Patents

Literature

40results about How to "Avoid polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

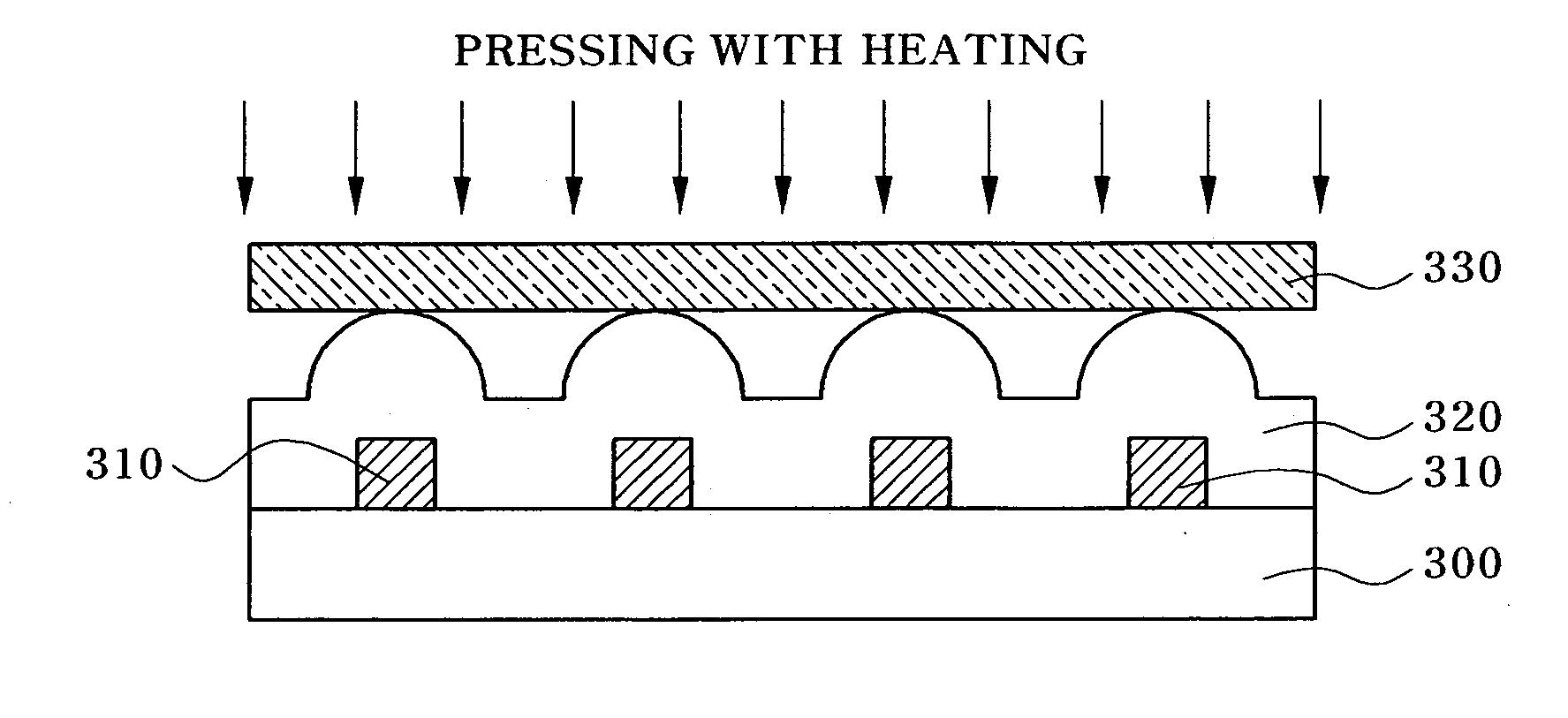

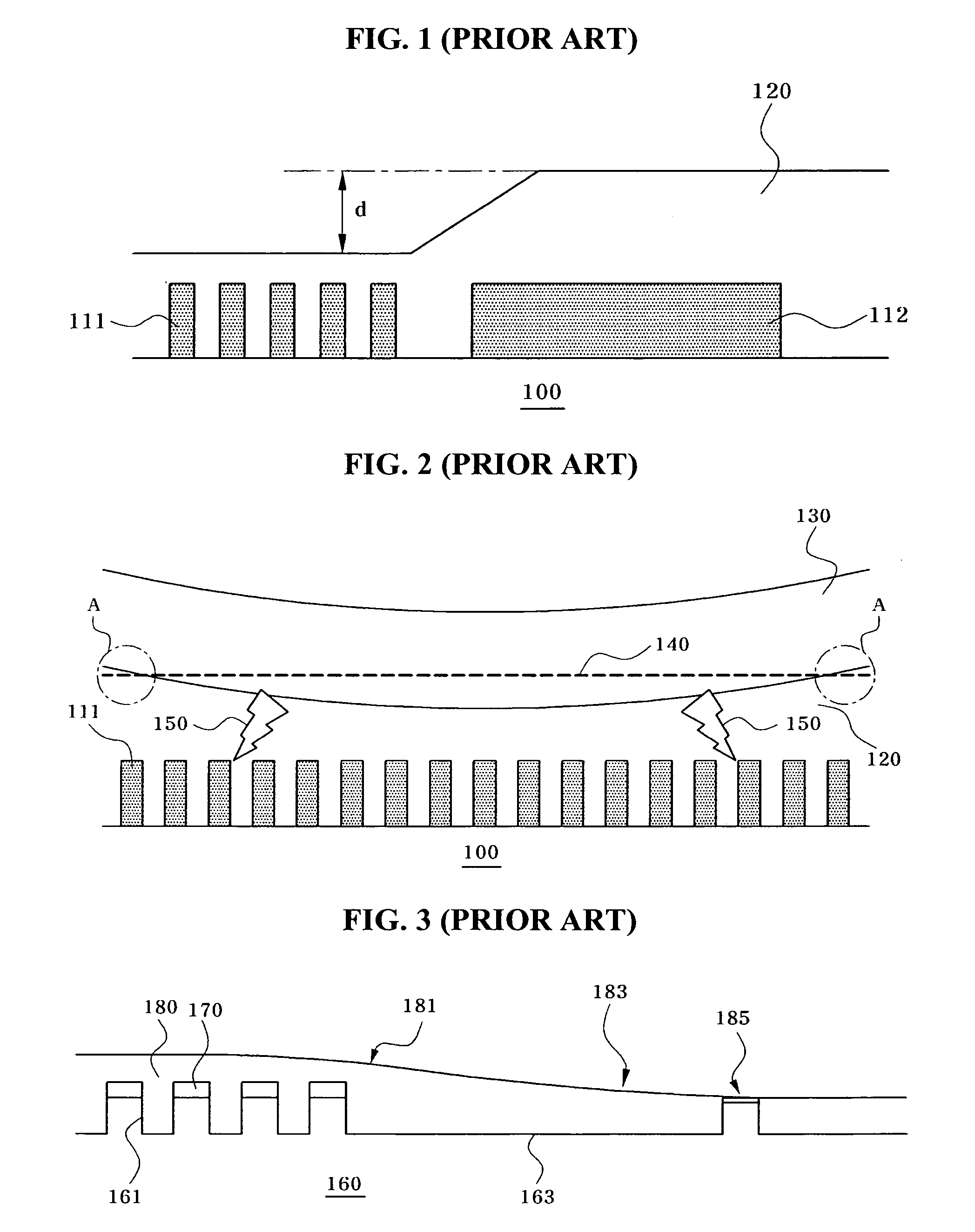

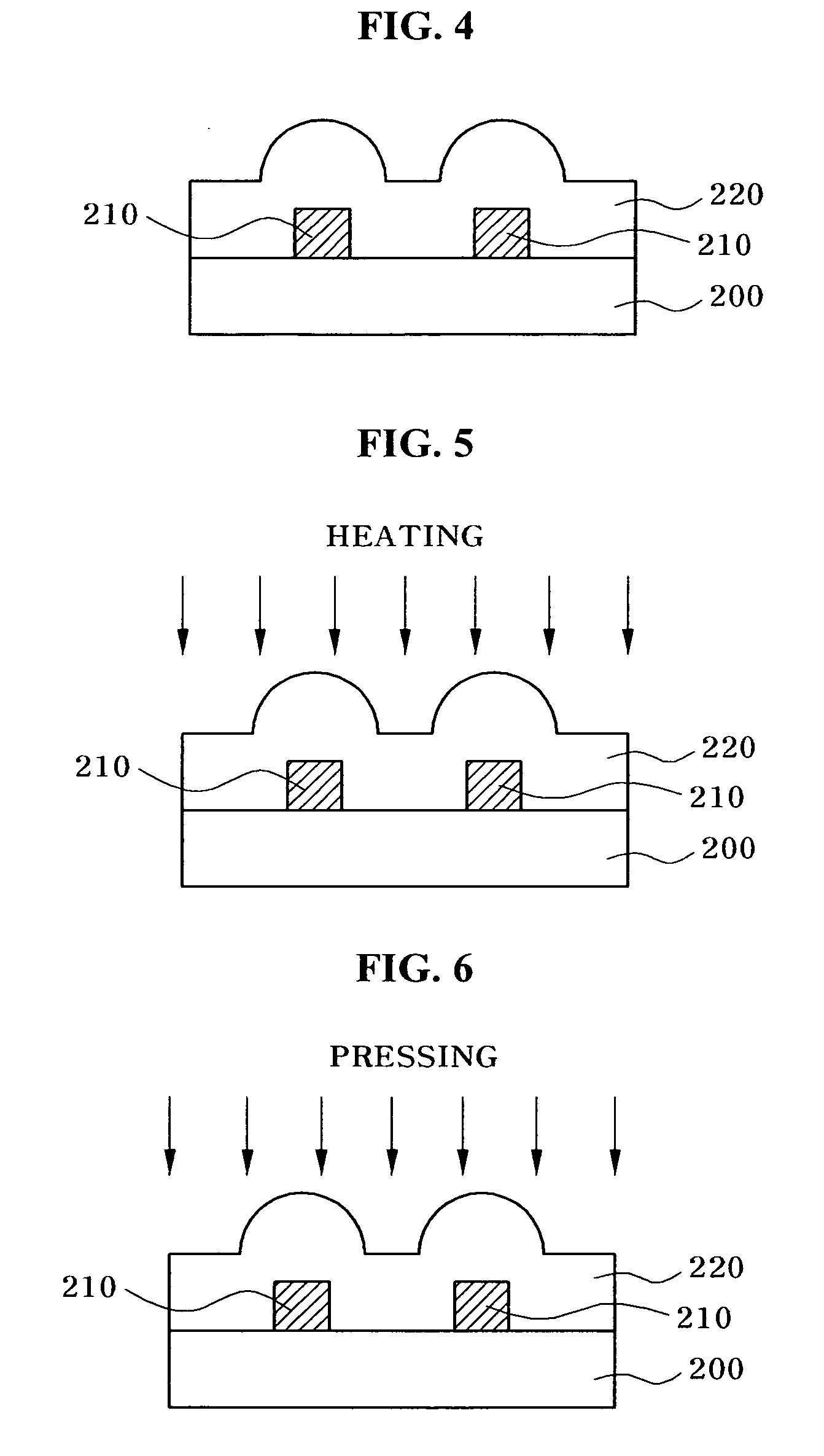

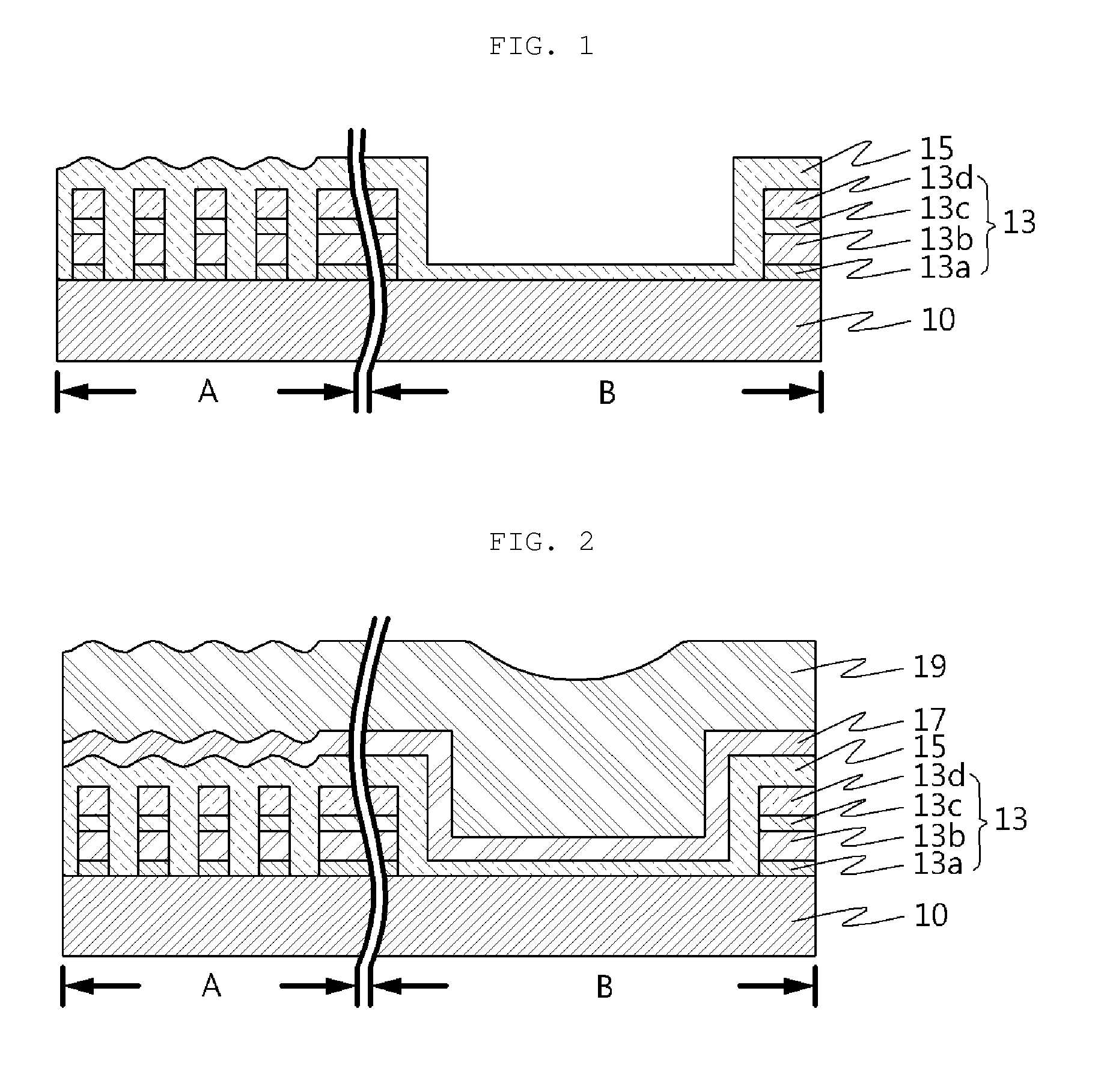

Planarization method for manufacturing semiconductor device

InactiveUS20070032083A1Avoid polishingSemiconductor/solid-state device manufacturingSurface layerDevice material

A method for planarizing a layer of a semiconductor device includes heating the layer to exhibit flowability, and applying pressure through an optically flat surface layer onto the layer to planarize the layer. And the planarizing method further comprises etch-back or chemical-mechanical polishing on the planarized layer.

Owner:SK HYNIX INC

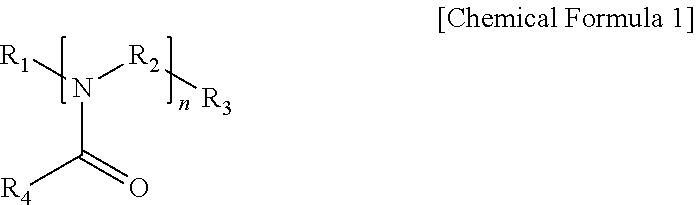

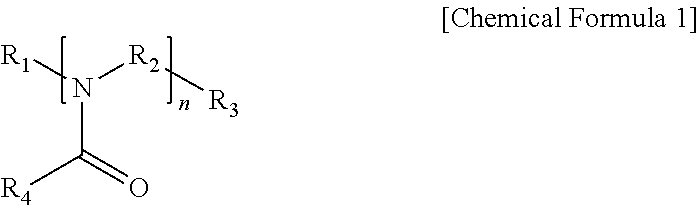

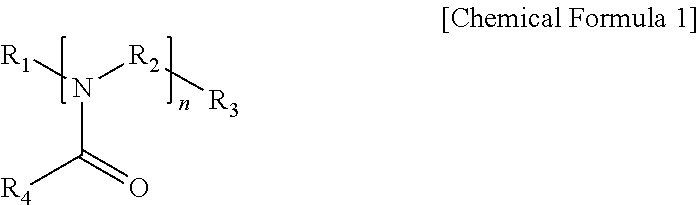

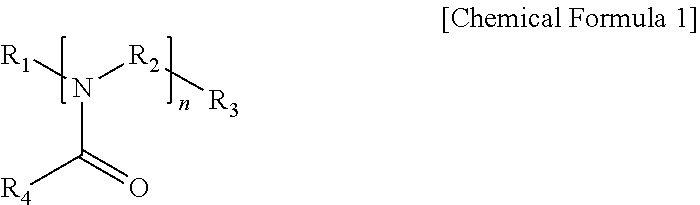

Polishing composition, polishing method using same, and method for producing substrate

ActiveUS20150132955A1Avoid polishingOther chemical processesSemiconductor/solid-state device manufacturingWater soluble polymersWater soluble

A polishing composition of the present invention contains a water-soluble polymer and abrasive grains. The water-soluble polymer is an anionic compound having an acid dissociation constant pKa of 3 or less. Specific examples of such a compound include polyvinylsulfonic acid, polystyrenesulfonic acid, polyallylsulfonic acid, polyethyl acrylate sulfonic acid, polybutyl acrylate sulfonic acid, poly(2-acrylamide-2-methylpropanesulfonic acid), and polyisoprenesulfonic acid. The abrasive grains exhibit a negative zeta potential at a pH of 3.5 or less. Specific examples of such abrasive grains include colloidal silica.

Owner:FUJIMI INCORPORATED

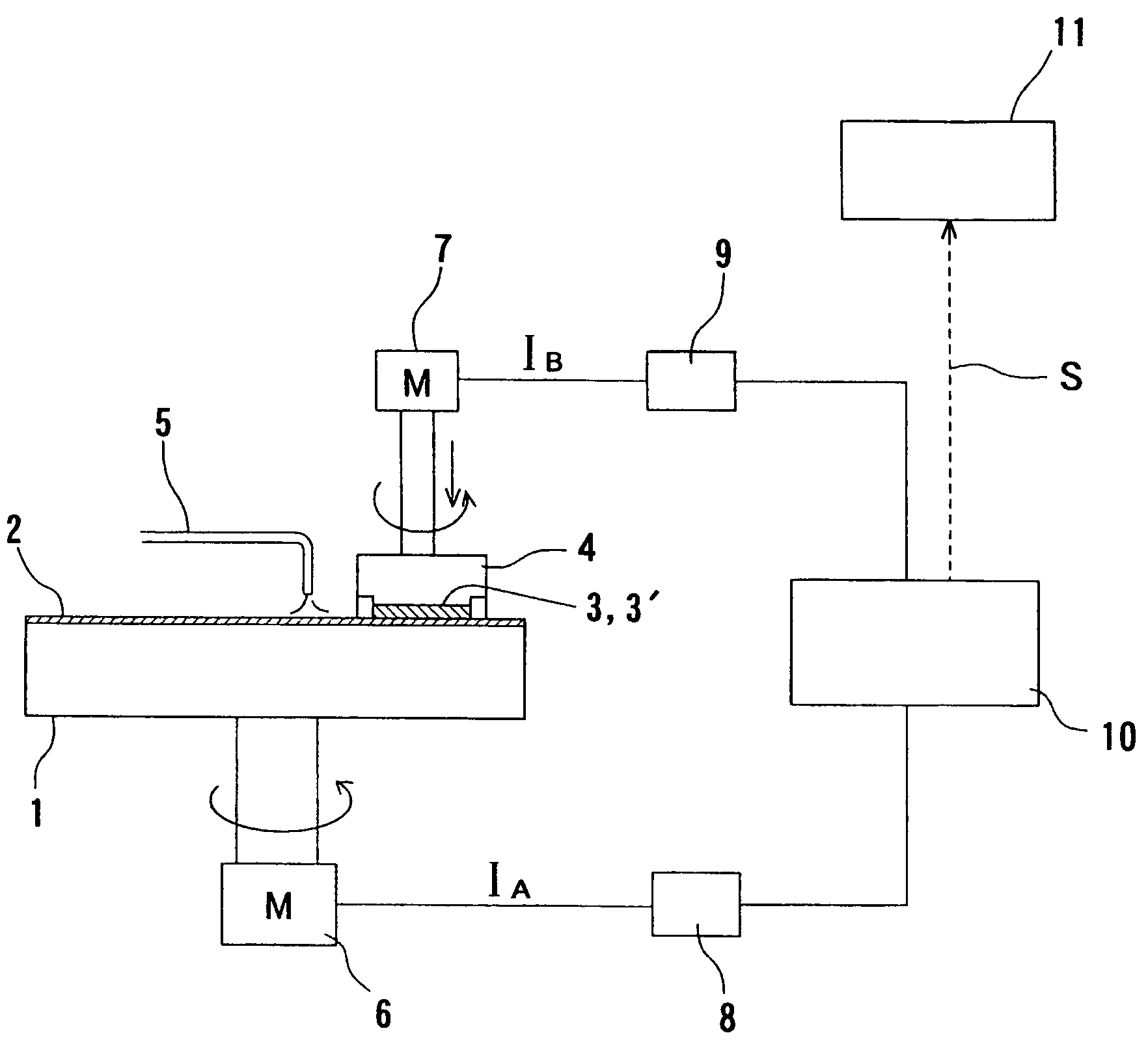

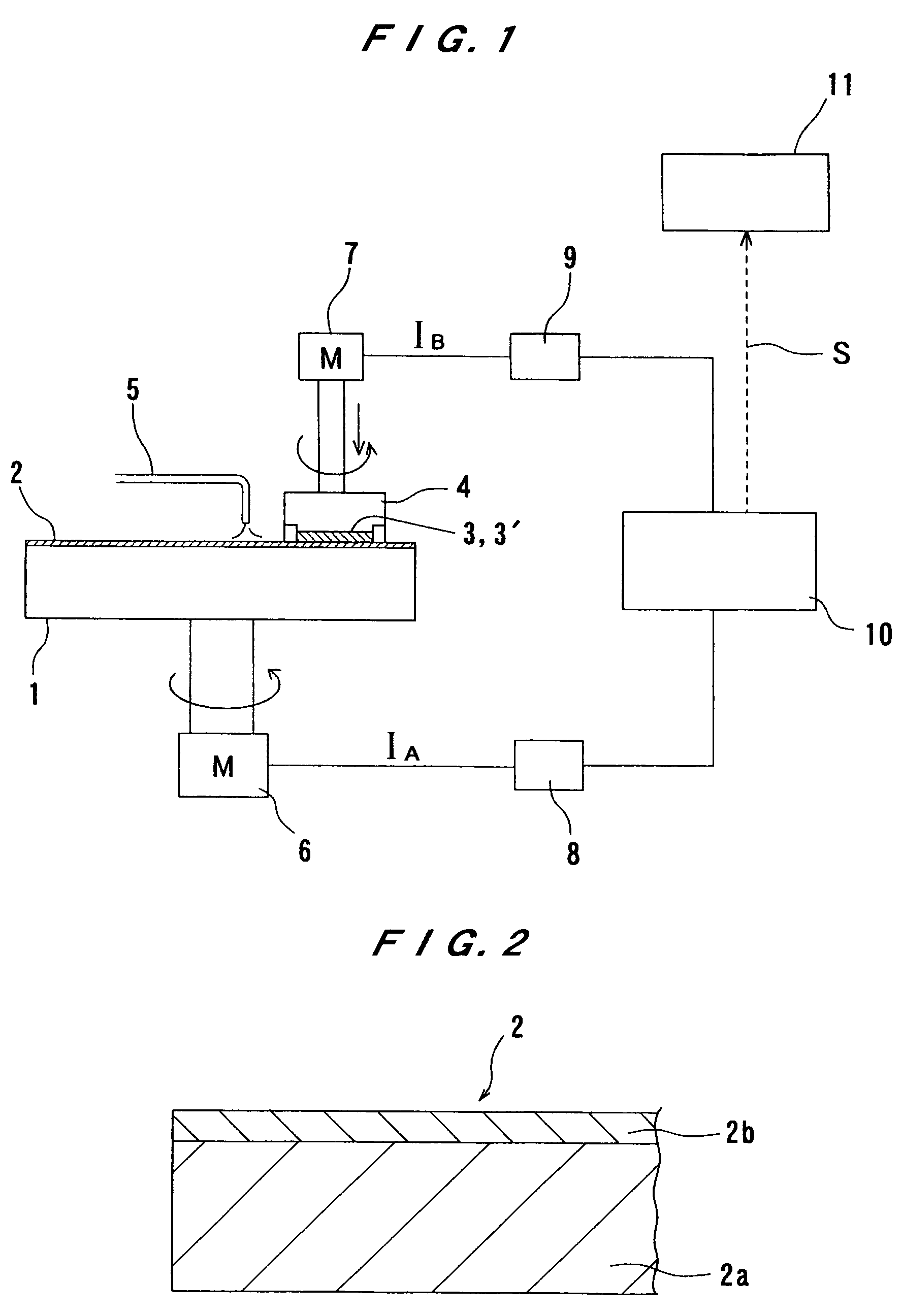

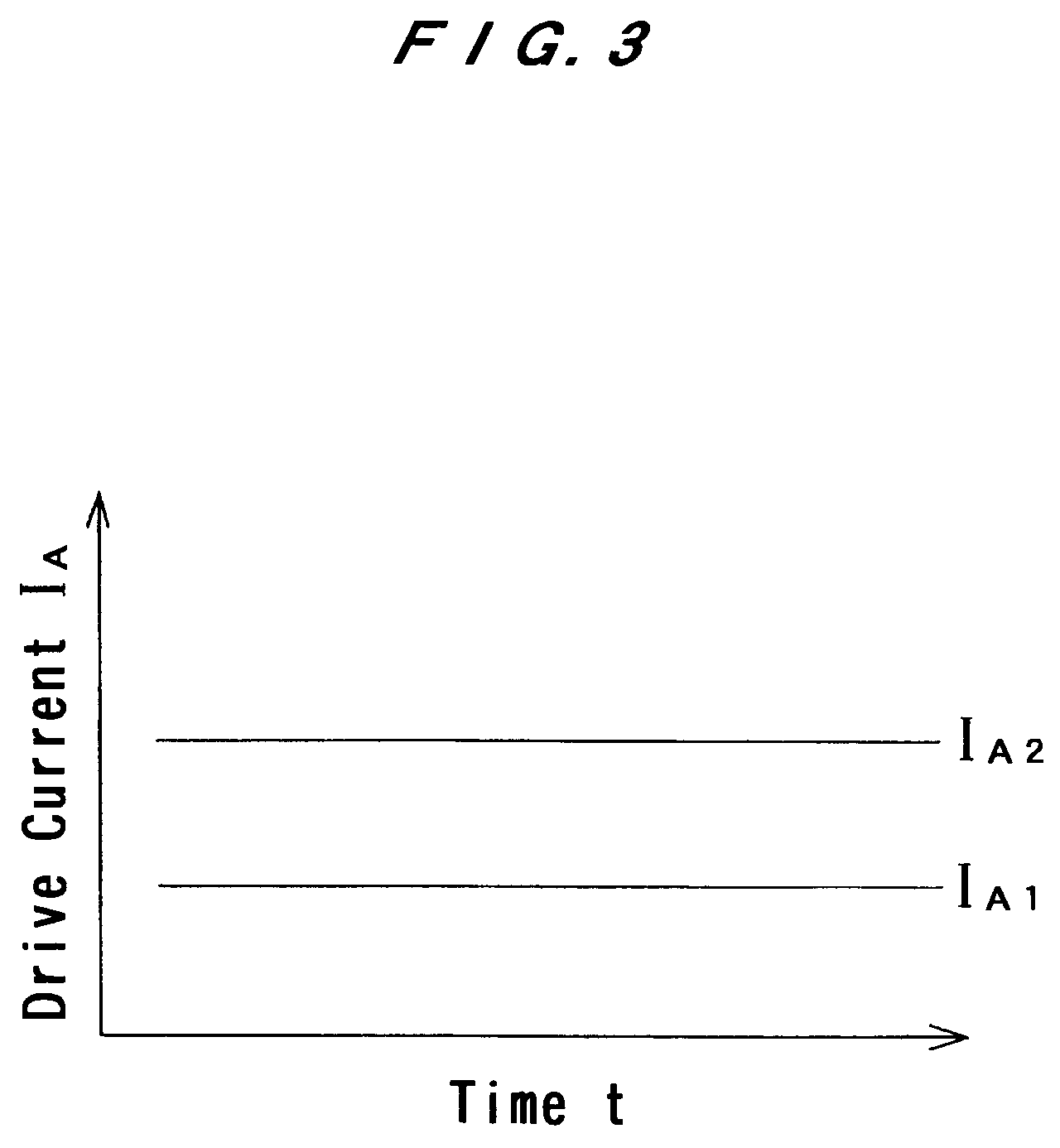

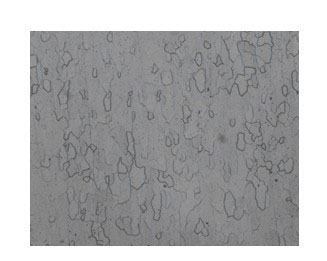

Polishing apparatus

InactiveUS7189139B2Avoid polishingEasy to operatePolishing machinesRevolution surface grinding machinesDriving currentCurrent sensor

A polishing apparatus can detect completion of initialization of a polishing pad quantitatively. The polishing apparatus has a polishing table having a polishing pad attached thereto and a substrate holder configured to bring a surface of a substrate into contact with the polishing pad and press the substrate against the polishing pad. The polishing apparatus also has a drive mechanism operable to drive at least one of the polishing table and the substrate holder so as to provide a relative movement between the polishing pad and the substrate. The polishing apparatus includes a current sensor operable to detect a drive current supplied to the driving mechanism. The polishing apparatus also includes a polishing pad condition detector operable to detect a condition of the polishing pad based on the drive current detected by the current sensor when the dummy substrate is polished by a relative movement between the polishing pad and a dummy substrate held by the substrate holder.

