Rolling friction trapezoidal screw rod

A rolling friction, trapezoidal technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high design load, can not replace trapezoidal screw, etc., achieve high production and use precision, grasp the technical principle quickly, Mature and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention should not be limited by this.

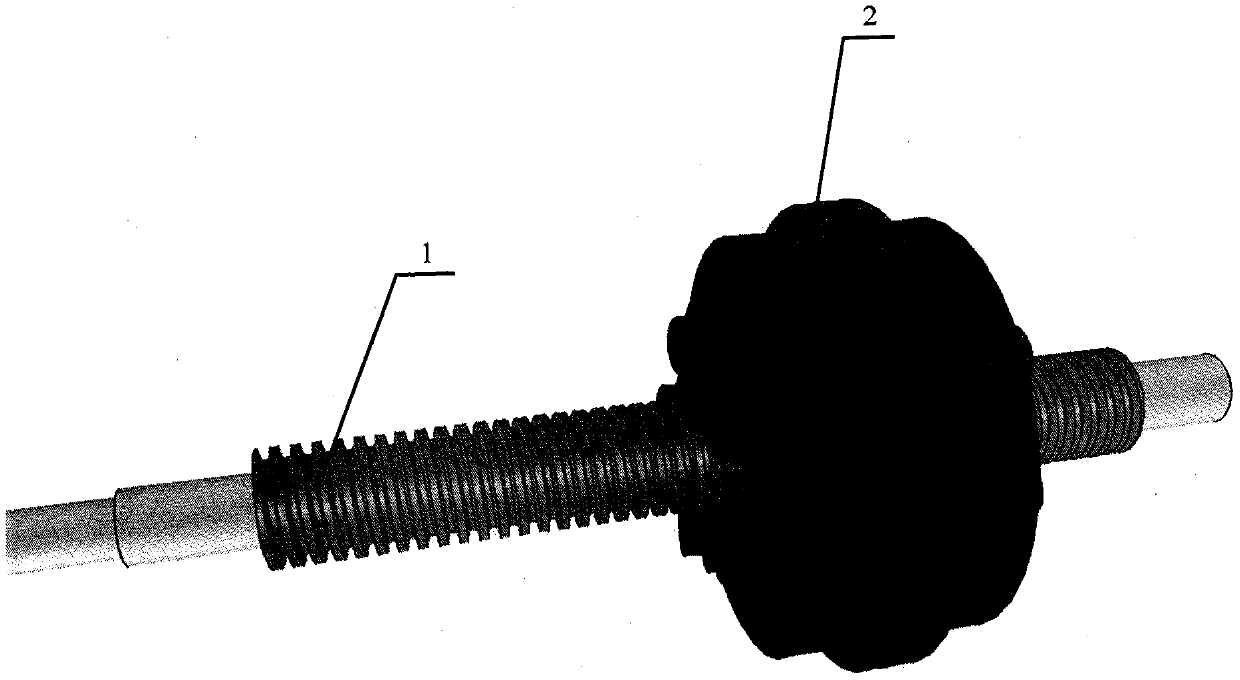

[0030] figure 1 Example, a classic external schematic for the Precision Fit principle, consisting of a trapezoidal screw (1) and a nut housing (2) already fitted with rolling friction components.

