Electromagnetic rheological fluid piston assembly

A rheological fluid, piston assembly technology, applied in the direction of springs, shock absorbers, springs/shock absorbers, etc., can solve the problem of failure to effectively utilize the magnetization effect of the inner cavity of the electromagnetic solenoid, limited space in the inner cavity of the electromagnetic solenoid, etc. Difficult to deal with problems such as piston guiding, to achieve the effect of simple and easy setting of fluid channels and magnetic isolation, avoiding polishing effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

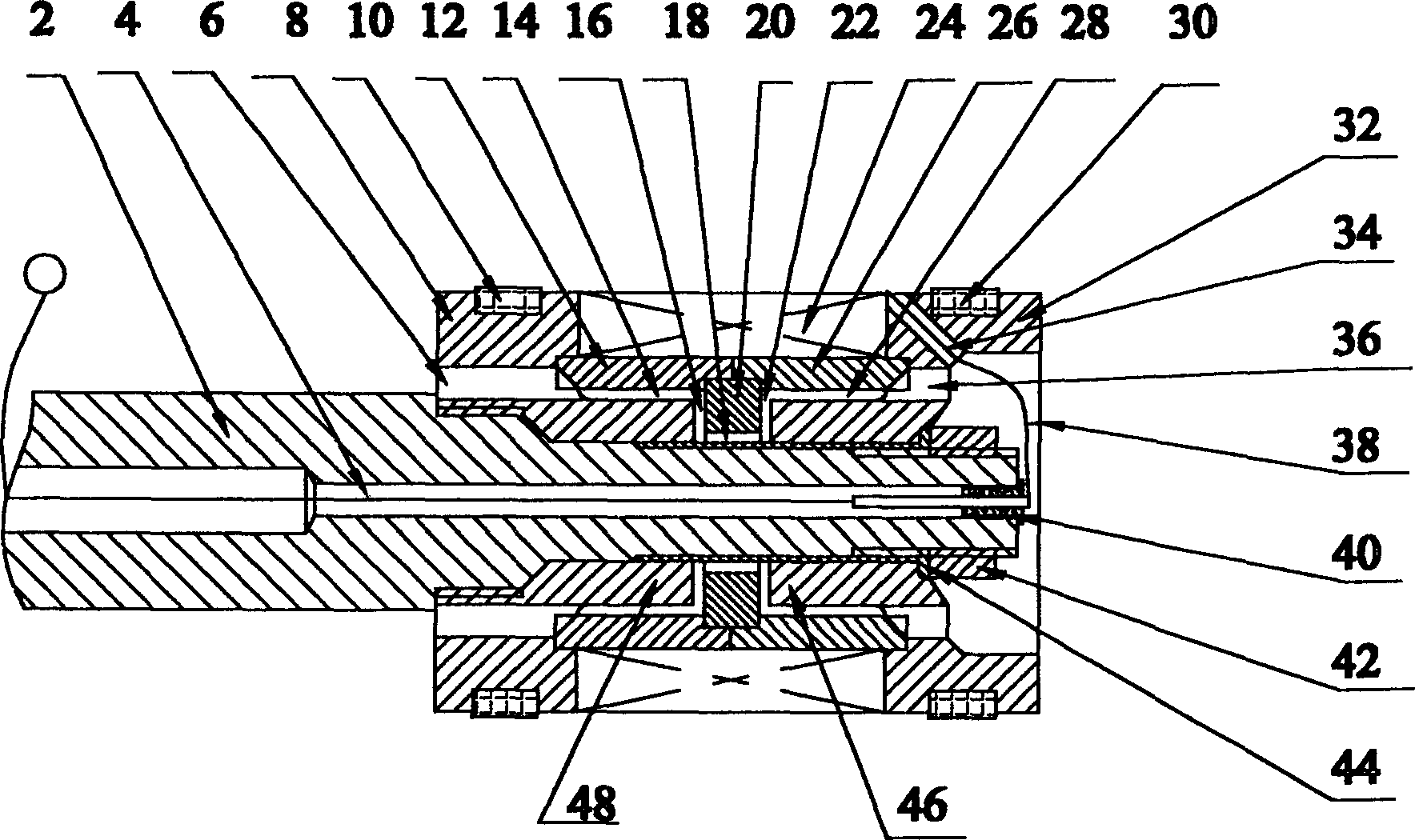

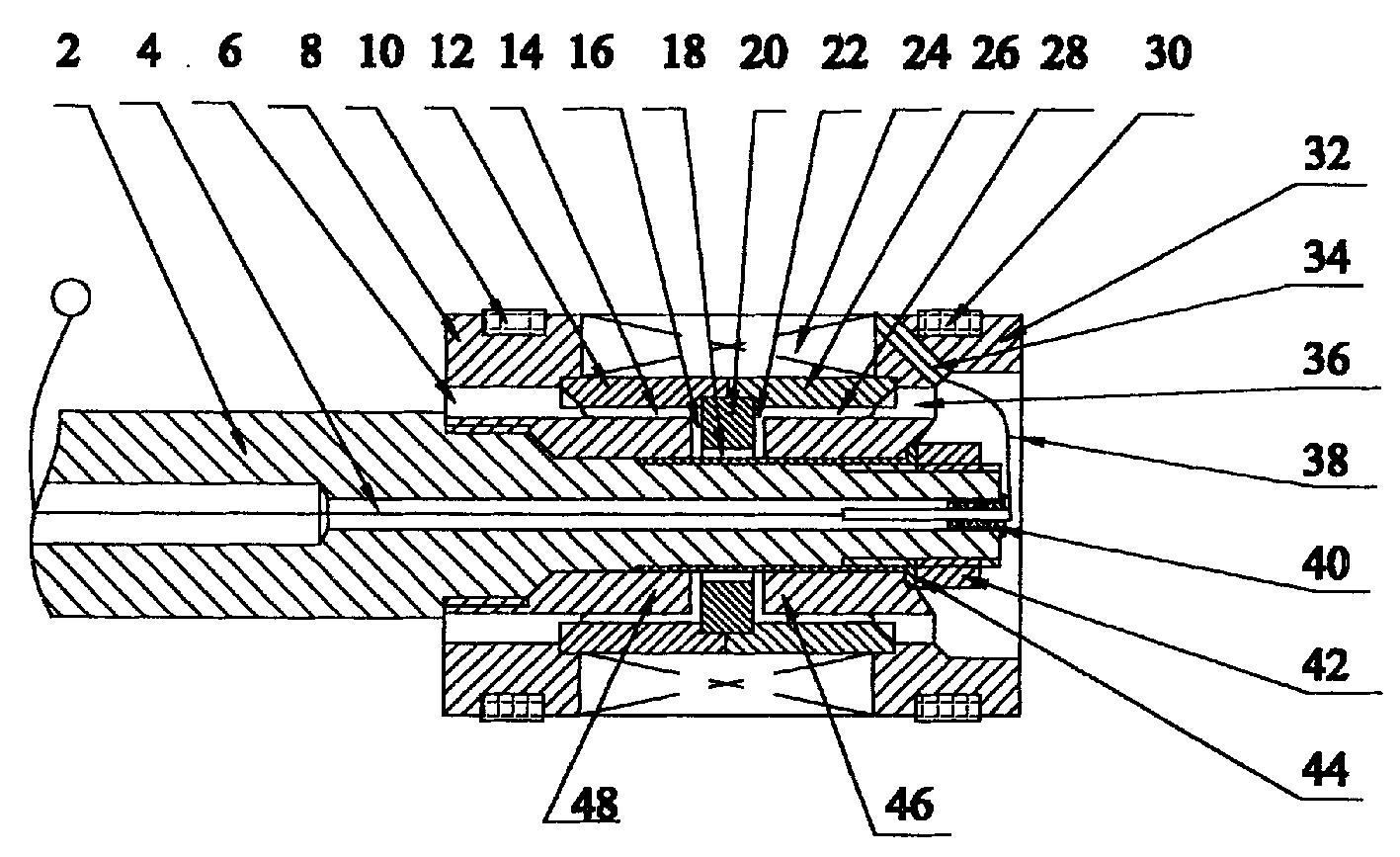

[0021] refer to figure 1 , a new type of electromagnetic rheological fluid composed of the upper magnetic conductor (8), the lower magnetic conductor (32), the magnetic conductor baffle plate (20), the electromagnetic solenoid (24), and the head of the piston rod (2) In the piston assembly, the upper magnetic conductor (8), the lower magnetic conductor (32), the magnetic conductor baffle plate (20), the electromagnetic solenoid (24), and the heads of the piston rod (2) are respectively split structures; the piston rod The head of (2) respectively passes through described upper magnetic conductor (8), described lower magnetic conductor (32), described magnetic conductor baffle plate (20), described electromagnetic solenoid (24) and will Each piece is firmly connected and positioned.

[0022]The detailed structural relationship is as follows: the magnetic conductor baffle plate (20) is positioned between the upper magnetic conductor (8) and the lower magnetic conductor (32), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com