Friction nanogenerator and manufacturing method thereof

A nanogenerator and triboelectric sequence technology, applied in the nano field, can solve the problems of expensive equipment and difficult to control the microstructure and morphology, and achieve the effects of improving output, easy miniaturization, and improving friction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

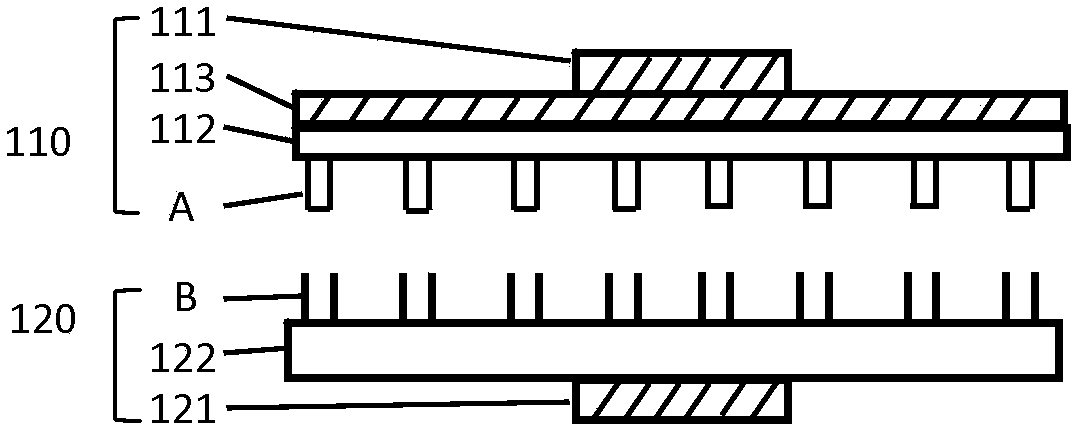

[0046] In Embodiment 1 of the present invention, a contact-separation friction nanogenerator is provided. figure 1 It is a schematic structural diagram of a friction nanogenerator packaged according to an embodiment of the present invention. Please refer to figure 1 , the present embodiment contact-separation friction nanogenerator comprises:

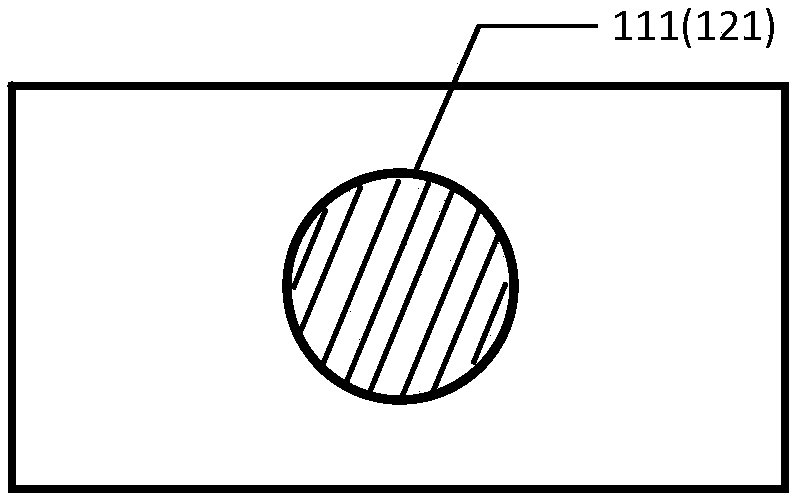

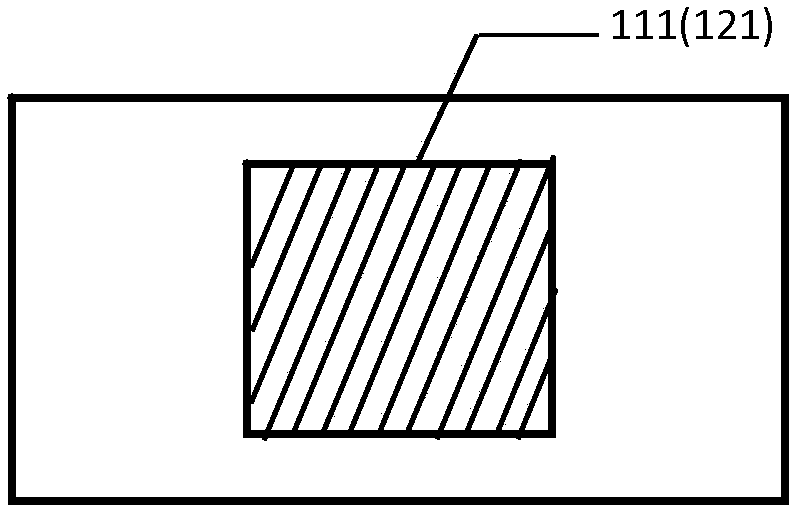

[0047] The first friction unit 110 includes a first magnetic part 111, a first friction layer 112 and an electrode layer 113, the electrode layer is formed outside the first friction layer, and the first magnetic part is formed on the electrode layer outside;

[0048] The second friction unit 120 is arranged opposite to the first friction unit, and the second friction unit includes a second magnetic part 121 and a second friction layer 122; the second magnetic part is formed on the second friction outside of the unit; where,

[0049] The first and second magnetic parts are oppositely arranged with the same poles, that is, N and N po...

no. 3 example

[0066] Image 6 It is a schematic structural diagram of the encapsulated triboelectric nanogenerator according to Embodiment 3 of the present invention. Please refer to Image 6 , the present embodiment contact-separation friction nanogenerator comprises:

[0067] The first friction unit 310, which includes a first friction layer 312 and an electrode layer 313, the first friction layer is formed of magnetic powder material and high molecular polymer;

[0068] a second friction unit 320, which is arranged opposite to the first friction unit, and the second friction unit includes a second friction layer 322 formed of a conductive magnetic material;

[0069] The opposite sides of the first friction unit and the second friction unit have the same polarity, so as to separate the first and second friction units after contact;

[0070] The materials on the opposite surfaces of the first friction unit and the second friction unit have different triboelectric series. During the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com