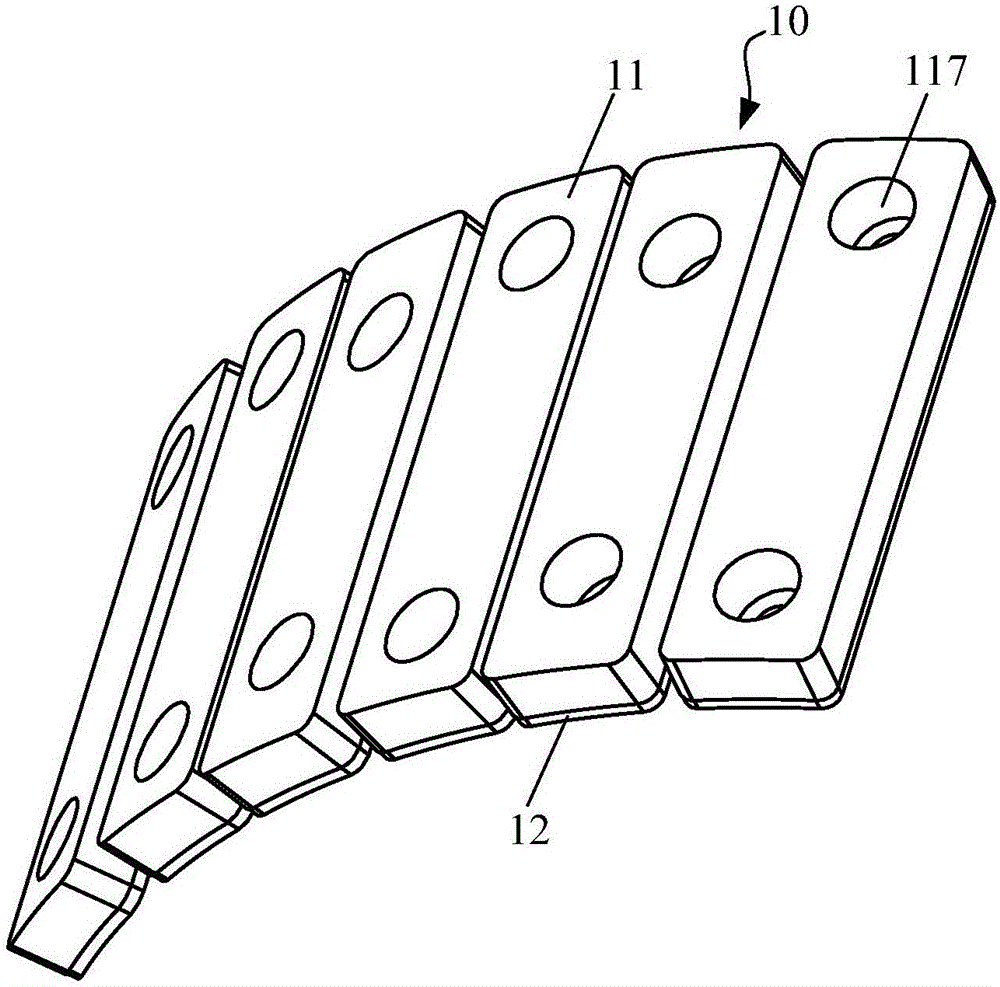

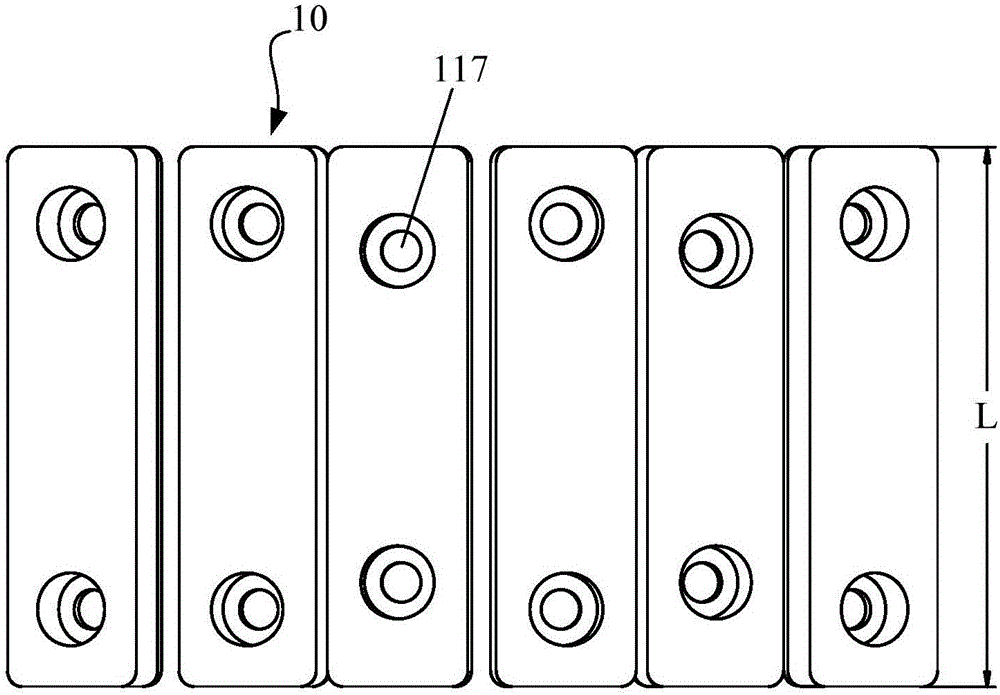

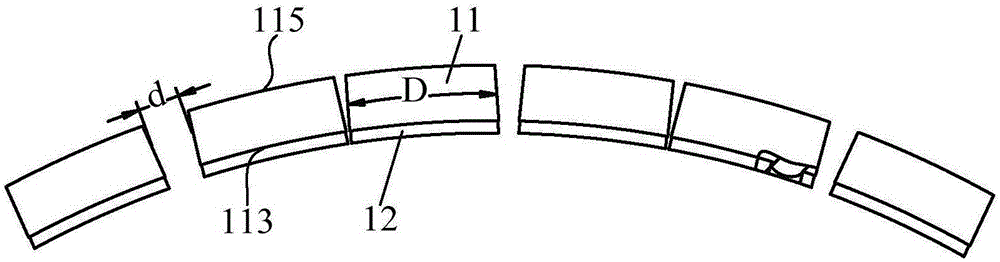

[0027] Such as Figure 1 to Figure 3 As shown, the drum brake lining according to this embodiment adopts a split structure, specifically including a plurality of sub-linings 10, the sub-linings 10 include a friction body 11 made of powder metallurgy materials, and the friction body 11 has a For the outer arc surface 115 matched with the brake drum, the ratio of the length L of the friction body 11 along the axial direction of the brake drum to the average arc length D along the circumferential direction of the brake drum ranges from 2:1 to 6:1 Therefore, the drum brake lining in this embodiment adopts a split structure, and at the same time, the shape and size of the split friction body 11 are limited, so as to ensure the braking performance of the drum brake lining and the difficulty of installation. Under the premise of small change in the degree of ease, the uneven pressing of drum brake linings made of powder metallurgy materials has been improved, and the stability of the...

Embodiment 2

[0033] An embodiment of the present invention also provides a drum brake, including a brake shoe and a drum brake lining installed on the brake shoe, the drum brake lining is the above-mentioned drum brake lining , so that the drum brake of the embodiment of the present invention has the advantages of high reliability and good stability.

[0034] Drum brakes usually use a transmission mechanism to expand the brake shoes outward, and press the drum brake linings to cooperate with the brake drum to obtain braking force. Force part, in the drum brake lining in the embodiment of the present invention, the ratio of the length L of the friction body 11 along the axial direction of the brake drum to the average arc length D along the circumferential direction of the brake drum is different , the proportion value of the friction body 11 installed in the main force receiving part is smaller than that of the friction body 11 installed in the auxiliary force receiving part, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com