A barrel type friction damper and its loading method

A friction damping and damper technology, applied in building types, protective buildings/shelters, buildings, etc., can solve the problems of uneven compressive stress of friction materials, large bending stress of damping outer cylinder, large compressive stress, etc. The effect of strong stability and durability, high friction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

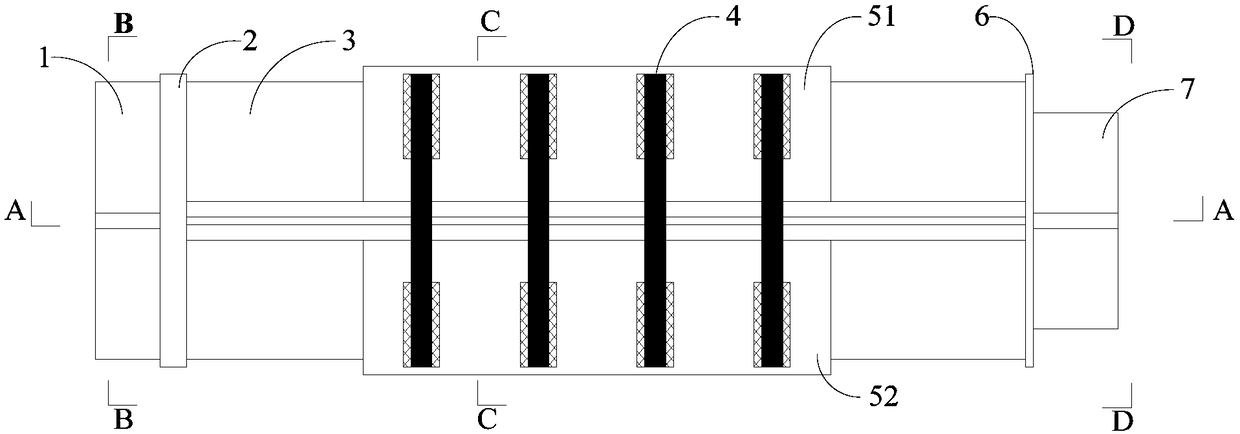

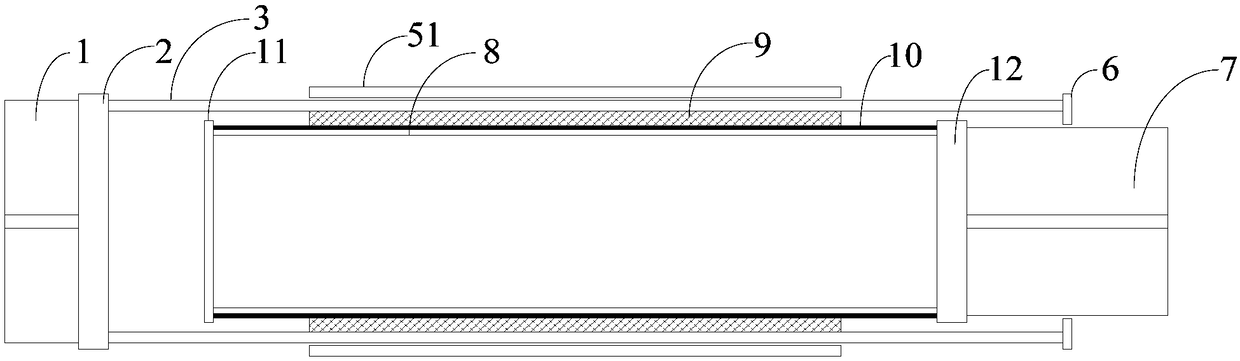

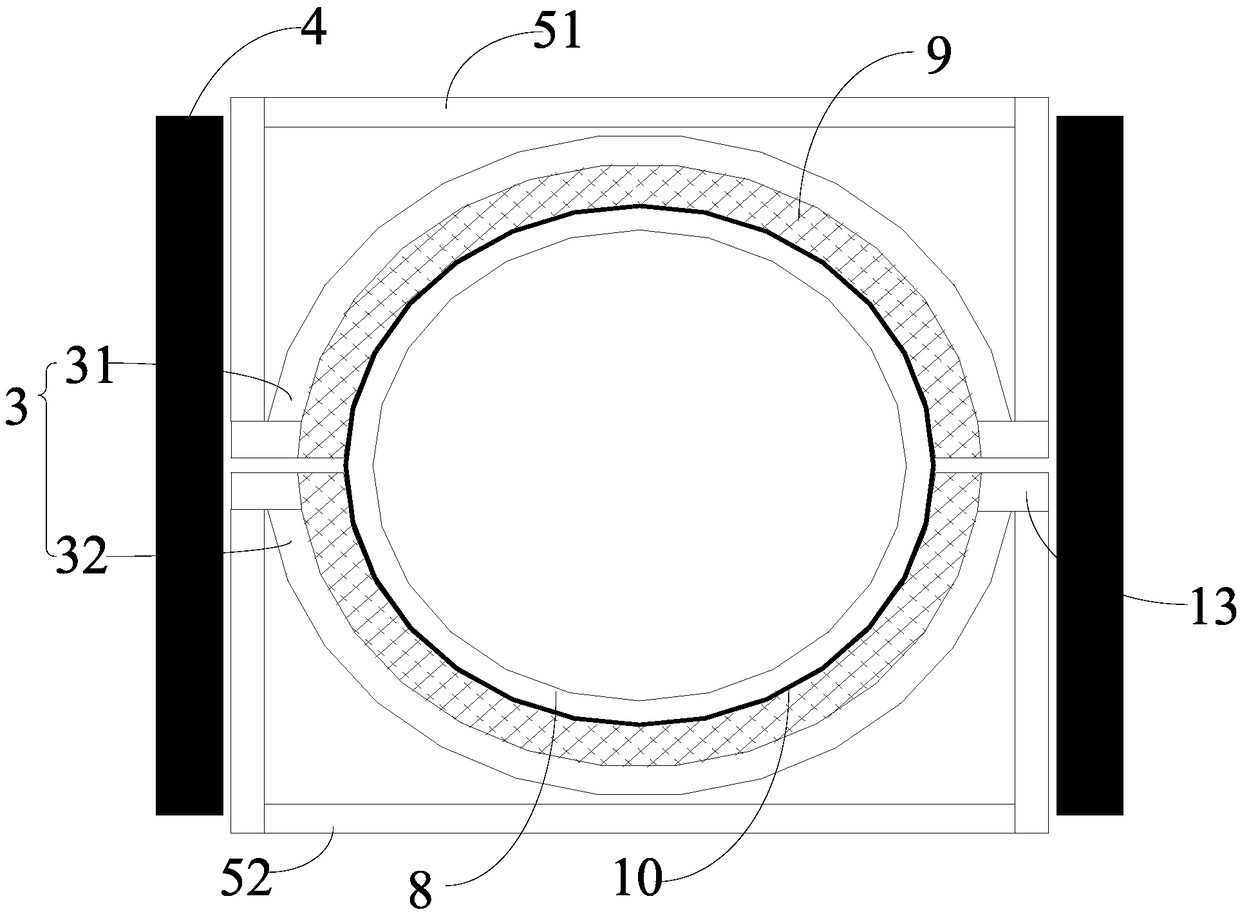

[0034] see figure 1 and figure 2 , figure 1 A schematic structural view of the cylindrical friction damper of the present invention is shown; figure 2 shown figure 1 Sectional view of A-A in the middle. The cylindrical friction damper of the invention provides a friction damping force along the friction direction. Realize by constraining the frictional force generated by the relative displacement between the inner cylinder 8 and the outer cylinder 3 of the hoop. The hoop outer cylinder 3; and the first connection device and the second connection device respectively connected to the constraint inner cylinder 8 and the hoop outer cylinder 3, and connected to the first main body component and the second main body component. Wherein, the knot-drawing device includes a first clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com