Trimming device and wafer polishing system

A technology for dressing devices and wafers, applied in grinding devices, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of poor wafer polishing effect and inability to judge the degree of wear of polishing pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

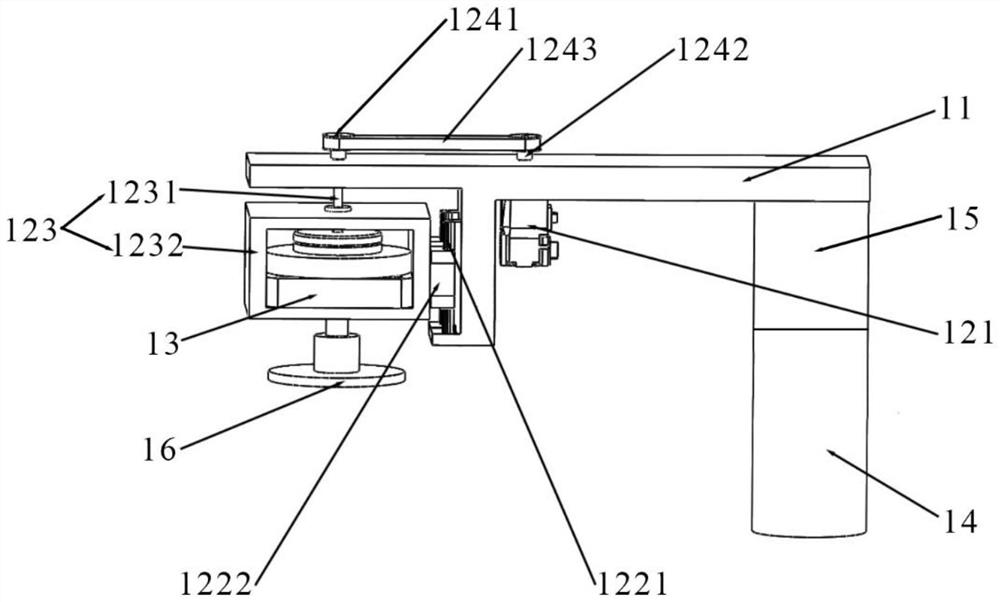

[0038] This embodiment provides a trimming device, such as figure 2 As shown, it includes a mounting frame 11, a lifting mechanism and a detection member. The cross section of the mounting frame 11 is T-shaped. The lifting driving mechanism has a lifting driving member 121. The lifting driving member 121 is a servo motor. On the right side of the mounting frame 11 , the lift driving member 121 drives the grinding head 16 to approach the polishing pad 4 .

[0039] like figure 2 As shown, in the trimming device provided in this embodiment, the lifting mechanism further includes a sliding component, a lead screw structure 123, and an overload prevention component. The overload prevention component is arranged on the top surface of the mounting frame 11. The overload prevention component includes a belt 1243, a first The pulley 1241 and the second pulley 1242, the drive shaft of the lift driving member 121 is fixedly connected to the first pulley 1241 through the mounting frame...

Embodiment 2

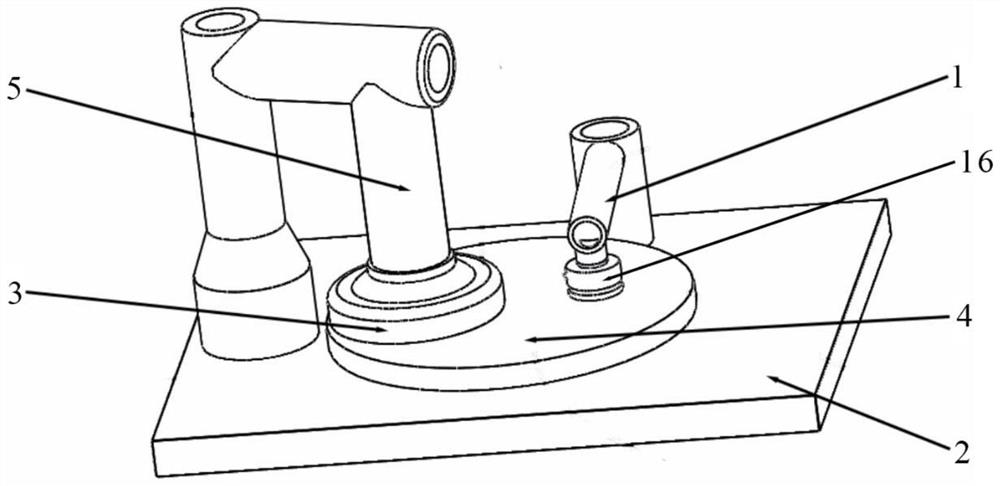

[0047] This embodiment provides a wafer 3 polishing system such as figure 1 As shown, the trimming device 1 of Example 1 is included.

[0048] like figure 1 As shown, the wafer 3 polishing system provided in this embodiment further includes a base 2, a wafer 3 and a polishing device 5. The trimming device 1 is arranged at one end of the base 2, and the polishing pad 4 is arranged in the middle of the base 2. The polishing device 5 is disposed on the other end of the base 2 , and the polishing end of the polishing device 5 is pressed against the wafer 3 , and the wafer 3 is placed on the polishing pad 4 .

[0049] In the wafer 3 polishing system provided in this embodiment, since the dressing device 1 can provide accurate data for replacing the polishing pad 4 , it is avoided to use the excessively worn polishing pad 4 to polish the wafer 3 , thereby improving the polishing effect of the wafer 3 , further improving the yield of wafer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com