Owner:EBARA CORP

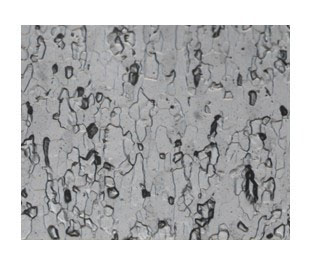

Method for displaying metallurgical structure of ultralow-carbon cold roll annealed interstitial-free steel

ActiveCN101984334AClear grain boundariesAvoid erosionPreparing sample for investigationAqueous alcoholDistilled water

The invention relates to a method for displaying the metallurgical structure of ultralow-carbon cold roll annealed interstitial-free steel, which belongs to the technical field of physical detection. The invention is used for realizing the aims of clear display and easy operation of the metallurgical structure of ultralow-carbon cold roll annealed interstitial-free steel. The method comprises the following steps: a. coarse grinding; b. polishing; c. erosion by a first reagent: eroding the polished sample in the first reagent for 10-20 seconds, wherein the first reagent is 5.5-6.5% nitric acid alcohol; d. erosion by a second reagent: eroding the sample in the second reagent immediately after taking out the sample from the first reagent, until the sample surface is evenly black, wherein the second reagent is prepared from 3-7g of sodium pyrosulfite, 9-12g of anhydrous sodium thiosulfate and 70-100ml of distilled water; and e. sample detection: wiping the sample with the first reagent to remove black on the surface, rinsing with alcohol, and blow-drying so that people can observe the sample. The method has the advantages of simpleness, simplified steps, easy master, resource conservation and high efficiency; the obtained structure has the advantages of clear grain boundary and no double grain boundary, and can properly reflect the annealing situation; and thus, the method is very suitable for field usage, and performs important functions on reasonably controlling technological parameters and ensuring product performance in the production field.

Owner:HEBEI IRON AND STEEL

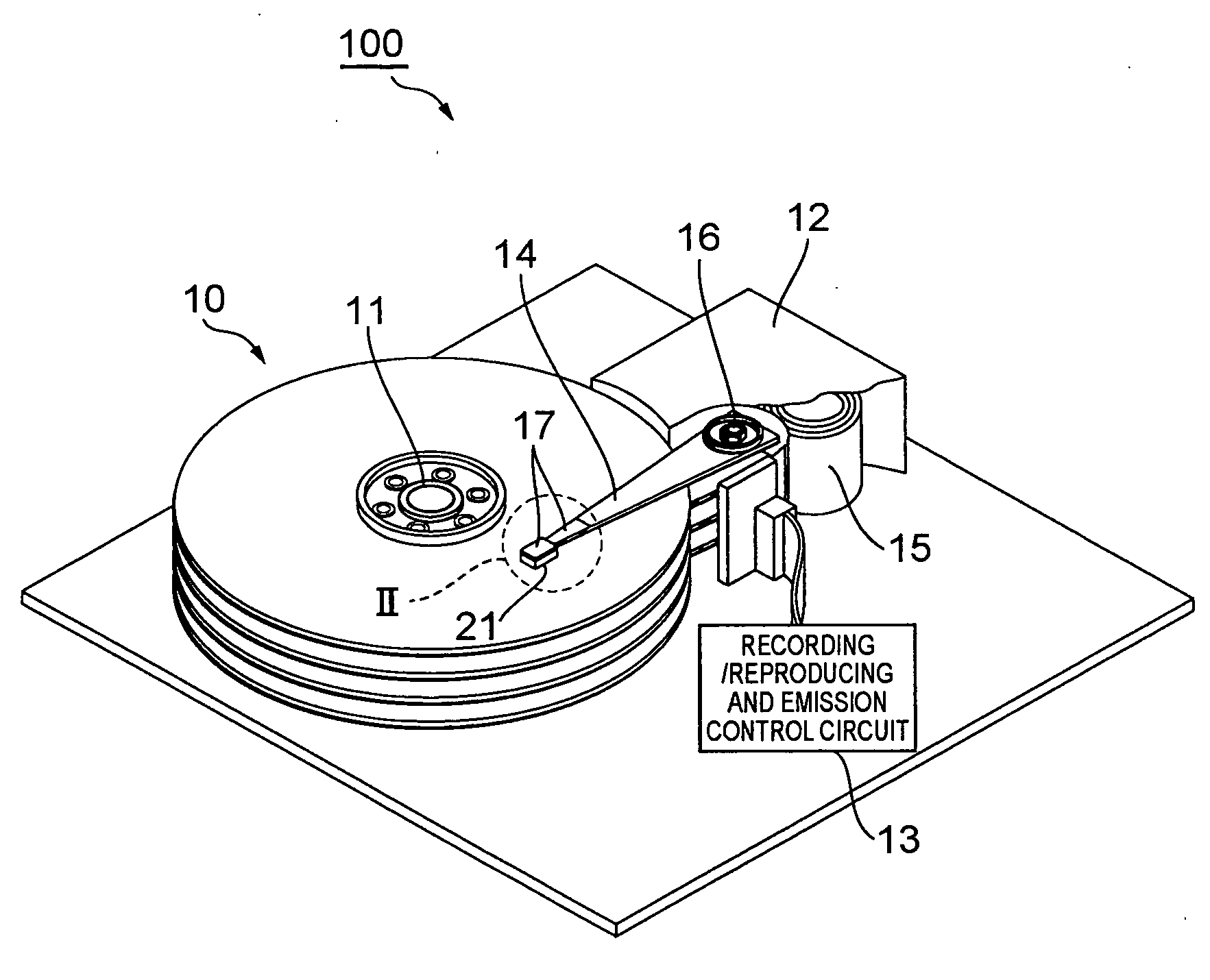

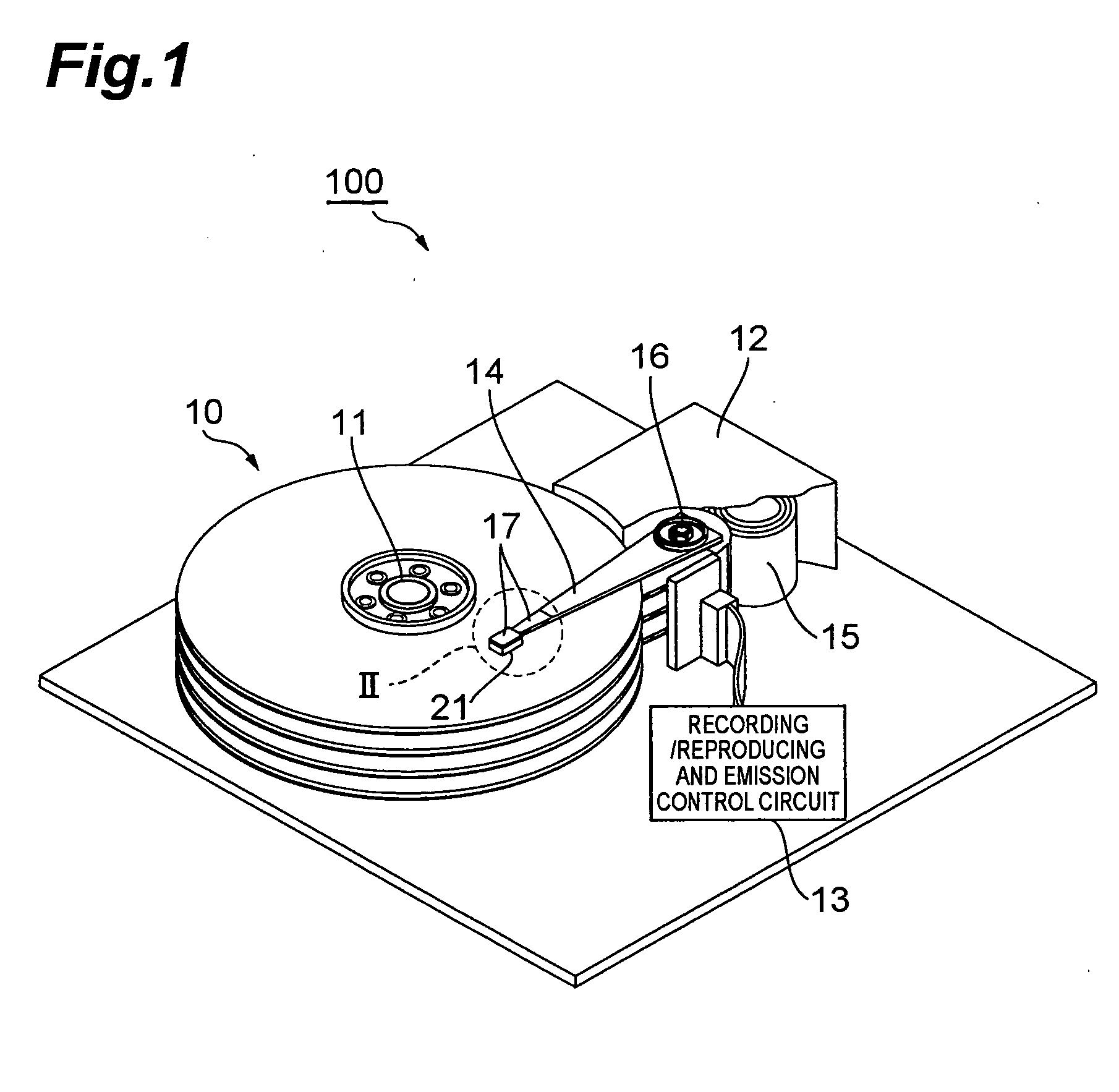

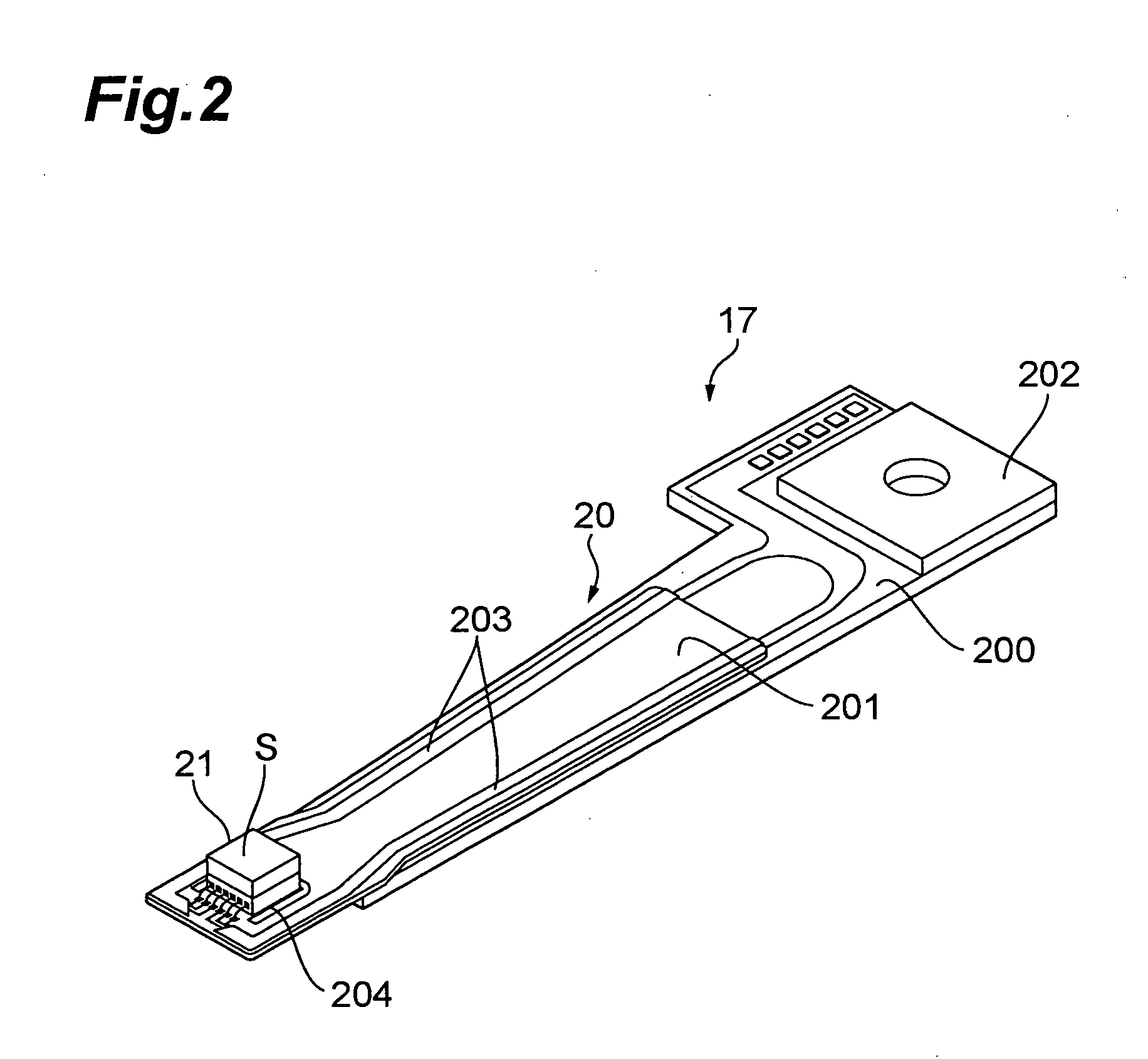

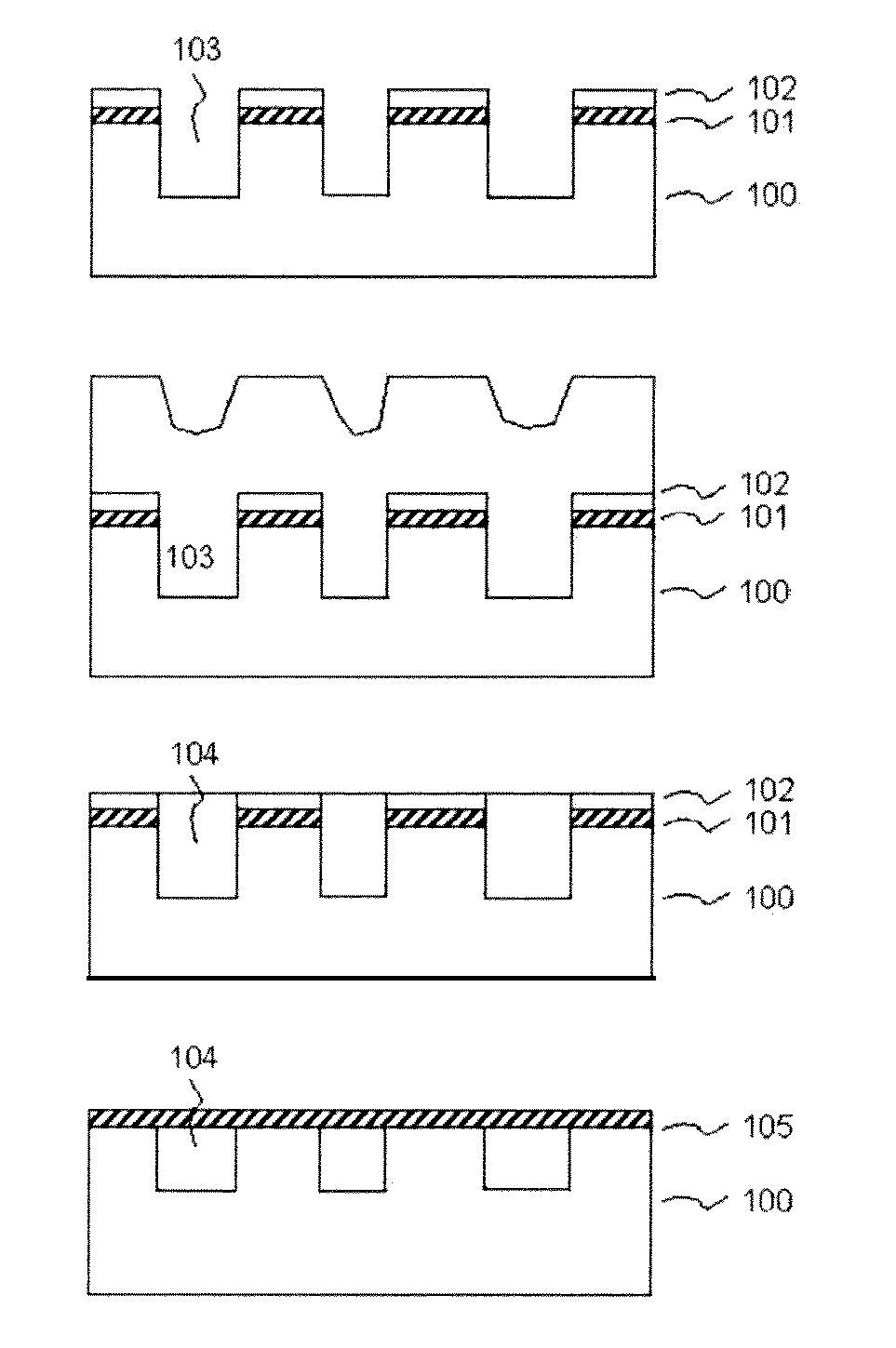

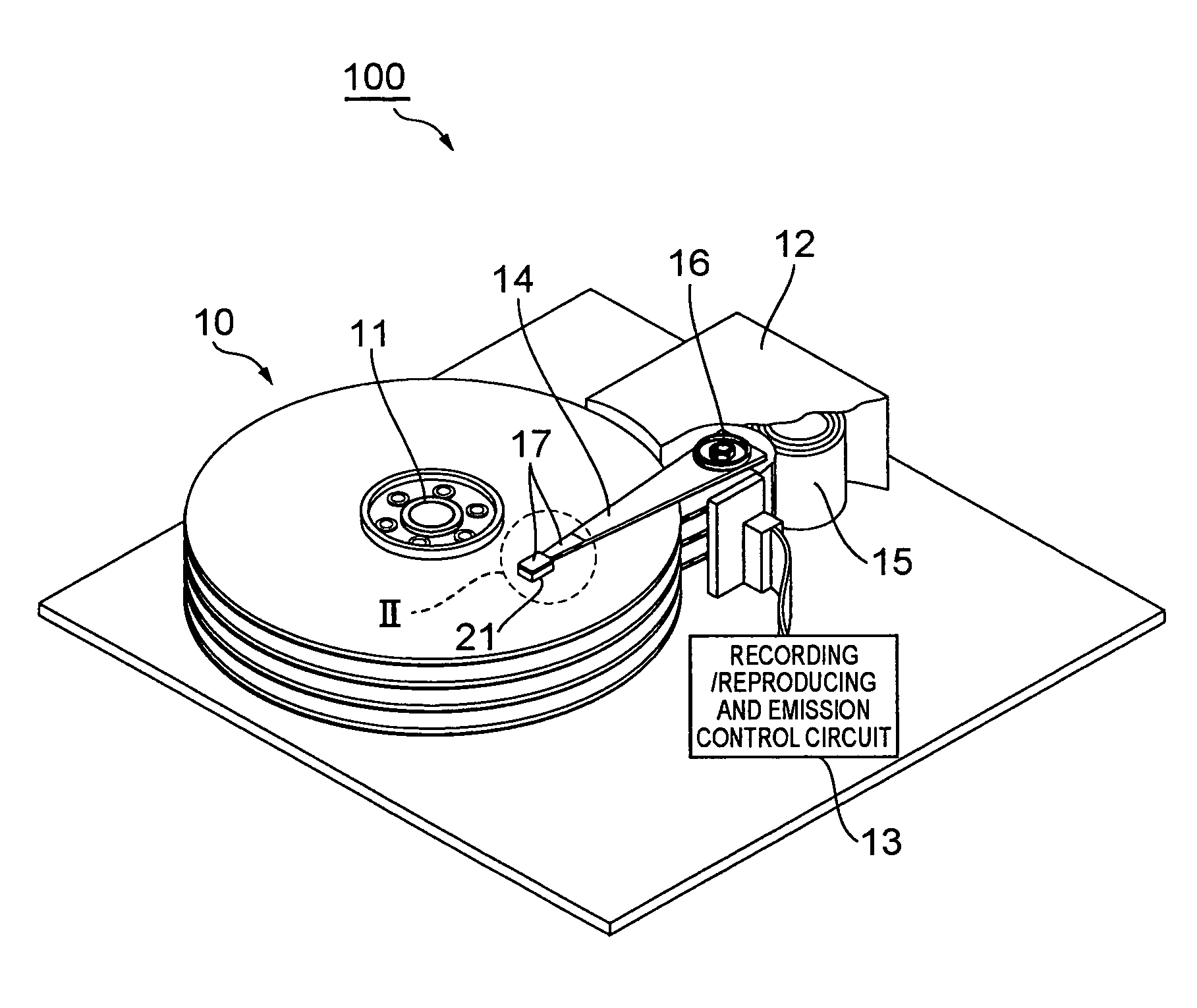

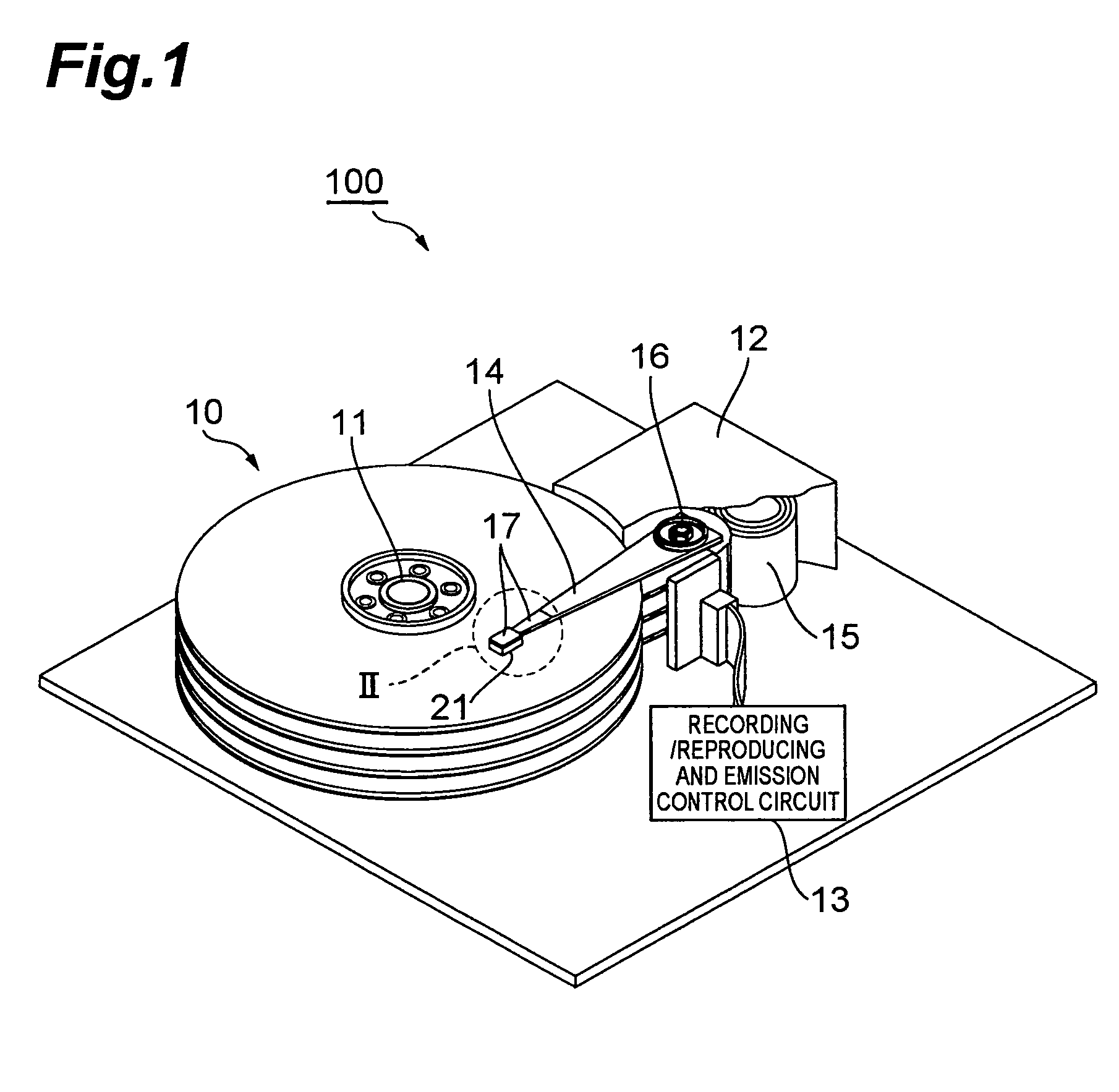

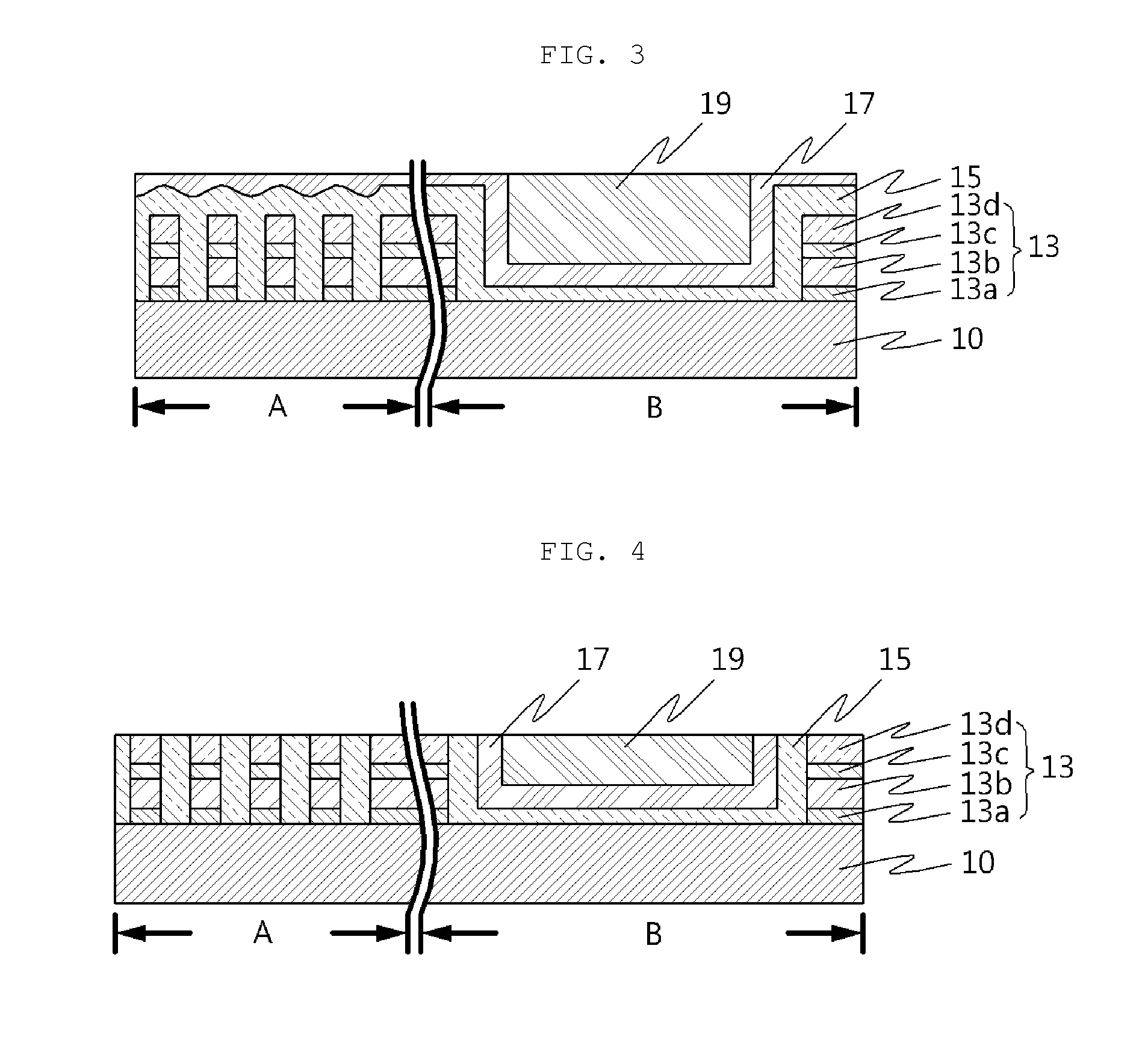

Method of manufacturing thermally assisted magnetic head

ActiveUS20090188891A1Easy to flattenEasy to controlDecorative surface effectsOptical articlesBody PatterningEngineering

