Method for displaying metallurgical structure of ultralow-carbon cold roll annealed interstitial-free steel

An interstitial atom-free steel and metallographic structure display technology, which is applied in the field of clearly displaying ultra-low carbon cold-rolled annealing interstitial atom-free steel metallographic structure and metallographic structure display method, can solve the problems of complicated operation, poor operability and high cost. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

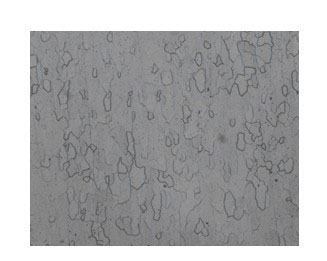

Embodiment 1

[0020] Example 1: Ultra-low carbon cold-rolled annealed interstitial-atom-free steel (weight percentage is C0.004, Mn:017, S:0.0016, P:0.012, Si:0.012, Als:0.028, O:0.0050, N : 0.0012, Ti0.008) to make a metallographic sample; put the sample on a surface grinder for rough grinding, and then polish and polish on 280#—320#—400#—600#—800# sandpaper Machine polishing; put the polished sample into the reagent 1 for 10 seconds, and the reagent 1 is 6% nitric acid alcohol; put the sample eroded by the reagent 1 into the reagent 2 and erode until the surface of the sample is uniform black, and the time is 30 Second, the proportion of the reagent two is as follows: 7 grams of sodium metabisulfite, 11 grams of anhydrous sodium thiosulfate, and 100 milliliters of distilled water; the sample corroded by the reagent two is taken out, and the surface is wiped clean with 6% nitric acid alcohol, and then used Rinse with alcohol, and then blow dry, you can observe the grain structure.

Embodiment 2

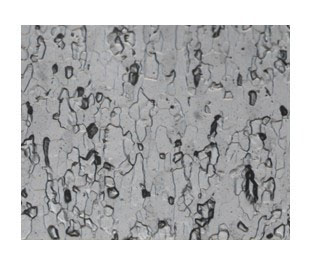

[0021] Example 2: Made of ultra-low carbon cold-rolled annealed interstitial atom-free steel (weight percent: C 0.004, Mn 0.18, S 0.017, P 0.012, Si0.012, Als 0.028, O 0.0050, N 0.0012, Ti 0.008) into a metallographic sample; put the sample on a surface grinder for rough grinding, and then polish it on 280#—320#—400#—600#—800# sandpaper in turn, and polish it with a polishing machine; put the polished sample on Put into the reagent one and corrode for 15 seconds, and the reagent one is 5.5% nitric acid alcohol; put the sample corroded by the reagent one into the reagent two and corrode until the surface of the sample is uniformly black for 30 seconds, and the reagent two is prepared such as Bottom: 3 grams of sodium bisulfite, 9 grams of anhydrous sodium thiosulfate, 70 ml of distilled water; take out the sample corroded by reagent two, wipe the surface with 5.5% nitric acid alcohol until it is clean, rinse it with alcohol, and then dry it. The grain structure can be observed....

Embodiment 3

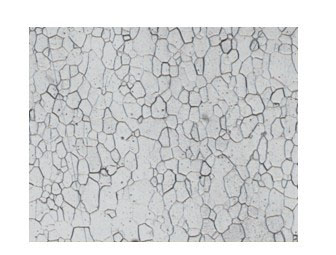

[0022] Example 3: Made of ultra-low carbon cold-rolled annealed interstitial-atom-free steel (weight percent: C 0.004, Mn 017, S 0.016, P 0.012, Si 0.016, Als 0.021, O 0.0020, N 0.0012, Ti 0.008) Metallographic sample; put the sample on a surface grinder for rough grinding, and then polish it on 280#—320#—400#—600#—800# sandpaper, and polish it with a polishing machine; put the polished sample into Corrode in reagent one for 20 seconds, reagent one is 6.5% nitric acid alcohol; put the sample corroded by reagent one into reagent two and corrode until the surface of the sample is uniformly black, the time is 80 seconds, the ratio of reagent two is as follows : 6 grams of sodium bisulfite, 12 grams of anhydrous sodium thiosulfate, 90 ml of distilled water; take out the sample corroded by reagent two, wipe the surface with 6.5% nitric acid alcohol until it is clean, rinse it with alcohol, and then dry it, that is The grain structure can be observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com