Oil-resistant anti-fouling practical silk fabric

A practical and fabric technology, applied in anti-coloring pollution/anti-fouling fibers, yarns, textiles and papermaking, etc., can solve the problems of fabrics being easily stained with oil, human discomfort, stain accumulation, etc., to improve sunscreen and oil resistance performance , prevent the accumulation of charges, prevent the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

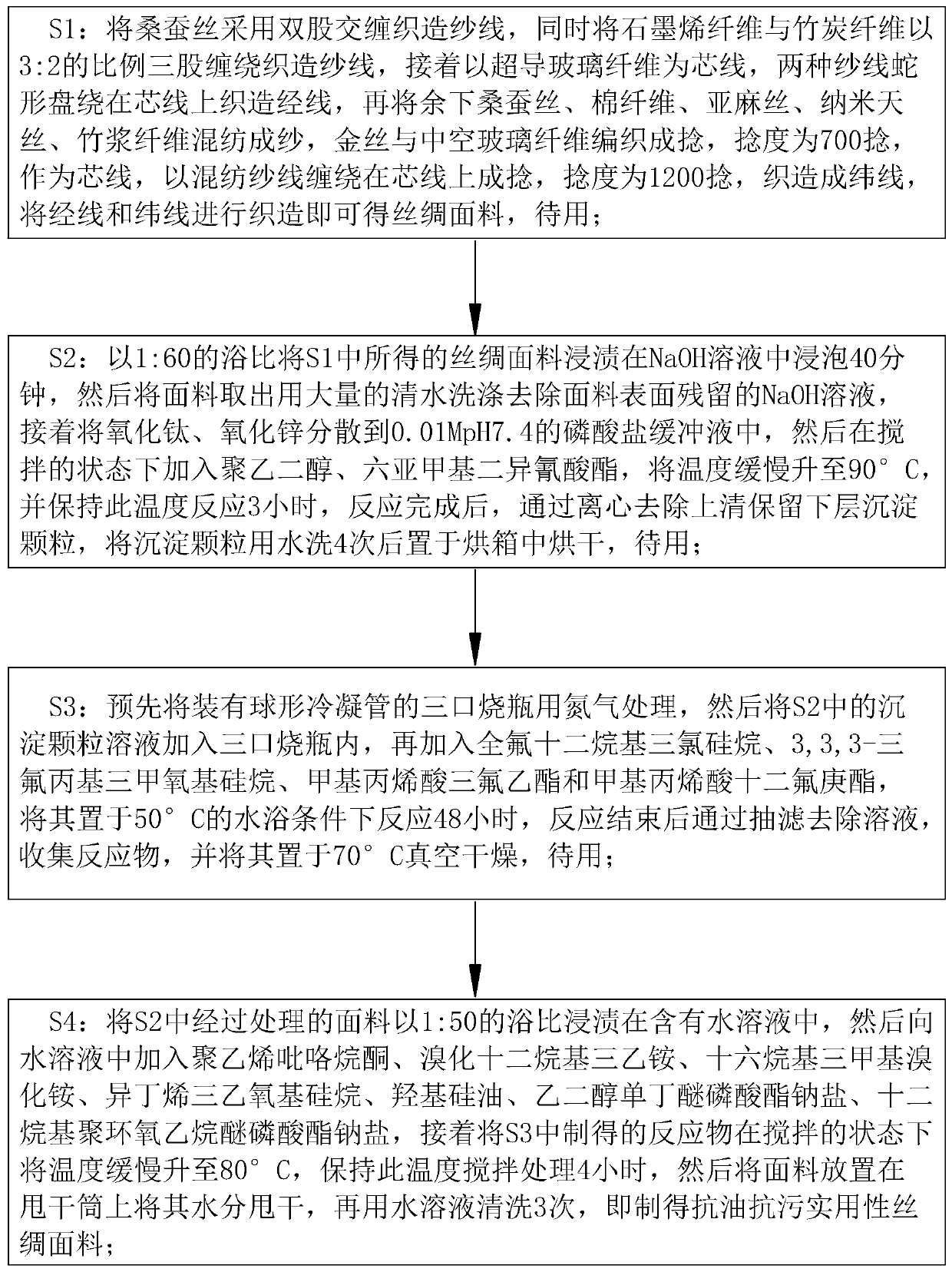

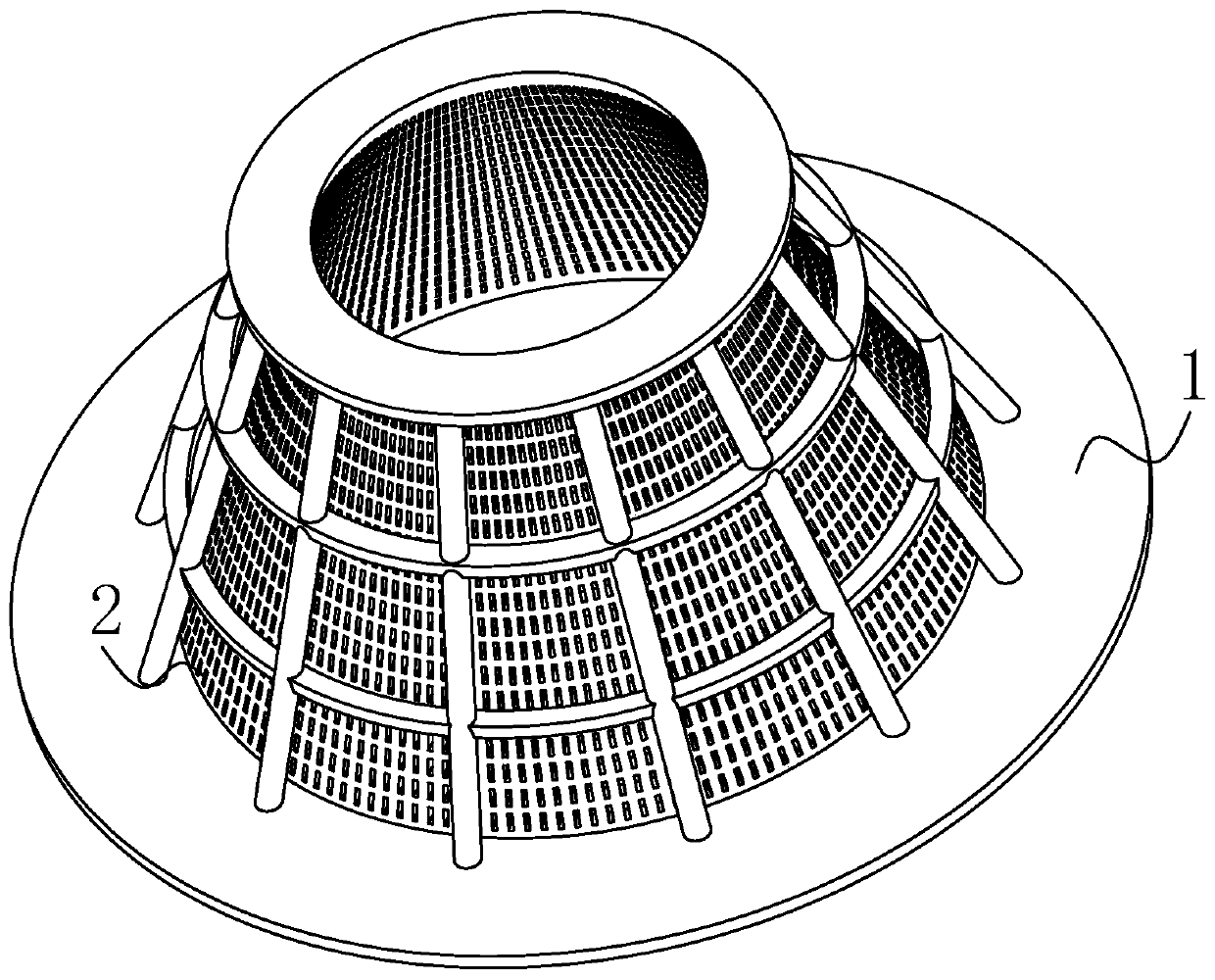

