Cutter wear monitoring method for numerically-controlled machine tool

A tool wear, CNC machine tool technology, applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem of lack of stable and accurate technical means for tool wear monitoring of machine tools, etc. Effects of processing, increasing frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

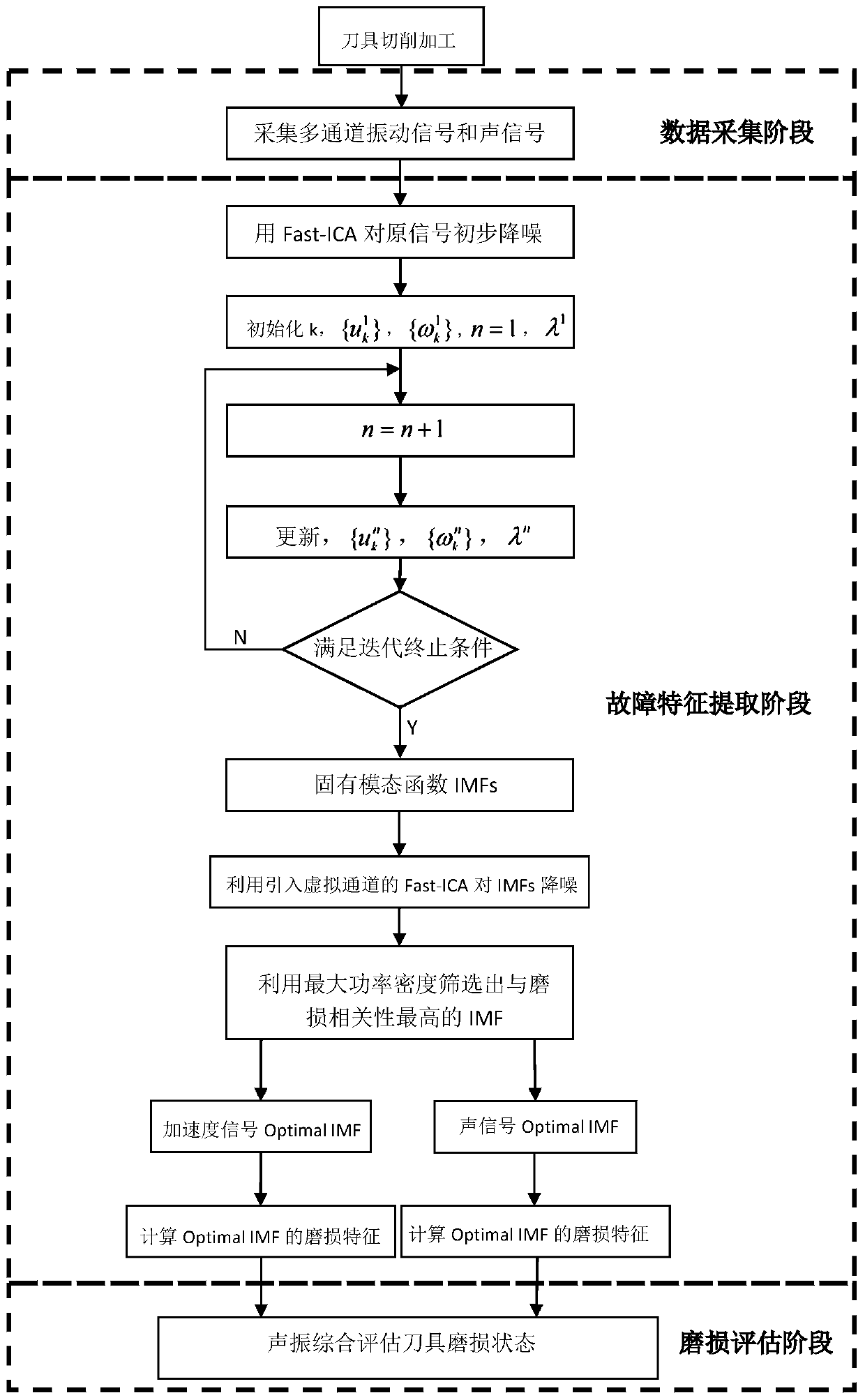

[0067] The following will combine Figure 1 to Figure 8 This embodiment will be specifically described.

[0068] see figure 1 As shown, the method for monitoring tool wear of CNC machine tools based on the combination of vibration acceleration and acoustic signals described in this embodiment has three stages: cutting data collection, wear feature extraction, and comprehensive evaluation of tool wear.

