Bag-type dust collector capable of continuously operating

A bag filter and bag technology, which is applied in chemical instruments and methods, separation of dispersed particles, and filtration of dispersed particles, etc., can solve the problem of smaller processing capacity of bag filter and reduce the efficiency of bag filter for air purification, etc., to reduce the possibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

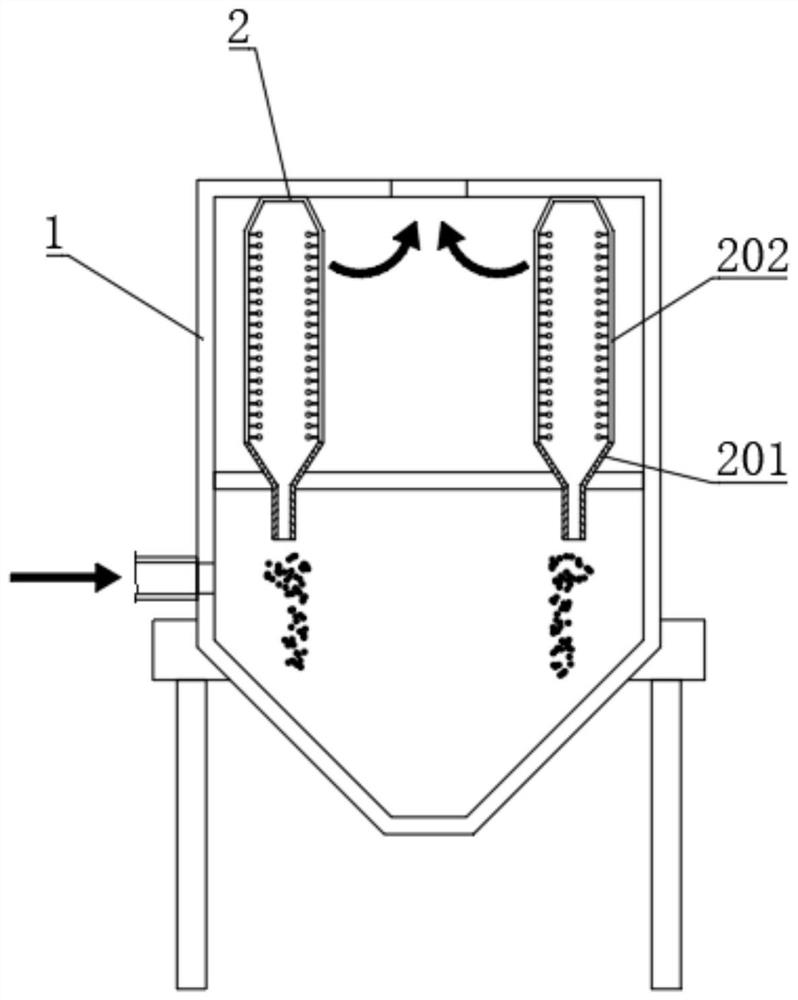

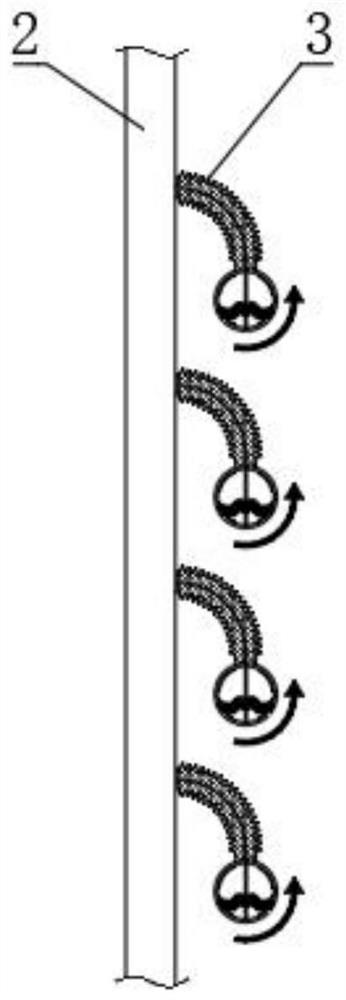

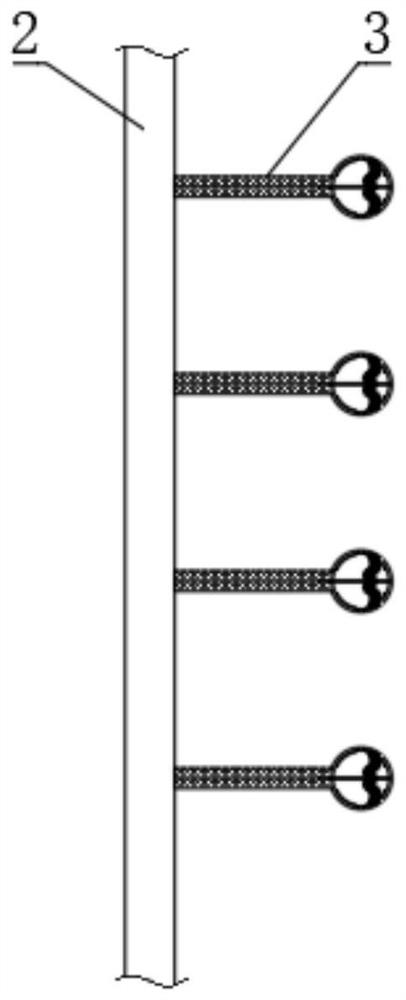

[0042] see Figure 1-4 , a bag filter for continuous operation, comprising a dust removal frame 1, the left end of the dust removal frame 1 is connected with an air inlet duct, and is provided with an air inlet hole communicating with it, and the upper end of the dust removal frame 1 is provided with an air outlet hole, and the dust removal frame 1 is provided with an air outlet. A pair of built-in dust-removing cloth bags 2 are installed in the frame 1, and the inner walls of the built-in dust-removing cloth bags 2 are connected with a plurality of evenly distributed dust pendulums 3. The capsule 4 is filled with an aqueous solution of carbon dioxide 5, and the end of the corrugated storage capsule 4 far away from the inner wall of the built-in dust-removing cloth bag 2 is connected with an end-deformed balloon 6, and the corrugated storage capsule 4 is provided with a heat-changing traction wire connected to the inner wall of the built-in dust-removing cloth bag 2 7. The end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com