A method comprises a first multilayer body forming step of forming a first multilayer body on a first cladding layer, the first multilayer body including a core layer and a first polishing stop layer in order from the first cladding layer side; a first multilayer body patterning step of pattering the first multilayer body, so as to expose the first cladding layer about the patterned first multilayer body; a second multilayer body forming step of forming a second multilayer body on the exposed first cladding layer and patterned first multilayer body, the second multilayer body including a second cladding layer and a second polishing stop layer in order from the first cladding layer side; and a removing step of polishing away a part of the second multilayer body formed on the first multilayer body.

Owner:TDK CORPARATION

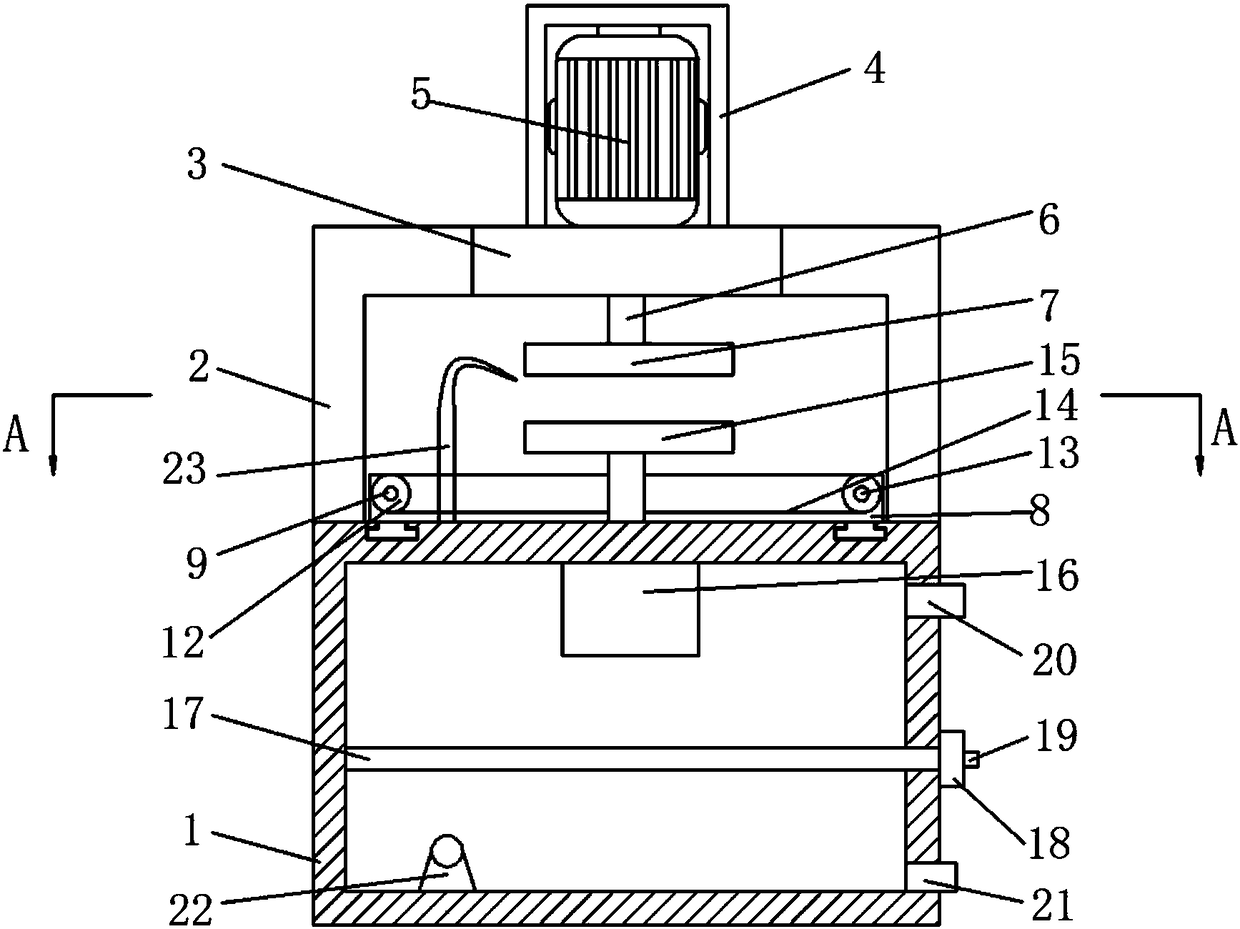

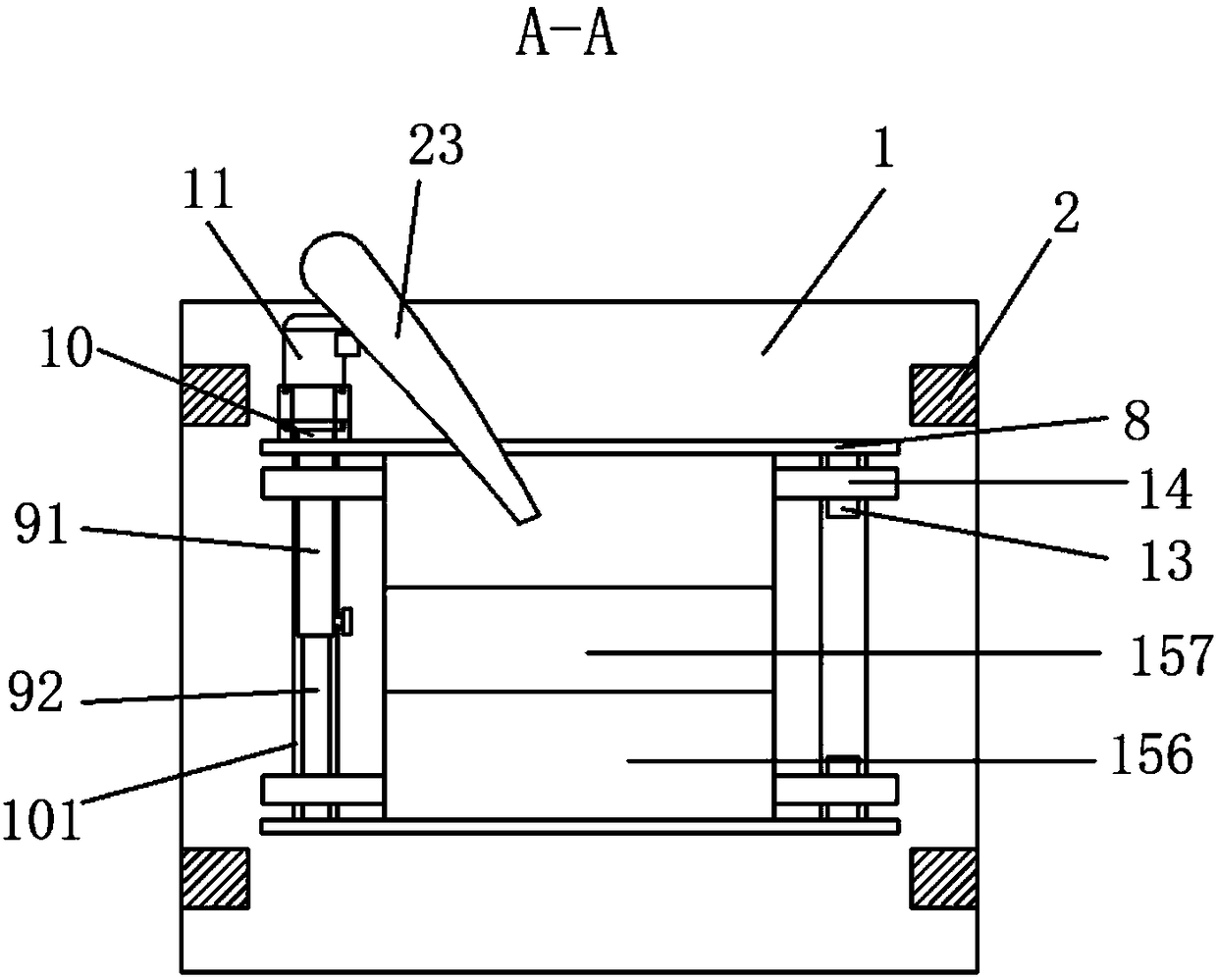

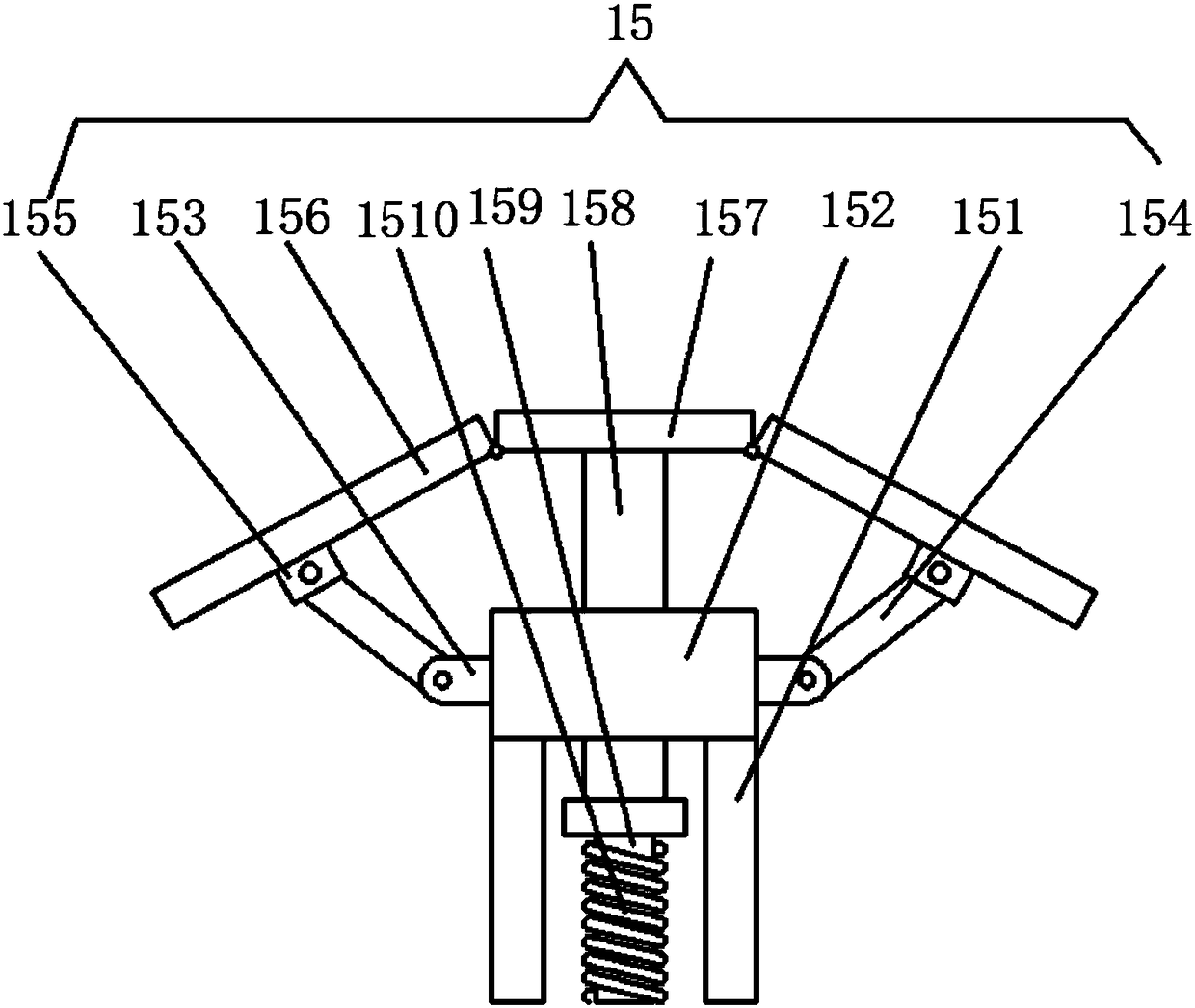

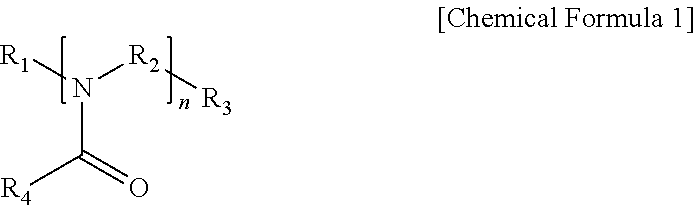

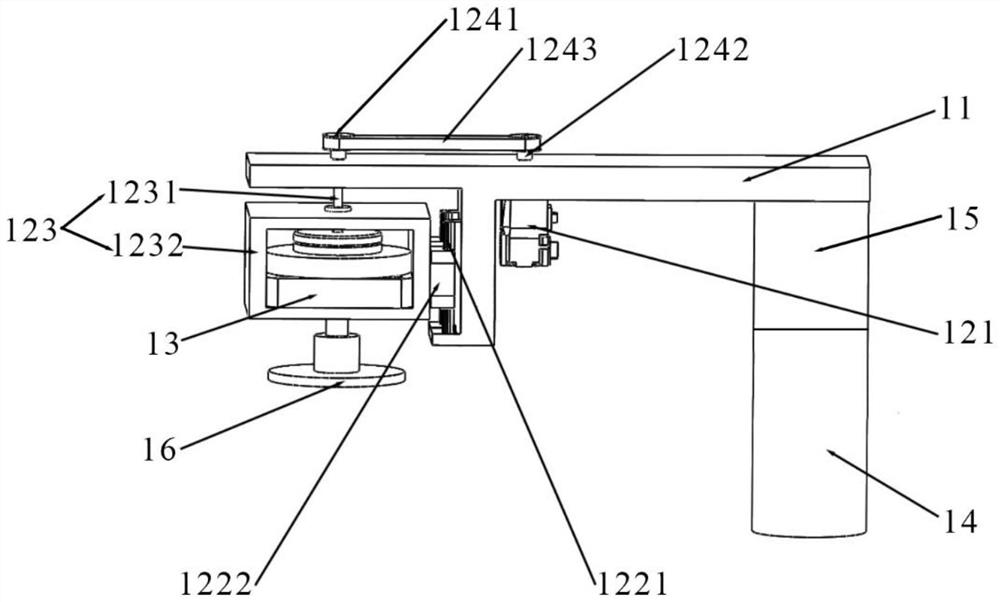

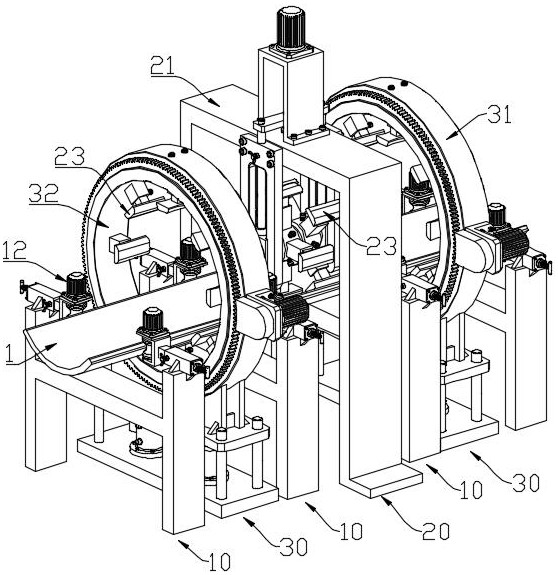

LED ceramic support polishing and grinding machine and grinding method

InactiveCN108115486AConsistent polishingStrong applicabilityGrinding feedersGrinding work supportsMotor shaftEngineering

The invention discloses an LED ceramic support polishing and grinding machine, and belongs to the technical field of ceramic support polishing and grinding. The LED ceramic support polishing and grinding machine comprises a box base, wherein two supports are arranged on the front side and the rear side of the top of the box base; a supporting plate is arranged between the tops of the two supports;a motor cover is arranged on the top of the supporting plate; a polishing motor is arranged in a cavity of the motor cover; a polishing motor shaft is arranged at a bottom output end of the polishingmotor; the polishing motor shaft penetrates through the supporting plate and is connected with a polishing grinding wheel plate; gears on the left side and the right side are connected through a chain; adjustable supporting platform is arranged in the middle of the top of the box base; a water pump is arranged on the bottom of the cavity of the box base and is connected with a water spraying goose neck pipe; and the water spraying goose neck pipe penetrates through the box base and extends to the left side of the polishing grinding wheel plate. The device is simple in working principle and high in applicability, and meets polishing and grinding of ceramic supports with various sizes.

