Anti-static child mask and production process thereof

A production process and anti-static technology, applied in the field of masks, to reduce the possibility, ensure safety, and improve the effect of humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

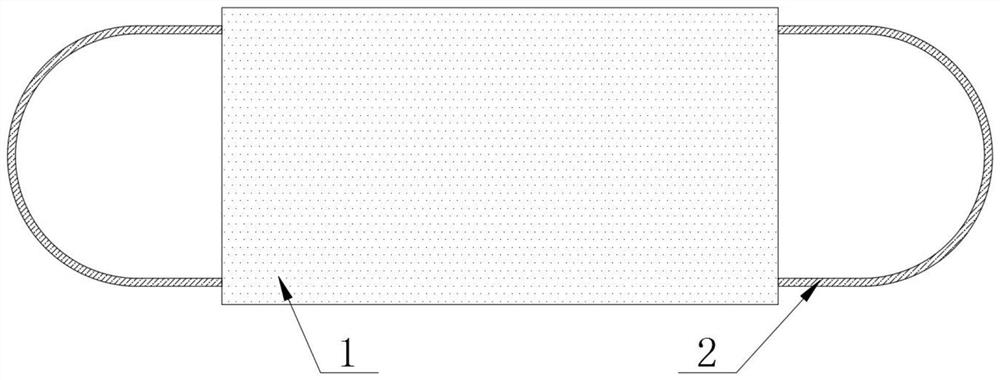

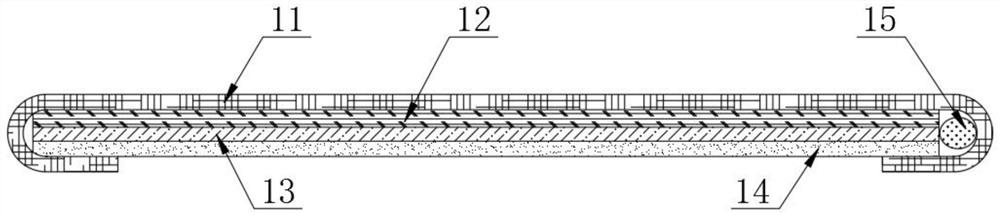

[0035] The present invention provides an anti-static children's mask, comprising a mask body 1, both ends of the mask body 1 are provided with wearing belts 2, and both ends of the wearing belt 2 are fixedly connected to both ends of the mask body 1, respectively. The mask body 1 includes a protective layer 11, a filter layer 12, a composite fiber layer 14 and a nose bridge strip 15;

[0036] The protective layer 11 is made of SS non-woven material;

[0037] The filter layer 12 is made of 22g / ㎡ meltblown non-woven fabric;

