A Gradient Correction Method of Surface Shape Error Based on Gradient Elastic Polishing Tool

A surface error, grinding and polishing technology, applied in the direction of grinding tools, manufacturing tools, workpiece feed movement control, etc., can solve the problems of low processing efficiency and processing quality, avoid inconsistencies in removal and surface quality degradation, and prolong use. Longevity, the effect of reducing the difficulty of planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

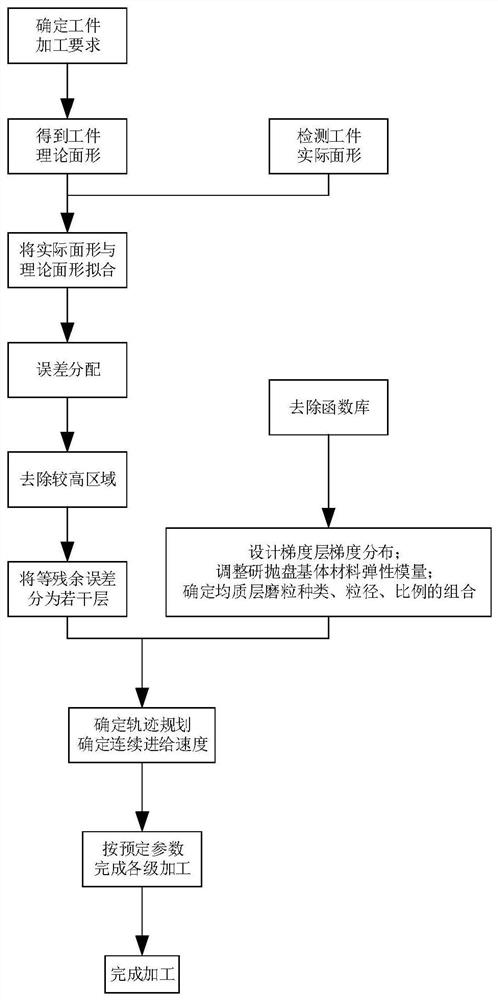

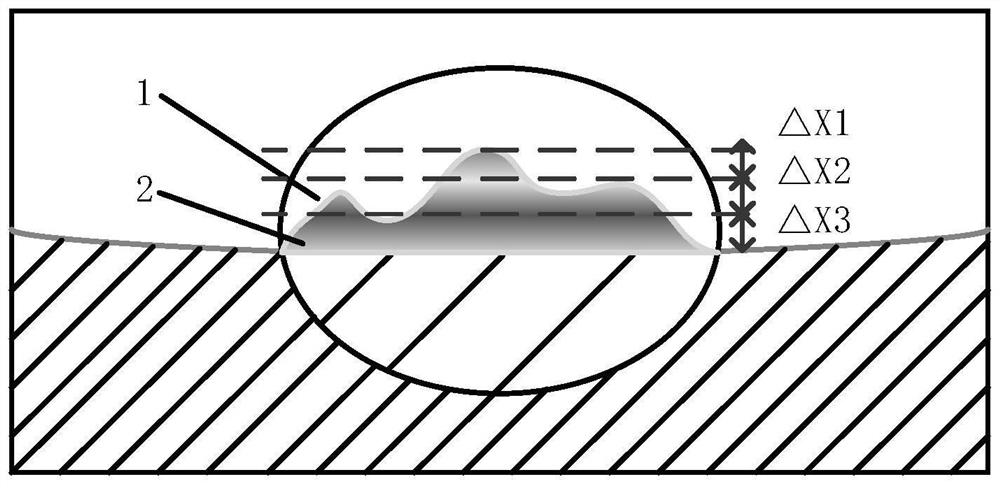

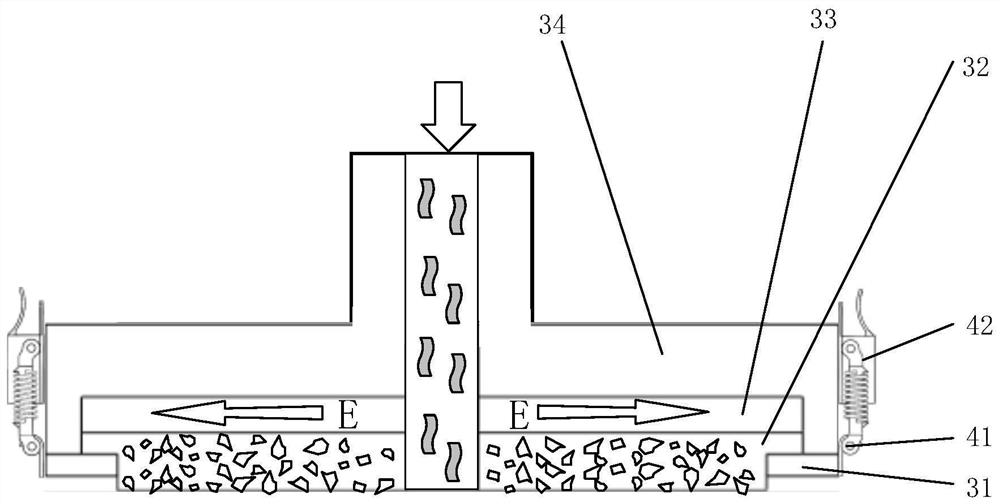

[0026] like Figure 1~5 as shown, figure 2 It is a schematic diagram of the hierarchical modification method involved in the present invention, in which 1 is the actual surface shape of the workpiece to be processed, and 2 is the theoretical surface shape of the workpiece to be processed; the present invention proposes a surface error classification based on gradient elastic polishing tools Correction method, this modification method comprises the following steps:

[0027] (1) Determine the theoretical surface shape of the workpiece according to the processing requirements of the workpiece;

[0028] (2) Use a laser interferometer to detect the actual surface shape characteristics of the workpiece, determine the difference PV value between the maximum peak value and the valley value of the initial surface shape of the workpiece, and the root mean square value RMS value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com