Owner:董桂芳

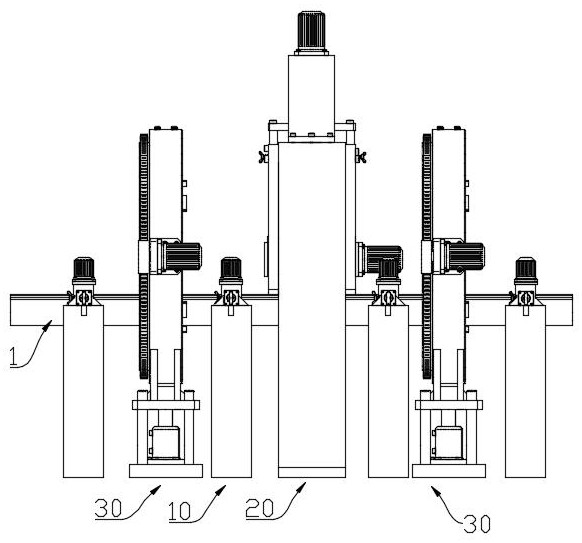

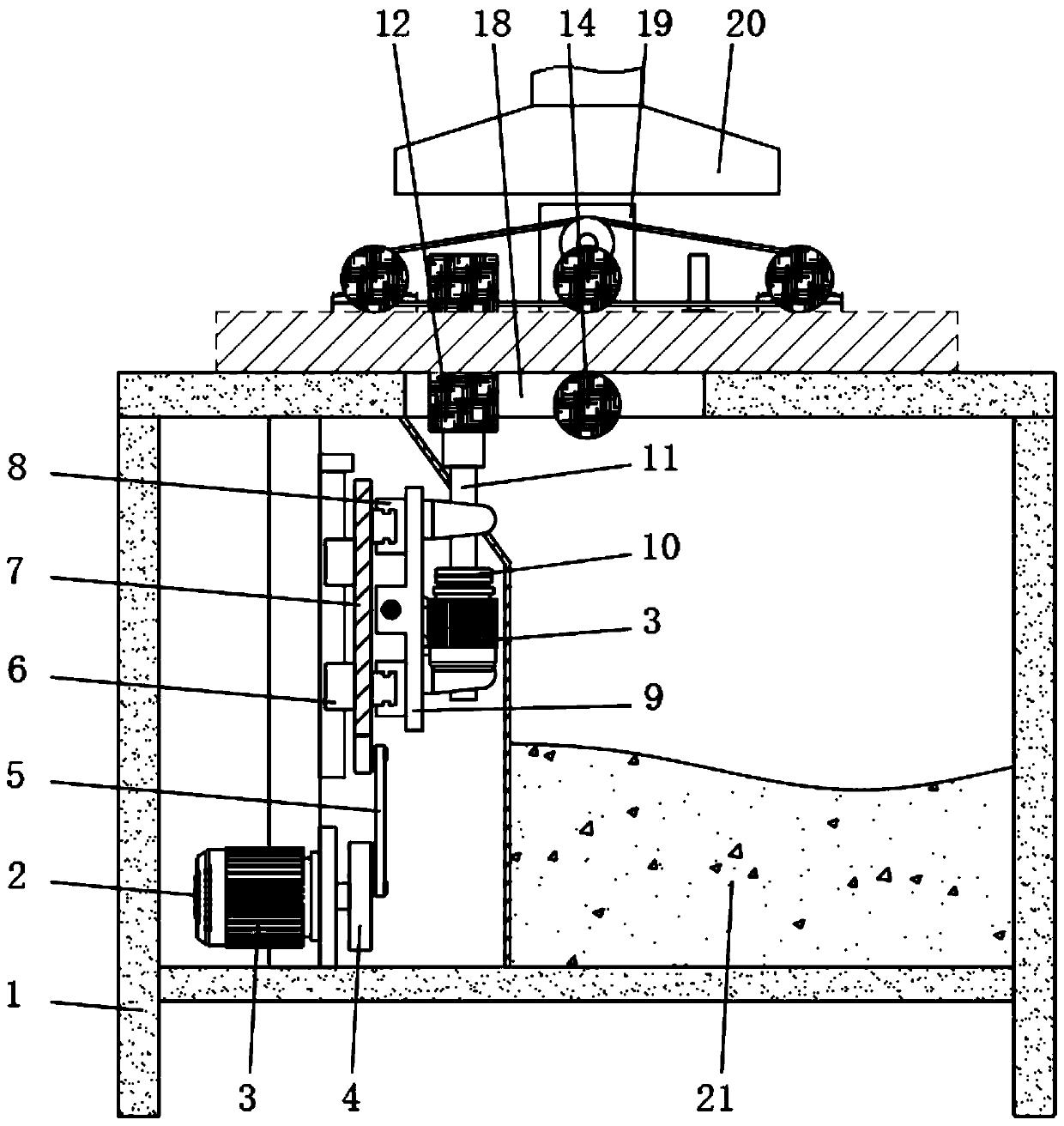

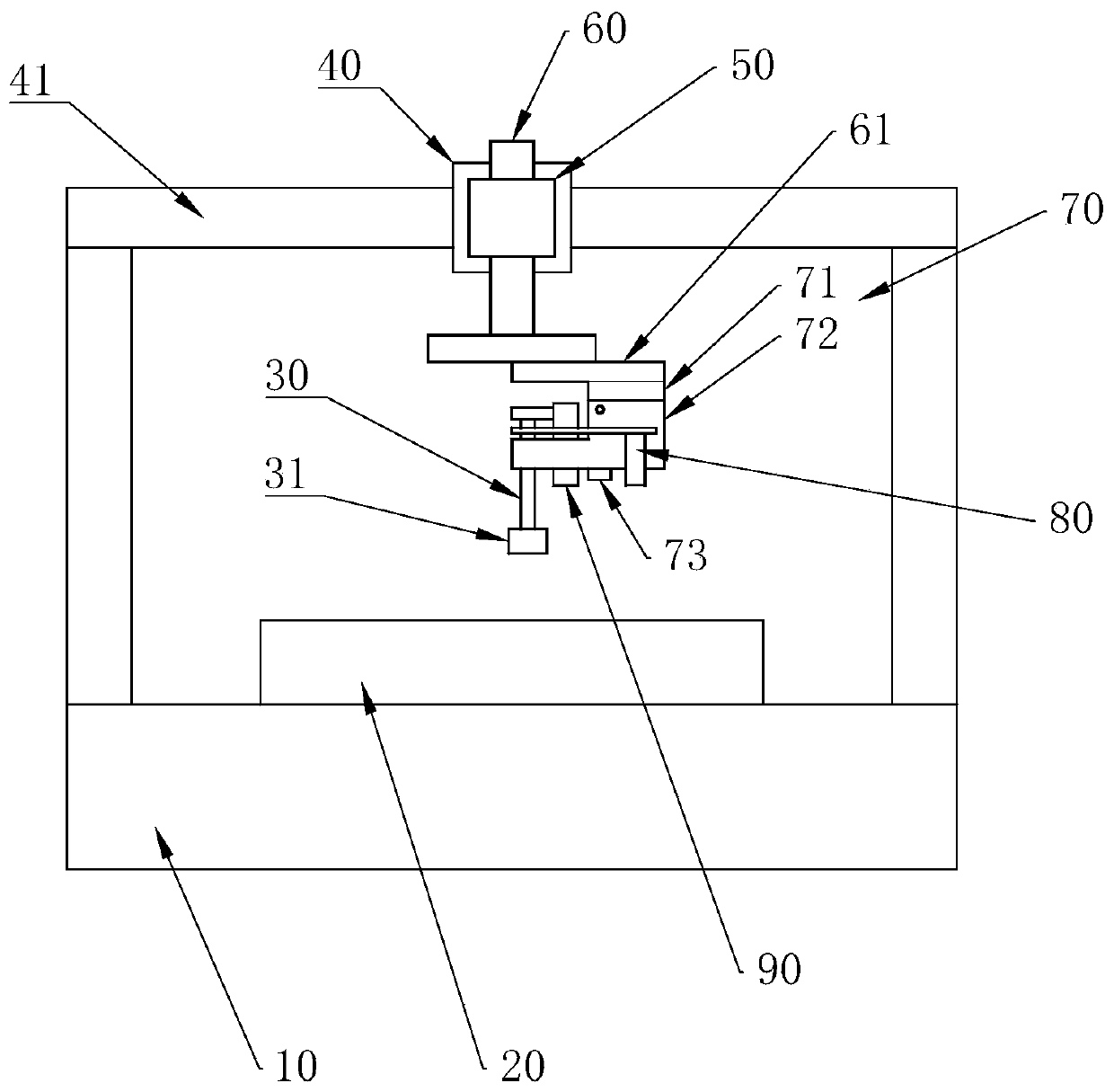

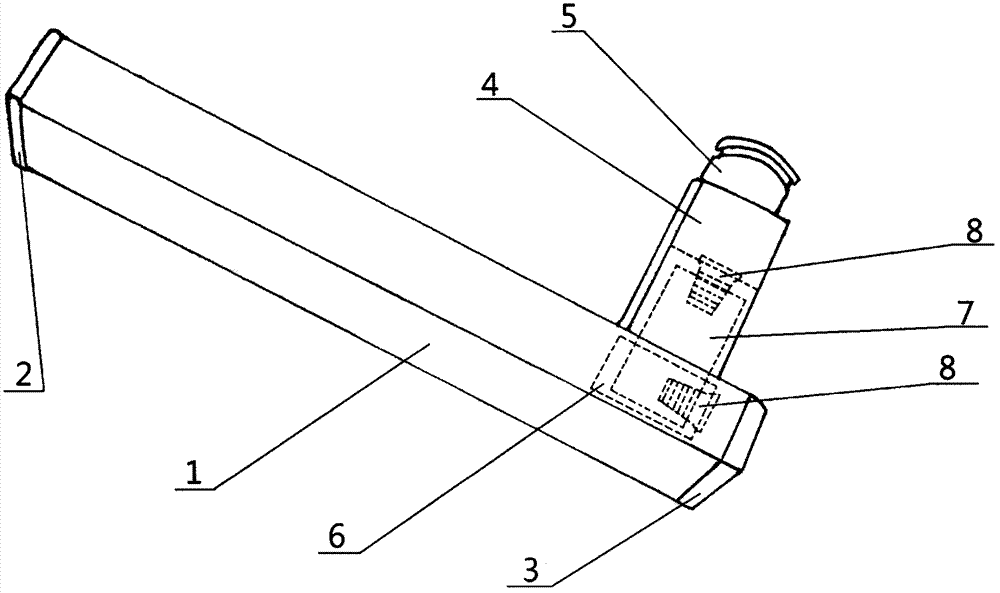

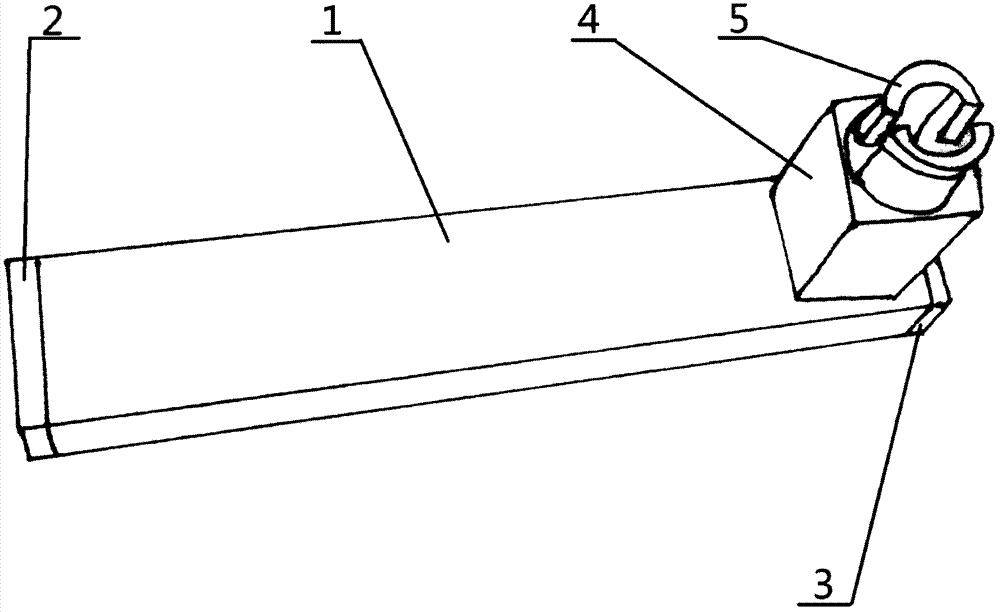

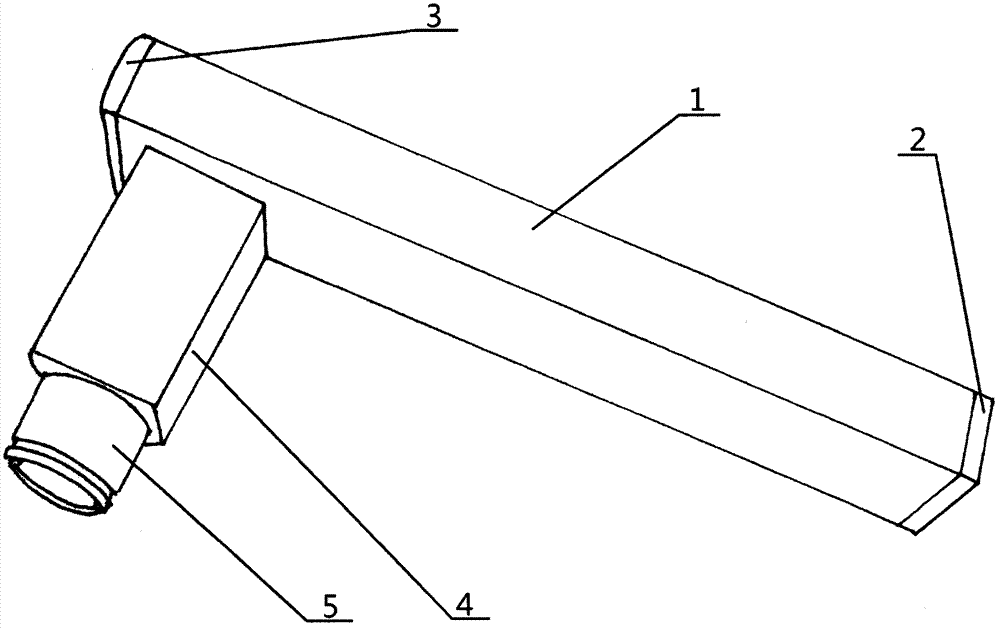

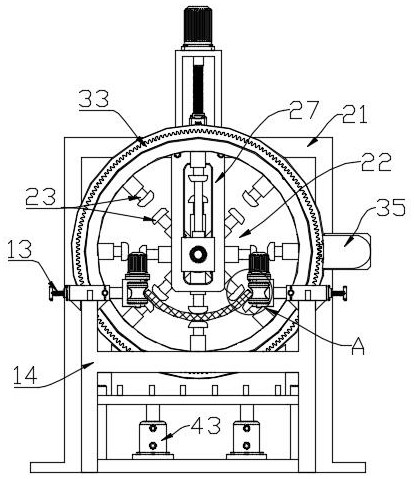

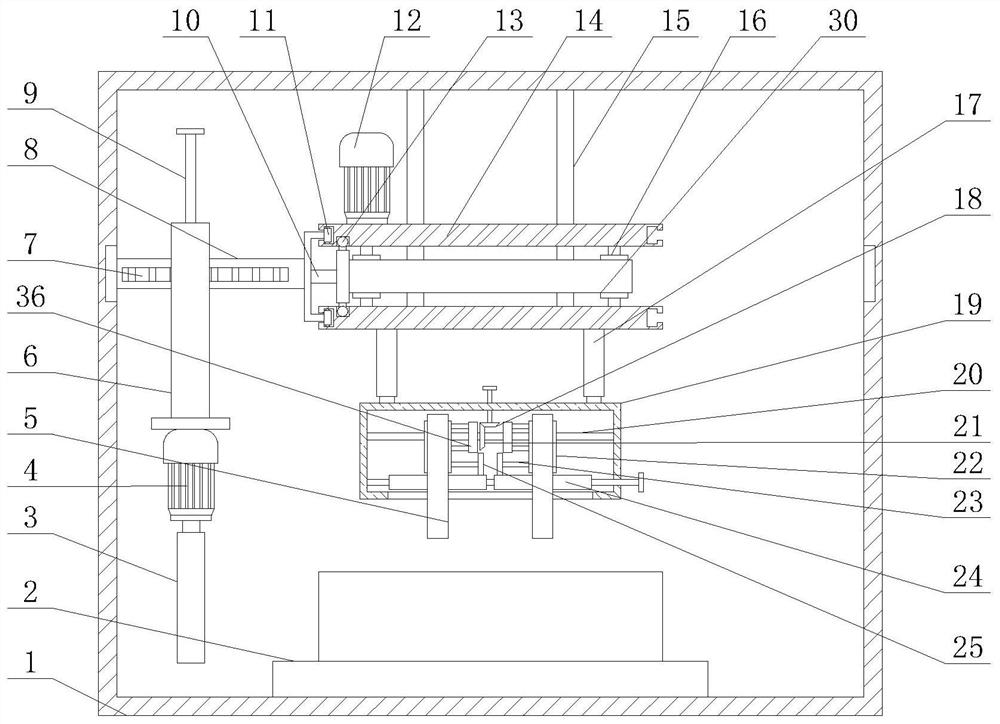

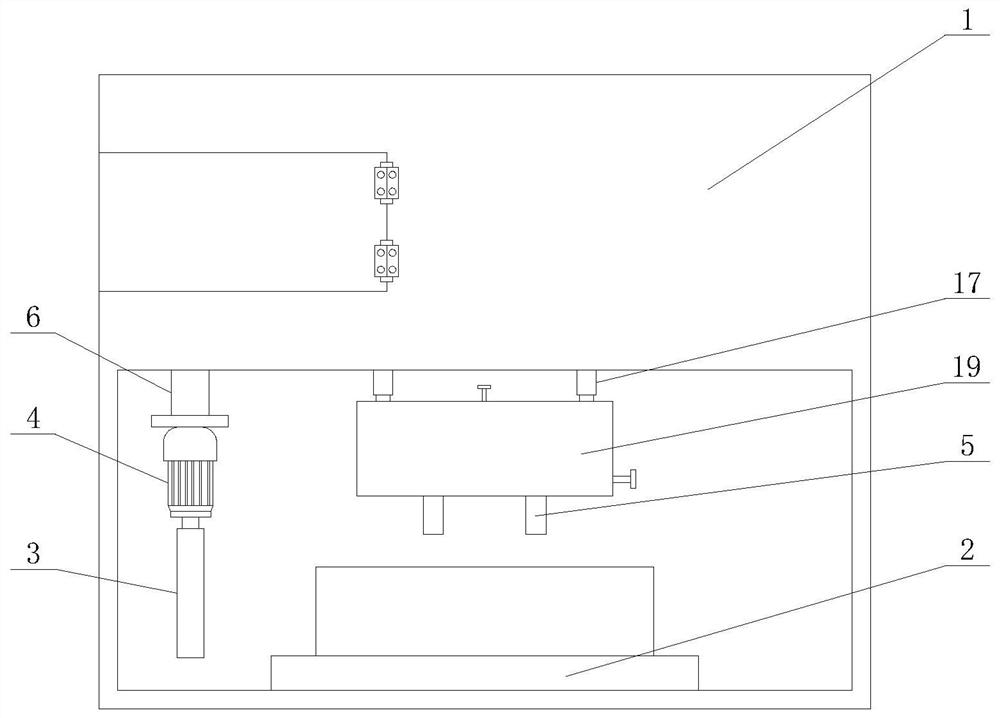

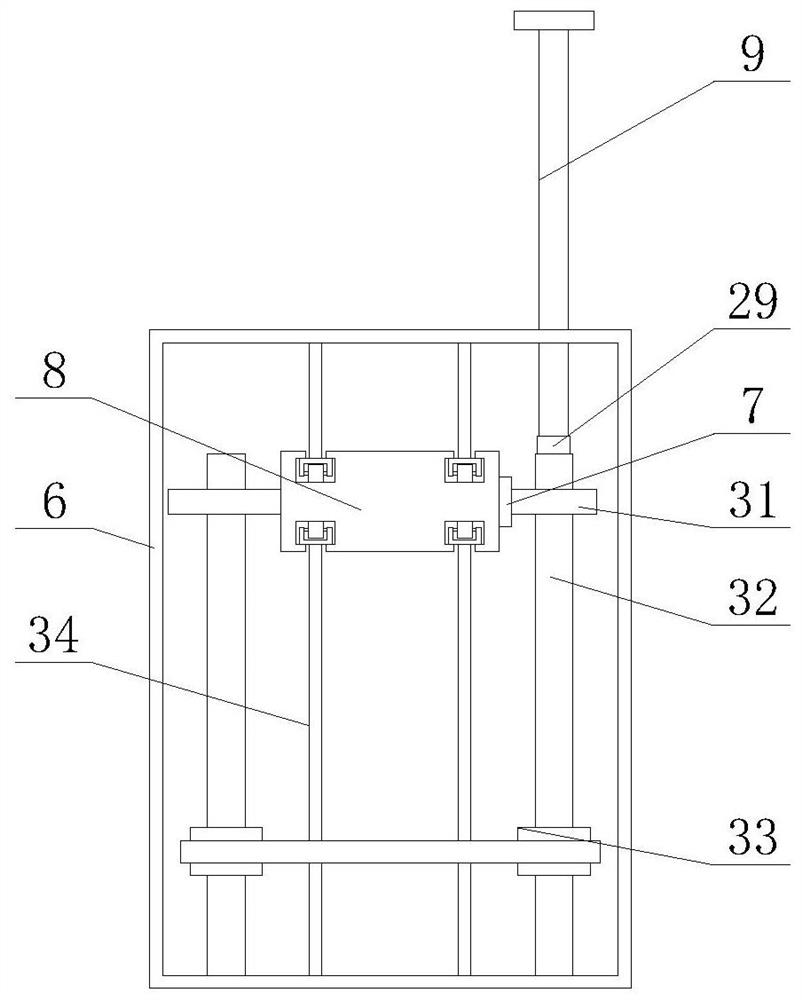

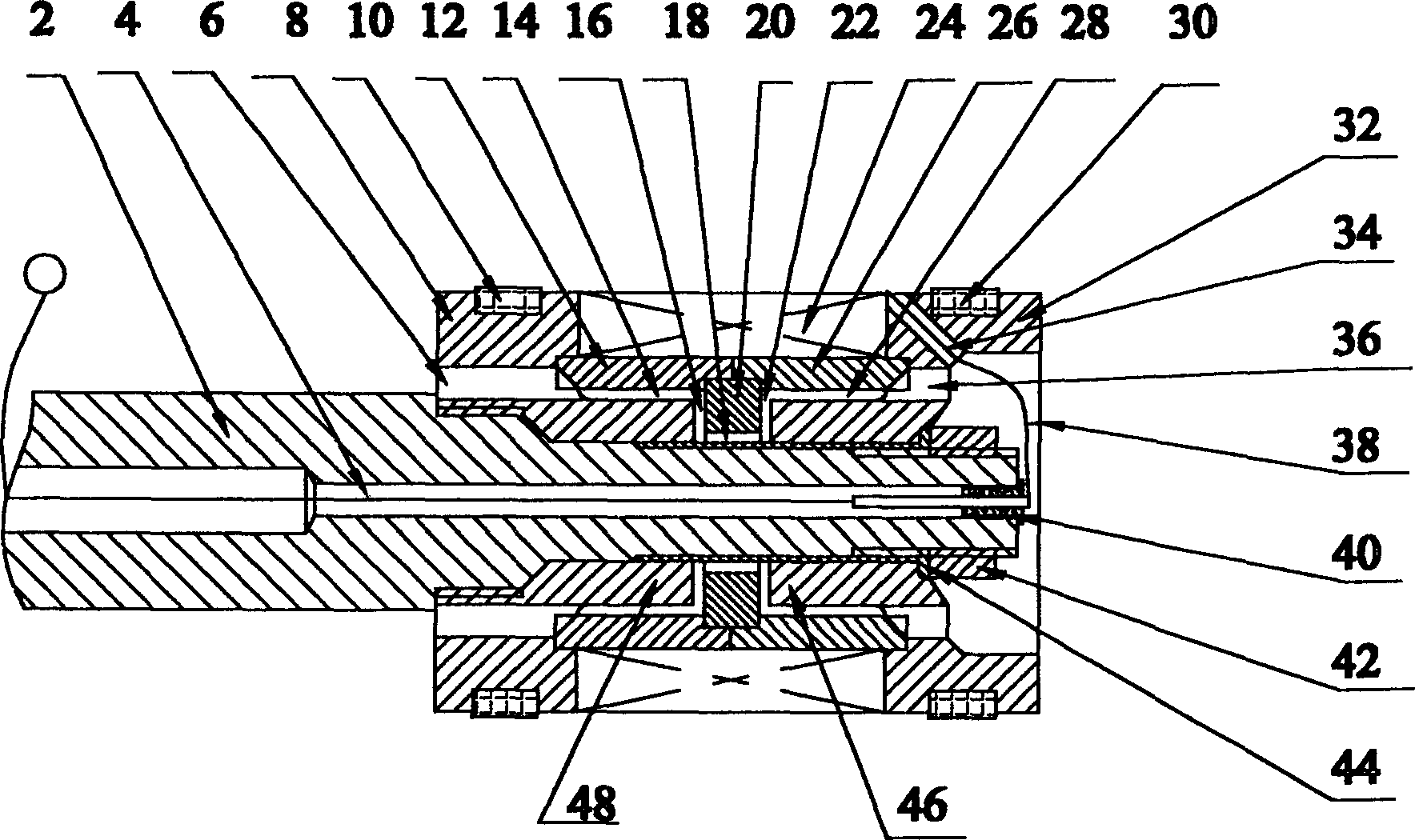

Polishing device for arc-shaped slot array antenna mounting plate

ActiveCN112454147AImprove polishing efficiencySave disassembly timePolishing machinesGrinding feedersPhysicsDrive motor

The invention relates to a polishing device for an arc-shaped slot array antenna mounting plate. The polishing device is characterized in that each conveying mechanism comprises a pair of parallel conveying wheels used for conveying the antenna mounting plate, the distance between the conveying wheels is adjustable, the conveying wheels are connected with driving motors, and multiple sets of conveying mechanisms are arranged; at least one set of inner cambered surface polishing mechanisms are arranged, each inner cambered surface polishing mechanism comprises a portal frame and a rotating part, a plurality of polishing brushes are uniformly arranged on each rotating part along the circumference, and the distance between the head of each polishing brush and a rotating shaft of the corresponding rotating part is adjustable; and at least one set of outer cambered surface polishing mechanisms are located between the conveying mechanisms, at least one set of conveying mechanisms are arranged between the inner cambered surface polishing mechanisms and the outer cambered surface polishing mechanisms, each outer cambered surface polishing mechanism comprises an outer ring base and an innerring coaxially and rotationally arranged in the outer ring base, a lifting mechanism is arranged at the bottom of each outer ring base, a plurality of polishing brushes are evenly arranged on the inner wall of each inner ring in the circumferential direction, and the positions of the polishing brushes in the normal direction of the corresponding inner ring are adjustable. According to the polishing device, mounting plates of different thicknesses and different structures can be polished, and the polishing efficiency is high.

Owner:CHENGDU NANJIAO TECH

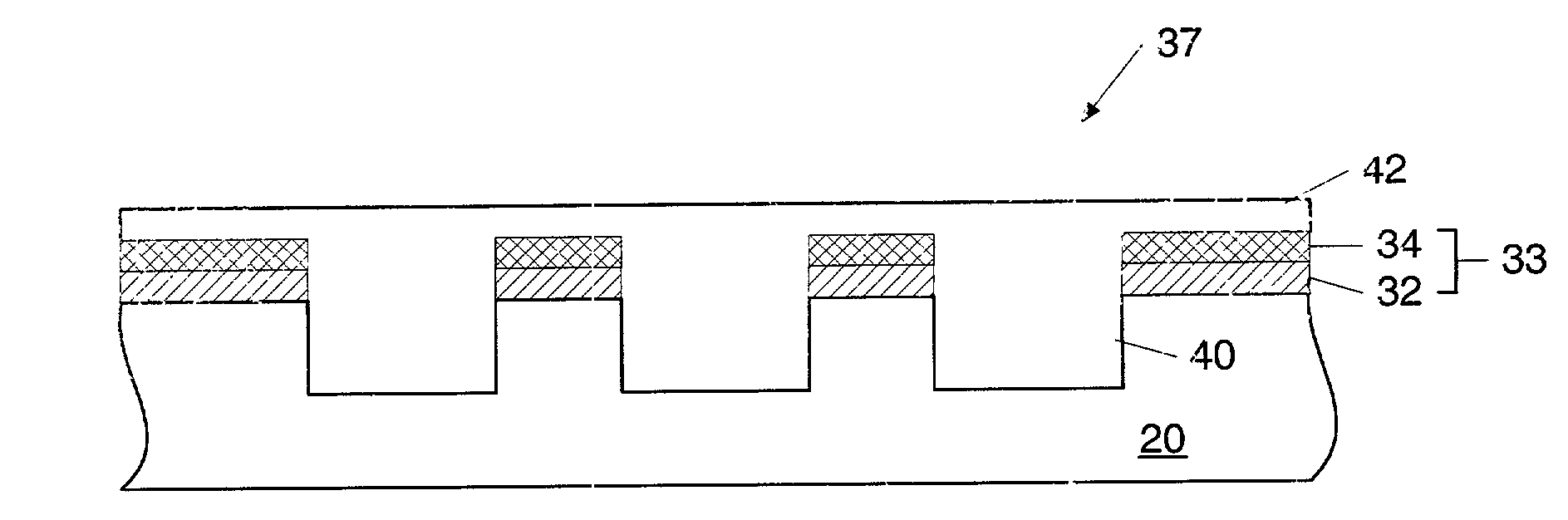

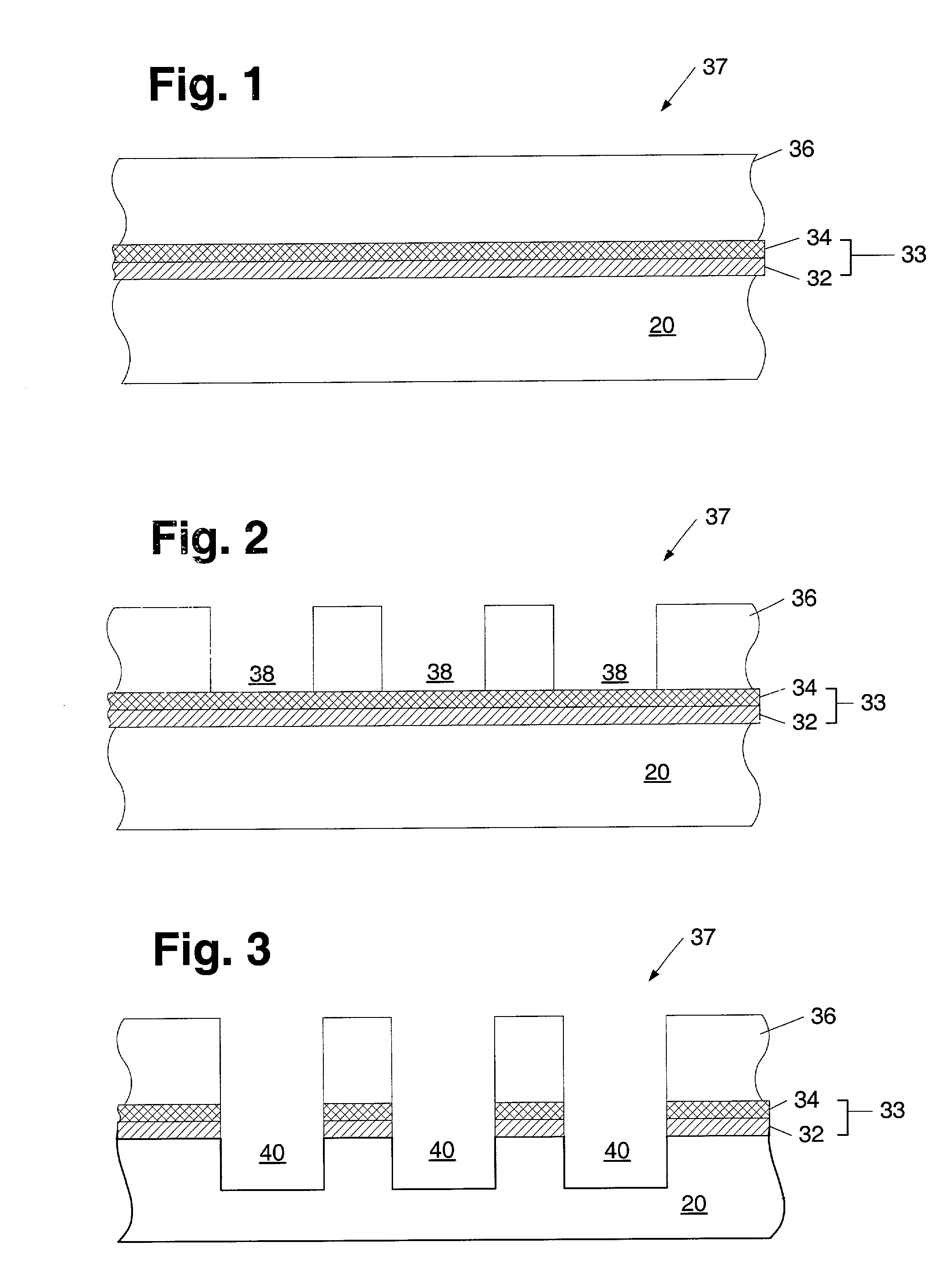

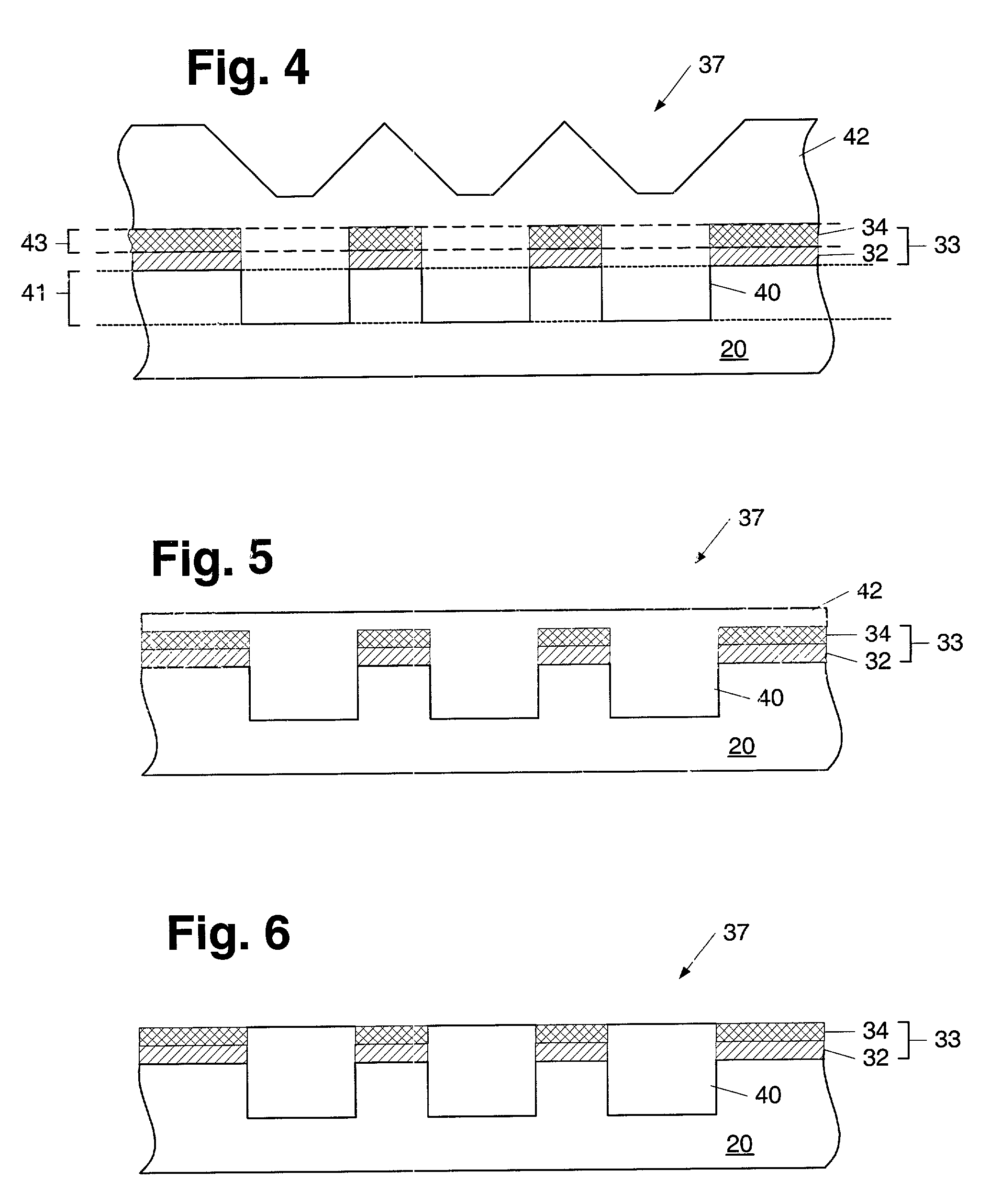

Method of making a planarized semiconductor structure

InactiveUS6969684B1Eliminate useReduce step heightSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

A method is provided for eliminating a polish stop layer from a polishing process. In particular, a method is provided which may include polishing an upper layer of a semiconductor topography to form an upper surface at an elevation above an underlying layer, wherein the upper surface does not include a polish stop material. Preferably, the upper surface of the topography formed by polishing is spaced sufficiently above the underlying layer to avoid polishing the underlying layer. The entirety of the upper surface may be simultaneously etched to expose the underlying layer. In an embodiment, the underlying layer may comprise a lateral variation in polish characteristics. The method may include using fixed abrasive polishing of a dielectric layer for reducing a required thickness of an additional layer underlying the dielectric layer. Such a method may be useful when exposing an underlying layer is desirable by techniques other than polishing.