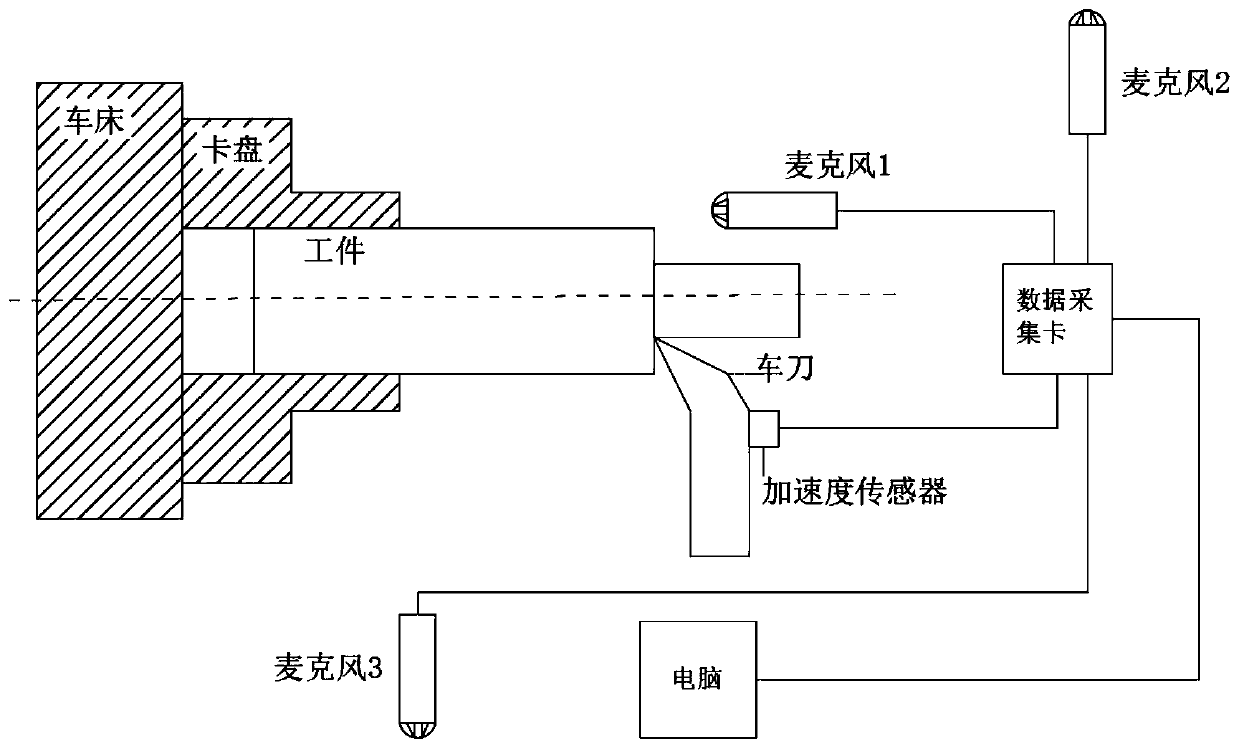

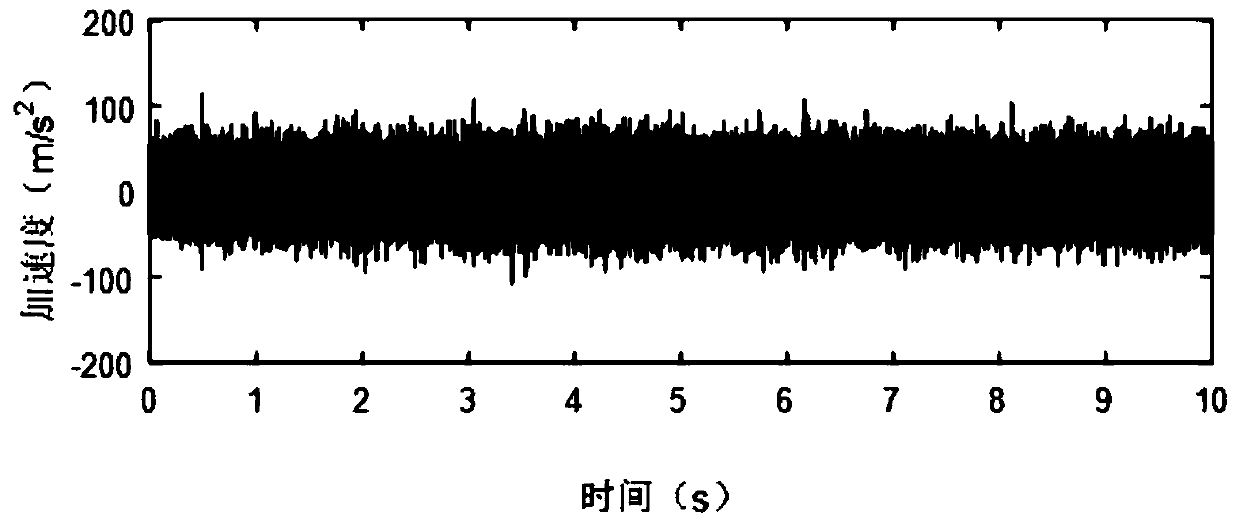

[0069] The data acquisition step includes the acquisition of vibration data and sound pressure data; the installation position of the sensor is as shown in Figure 2, and the three-axis acceleration sensor is installed on the tool handle of the tool; three microphone sensors are respectively installed on the machine tool adjacent to the cutting point, near the The straight-line distances from the machine tool and away from the machine tool to the cutting point are 0.3m, 0.6m and 1.2m respectively. The cutting signals of three groups of tools with different wear degrees were co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com