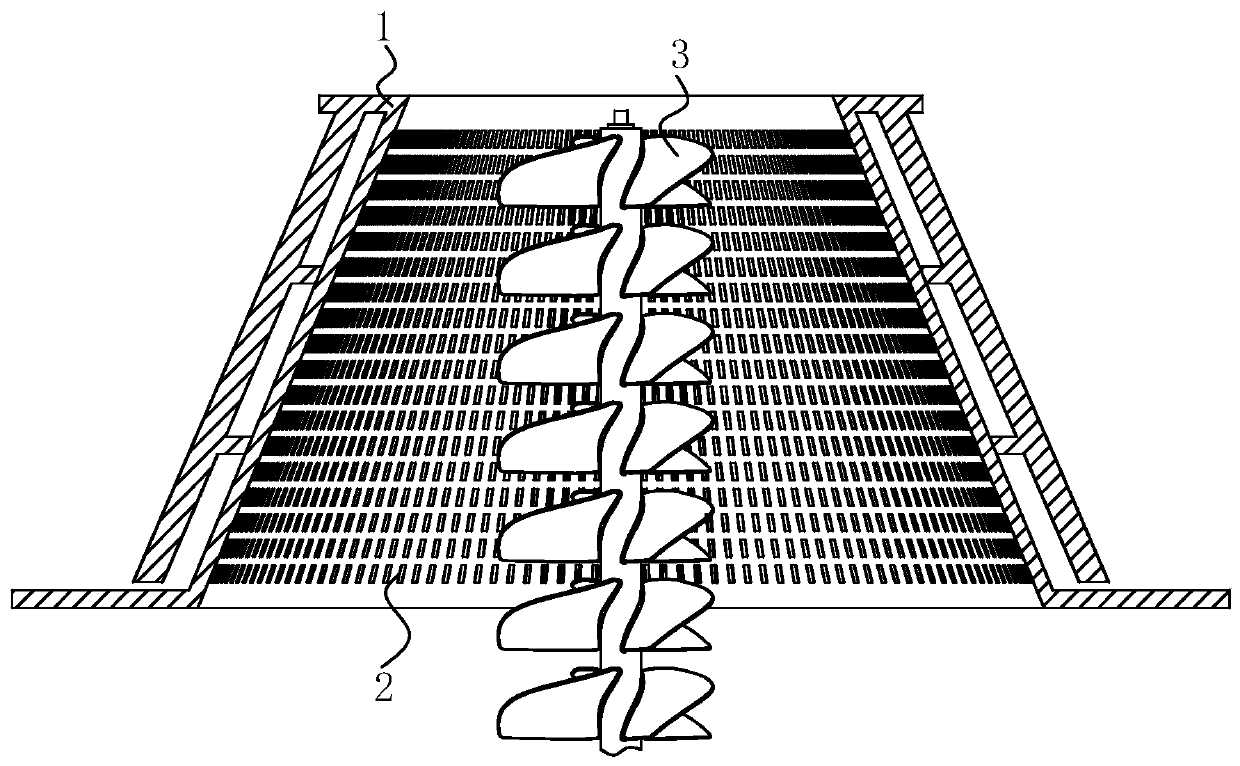

[0028] use Figure 1-Figure 4 An oil and dirt repellent practical silk fabric according to an embodiment of the present invention is described as follows.

[0029] Such as Figure 1-Figure 4 As shown, a kind of anti-oil and anti-fouling practical silk fabric of the present invention comprises the following components of required parts by weight for making:

[0030] 50 parts of mulberry silk, 30 parts of cotton fiber, 10 parts of graphene fiber, 9 parts of superconducting glass fiber, 12 parts of hollow glass fiber, 2 parts of bamboo charcoal fiber, 0.6 part of gold silk, 3 parts of flax silk, 11 parts of nano tencel, 2 parts of bamboo pulp fiber, 30 parts of NaOH solution, 40 parts of titanium oxide, 30 parts of zinc oxide, 10 parts of phosphate buffer, 8 parts of polyethylene glycol, 5 parts of hexamethylene diisocyanate, 14 parts of toluene, perfluorinated 7 parts of dodecyltrichlorosilane, 13 parts of 3,3,3-trifluoropropyltrimethoxysilane, 6 parts of trifluoroethyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com