Owner:INFINEON TECH LLC

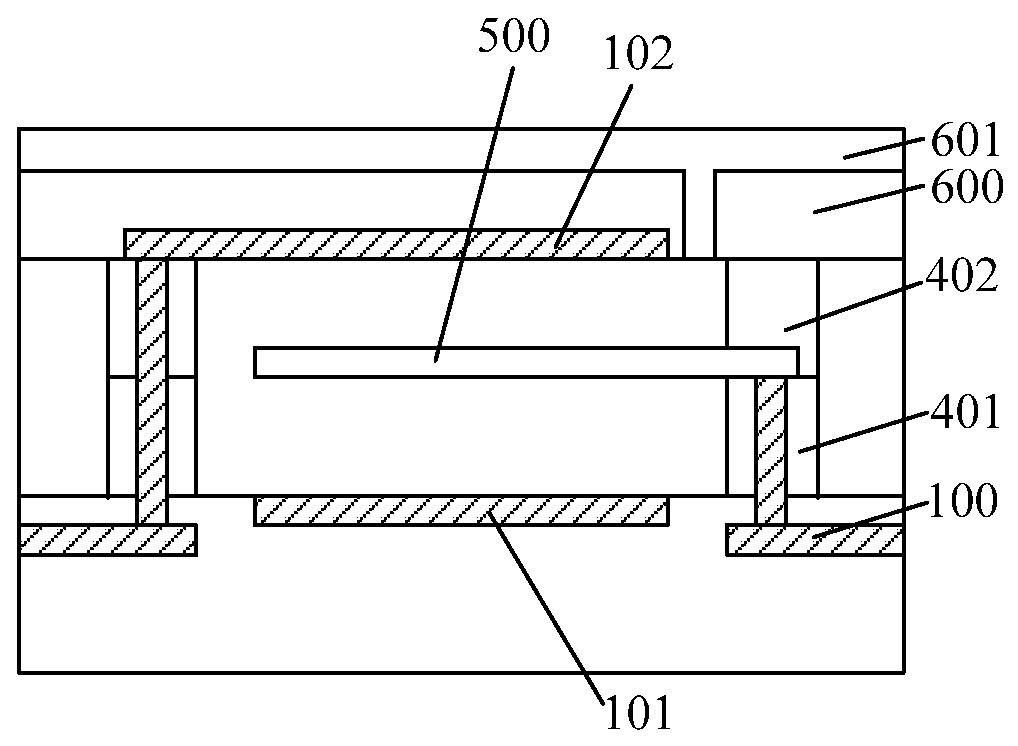

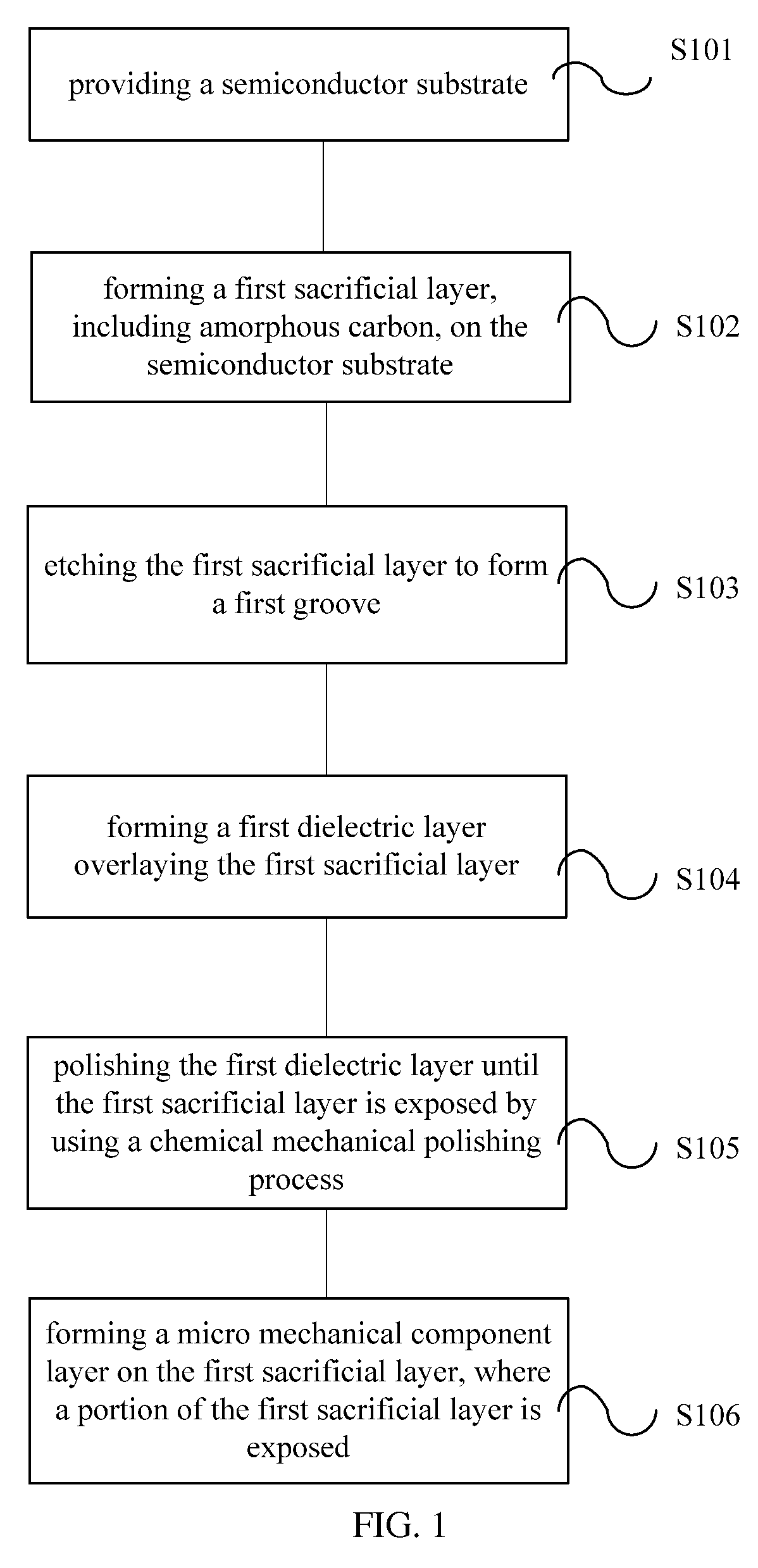

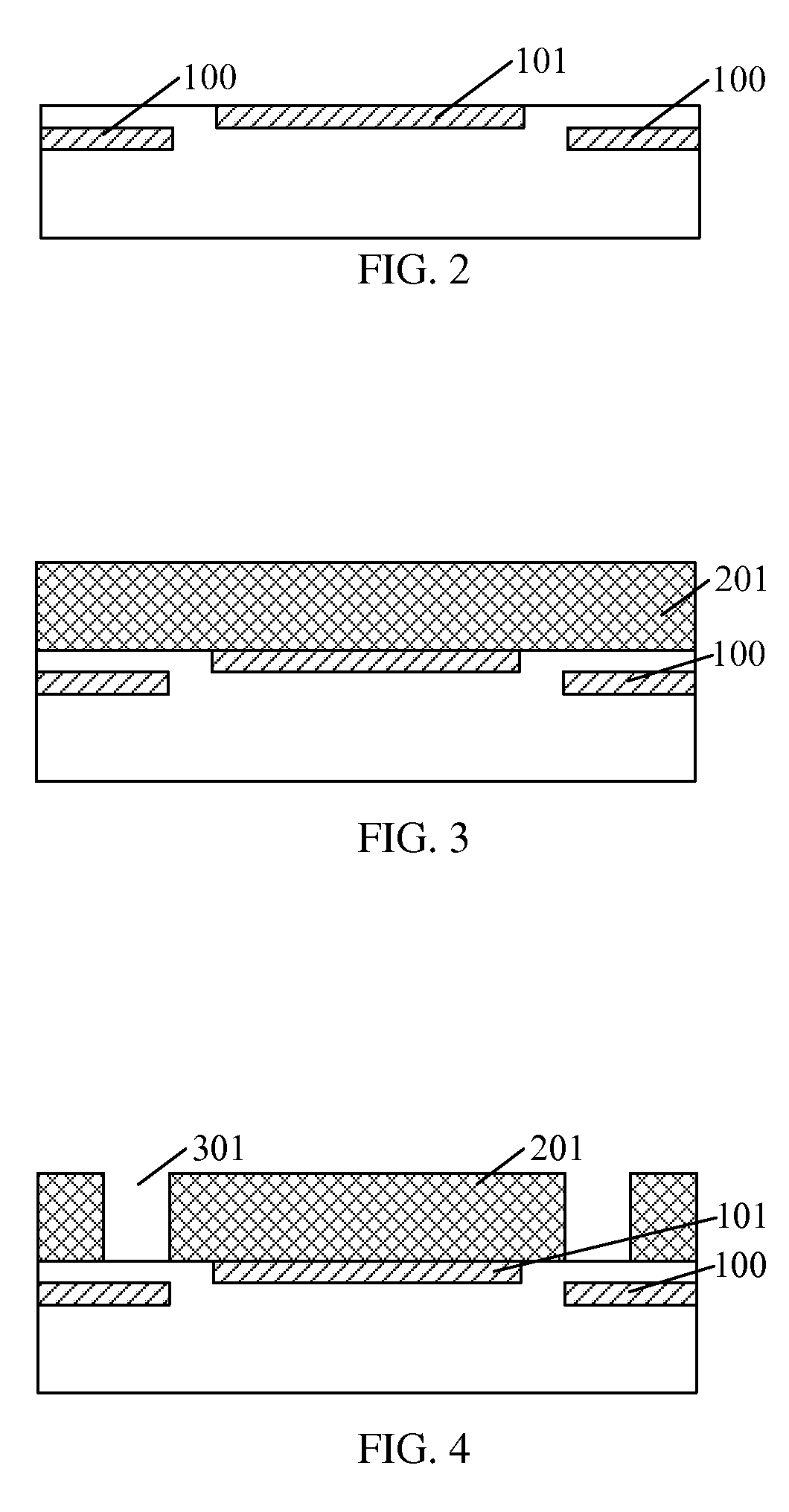

Method for manufacturing MEMS device

ActiveUS8877537B2Increase polishing speedAvoid over polishingAcceleration measurement using interia forcesImpedence networksInterconnectionDielectric layer

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

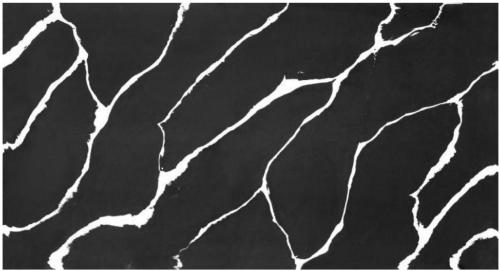

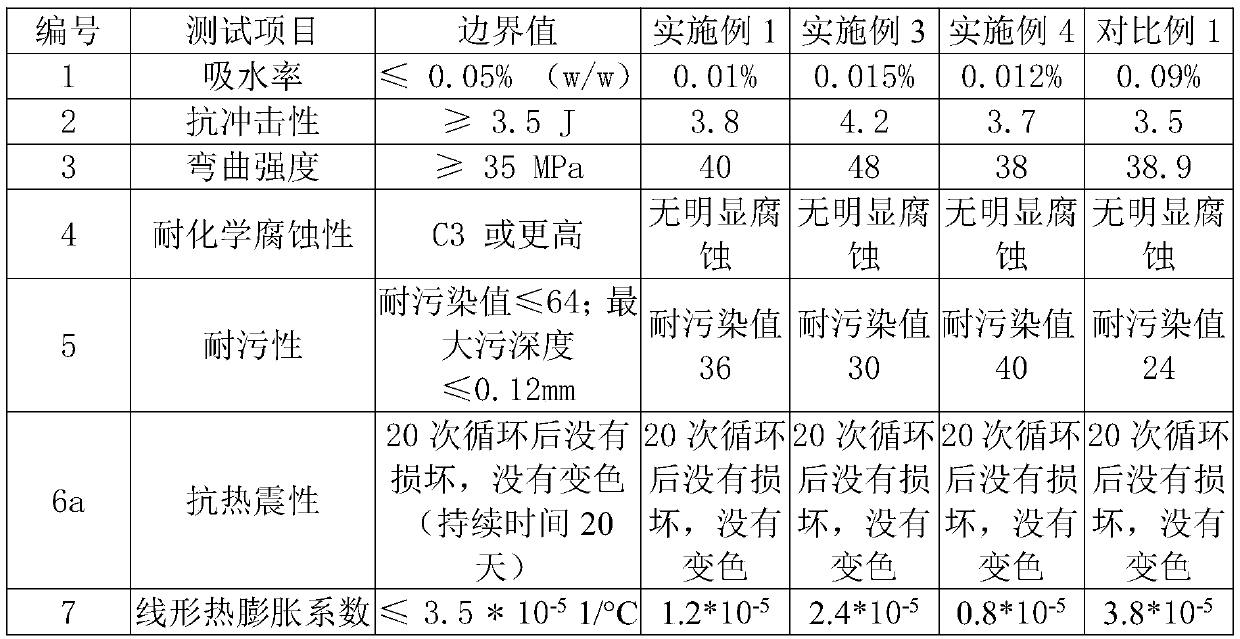

Marbleized quartzite plate and preparation method thereof

InactiveCN109664395ARich in colorImprove toughnessCeramic shaping apparatusMaterials preparationMaterials science

Owner:SUZHOU COZY HOUSE EQUIP

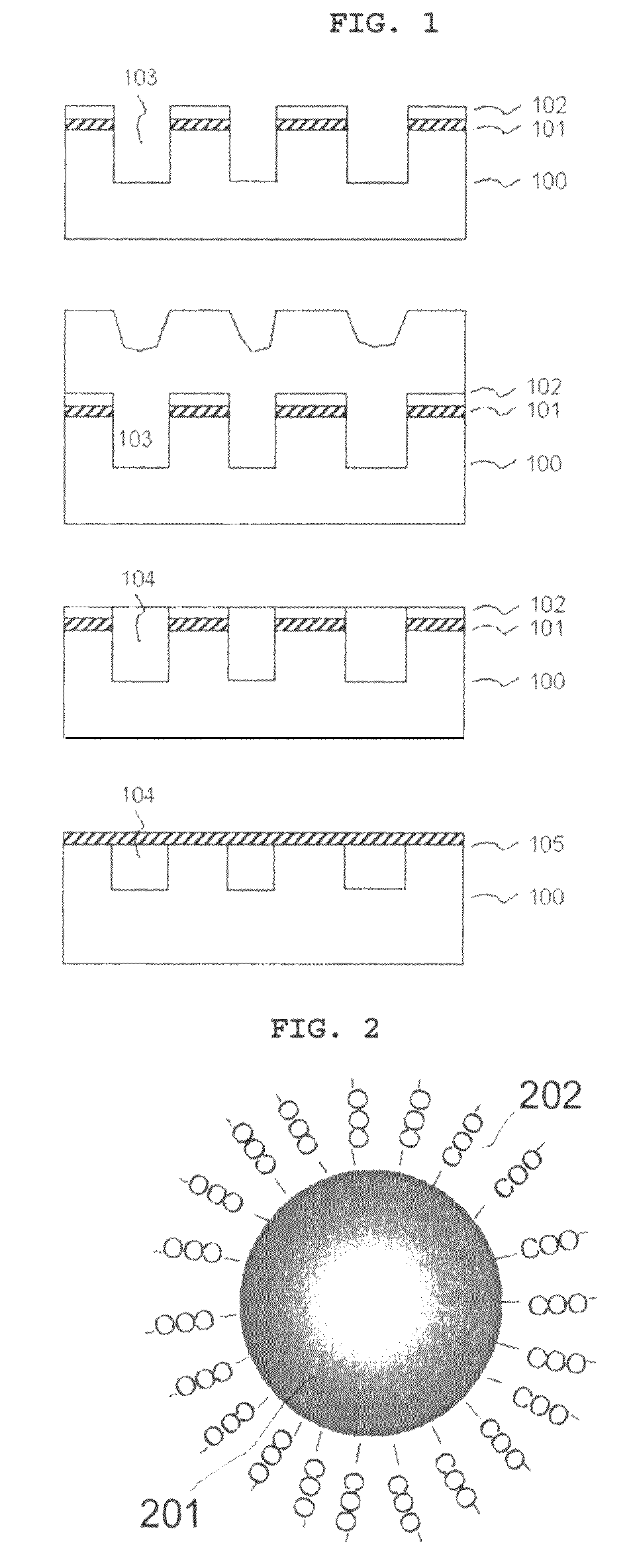

Adjuvant for CMP slurry

ActiveUS8062395B2Prevent materialImprove polishing selectivityPigmenting treatmentOther chemical processesAdjuvantSlurry

Disclosed is an adjuvant in use for a process of polishing a cationically charged material and an anionically charged material at the same time with abrasive particles, which is absorbed onto the cationically charged material thereby to restrain the cationically charged material from being polished, resulting in raising a polishing selectivity of the anionically charged material, wherein the adjuvant comprises polymer particles having a core-shell structure with a nano-scale particle size smaller than that of the abrasive particles, surfaces of which are anionically charged. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed.

