A polishing device for the joint of a spherical sound box shell with a disc sliding structure

A polishing device and sliding technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of roughness not meeting production requirements, poor polishing effect, low work efficiency, etc. Better processing effect, avoid over-polishing, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

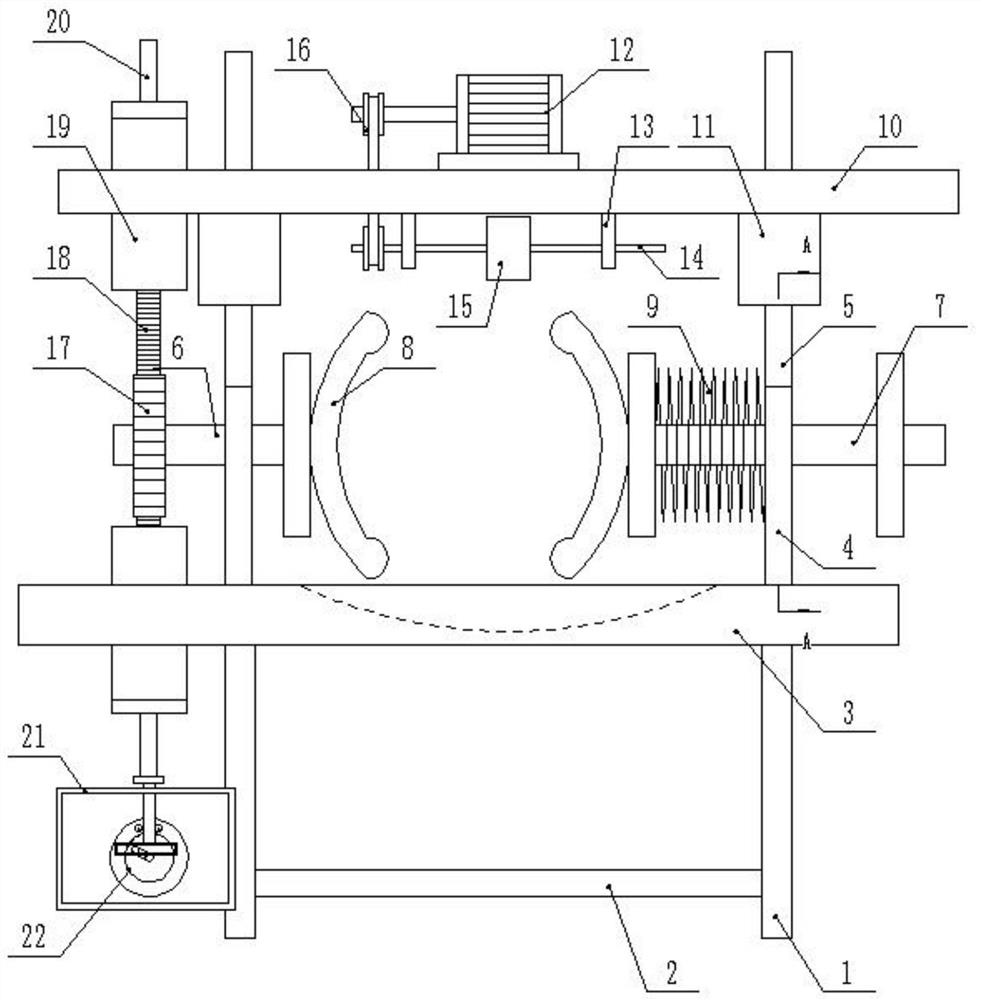

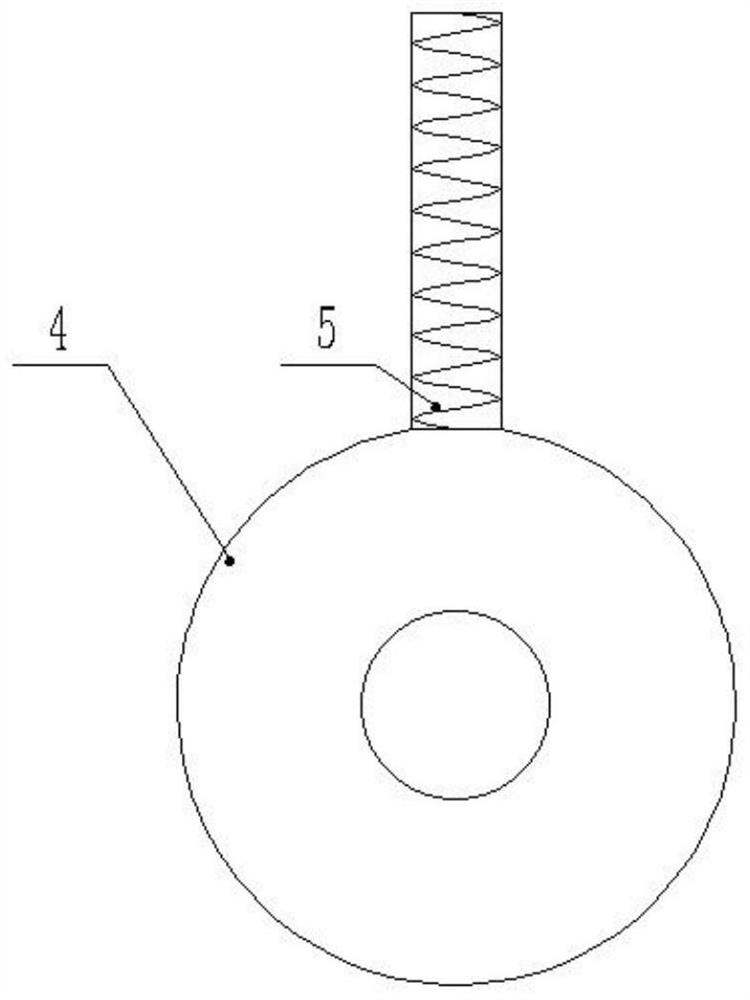

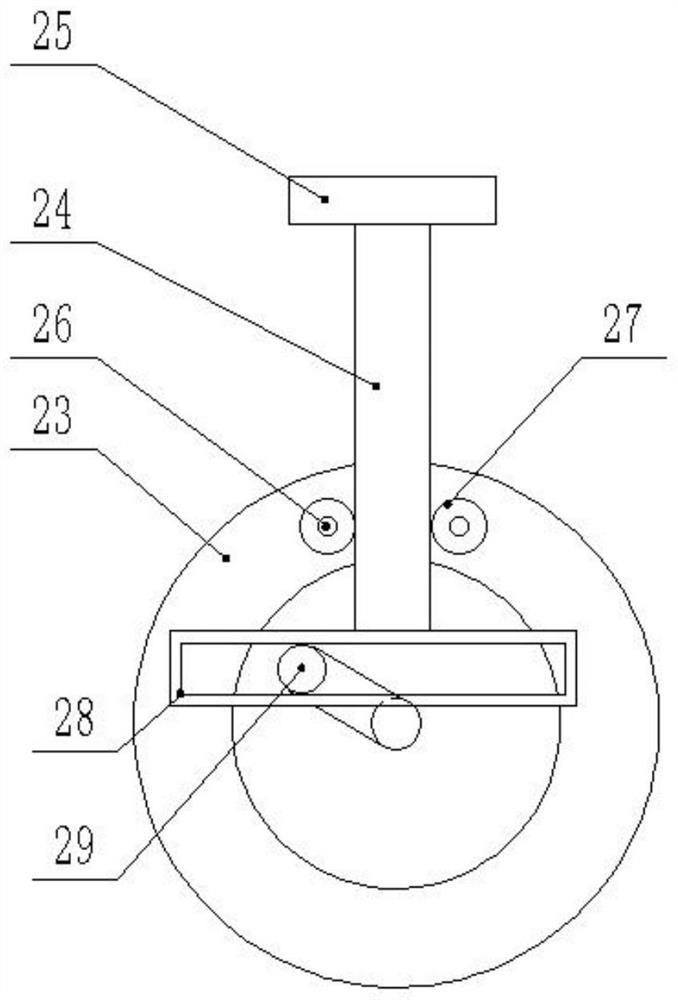

[0019] see Figure 1-3 , a polishing device for the joint of a spherical sound box shell with a disc sliding structure, including a device body, the device body is provided with a support frame 1, and a support beam 2 is arranged on the support frame 1, and the support beam 2 and the support frame 1 They are fixedly connected by welding, the top of the support frame 1 is provided with a support plate 3, and the support plate 3 is welded with the support frame 1, and the top of the support plate 3 is provided with a fixed frame 4. The frame 4 and the support plate 3 are fixedly connected by screws, the top of the fixed frame 4 is provided with a threaded column 5, and the threaded column 5 and the fixed frame 4 are integrally formed, and the fixed frame 4 is provided with a Turning lever A6 and turning lever B7, described turning lever A6 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com