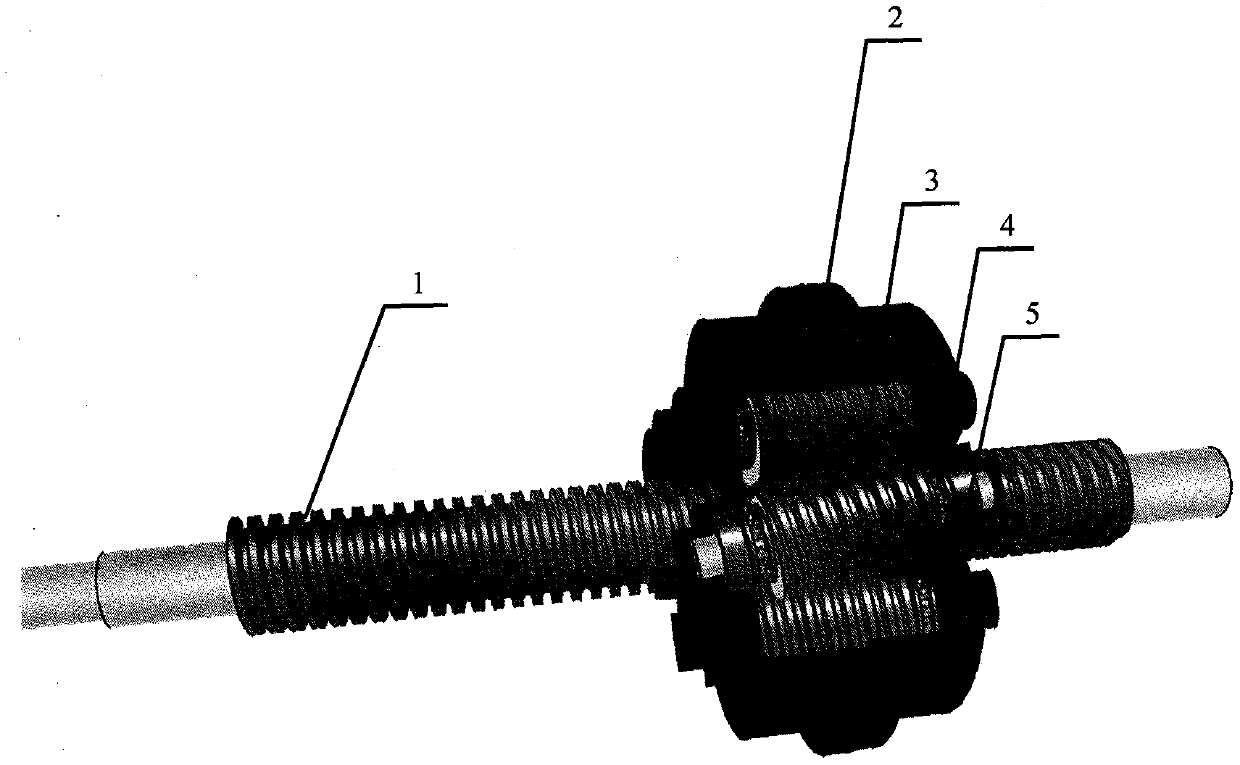

[0031] figure 2 ,for figure 1 The schematic diagram of the internal assembly of the example can clearly show that it is composed of a trapezoidal screw (1) and a nut housing (2) that has been assembled with a rolling friction assembly. The rolling friction assembly has a trapezoidal spiral rolling body (3) thrust bearing (4) rolling bearing ( 5) Form the assembly.

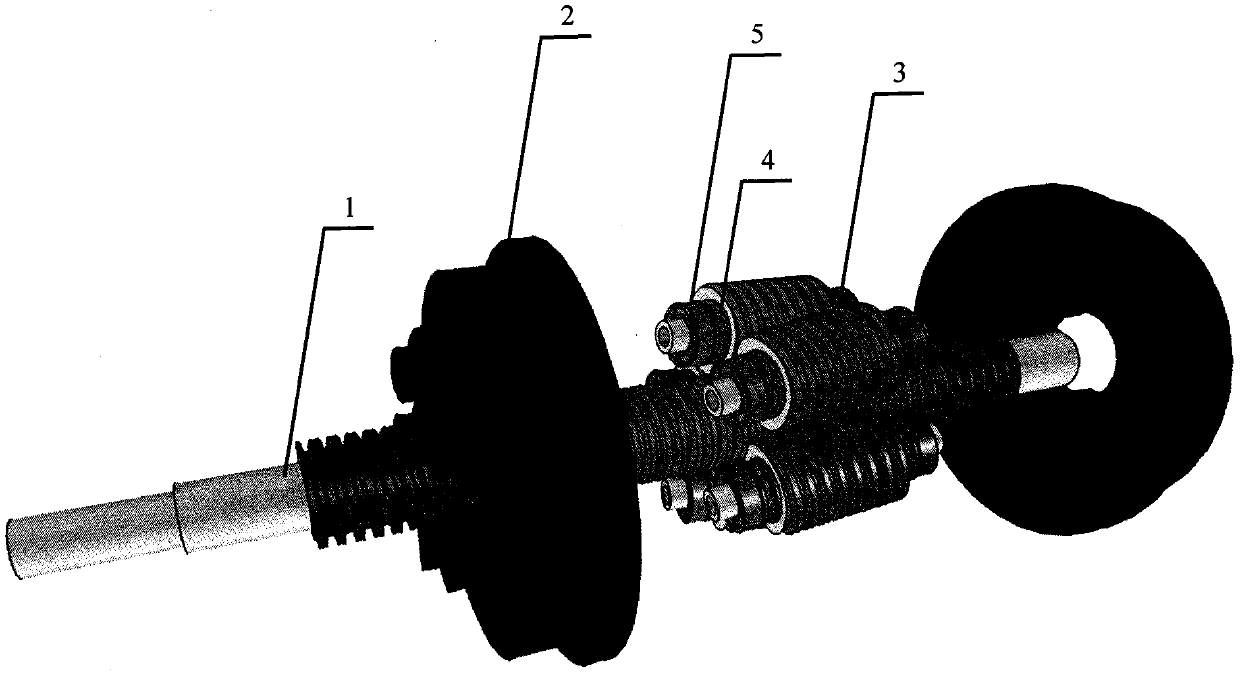

[0032] image 3 ,for figure 1 The schematic diagram of the assembly and disassembly of the example can clearly show that it is composed of a trapezoidal screw (1) and a nut housing (2) that has been assembled with a rolling frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com