Owner:LG CHEM LTD

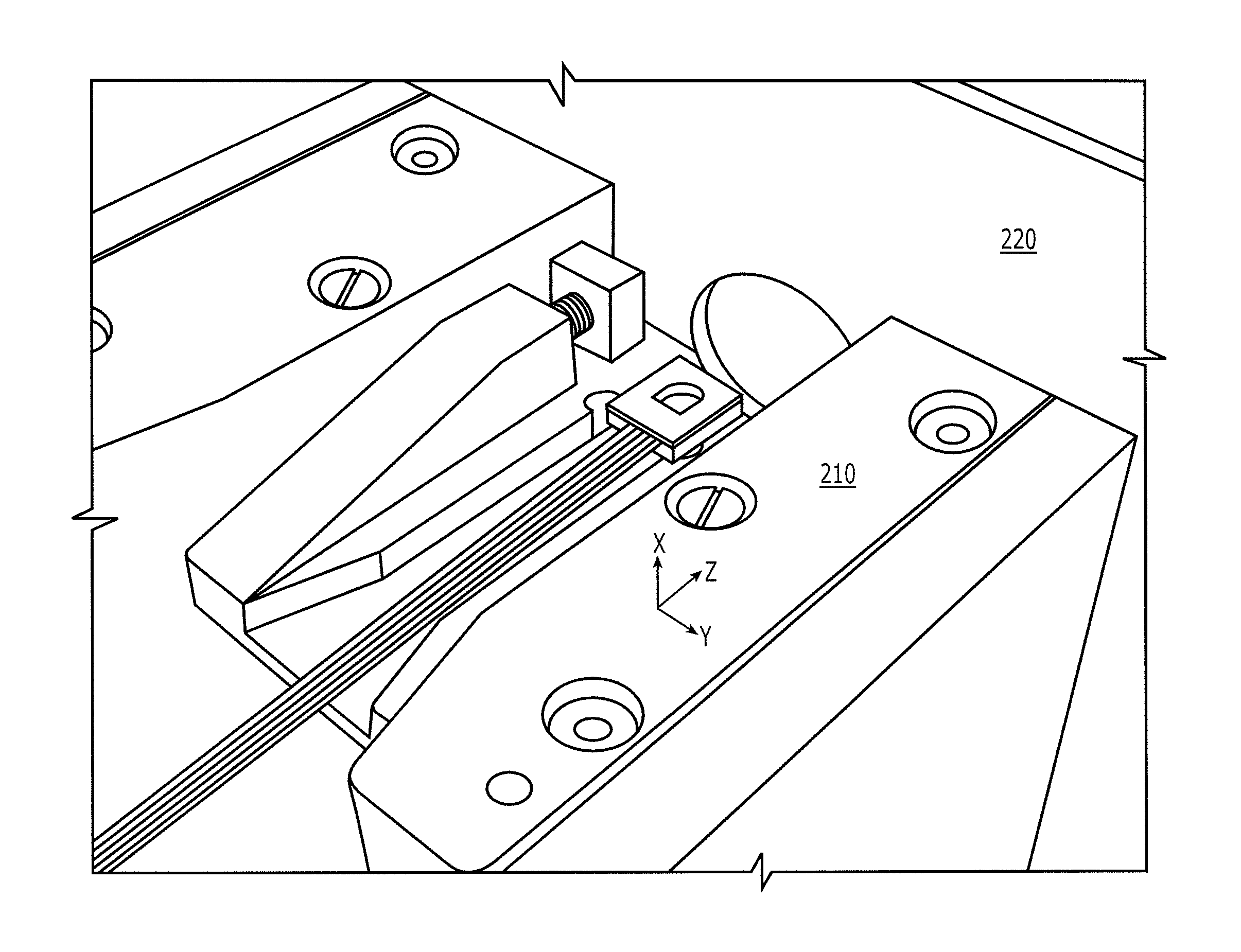

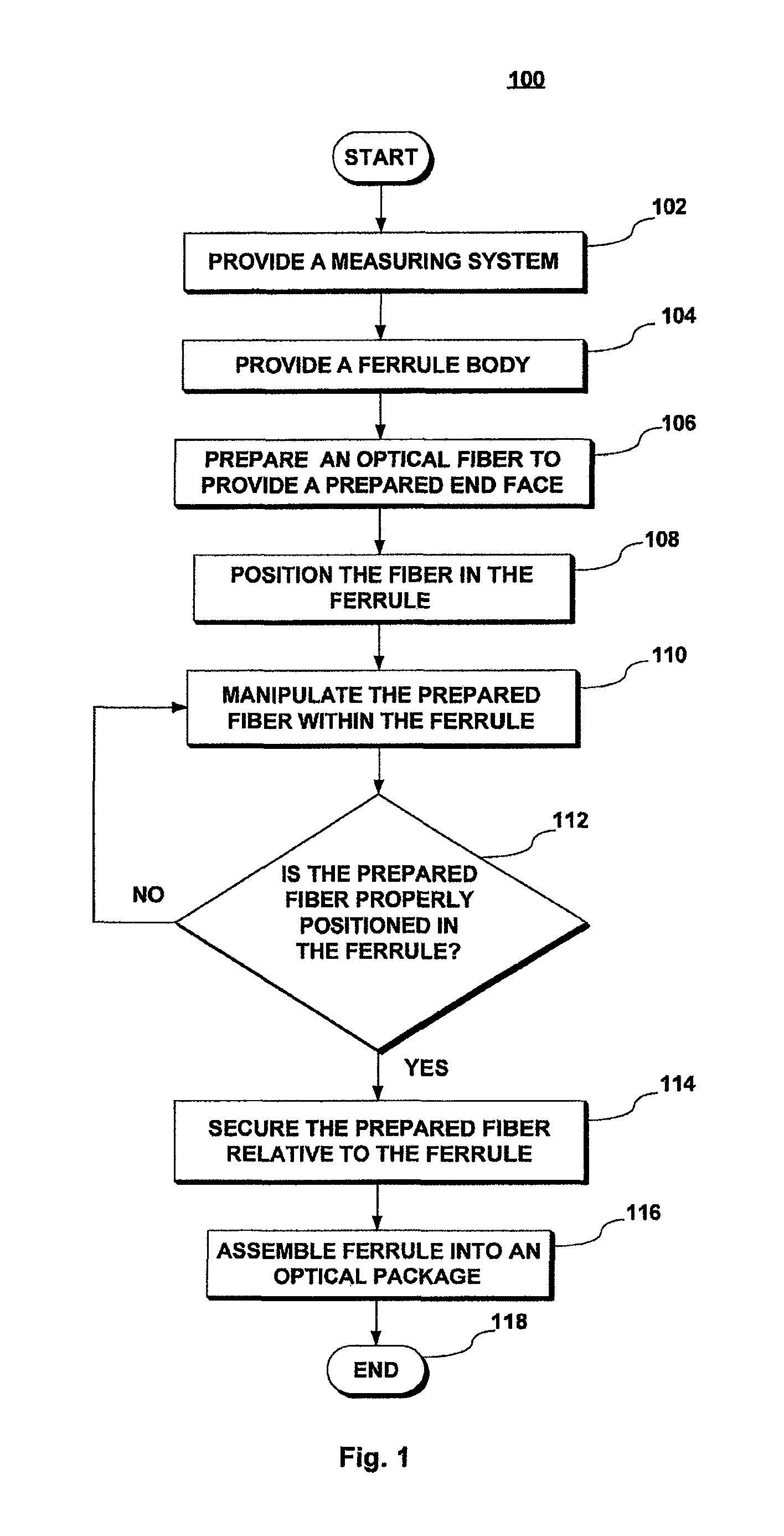

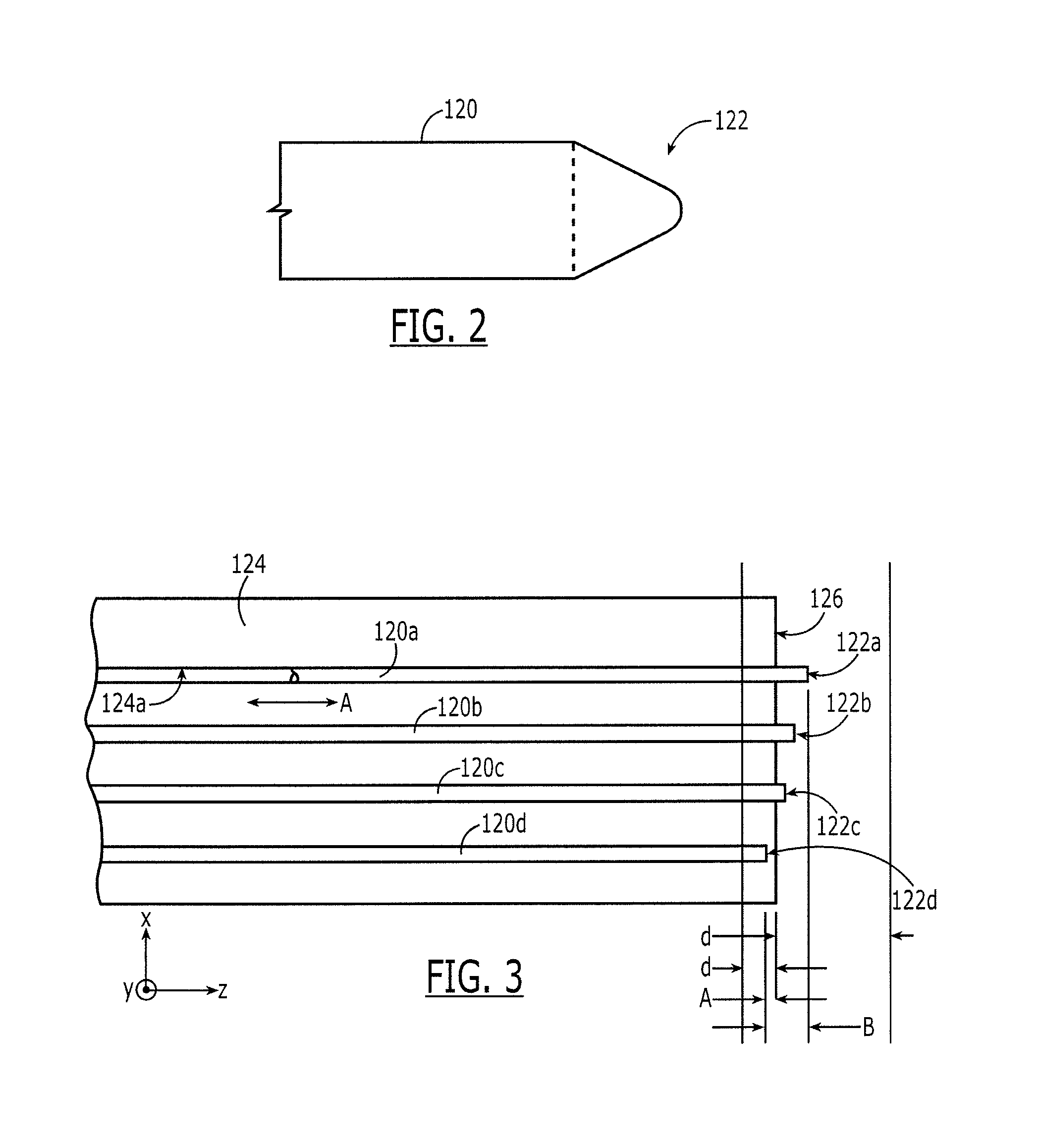

Method for preparing a ferrule assembly

ActiveUS8573856B2Avoid polishingReduce wasteUsing optical meansCoupling light guidesFiberEngineering

A method for preparing a ferrule assembly avoids polishing while providing adequate control over fiber end protrusion and co-planarity. A distal end of the fiber is prepared before securing the fiber in a ferrule, and before or after inserting the fiber into the ferrule. The prepared fiber is manipulated to provide a desired spatial relationship between the fiber end and the ferrule's end face, and then secured to maintain the desired spatial relationship. Preferably, the fiber end is prepared using a laser cleaving technique to provide a suitable end without abrasive polishing. An interferometer may be used to obtain measurements, during manipulation of the prepared fiber within the ferrule, that indicate whether the prepared fiber is satisfactorily positioned. In accordance with other aspects of the invention, a ferrule assembly prepared in accordance with the method, and a connector or other optical package including such a ferrule assembly are provided.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

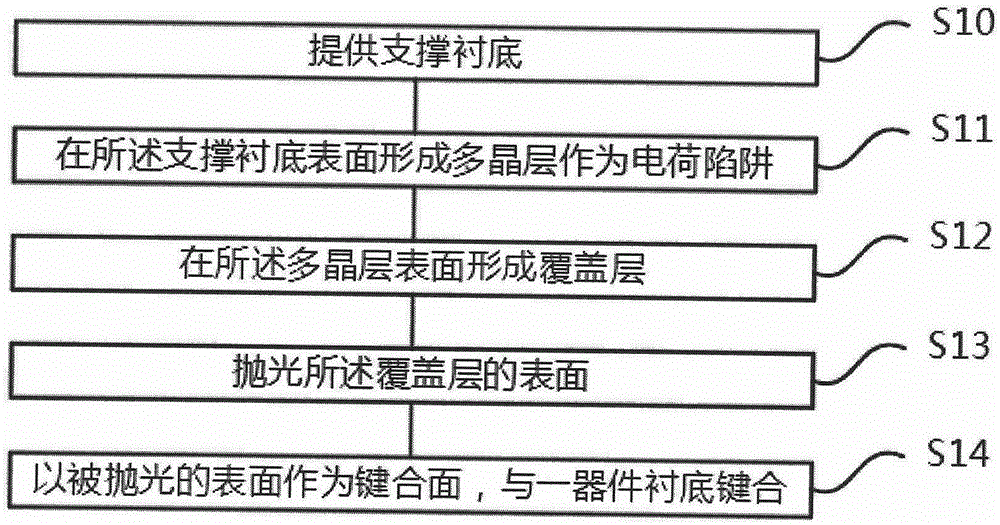

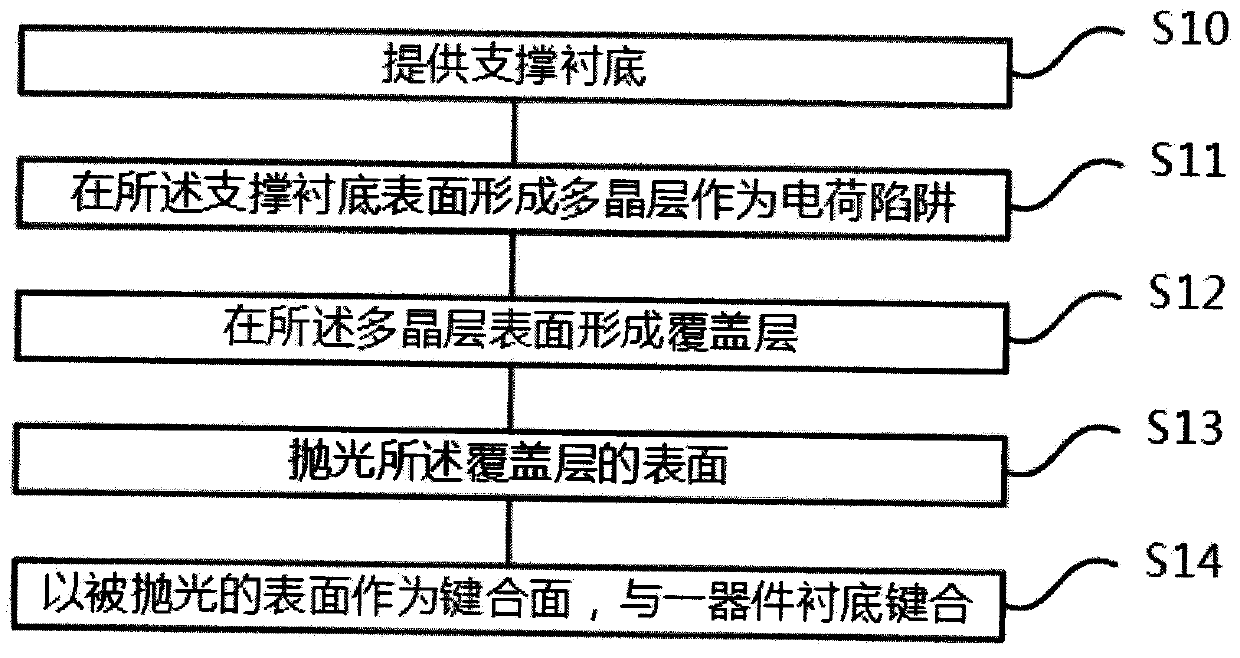

Preparation method for substrate with charge trap and insulation buried layer

ActiveCN105140107AAvoid polishingAvoid bondingSemiconductor/solid-state device manufacturingOptoelectronicsOverlayer

Owner:SHANGHAI SIMGUI TECH

Method of manufacturing thermally assisted magnetic head

ActiveUS8076246B2Easy to controlIncreasing the thicknessDecorative surface effectsSemiconductor/solid-state device manufacturingEngineering

A method comprises a first multilayer body forming step of forming a first multilayer body on a first cladding layer, the first multilayer body including a core layer and a first polishing stop layer in order from the first cladding layer side; a first multilayer body patterning step of pattering the first multilayer body, so as to expose the first cladding layer about the patterned first multilayer body; a second multilayer body forming step of forming a second multilayer body on the exposed first cladding layer and patterned first multilayer body, the second multilayer body including a second cladding layer and a second polishing stop layer in order from the first cladding layer side; and a removing step of polishing away a part of the second multilayer body formed on the first multilayer body.

Owner:TDK CORPARATION

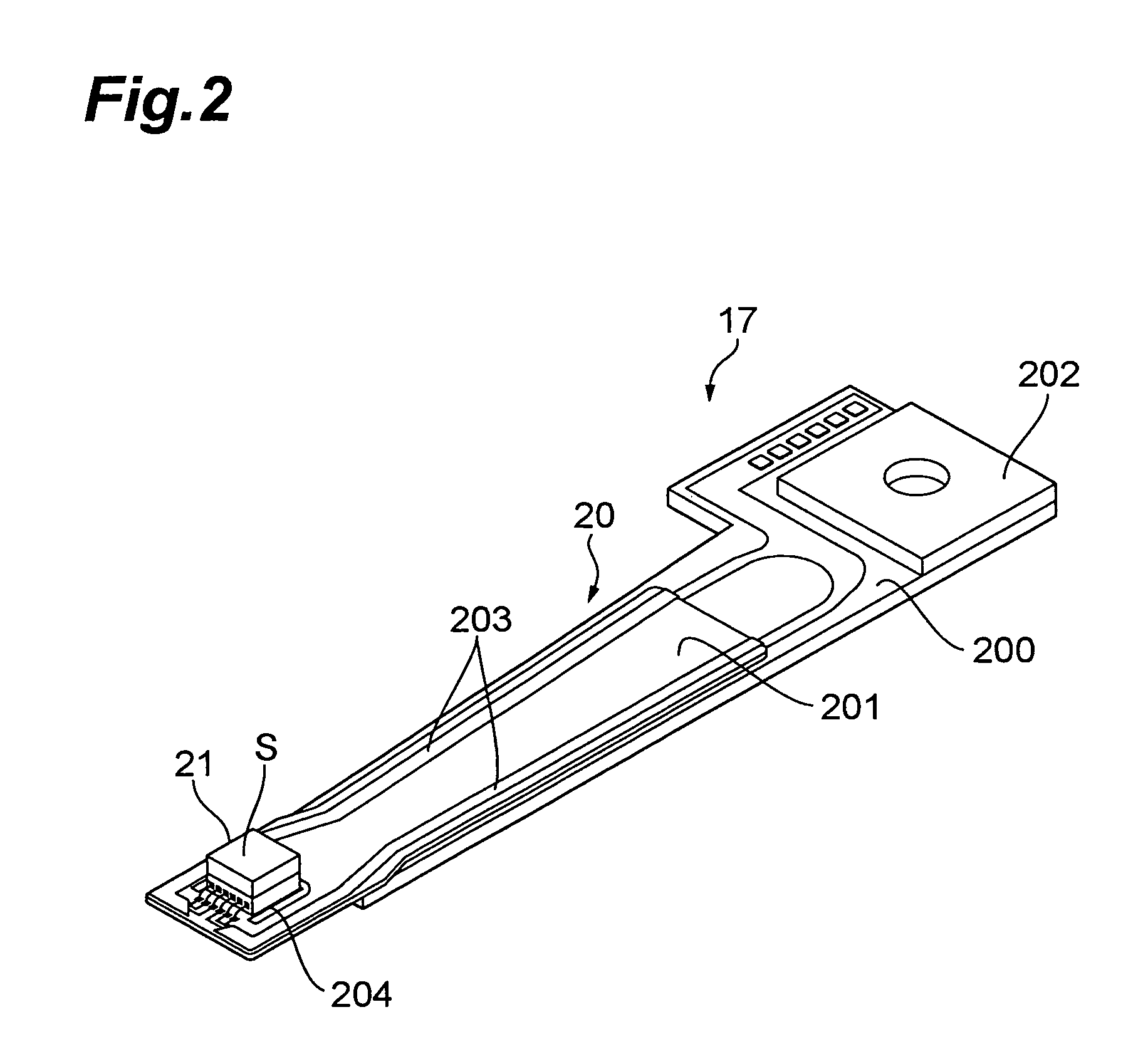

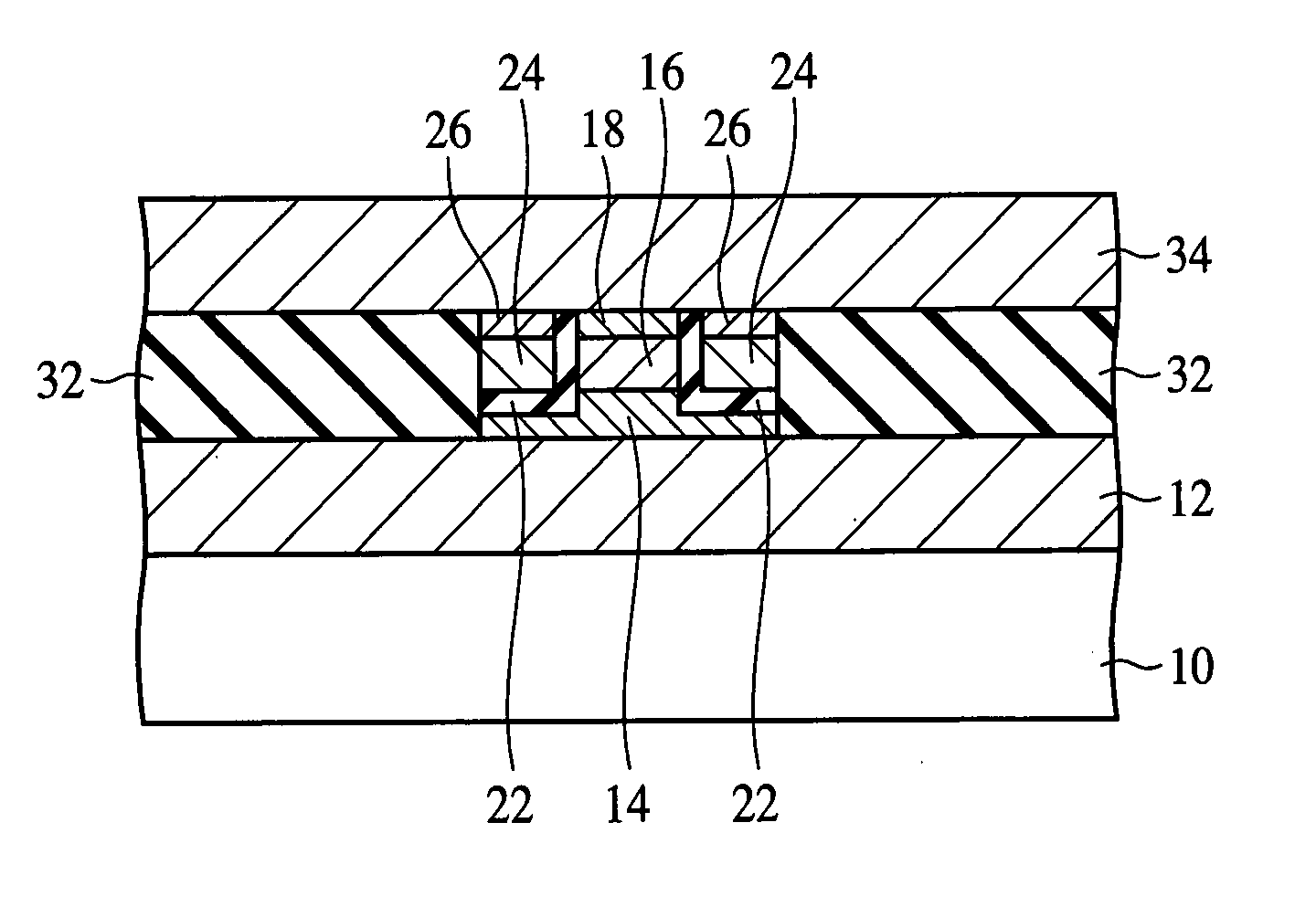

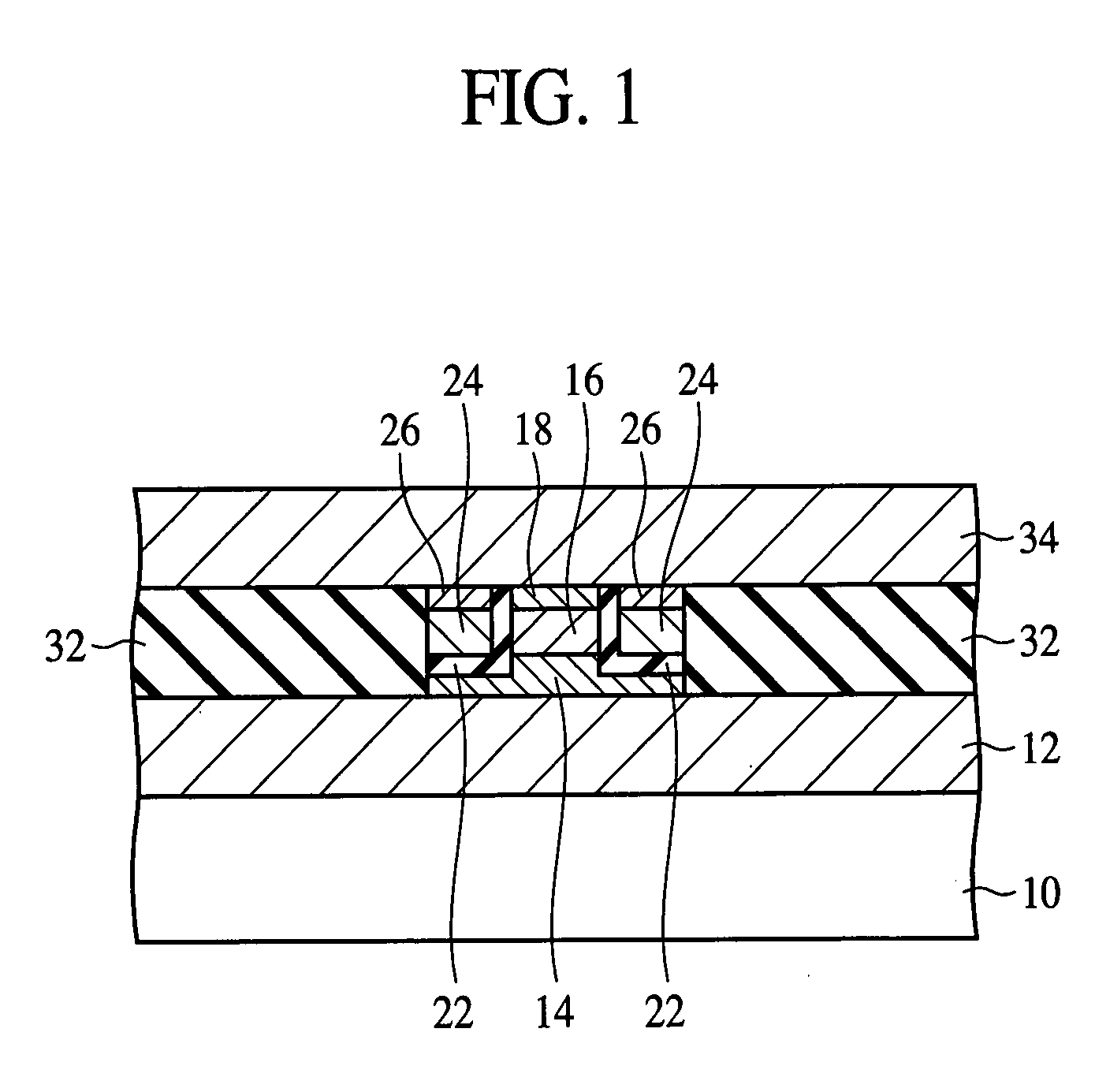

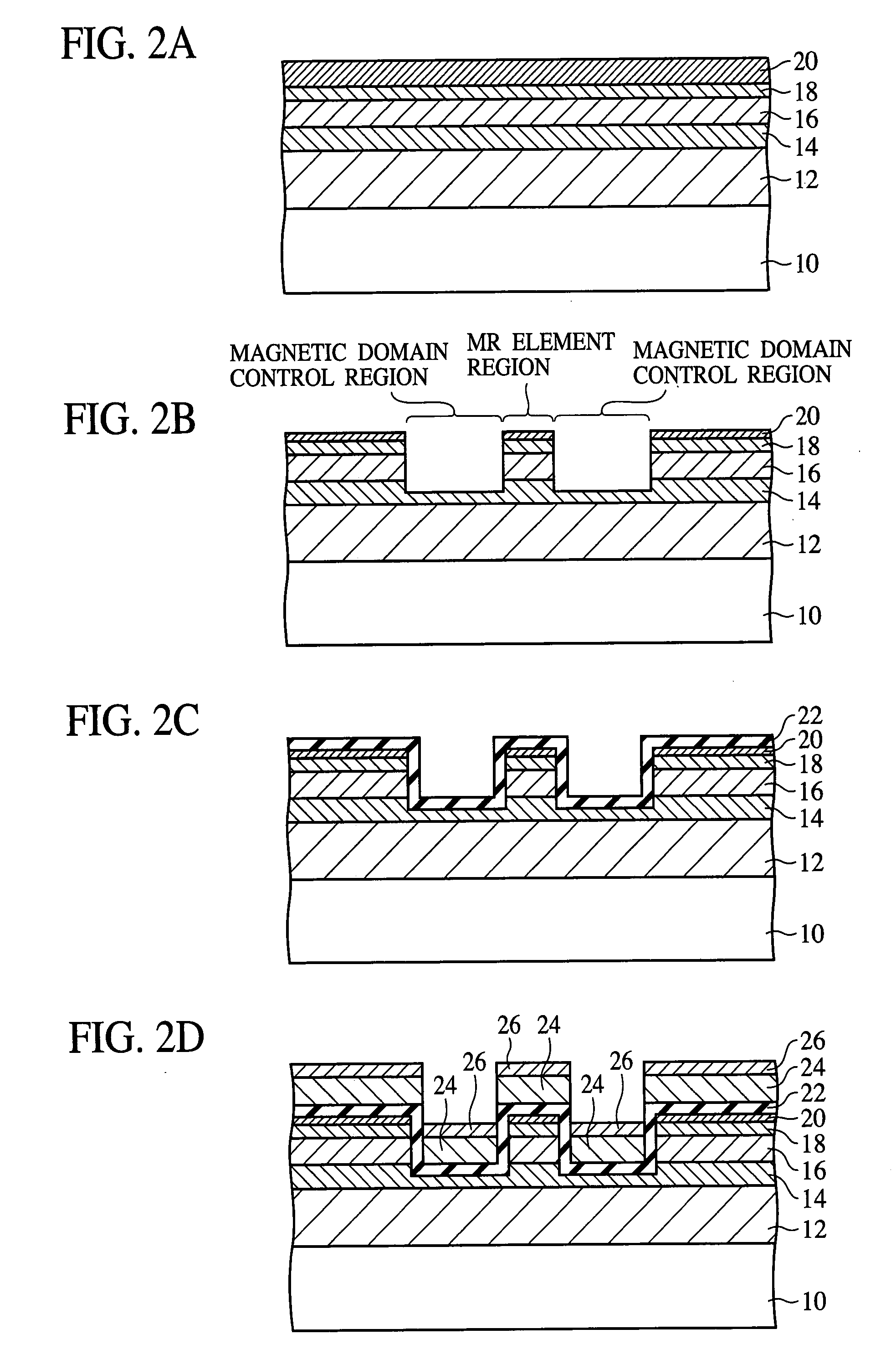

Method for fabricating magnetic head

InactiveUS20070230061A1Stable device configurationImprove accuracyRecord information storageManufacture of flux-sensitive headsEngineeringElectrical and Electronics engineering

The method for fabricating the magnetic head comprises the step of forming over a lower electrode a magnetoresistive effect film 16 with a polishing resistant film 20 formed over the upper surface, the step of forming a magnetic domain control film 24 over the entire surface of the lower electrode 12 including a region where the magnetoresistive effect film 16 has been formed, the step of selectively removing the magnetic domain control film 24 over the magnetoresistive effect film 16 by polishing with the polishing resistant film 20 as the stopper, the step of removing the polishing resistant film 20, and the step of forming an upper electrode 34 over the magnetoresistive effect film 16, from which the polishing resistant film 20 has been removed.