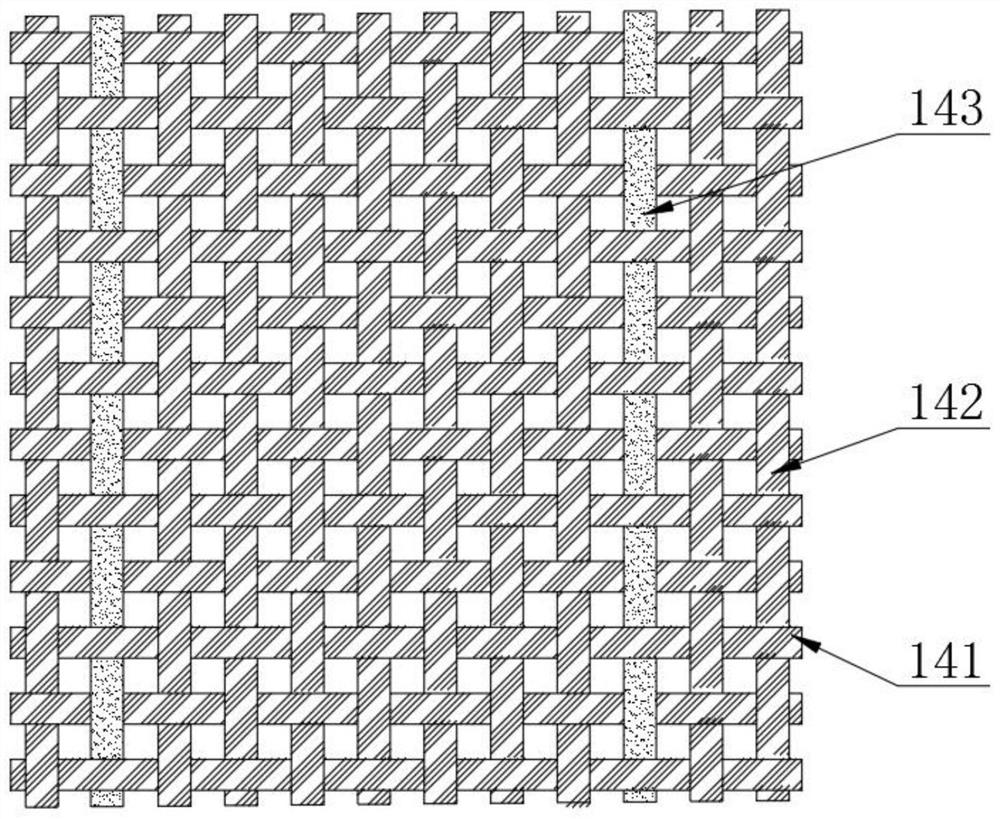

[0038] The composite fiber layer 14 includes warp fibers 141 , weft fibers 142 and conductive fibers 143 , the warp fibers 141 are arranged laterally, the weft fibers 142 and the conductive fibers 143 are both arranged longitudinally, and the weft fibers 142 The ratio with the number of conductive fibers 143 is set to 7:1;

[0039] The nose bridge strip 15 is configured to be made of PE and stainless steel strip materials.

[0040] The length and width o...

Embodiment 2

[0046] The present invention provides an anti-static children's mask, comprising a mask body 1, both ends of the mask body 1 are provided with wearing belts 2, and both ends of the wearing belt 2 are fixedly connected to both ends of the mask body 1, respectively. The mask body 1 includes a protective layer 11, a filter layer 12, a moisturizing layer 13, a composite fiber layer 14 and a bridge of the nose 15;

[0047] The protective layer 11 is made of SS non-woven material;

[0048] The filter layer 12 is made of 22g / ㎡ meltblown non-woven fabric;

[0049] The moisturizing layer 13 is set as a non-woven fabric impregnated with glycerin;

[0050] The composite fiber layer 14 includes warp fibers 141 , weft fibers 142 and conductive fibers 143 , the warp fibers 141 are arranged laterally, the weft fibers 142 and the conductive fibers 143 are both arranged longitudinally, and the weft fibers 142 The ratio with the number of conductive fibers 143 is set to 7:1;

[0051] The nose ...

Embodiment 3

[0060] The present invention provides an anti-static children's mask, comprising a mask body 1, both ends of the mask body 1 are provided with wearing belts 2, and both ends of the wearing belt 2 are fixedly connected to both ends of the mask body 1, respectively. The mask body 1 includes a protective layer 11, a filter layer 12, a moisturizing layer 13, a composite fiber layer 14 and a bridge of the nose 15;

[0061] The protective layer 11 is made of SS non-woven material;

[0062] The filter layer 12 is made of 22g / ㎡ meltblown non-woven fabric;

[0063] The moisturizing layer 13 is set as a non-woven fabric impregnated with glycerin;

[0064] The composite fiber layer 14 includes warp fibers 141 , weft fibers 142 and conductive fibers 143 , the warp fibers 141 are arranged laterally, the weft fibers 142 and the conductive fibers 143 are both arranged longitudinally, and the weft fibers 142 The ratio with the number of conductive fibers 143 is set to 7:1;

[0065] The nos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com