Owner:FUJITSU LTD

Polishing slurry composition for STI process

ActiveUS11384255B2High rateGood reliability and characteristicOther chemical processesSemiconductor/solid-state device manufacturingMetallurgySlurry

Owner:K C TECH

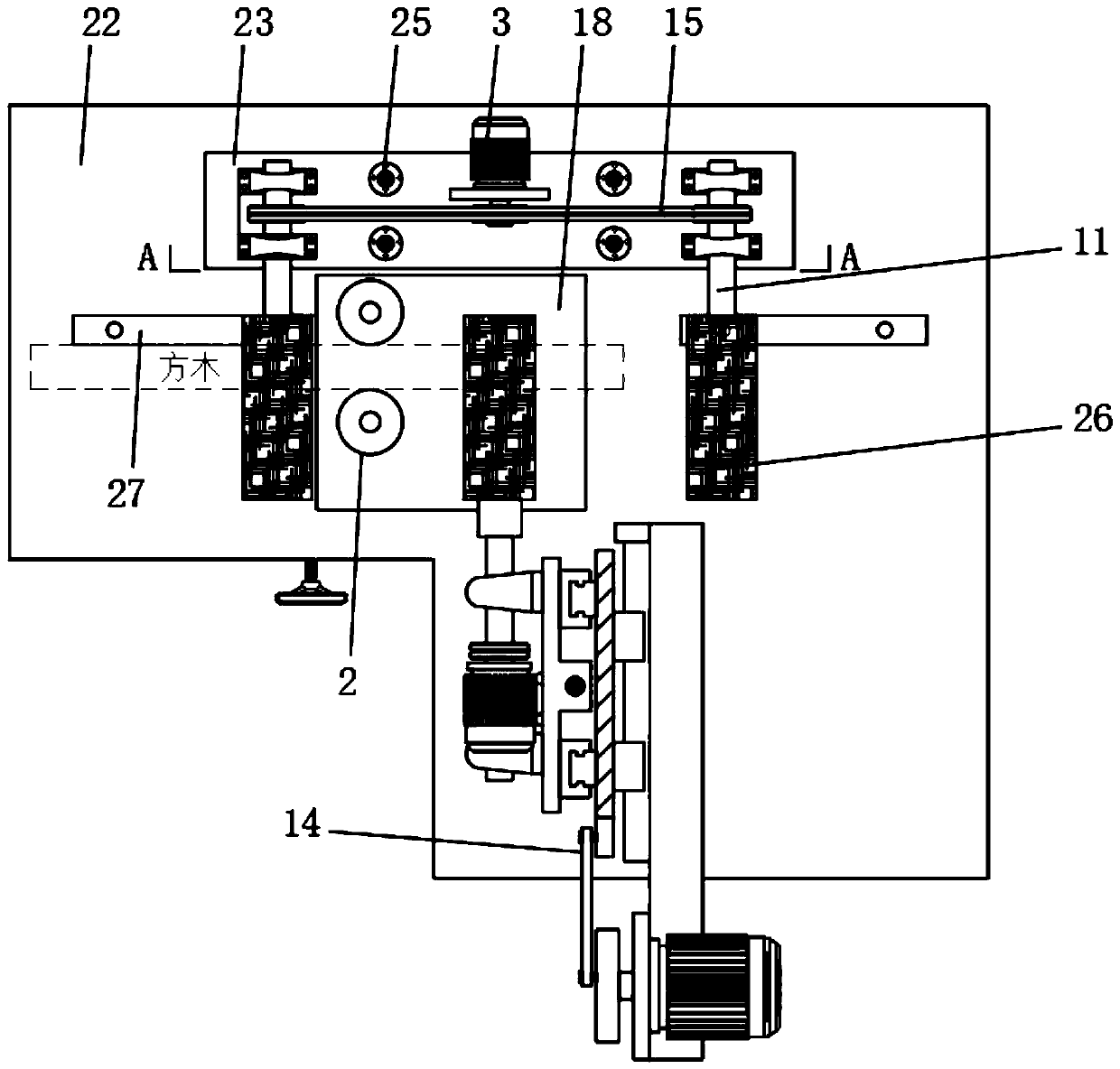

Square timber machining surface polishing device

PendingCN111002190AImprove applicabilityExtended service lifePolishing machinesGrinding drivesGrindingPolishing

The invention discloses a square timber machining surface polishing device. The device comprises a frame body, a first grinding mechanism, a second grinding mechanism and a material table; the first grinding mechanism is arranged on one side of the interior of the frame body; the material table is arranged at the top of the frame body; a receding groove is formed in the middle of the upper surfaceof the material table; a material pressing assembly is arranged above the receding groove; and the second grinding mechanism located below the material pressing assembly is arranged on the surface ofthe front end of the material table. According to the square timber machining surface polishing device of the invention, the four side faces of square timber can be ground at the same time through adjusting rollers and driving rollers arranged in the first grinding mechanism and the second grinding mechanism; polishing machining can be completed with one-time feeding of the square timber; the machining efficiency of the device is improved; and the condition that the square timber is overturned many times for polishing treatment is avoided. An adjusting handle can be rotated, so that an adjusting plate connected through an adjusting screw can be driven to move along a second linear guide rail pair, so that square timber of different sizes can be polished within a certain range, and therefore, the applicability of the device is improved.

Owner:义乌市裕晨科技有限公司

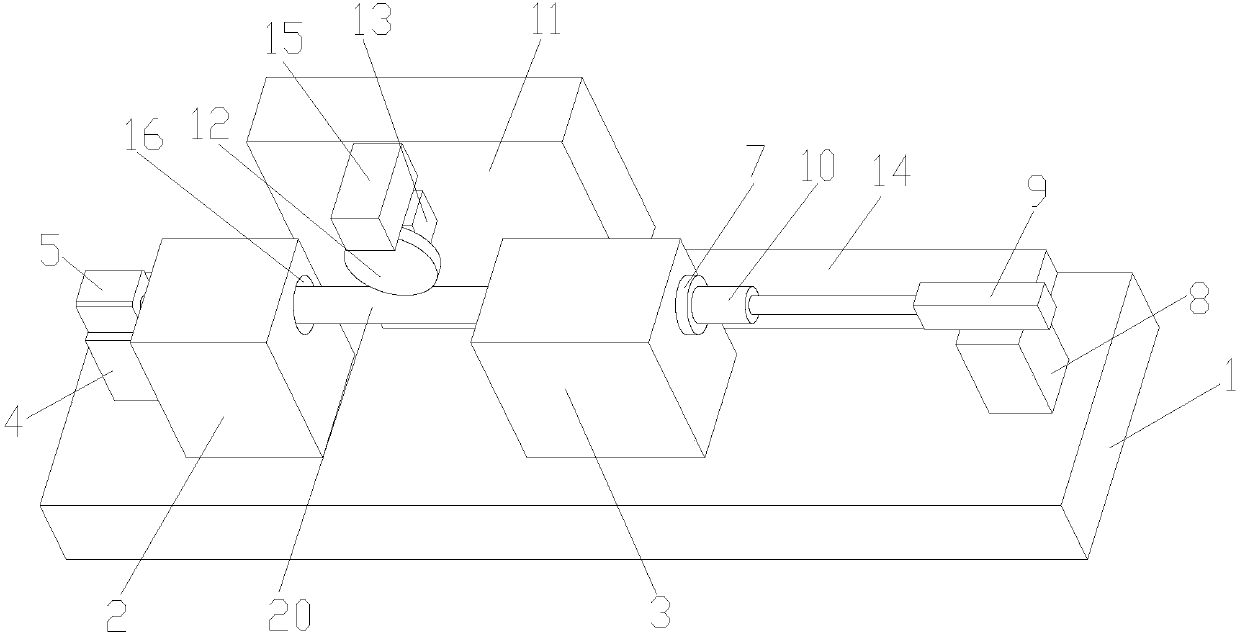

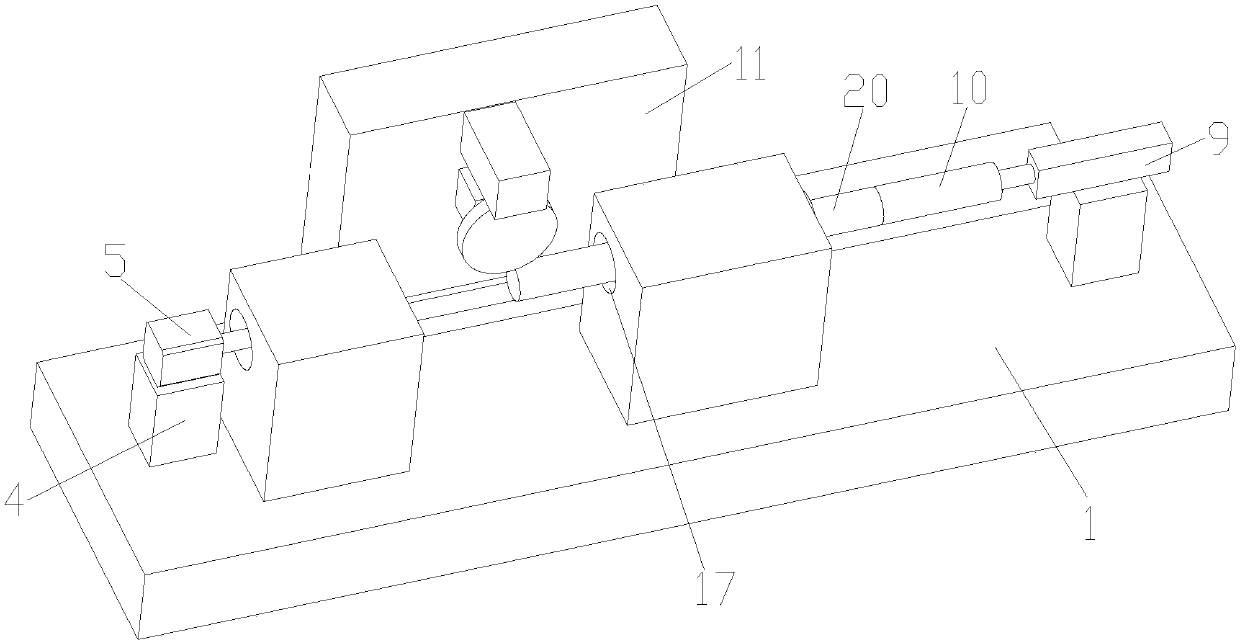

Polishing device of motor shaft

InactiveCN107813214AMeet production and processing needsCompact structurePolishing machinesGrinding drivesAgricultural engineeringHolding tank

The invention relates to a polishing device for a motor shaft. A left positioning block and a right positioning block are arranged on a base; a left positioning hole and a right positioning hole are respectively opened on the left positioning block and the right positioning block, and the above two positioning holes are located at On the same axis; one side of the left positioning block is provided with a motor on the motor base; one side of the motor shaft is provided with a left cylindrical block located in the left positioning hole, and the left cylindrical block has a receiving groove; the right positioning block There is a fixed cylinder in the hole, and the inner diameter of the fixed cylinder is the same as the diameter of the motor shaft; the materials of the left cylindrical block and the fixed cylinder are electromagnets; there is a telescopic cylinder on the side of the right positioning block; There is an electromagnet block inside; a slidable substrate is provided between the left positioning block and the right positioning block; a polishing assembly that can be lifted up and down is provided on the substrate. , save labor, improve polishing efficiency and polishing quality.

Owner:苏州市润达机械制造有限公司

Polishing slurry composition for sti process

PendingUS20210163785A1High polishing rateImprove reliabilityMaterial nanotechnologyOther chemical processesMetallurgySlurry

The present invention relates to a polishing slurry composition for an STI process and, more particularly, to a polishing slurry composition for an STI process, the composition comprising: a polishing solution including polishing particles; and an additive solution containing a polysilicon film polishing barrier inclusive of a polymer having an amide bond.

Owner:K C TECH

Polishing machine and polishing technology

PendingCN110039432AAvoid partial wearIncrease contact areaPolishing machinesGrinding drivesMotor driveEngineering

The invention discloses a polishing machine and a polishing technology. The polishing machine comprises a rack. The rack is provided with a clamp and a polishing shaft. The clamp can move in the Y direction. The rack is provided with an X-direction moving assembly. The X-direction moving assembly is provided with a Z-direction moving assembly. The Z-direction moving assembly is provided with a Z-direction rotating assembly. The Z-direction rotating assembly is provided with a horizontal moving assembly. The horizontal moving assembly is provided with a swing assembly. The swing direction of the swing assembly is perpendicular to the horizontal moving direction of the horizontal moving assembly. The swing assembly comprises a first frame body connected with the horizontal moving assembly and a second frame body rotationally connected with the first frame body, the first frame body is provided with a first motor driving the second frame body to swing and adjust, and the second frame bodyis connected with the polishing shaft. The second frame body is provided with a second motor driving the polishing shaft to rotate. The polishing shaft is arranged above the clamp, the axis directionof the polishing shaft is arranged in the up-down direction, and the polishing shaft is sleeved with a polishing wheel. By means of the polishing machine and the polishing technology, eccentric wearof the polishing wheel can be reduced, and the polishing quality is ensured.

Owner:珠海广鑫厨卫科技有限公司

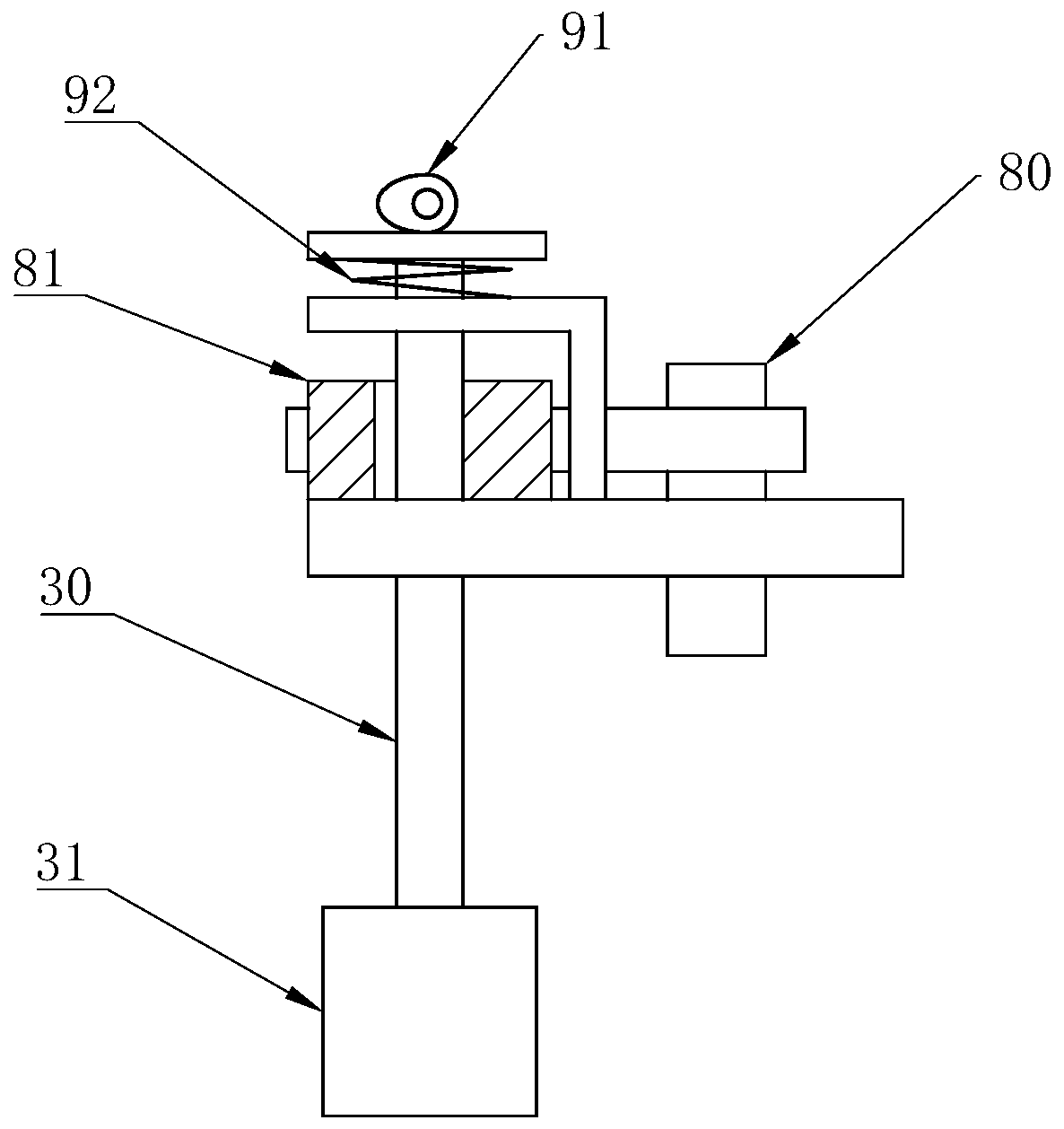

Trimming device and wafer polishing system

PendingCN114633206AAccurate judgment of wear degreeTimely replacementGrinding drivesLapping machinesWaferPolishing

The invention discloses a trimming device and a wafer polishing system.The trimming device comprises a mounting frame, a lifting mechanism and a detection piece, the lifting mechanism is provided with a lifting driving piece, the mounting end of the lifting driving piece is connected with the mounting frame, and the driving end of the lifting driving piece is suitable for being connected with a grinding head; the lifting driving piece has a grinding state for driving the grinding head to be close to or away from the polishing pad; the detection piece is suitable for forming position information according to the detected displacement distance of the grinding head, the lifting driving piece drives the grinding head to move towards the polishing pad until the polishing pad abuts against the grinding head, the abrasion degree of the polishing pad is increased along with grinding and polishing work, and the lifting driving piece drives the grinding head to abut against the polishing pad all the time. A worker can accurately judge the abrasion degree of the polishing pad according to the displacement distance change detected by the detection piece, so that the polishing pad is replaced in time, and the situation that the polishing pad which is excessively abraded is used for polishing a wafer is avoided.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

Inlaid type handle

An inlaid type handle specifically comprises a hand lever, a first plug, a second plug, a connector, a handle head, a fastening seat, a fastening connecting piece and screws. The handle is divided into a plurality of parts, and a handle formed body is formed by fastening the parts through the screws after the multiple parts are combined. Meanwhile, the contact surface of each part has the dip, in the application process, the handle is pulled, all the parts are tighter along with pulling, then the handle formed body is also stable, and no obvious gap exists among the parts. The handle only needs simple combination and is fastened with the screws in the combined process, so that professional facilities and devices such as upper lathes and sawing machines can be avoided, the processes of welding, polishing, wire drawing and the like are avoided, and finished product preparation can be completed without the need of professional technical personnel. The process is optimized, so that multiple processes and working procedures are omitted, in the production working procedures, energy saving and environmental protection are achieved, and the production cost is reduced by a large margin.

Owner:广西力保佳科技有限公司

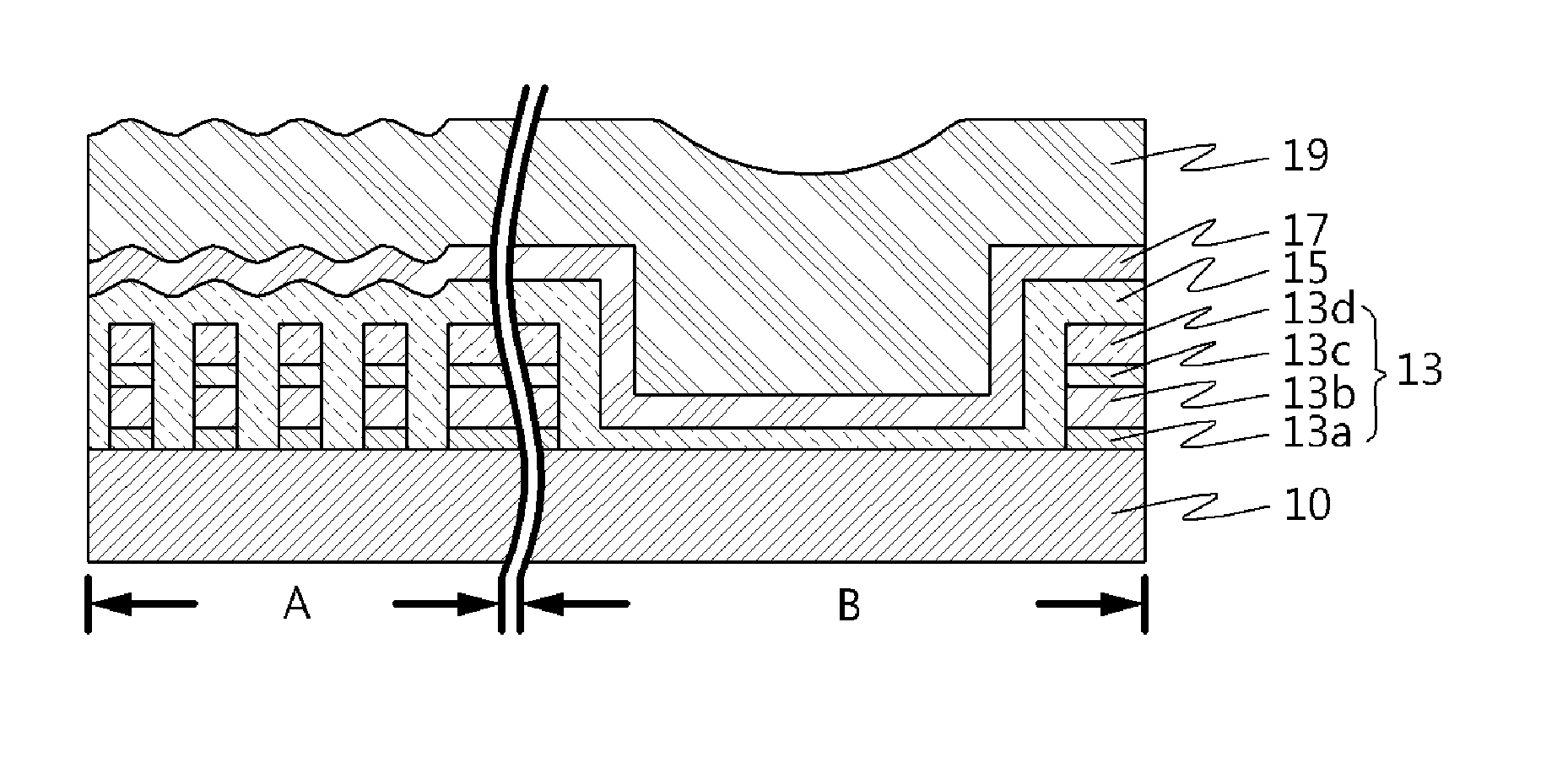

Multi-selective polishing slurry composition and a semiconductor element production method using the same

ActiveUS20150179470A1Reduce ratePrevent over-polishingOther chemical processesSemiconductor/solid-state device manufacturingSilicon membraneSilicon oxide

Provided are a multi-selective polishing slurry composition and a semiconductor element production method using the same. A silicon film provided with element patterns is formed on the uppermost part of a substrate having a first region and a second region. The element pattern density on the first region is higher than the element pattern density on the second region. Formed in sequence on top of the element patterns are a first silicon oxide film, a silicon nitride film and a second silicon oxide film. The substrate is subjected to chemical-mechanical polishing until the silicon film is exposed, by using a polishing slurry composition containing a polishing agent, a silicon nitride film passivation agent and a silicon film passivation agent. The polishing slurry composition may be a mixture of 100 parts by weight of a polishing agent suspension, containing a polishing agent, and from 40 to 120 parts by weight of an additive solution, and the additive solution can contain 100 parts by weight of a solvent, from 0.01 to 5 parts by weight of a silicon nitride film passivation agent and from 0.01 to 5 parts by weight of a silicon film passivation agent.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Method for manufacturing MEMS device

ActiveUS8841155B2Increase polishing speedAvoid over polishingAcceleration measurement using interia forcesImpedence networksInterconnectionDielectric layer

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

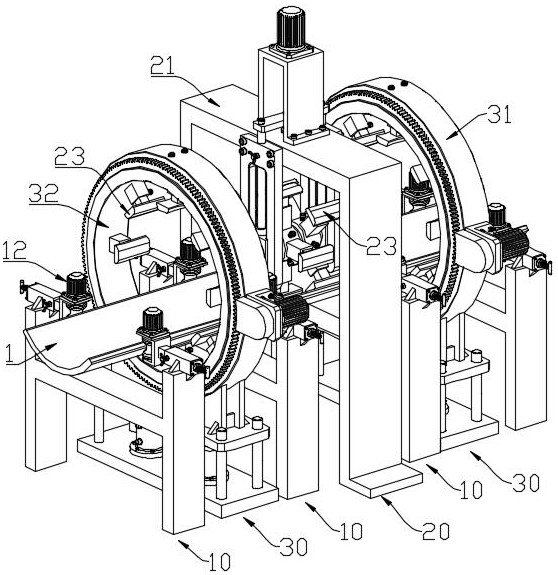

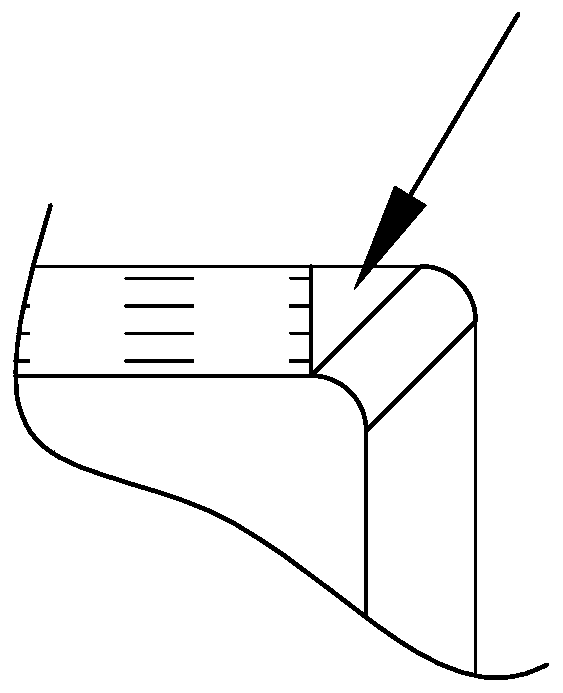

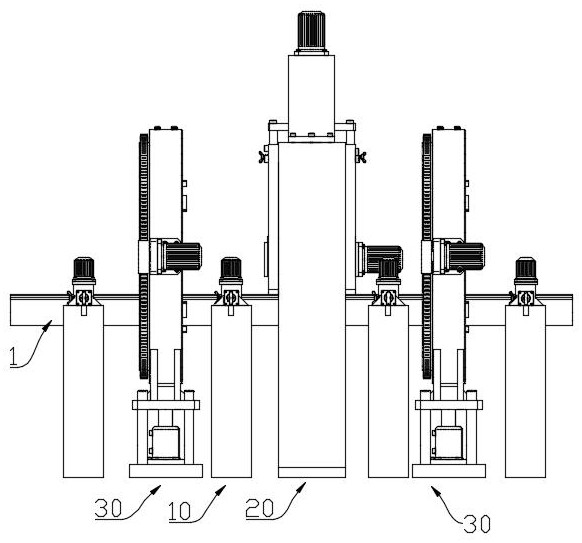

A Polishing Device for Arc Slit Array Antenna Mounting Board

ActiveCN112454147BAvoid polishingImprove polishing efficiencyPolishing machinesGrinding feedersPolishingElectric machine

A polishing device for arc-shaped crack array antenna mounting plate, the conveying mechanism includes a pair of parallel conveying wheels for conveying the antenna mounting plate, the distance between the conveying wheels is adjustable, and the conveying wheels are connected with driving motors, the conveying mechanism There are multiple groups; there is at least one set of inner arc surface polishing mechanism. The inner arc surface polishing mechanism includes a gantry frame and a rotating part. The rotating part is evenly equipped with multiple polishing brushes along the circumference. The distance is adjustable; there is at least one set of outer arc surface polishing mechanism, which is located between the conveying mechanisms, at least one set of conveying mechanisms is provided between the inner arc surface polishing mechanism and the outer arc surface polishing mechanism, and the outer arc surface polishing mechanism includes the outer ring The seat and the inner ring coaxially rotated in the outer ring seat, the bottom of the outer ring seat is equipped with a lifting mechanism, and the inner wall of the inner ring is evenly equipped with a plurality of polishing brushes along the circumference, and the position of the polishing brushes along the normal direction of the inner ring can be adjusted . It can polish mounting plates with different thicknesses and different structures, and the polishing efficiency is high.

Owner:CHENGDU NANJIAO TECH

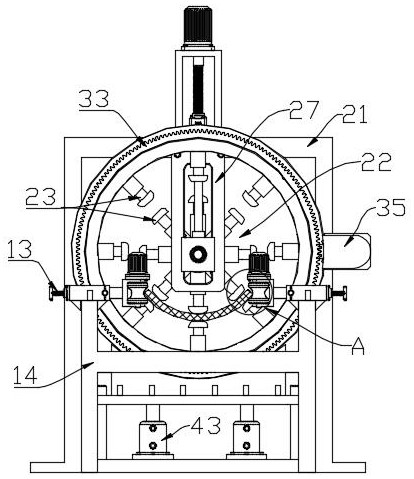

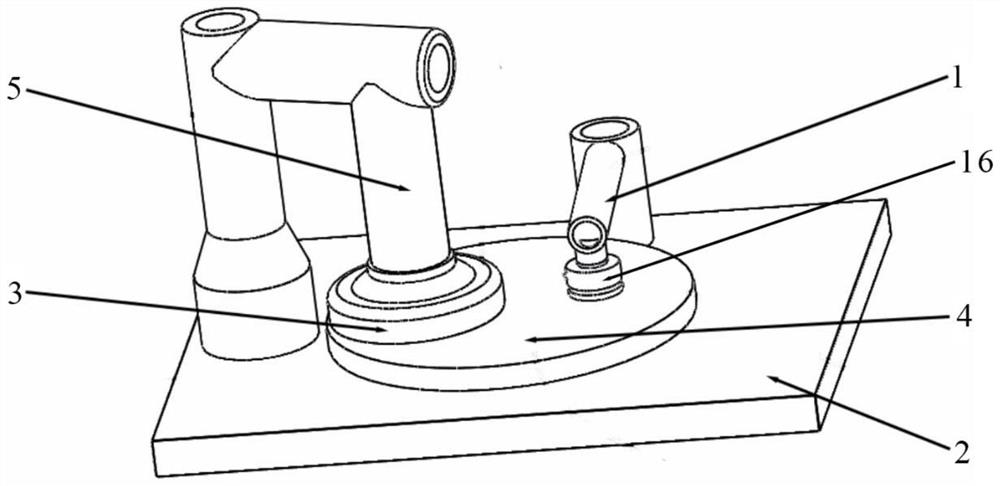

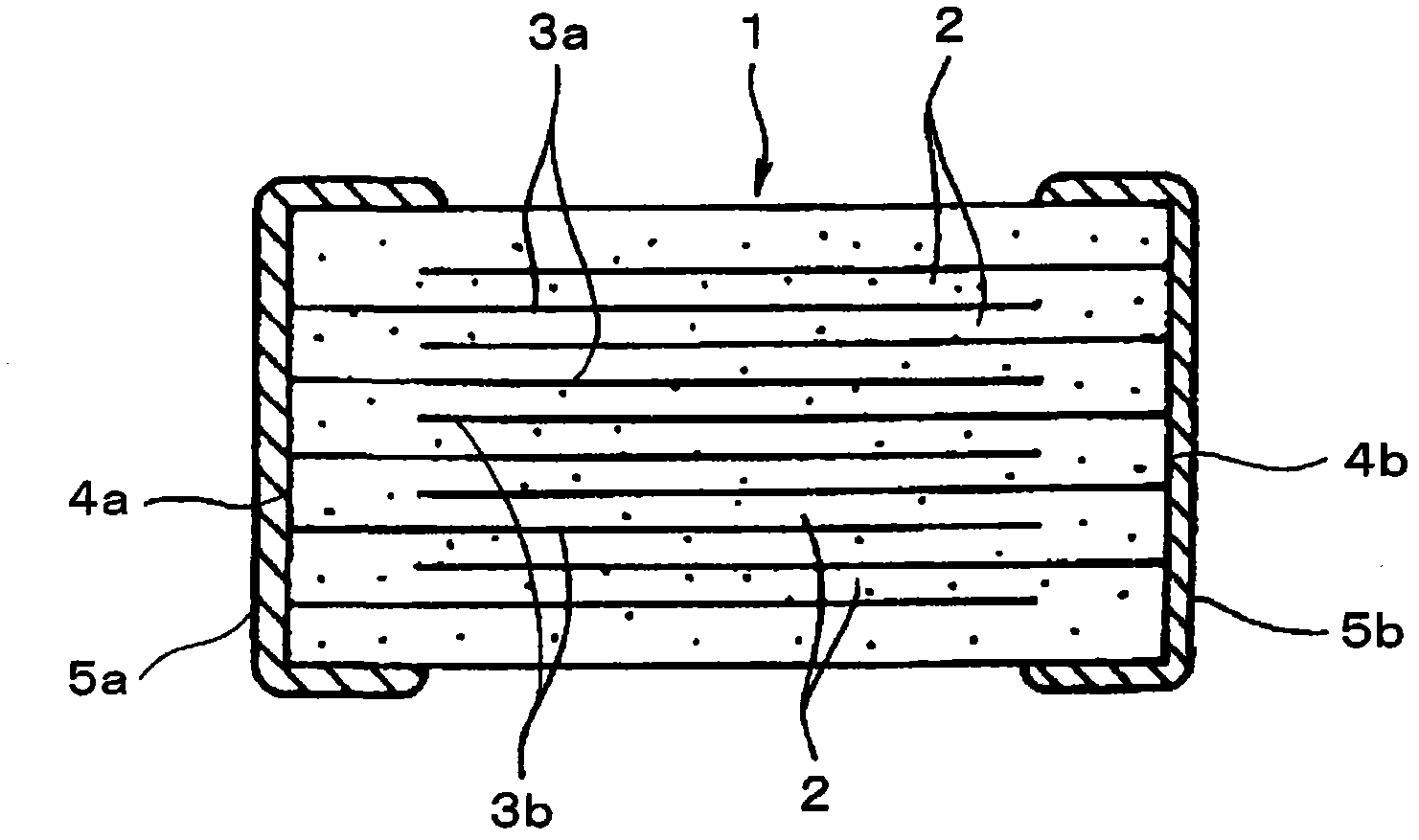

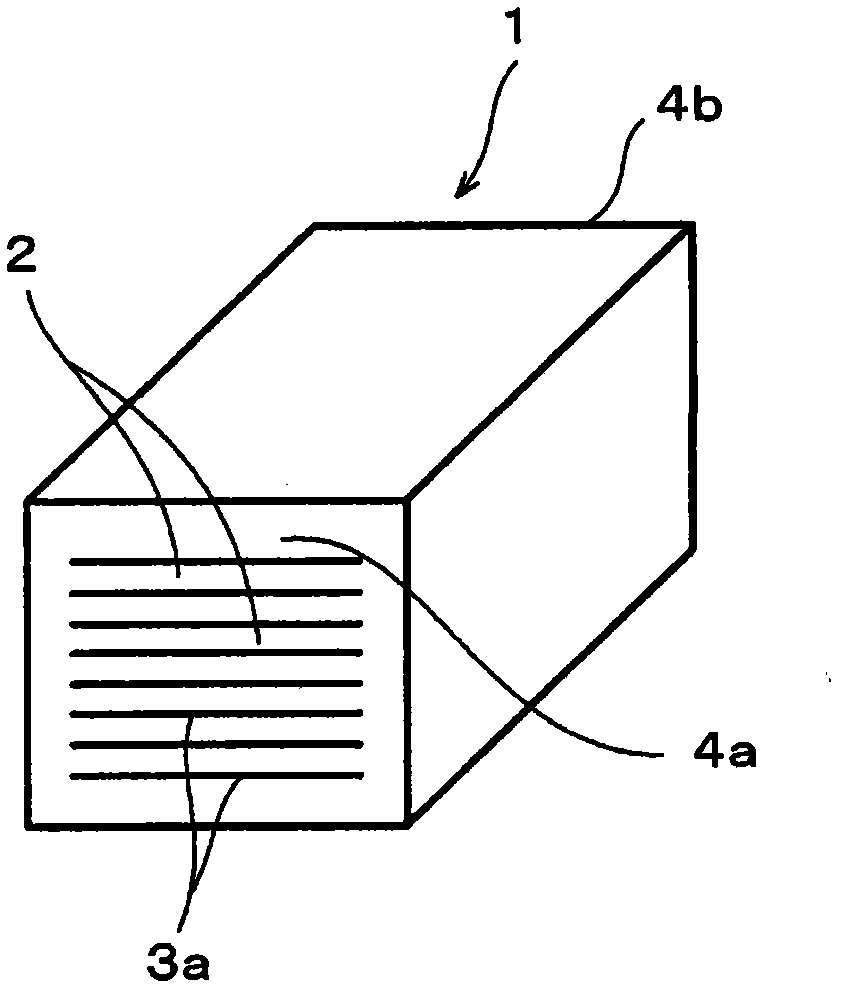

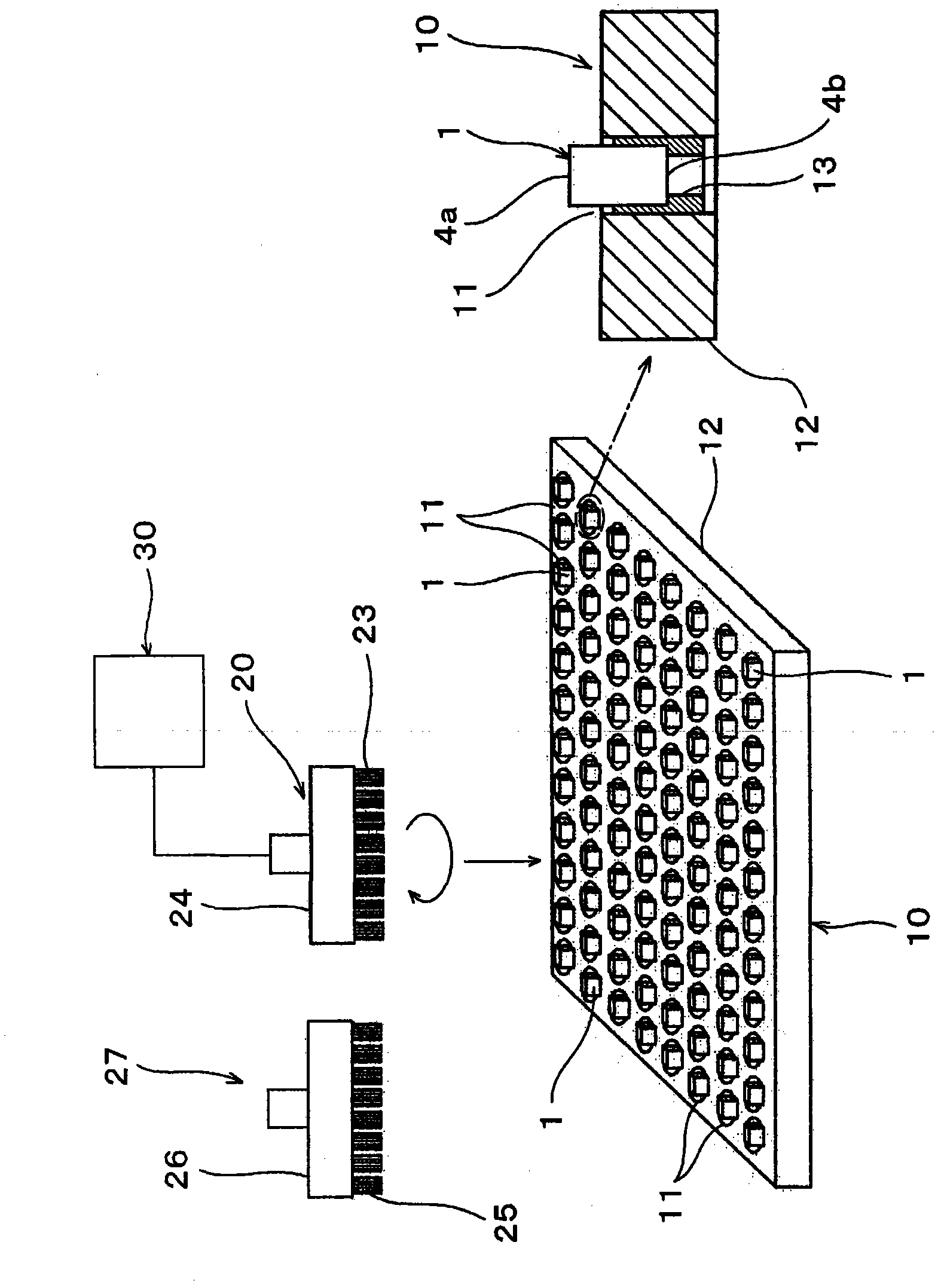

Apparatus for manufacturing chip-type ceramic electronic component and method for manufacturing chip-type ceramic electronic component

ActiveCN101990691AImprove efficiencyWon't fly awayFixed capacitor dielectricStacked capacitorsElectronic componentMaterials science

A chip-type ceramic electronic component, which is to be manufactured through a step of polishing an end surface, can be efficiently manufactured by efficiently polishing an end surface of a chip-type element, while eliminating generation of cracks and chipping by relatively simple configuration. Provided is an apparatus for manufacturing a chip-type ceramic electronic component, which is to be manufactured through a step of polishing a pair of facing end surfaces (4a, 4b) of a chip-type element (1) having ceramic as a material. The apparatus is provided with a holding member (10), which arranges and holds the chip-type elements (1) such that the chip-type elements are spaced apart from each other with one of the pair of end surfaces (4a, 4b) of each chip-type element on the same flat surface; a polishing brush (20) wherein a brush holder (24) holds a brush main body (23), which has a polishing material embedded in a flexible resin; and a driving mechanism (30) which drives the polishing brush (20) so that the brush main body slides on the one end surface in a state where the brush main body is brought into contact with the one end surface of the chip-type element.

Owner:MURATA MFG CO LTD

An outer edge polishing device for processing parts of a hydraulic press

ActiveCN113001383BEasy to polishAvoid polishingEdge grinding machinesGrinding carriagesMachine partsGear wheel

The invention discloses an outer edge polishing device for parts processing of a hydraulic press, comprising a mounting cylinder, a placement seat, a polishing roller, a first stepping motor, a limit column, a sliding seat, a rack, a guide seat, a threaded rod, and a mounting frame , the first roller, the second stepping motor, the second roller, the mounting plate, the fixed shaft, the transmission roller, the electric push rod, the driving bevel gear, the mounting seat, the long left and right screw, the driven bevel gear, the adjustment seat, the worm , cylindrical gear, driven gear, telescopic rod, worm gear, short left and right screw, slider, conveyor belt, rolling gear, square drum, sprocket, third roller, tubular drive seat and frame drive seat. The invention can better polish the outer edge of the hydraulic press parts, avoiding manual polishing by the staff, thereby greatly reducing the working intensity of the staff, and also avoiding the close contact of the staff with the hydraulic press parts, thereby causing dust It is inhaled into the lungs by the staff, which greatly improves the safety.

Owner:芜湖普尔机械有限公司

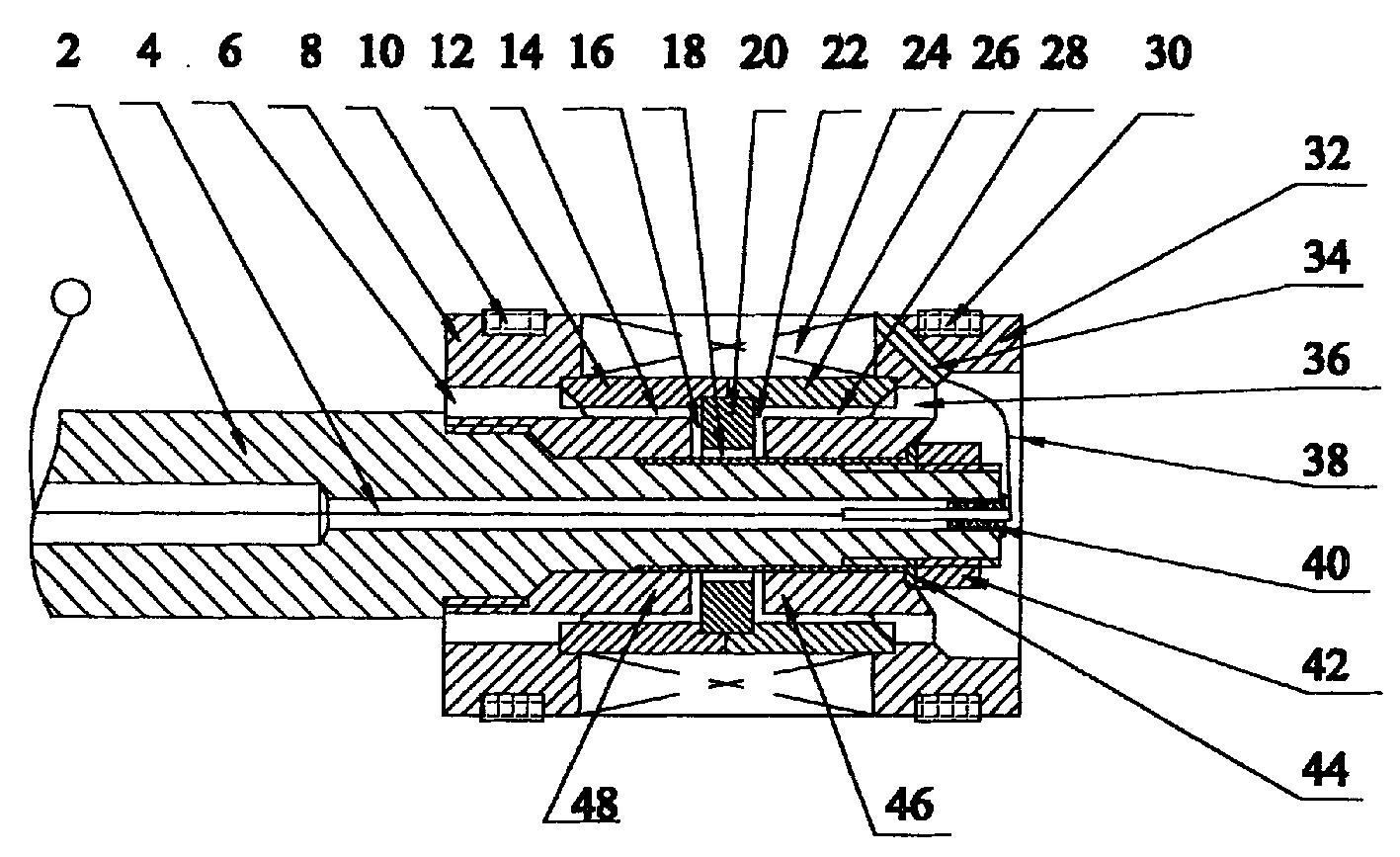

Electromagnetic rheological fluid piston assembly

InactiveCN1260493CLow costAvoid polishingSpringsNon-rotating vibration suppressionEngineeringPiston rod

The invention relates to a novel electromagnetic rheological fluid piston assembly, which is composed of an upper magnet conductor, a lower magnet conductor, a magnet conductor baffle plate, an electromagnetic solenoid, and a piston rod. The piston rod passes through the central channel of the upper magnetizer, the magnetizer baffle and the lower magnetizer respectively, and the head of the piston rod passing part is covered with a magnetic isolation sleeve, and at the same time, the upper magnetizer, the magnetizer baffle, and the lower There are two magnetic isolation sleeves between the magnetic conductor and the electromagnetic solenoid, and the magnetic isolation fastener located at the head of the piston rod connects the upper magnetic conductor, the magnetic conductor baffle plate, the lower magnetic conductor, the electromagnetic solenoid and the two magnetic conductors through the piston rod. A magnetic isolation sleeve is tightly connected.

Owner:邱玲

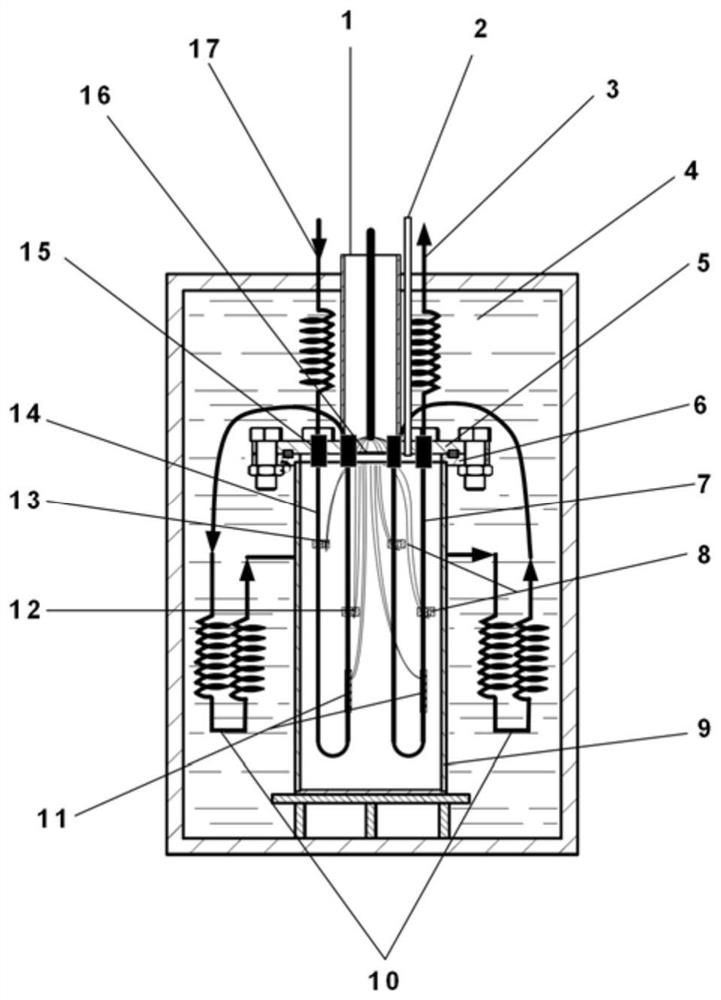

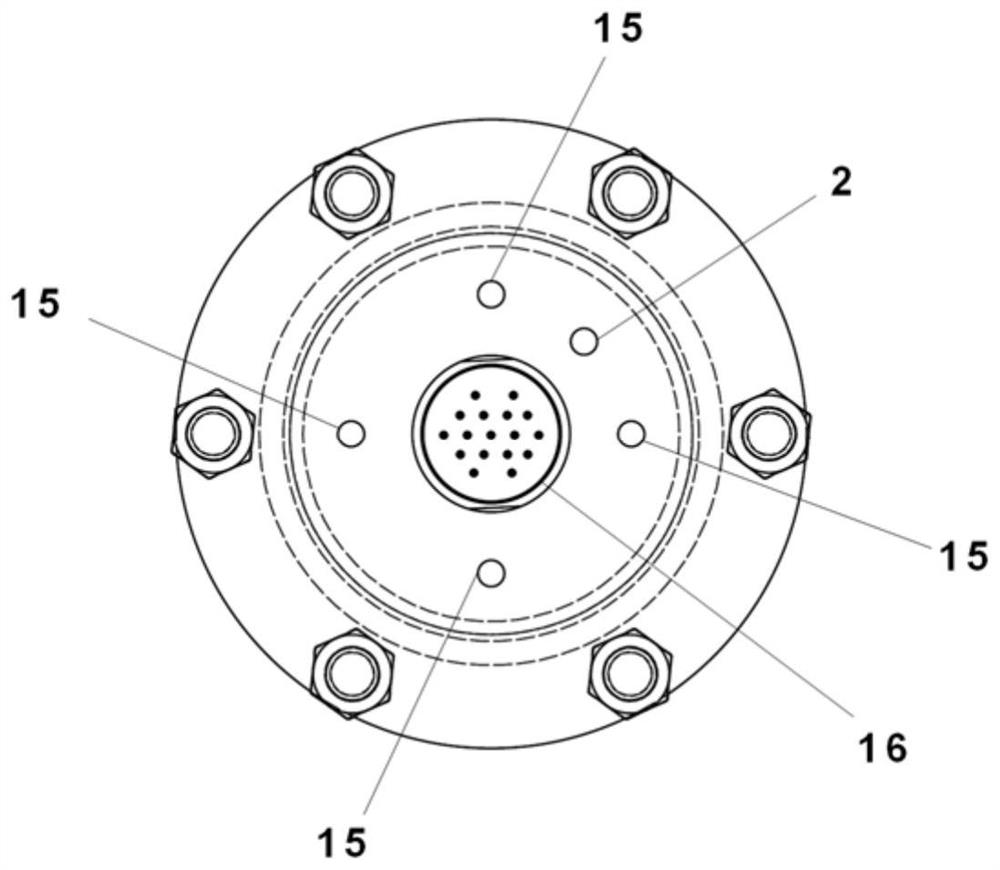

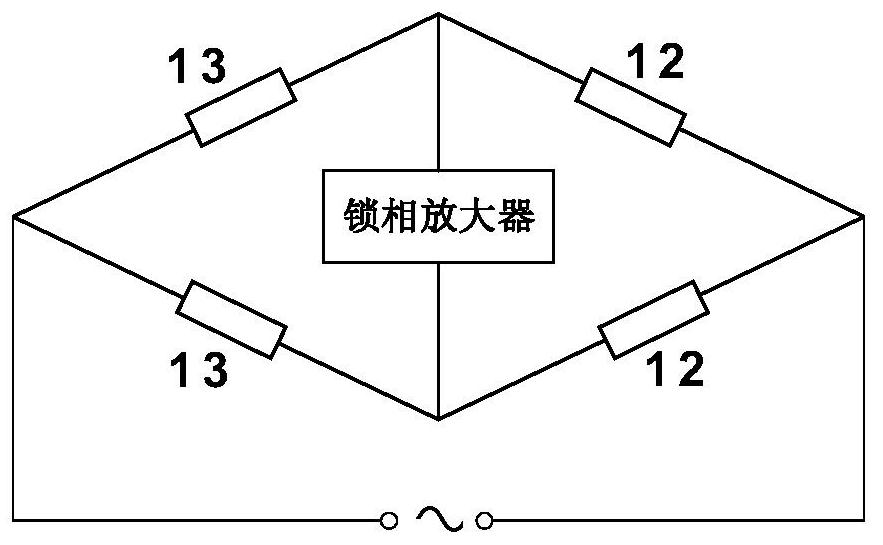

Device and method for measuring specific heat capacity by dual-flow method

ActiveCN112748145BElimination temperatureHigh precisionMaterial heat developmentSpecific heat investigationMeasurement deviceEngineering

A device and method for measuring specific heat capacity by a double-flow method, including a calorimeter part and a heating control part; the calorimeter part includes a vacuum chamber, the top of the vacuum chamber is provided with a lower flange and an upper flange end cover matched with the lower flange , the upper flange end cover is provided with a vacuum pipe; the inside of the vacuum chamber is provided with a second U-shaped tube and a first U-shaped tube with the same structure, and the upper ends of the second U-shaped tube and the first U-shaped tube are connected to the two-way The lower end is connected, the second U-shaped tube and the first U-shaped tube are wound with a heating wire, and the two ends of the heating wire are respectively provided with through holes for the first temperature sensor and the second temperature sensor; the heating control part is located outside the calorimeter , the heating control part is connected with the heating wire. The invention can accurately measure the specific heat capacity of the liquid, the device has good stability, and the measurable temperature and pressure range is wide. It can be used for the specific heat measurement of dilute electrolyte solutions and organic matter in industry and scientific research, and can also be used in energy and power related fields. The teaching of course experiments.

Owner:XI AN JIAOTONG UNIV

Fabrication method of substrate with charge trap and insulating buried layer

ActiveCN105140107BAvoid polishingAvoid bondingSemiconductor/solid-state device manufacturingOptoelectronicsCrystal

The invention provides a preparation method for a substrate with a charge trap and an insulation buried layer, comprising the following steps: providing a support substrate; forming a polycrystal layer on the surface of the support substrate to be used as the charge trap; forming a covering layer on the surface of the polycrystal layer, wherein the covering layer is non-crystal insulation material; polishing the surface of the covering layer; and taking the polished surface as a bonding surface, and bonding with a device substrate. The preparation method for the substrate has the advantages that: the non-crystal insulation covering layer is adopted as the bonding surface, so that direct polishing and bonding on the polycrystal layer are avoided, and the difficulty in polishing and bonding is lowered.

Owner:SHANGHAI SIMGUI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com